MSwiss

Sounds like you've had plenty of experience with slot cars and vacuum forming.

Your 2 questions did we hollow out our molds or did they ever crack are good.

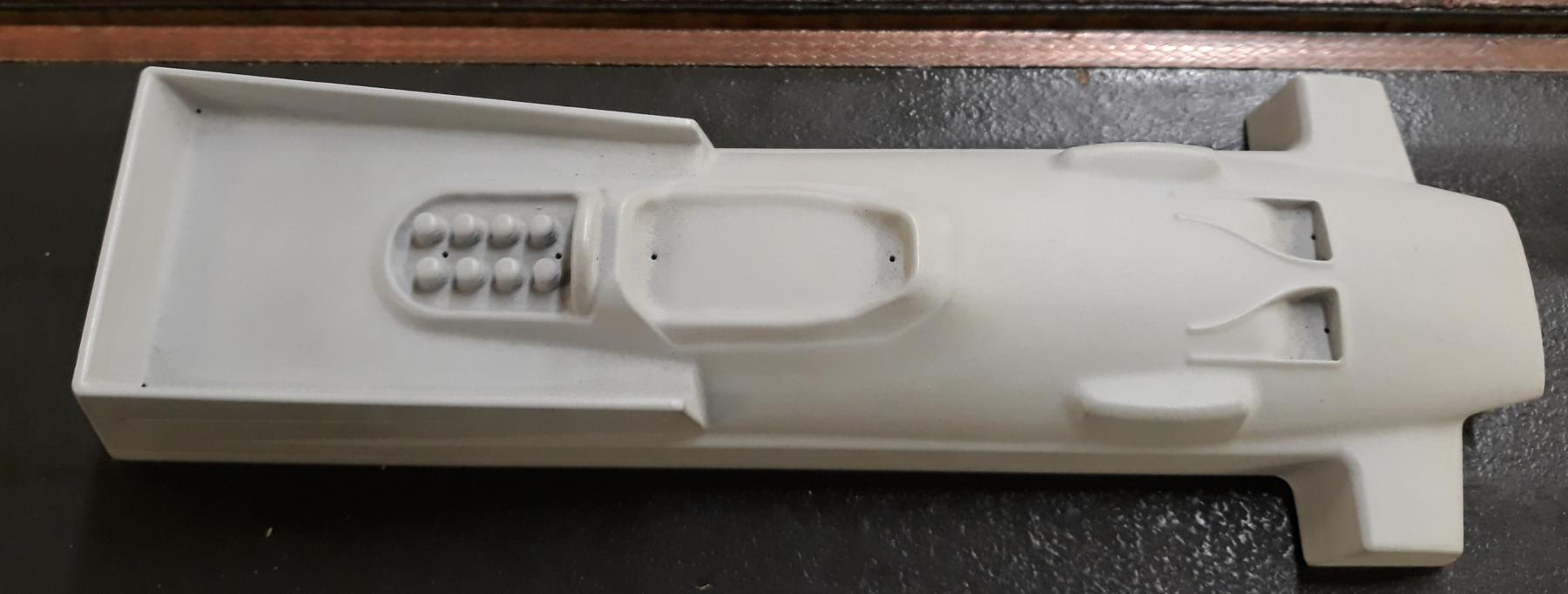

We never hollowed out the molds we made and the aluminum filled epoxy resin was

so strong you could throw one of our molds as hard as you wanted against the floor

or a wall and they'd just bounce, but not break. We had heard of that and so we

took a reject blank and tried it and got the above results.

Yes, plenty of experience in slot cars.

19 years as GM of Koford Eng., sort of the Ferrari of slot racing, and 13 years as a raceway owner, building both of my tracks.

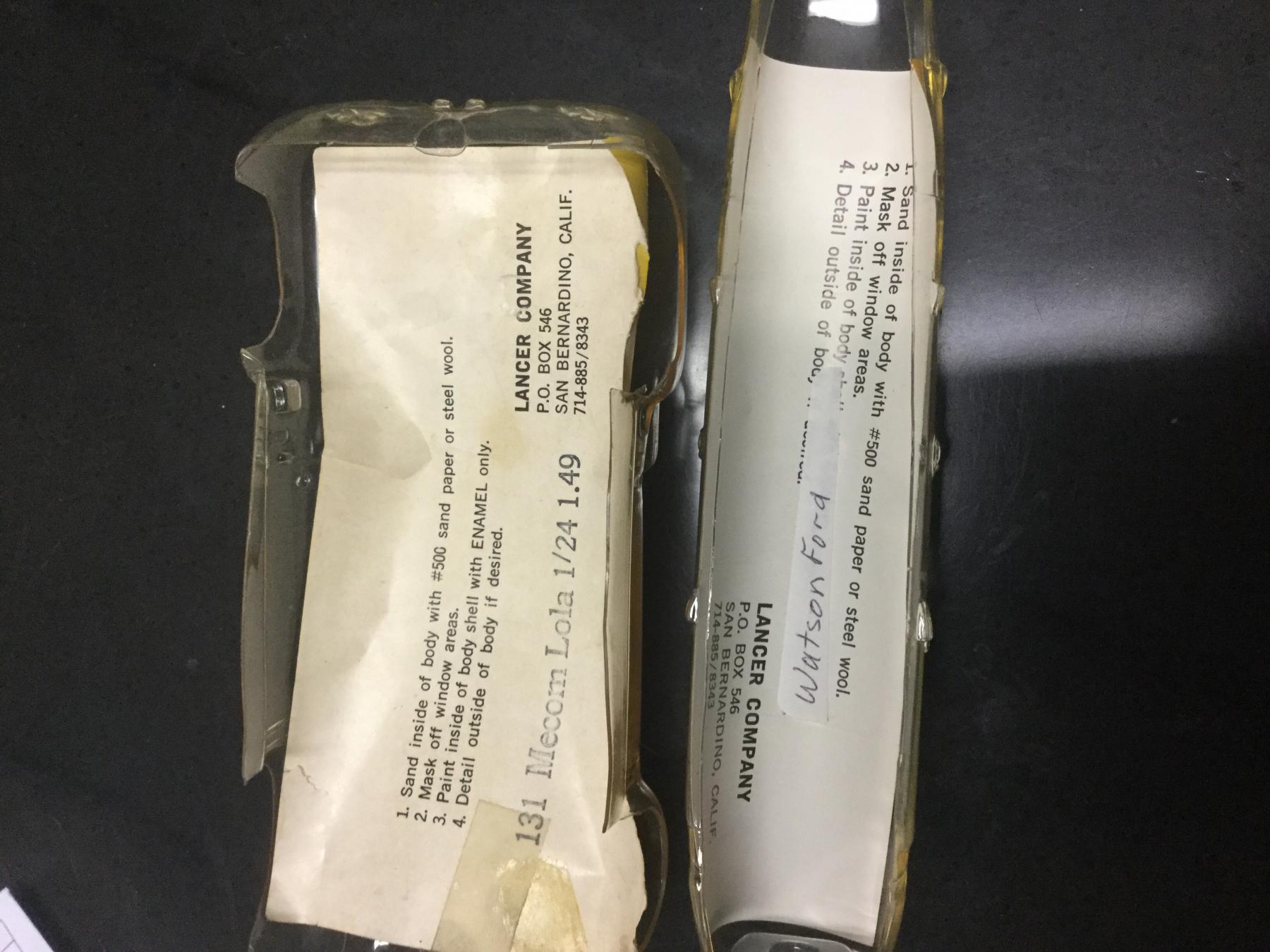

All that, along with, racing in the golden era of

Lancer.

Not a ton of experience vacuum forming.

Most of it was yelling across the Koford factory floor, "Rick I need 100 bulk Peugeots, for XXXX".

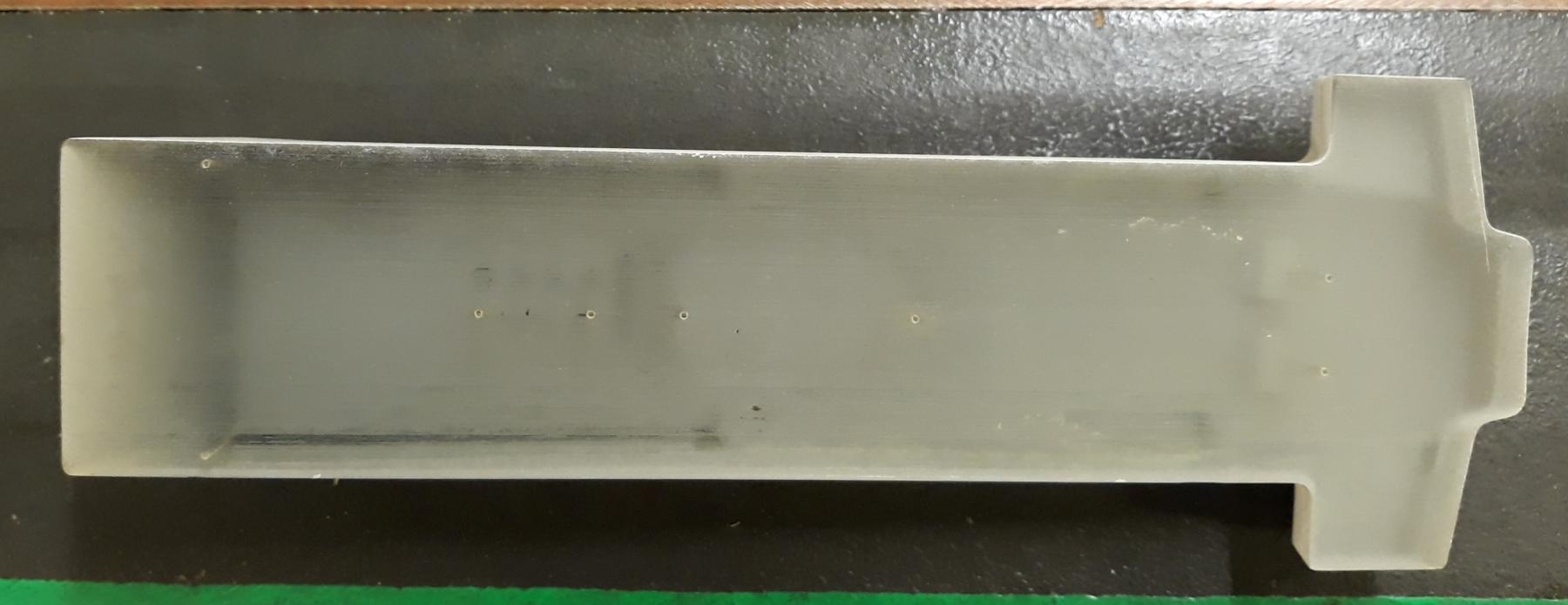

Koford is mainly a "wing car" company, and the bodies are/were quite simple, with us never having more than 6-8 different bodies, at any one time.

We had a small vacuum from machine, which held an approx. 12" X 15" perforated base plate.

We originally had 2 bodies mounted on each plate, but later went to one per plate, with a more angled back (which is cut off on a wing body), so the body would pull off of the mold easier.

Those "one per plate" bodies, were highly regarded for their even pulls.

I did make a few of my own crude molds, from Bondo.

I would get a few bodies off of the mold, before it would crack.

Just enough usable copies to confirm I didn't know much about aerodynamics.

As far as my questions, I asked about possibly hollowing out the bottom, as I while saw the small holes on the top of the mold, I never remember watching when Stu Koford would glue the mold to the perforated base, so I wondered how was it assured those holes would he effective.

Your post #115, with the counter holes, and the channeling, that connected them, explains it clearly.

I had missed that post, when I asked that hollowing question.

As far as mold breakage, I know the aluminum filled epoxy was/is quite strong.

What happened once or twice, at Koford, was the operator would get distracted, with the heater in the down position.

Without the air from the vacuum pump, or the cooling from the plastic, forming over it, the mold would just get hotter and hotter, and eventually crack.

Along with the nuts and bolts about vacuum forming, I've also enjoyed your stories about the factory hijinks.

One at Koford, involved the vacuum form machine.

I was checking an order that was going to go out to a distributor.

I noticed there appeared to be blood on one of the packages bodies.

I told our packer, Phyllis, that she need to put on a band aid, if she cuts herself.

She insisted she hadn't, so when I opened the package to clean off the body, before having her repack it, I took a good look at it, smelled it, and discovered it was spaghetti sauce.

After some investigating, I got Tim, my girlfriend's cousin, who I had gotten job for, to fess up that, Juan, Phyllis' boyfriend, had shown him how to warm up his lunch, using the vacuum form, overhead heater.

I explained to him that wouldn't be happening anymore, and shortly after, someone brought a used microwave from home, so it wasn't really an issue anymore.

Fast forward about 3 months later, I was working late every night preparing for the Nat's.

At around 6:30 every night, with Juan working overtime, and a high school kid, working after school, I would notice the factory would start smelling fabulous, like a good steak house.

I would glance over to the microwave, which I could see from my work area, but the light was never on.

After about 3-4 nights of driving me nuts, since I wasn't eating dinner until I picked it up on my way home, after 9 or 10 PM, I started looking around.

I spotted Juan, in another part of the factory, walking along, holding and happily munching on a vacuform machine "broiler cooked", T-bone steak.

As I was chewing him out, in typical Juan, "I got a b*llsh*t explanation for everything" fashion, blamed it on the designated cook for that night; "It was the boy, it was the boy".