#2651

Posted 05 March 2011 - 12:47 PM

So hard a judge they hope never to meet as themselves.

#2652

Posted 05 March 2011 - 02:01 PM

This one's not for anyone specifically, for now it's just my own little project. Right now, the arm diameter is a little over .500" (NOT what you're looking for). The reason I chose these lams is that the web is thick, but the crown is thinner so there's a bit more room in there to wind with so much big wire and still be neat and tight. There is still some room to grind the stack though, but I think about .480 would be the most you could take it down. I'll keep you in mind though

-john

#2653

Posted 05 March 2011 - 04:25 PM

Bought a Falcon 7 last night and the guy at the counter says all there good for is shim stock for Euro motor

So hard a judge they hope never to meet as themselves.

#2654

Posted 05 March 2011 - 05:17 PM

If that thing's looking for a home its three brothers said they would be glad to make room for it here

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2655

Posted 05 March 2011 - 06:18 PM

Bought a Falcon 7 last night and the guy at the counter says all there good for is shim stock for Euro motor

Hi Marty,

Nah...tell you what, those motors are still an amazing value for the performance level they have. Minds would have blown if someone ran one of those things in the 60's

I have no idea how thick these cans are anyway

I think they're .020", but that's from memory

I'm thinking strap myself.

...my fave!

If that thing's looking for a home its three brothers said they would be glad to make room for it here

!

Let me get it sorted first and see what's what Don

-john

#2656

Posted 06 March 2011 - 08:10 AM

So hard a judge they hope never to meet as themselves.

#2657

Posted 06 March 2011 - 09:23 AM

John or Bill, Bill Bugenis' comms, are these .325" long? I have one but it was a proto type and don't know if he settled on that as a final dimension.

Yes, they are 0.325" . I shorten them when needed with a facing tool ( an endmill with a 2mm hole).

#2658

Posted 06 March 2011 - 11:15 AM

-center the magnets (you can center them in these without cutting the can shim bottom off by making a second magnet spring clip thicker than the stock one)

-solder the brush hoods

-add spring post protectors

-center the arm in the field

-60T/#28 rewind

-new arm shaft (the one sent was splined)

-new com, other than this mystery com (?) I only had the stock Mabuchi coms

-wind new brush springs

-drill can and end bell for end bell retaining screws

Motor runs strong, draws about an amp or less (no load) and stays pretty cool. It should be a good runner...a nice upgrade from stock and still not a risky wind.

-john

#2659

Posted 06 March 2011 - 02:45 PM

#2660

Posted 06 March 2011 - 05:23 PM

Yes, they are 0.325" . I shorten them when needed with a facing tool ( an endmill with a 2mm hole).

Thanks Bill. Now I can finish my drawings for my arm.

So hard a judge they hope never to meet as themselves.

#2661

Posted 06 March 2011 - 06:16 PM

What an outstanding build! She looks great...I look forward to the motor's arrival. John, you went above and beyond the call of duty. Thank you for investing your time and the extras that went into the motor.

Rob

I just finished-off a nice Champion FT36D with Arcos for Rob Fredrick. The motor got pretty much the full treatment

-center the magnets (you can center them in these without cutting the can shim bottom off by making a second magnet spring clip thicker than the stock one)

-solder the brush hoods

-add spring post protectors

-center the arm in the field

-60T/#28 rewind

-new arm shaft (the one sent was splined)

-new com, other than this mystery com (?) I only had the stock Mabuchi coms

-wind new brush springs

-drill can and end bell for end bell retaining screws

Motor runs strong, draws about an amp or less (no load) and stays pretty cool. It should be a good runner...a nice upgrade from stock and still not a risky wind.

-john

[/quote]

#2662

Posted 06 March 2011 - 07:28 PM

As much as I enjoy just building these things, I get even more pleasure "bringing them back to life" for the owners who (like yourself) really appreciate the effort. You have a strong runner now with this old Champion, so it doesn't have to be a shelf-queen. Enjoy!

-john

#2663

Posted 07 March 2011 - 12:09 AM

So hard a judge they hope never to meet as themselves.

#2664

Posted 07 March 2011 - 06:27 AM

-john

#2665

Posted 07 March 2011 - 11:13 AM

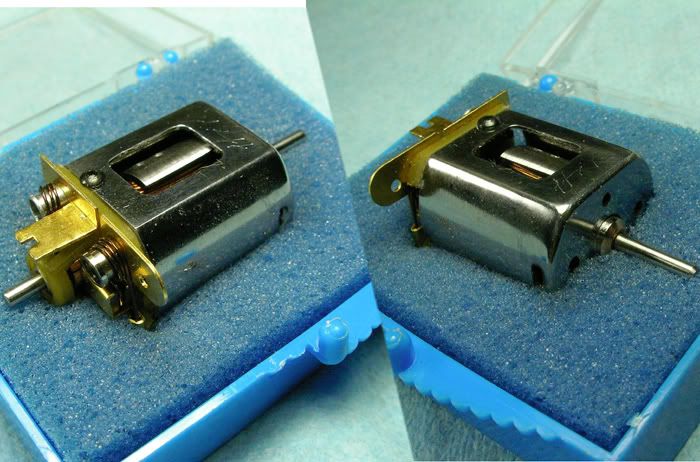

...and this arm, a 25/25 on a blank made of mystery lams with a Bill Bugenis com:

I left the arm diameter alone at around .510" or somewhere around there, and left a big hole in the can because of the strength of those Emovendo neos (it's difficult to insert the arm with those things in there)

This is what I got:

The motor runs like a champ and personally, I like the bigger airgap with these magnets. When you tighten things up with these, I have the strong suspicion that there's almost too much force for the armature to overcome...but that's strictly unscientific "intuition" on my part. The interesting thing about this motor is that I was not expecting it to run as well as it does with that much big wire on the arm...25 turns of #25awg seems like an awful lot of wire on an approximately .400" stack...but this thing sings AND seems to have lots of torque to boot. I also ran it on the power supply for several minutes at 6V and it didn't seem to get all that hot, but no doubt it would get warmer under actual running with a chassis load. I think (because of the neos not liking heat) it might still be more of a drag motor where it has a good chance of holding up under those ridiculous voltages, but it seems like it might not get hot enough to weaken the neos. Maybe a compromise between the two applications...maybe not. My only reservations about the motor is that the endbell seems sort of fragile, but I have no experience with this particular endbell.

I'd like this to be one of my periodic "giveaways" to a Slot Blog member... as a way to say thanks to Philippe, Greg and all the rest of the community, and would prefer that it go to someone that hasn't got one of my motors at least recently. It should also be headed for a proper lightweight modern car whether it's a road car or a drag car. Keep in mind that this is even a little more experimental than most of my motors,

Can-original a F7 minimotor (additional vertical mounting screw hole added, can cut down and top/bottom holes opened-up)

Endbell- I think Koford

Magnets-Emovendo Neodymium, glued-in

Armature-Unknown .014" lams, approx. .400" stack length, diameter approx. .510"

Airgap-Large. I'm being coy here because the number sounds stupid, but I think it's about appropriate

Wind-25 turns of #25awg

Current draw-A little north of 2 amps at 6V no load

Springs-Champion lights

I added the extra screw hole figuring that it would be best not to solder-in this motor because of the neos. The only other thing it could use would be shunts and spring insulation...but it runs great as-is and anyone getting a free motor can at least do that much...if they want to

-john

#2666

Posted 07 March 2011 - 11:22 AM

My motors haven't arrived yet so does that qualify as not getting one of your motors lately

FWIW: I can't imagine this motor/magnet would survive anything but drag racing or maybe a couple of 'hare' laps because of the heat problem with the Emovendos.

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2667

Posted 07 March 2011 - 12:53 PM

I guess you "qualify" , but you were supposed to send me a PM (just kidding)

FWIW: I can't imagine this motor/magnet would survive anything but drag racing or maybe a couple of 'hare' laps because of the heat problem with the Emovendos.

Well, that would depend on the voltage...the motor actually doesn't seem at all to get very warm and with spring insulation and shunts, it might (or might not) even run a bit cooler.

-john

#2668

Posted 07 March 2011 - 01:16 PM

I was just kidding about qualifying for your motor give away.....I'm going to be more than content to play with my drag motors when they arrive (hopefully today).

Maybe you're right about the heat and it won't affect the magnets. That Falcon is going to have a hell of set of brakes!!

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2669

Posted 07 March 2011 - 04:45 PM

No worries...the motor's gone

-john

#2670

Posted 07 March 2011 - 06:07 PM

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2671

Posted 07 March 2011 - 06:15 PM

Mike Boemker which is cool because I've never done any work for him! I'm sure it will (as he said) get a nice home

-john

#2672

Posted 09 March 2011 - 01:00 AM

So hard a judge they hope never to meet as themselves.

#2673

Posted 10 March 2011 - 07:59 AM

-john

#2674

Posted 11 March 2011 - 08:59 AM

So hard a judge they hope never to meet as themselves.

#2675

Posted 11 March 2011 - 10:02 AM

Your question brings up an important detail about winding/rewinding that I don't think I've seen discussed here...I'm pretty sure I've never talked about it anyway. When I'm working up a wind for a particular wire size, # of turns and arm blank (either by myself or lately with Bill Bugenis for his eurosport arms), I always try and avoid patterns that not only are "messy" but that leave the last wind in a precarious position on the coils. I don't remember seeing arms, especially big wire arms, done this way in the old days. The patterns seemed to pretty much always produce a fairly "full" last layer, and of course, it's nice that the last layer end up close to the com rather than the outside of the stack. Smaller gauge winds generally produce "rounded" ends on the coils because of the way the wire naturally wraps the pole pieces and even "cheating" the last turn over towards the com is usually not a big problem. Big wire requires much more attention be paid to the patterns...not to mention more tension on the wire as it's wound. That tension can make the last winds cause the lower layers to fall apart and it's a frustrating thing to see a beautiful pattern fall apart in the last few turns because tension on the top layer forces the underlying layers to slide sideways.

Since there are always many different ways to approach winding a certain number of turns of wire on a given blank, I try and have things work out with a pretty full last layer as well as the last turn ending up at least "near" the com. That's a long way of me saying that I would have to work out the exact number of turns of #23 wire on the particular blank I'm winding. With CNC type winding, I've seen many arms where the last turn ends up away from the com and the wire is then "crossed over" the top of the stack to get it back to the com. I've never heard about these arms failing and modern epoxying and the way the arms are tied probably makes this less of a concern...or maybe no concern at all!? I still don't like it though.

-john

This topic is locked

This topic is locked