#3226

Posted 26 October 2011 - 03:43 AM

Jairus, just for info, Certus did make complete motors, but distribution seems to have been very much limited to the Midwest. They were one of the hot powerplants at the end of my first slot racing career in Chicago...

Don

#3227

Posted 26 October 2011 - 05:21 AM

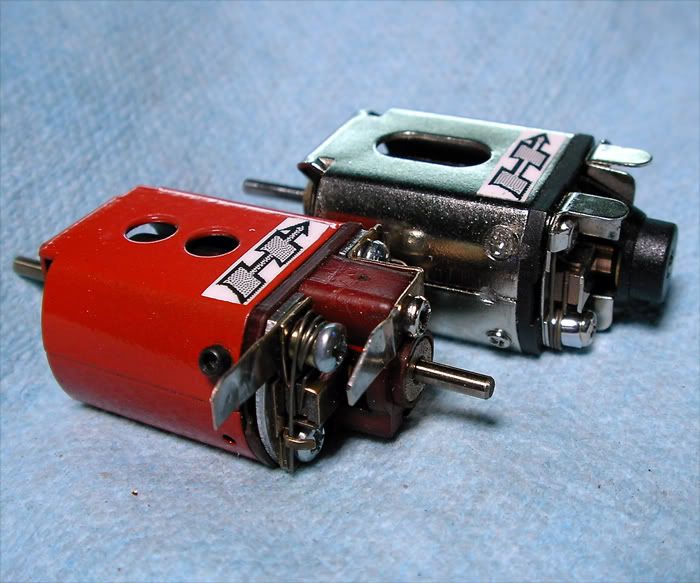

Nice looking motors guys! Kind of giving me an inferiority complex with my Russkit 23s...

Why Don? They're both just two different shades of "lovely"

-john

#3228

Posted 26 October 2011 - 08:14 AM

I intend to live forever! So far, so good.

#3229

Posted 26 October 2011 - 10:09 AM

Don

#3230

Posted 26 October 2011 - 02:22 PM

-john

#3231

Posted 28 October 2011 - 04:14 PM

-john

#3232

Posted 28 October 2011 - 06:28 PM

So, if it runs backwards, why did you not flip the can and re-bend the buss bars?

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3233

Posted 28 October 2011 - 06:43 PM

I figure he can bend the bussbars however works for his chasis when he sees what needs to be done....but I just thought of something that would be safe and easy

-john

#3235

Posted 29 October 2011 - 11:38 AM

I finished off your second motor...both run "backwards" now (CW timing viewed from the end bell). I rebent the buss bars on the Mura to accomodate the new running direction...I was going to try something else, but it would have been a PITA and would have meant different hardware, better to keep the old Mura "all Mura"

-John

#3236

Posted 31 October 2011 - 04:14 PM

-john

#3237

Posted 31 October 2011 - 04:19 PM

11/4/49-1/23/15

Requiescat in Pace

#3238

Posted 31 October 2011 - 04:34 PM

-john

#3239

Posted 31 October 2011 - 05:22 PM

For me anyway... nice work sir.

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3240

Posted 31 October 2011 - 06:40 PM

11/4/49-1/23/15

Requiescat in Pace

#3241

Posted 31 October 2011 - 06:40 PM

-john

#3242

Posted 02 November 2011 - 06:28 AM

This one was done using the stack off a standard blue-wire Mabuchi arm, with a Mura com added for extra goodness (brazed/hard-soldered com connections of course). The 26D is always an "interesting" arm to wind as there's gobs of space inside the stacks, but not much real estate on the com and tail ends at all. I always wonder when I see old 26D rewinds where the wire is packed on there almost flush to the face of the poles and absolutely no tail-spacer showing and the com sitting ON the coils

Anyway, this is a sweet wind for a 26D and this one balanced out really nicely. No doubt it will be a great runner.

-john

#3243

Posted 02 November 2011 - 09:07 AM

11/4/49-1/23/15

Requiescat in Pace

#3244

Posted 02 November 2011 - 04:41 PM

Hoods are soldered and you got a spankin' NOS Champion endbell that I installed the bearing in. I wound you a set of .015" springs because they work better than new springs on these motors...you can make the "short leg" long enough to ride in both sides of the brush tube slots for positive alignment of the spring and brush. Of course, I sleeved the spring posts and gave it a spin for about 5 minutes. It howls like a stuck dog, draws only about an amp, runs sooooooooper smooth and doesn't get warm at all. I'd say that it's near-perfect for a 26D that's going to be run fairly hard. You can maker them faster, but they'll flame out before too long. I hope you have an awfully nice car to put this thing in!

-john

#3245

Posted 03 November 2011 - 06:05 AM

-john

#3246

Posted 05 November 2011 - 11:00 AM

Starting with the can, I removed the stock caged bushing and replaced it with a 5mm ball bearing. I figured for what I had planned for the little guy, it would be a good addition. Then I whittled down a pair of modern ceramic magnets, and wedged them into the can while the epoxy holding them in cured. They measure up solidly in "Arco" territory after I removed the wedges...so far, so good! After drilling the can for retaining screws, I could turn my attention to the endbell and this time, I adapted some FT16D hardware to the 13UO end bell. That turned out to be more difficult than I had thought it would be, having to pretty much whittle/carve/solder/cajole all the hardware and the end bell itself. I even had to shorten the little FT16D brush tubes a bit as I kept coming up against roadblocks every time I thought I was making progress. I finally did get it all together and it would have been soooooo much easier to just slap a modern endbell on there, but there would have gone all the "vintage" mojo

Finally, I could assemble an arm to fit the setup and I built one using Mura .007" lams that I added some Mabuchi stack insulators to. I pressed the lams onto a new drill blank shaft and installed a modern D-motor com as it was the only one I had that would fit...even after radiusing out the inside of the endbell. When I got that all done, I did a #29 wind for the little guy which balanced up really nicely. On this slightly short stack arm, the wind comes in at .340 ohms.

This was one of those motors where (even though the arm metered perfectly, the magnets are strong and aligned well in the setup with a nice tight airgap, and the brush hardware seemed to be fine)...I had no idea what was going to happen when I fired it up. Well dagnabbit...this motor just stormed to life when I hit it with 6V and it quickly settled down to about 1 amp current draw. I figured it would run well...but not THAT well, but it just howls and doesn't get at all warm. This should make one heck of an interesting F1 car powerplant!

#3247

Posted 05 November 2011 - 12:35 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#3248

Posted 05 November 2011 - 12:53 PM

-john

#3249

Posted 05 November 2011 - 06:45 PM

-john

#3250

Posted 05 November 2011 - 07:33 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

This topic is locked

This topic is locked