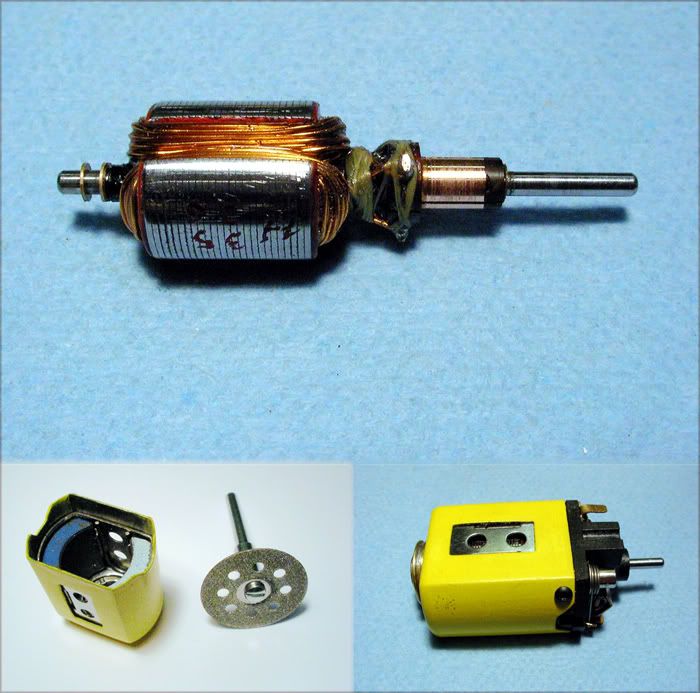

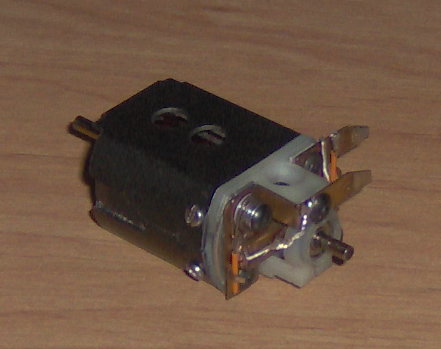

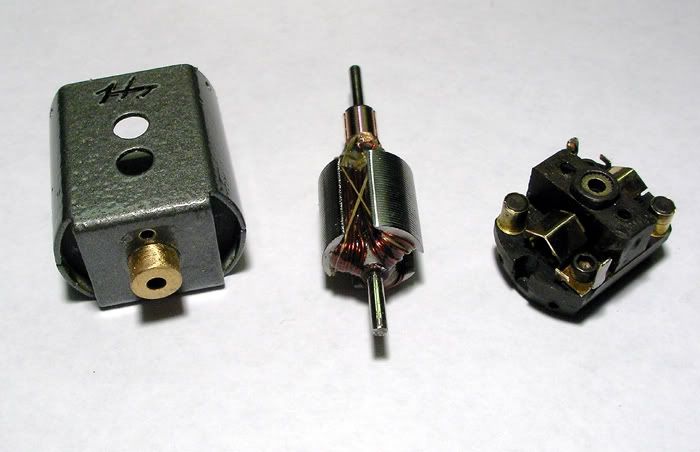

On winding my first 26D (I'm all but certain I never did one as a kid), I ran across some challenges. Obviously, the stack diameter itself is quite large compared to 16D and the web profile leaves lots of room for wire. The problem is that the can (and therefore the arm) is short so when setting up the blank for winding, you don't get a lot of room under the com for wire. You also don't get much on the can end of the arm before you have the wire getting close to the can bearing and maybe getting damaged. So plenty of room inside the web and very little on either end of the arm.

The other thing is the endbell is kind of short so with upgraded coms where there's an end cap like the Tradeship and Kirkwood, the brushes would be sitting partially on or very close to the non-conducting end of the com. The Kirkwood I used here had already been shortened by whoever gave it to me which was what I needed. Also, the taller the com...the less room there will be on the stack ends for wire, making things even tighter than they already are. I guess you could always shorten the stack by a few plates, but it already seems short. So a little planning and testing ahead of time was necessary for me to figure this thing out. The smaller 16D arms are actually easier (for me anyway) than these and I had to do some trial runs to work patterns out...tossing magnet wire in the trash each time.

-john

This topic is locked

This topic is locked