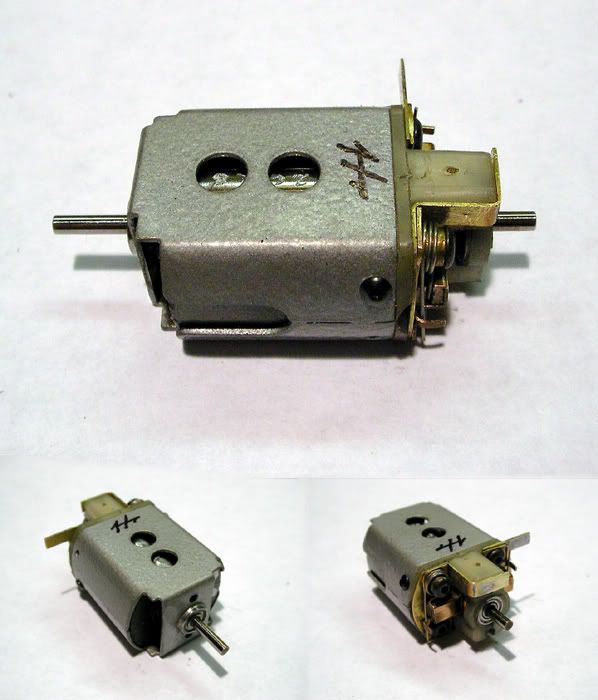

Nice setup John. That textured finish Rustoleum paint is really cool. I've used the dark green good stuff.

Hi Rick,

I've only found the Rustoleum Textured Finish paint in black...dark green sounds like it would be really nice. For this old Champion, the black seems cool since the can was that matte black originally. The "Hammered Finish" Rustoleum is also great stuff...

very hard/shiny/durable and available in several nice colors.

I haven't put ball bearings in a Champion setup......yet. Now I know how. Thanks!

Rick

oh...I don't know...I think you'd manage just fine

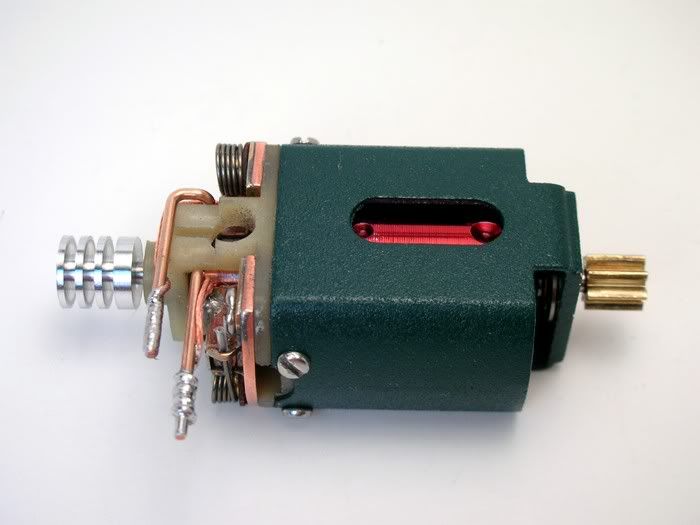

The can end is pretty easy, but the endbell was a bit more of a problem...but still plenty doable.

Sleeving the bearing and then cutting the assembly off the larger brass tube you sleeved it with always presents the potential of getting brass powder and flux residue inside even a shielded bearing and sure enough the bearing felt a little rough when I cut it and the sleeve away from the tube. Also, washing it in baking soda and water with a small brush afterwards to be sure to get any flux residue neutralized and out of there probably doesn't help. I spent a while with some

Slick 7 bushing/bearing lube spinning the bearing by hand with an old arm shaft, cleaning & re-soaking with more lube until it felt smoooooooth. Then I mounted the sleeved bearing on an arm shaft chucked in the Dremel and soaked it some more in Slick 7 and spun it while holding the sleeved bearing in my fingers...clean/re-soak just to be sure it was golden.

I was able to get a really nice "snap-fit" of the bearing into the bearing pocket of the Champion endbell by just taking down the OD a teensy weensy bit at a time, so that wasn't a major deal. However, because I like to live dangerously

...I also roughed-up the inside of the bearing pocket and applied a few molecules of hi-temp epoxy with the end of a round toothpick before popping the sleeved bearing in for good. I then baked the endbell at a very low temp in my easy-bake oven for 15 minutes to help force-cure the epoxy and that bearing isn't going anywhere soon! This was the most worrisome part of the whole deal because the epoxy I use is

very low-vis and gets even more so with a little heat. The slightest amount running into the bearing would have ruined the bearing I just worked so hard on

, but I got lucky

I don't know how applicable any of this is to what you do anyway Rick because even though there were bearings in use back then, the ones I've seen have been larger and even less "precision" than the bushings. So to be true to the period, there'd have to be some good quality bearings that would fit from back then??? If there are, I'm SURE you'd find them!

Man, that is some nice, precision work, John. I don't know how you can solder the bearing to that small ring of brass, though. Id have a nice blob of round silver solder when I was done. The paint came out nice also!

Hi Gary and thanks! Really, it's not all

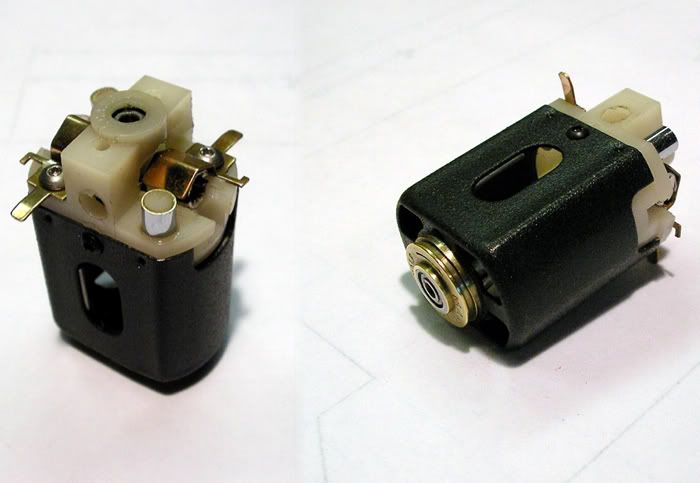

that hard, more tedious than anything, and I did a little figuring beforehand of how I could attack the problem with the tools I have. First off, the small ring of brass wasn't a small ring when I did it. I first reamed out the end pf a full 12" piece of brass tubing until the bearing could be tapped-in flush with the square end of the tubing. Because the tubing was pretty thin-walled at that point from the reaming, the previous "slide-fit" to the endbell now was a very tight fit as it expanded a bit tapping in the bearing...too tight to not worry about splitting the endbell around the bearing pocket which is/was a common problem even with the factory setups. I also used just a tiny amount of acid flux on a very small artist brush before heating the assembly to solder it and then tinned the whole outside . I used a flanged bearing to be double sure that when the bearing seated to the square end of the brass tubing it would have a positive stop, even though the bearing flange OD was too large for the bearing pocket of the endbell. I figured I would be taking down the OD of the whole mess afterwards to get the right fit anyway and grinding off the bearing flange until it was flush with the bearing sleeve was just part of getting the whole OD right for the endbell.

Anyway, I cut off the bearing and sleeve from the big piece of tubing only when it had to be done and then carefully ground the overcut flush with the end of the bearing that had been inside the tube. The result was that the bearing and sleeve all ground down looked like an unflanged bearing with an OD of a little under 6.5mm. Like I said, it was tedious...especially just to get a bearing to fit, but not that difficult.

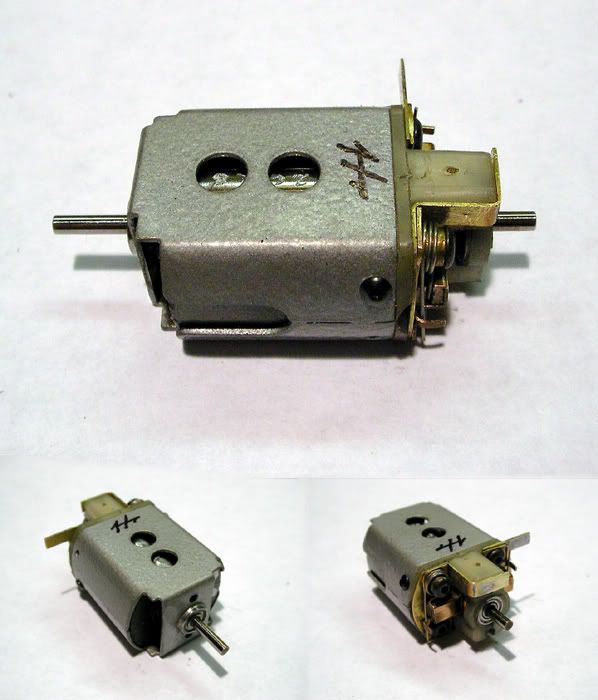

Why go through all this? Well I've done a bunch of these lately and even when I'm sure the arm is balanced and the shaft is true, they never seem to run super smooth like the later Muras for example, and even a little "buzz" from an arm spinning in a sloppy bushing is a motor-killer. The com will wear faster and arc more (drawing a bit more current) and the relatively soft bushings will wear making the problem get worse over time. Under a bright light, I have been able to hold the shaft and even see a tiny bit of side play when I try and wiggle it. I guess racers from the period may have just dealt with it, but it seems more likely they had access to better bushings and bearings (???). Of course, if I had better tools a simpler thing to do would have been to use an oversize but tight-fitting bushing and turn it down to fit.

That would even be a simple way to get a slick bushing to fit even the tiny pocket of say a Tradeship endbell! It would be a snap (with the right tools) to get a few current, and inexpensive, bushings and turn them down to whatever OD you need. Anyway, thanks for looking Gary.

-john