#451

Posted 17 July 2009 - 10:09 AM

"Everything you love, everything meaningful with depth and history, all passionate authentic experiences will be appropriated, mishandled, watered down, cheapened, repackaged, marketed, and sold to people you hate." Von Dutch [Kenneth R. Howard] 1929-1992

."If there is, in fact, a Heaven and a Hell, all we know for sure is that Hell will be a viciously overcrowded version of Pheonix." Dr Hunter S Thompson 1937-2005

"Whither goest thou, America, in thy shiny car in the night?" - Jack Kerouac 1927-1969

"Hold my stones". Keith Stone

My link

#452

Posted 17 July 2009 - 01:52 PM

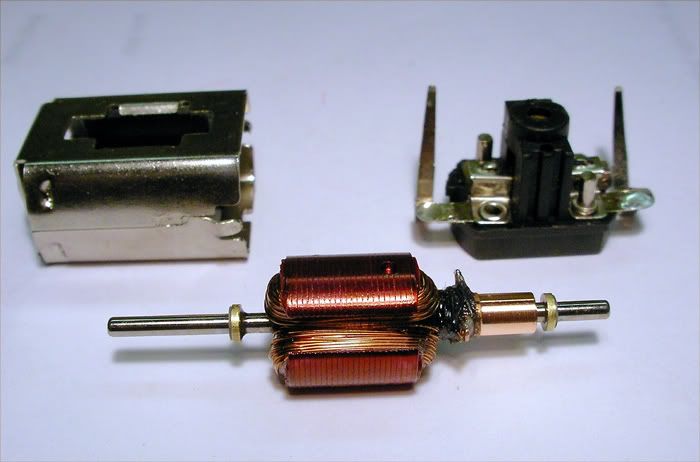

I've done exactly the same thing...m-m-must resist temptation and then...POOF! It really is a great feeling to hear them spin up though and I always spin mine all the way up (but after tieing/epoxying/balancing). I've got one experiment right now that I've run for really pretty long periods at 6V and then for 20-30 second bursts at a full 12V.

-john

John

The magnets in the SCX motors are realy quite good, not sure they would work with a 25 gauge arm though but good enough for milder use.

Been fitting them into old Johnson 13uo cans [some fit, some don't!] and winding 130 x 38swg [approx 0.15mm] with only enough advance for the direction i wanted it to turn, good for 1/32 scale racing and giving them old Scalex cars extra legs!

Hey thanks for the info John! The little motor is interesting and I might get one to do up all the way and see what happens. There's a lot of extra length in the can so I think I'd start by cutting the can down some. I did a quick check and the Tradeship com fits in the endbell and I might even do some endbell mods to fit regular springs on there. I wouldn't go any hotter than a #28 wind (which can be pretty hot), but I think such a small motor would be cool for say a 1/32 sidewinder...or maybe an itty bitty thingie...or maybe a 1/32 sidewinder thingie. Thanks again John

-john

#453

Posted 17 July 2009 - 04:50 PM

little bugger actually sounds really good!

...actually, I take that back...it doesn't sound really good, it sounds great.

-john

#454

Posted 17 July 2009 - 09:22 PM

We are glad you are having fun rewinding arms. We will be looking forward to trying this motor out. I'm sure like all of your arms it will be top notch.

I will keep you posted on this little SCX motor makeover.

The arm looks great!!!

Thank you,

Ed

S&E Raceway

S&E Motorsports

S&E MOTORSPORTS

S&E Raceway

#455

Posted 18 July 2009 - 05:44 AM

-john

PS: For the record, the above arm was done with 50T/#29 awg wire with only a moderate advance to favor CCW (as viewed from the endbell) rotation. From my brief testing on the power supply, I'm pretty confident the motor will hold up well at 12V...the one question being the commutator??? I'm sending the motor back to you today (Saturday), so you should have it I guess by Tuesday/Wednesday. Let me know when it arrives.

#456

Posted 18 July 2009 - 07:11 AM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#457

Posted 18 July 2009 - 07:44 AM

From what I've read the original RX-42 was rated as a 15000 RPM motor (at best), and RX-42B was 18-20K, which was quite a performance jump and most racers have changed them out to at least the "B" version, and some even to the later version which I think is "E"??

I've been tempted to build up a couple of COT cars and decal them out in my favorite Dodge livery's and give it a shot, but I have so much tied up in other 1/24th scale stuff and Retro, I'd have to unload a lot of good cars to go that route.

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

#458

Posted 18 July 2009 - 09:09 AM

Question: Whar does an SCX RX-42 normally run in? What kind/brand of slot car?

Hi Tex,

From doing a little online checking, what Michael says is spot on. It seems the original (the one I rewound) was widely regarded as pretty anemic, so they came out with the "B" version. Guessing that they probably have a trillion of so produced when they make the things

Hi Michael,

I'm not sure if my local shop owner would let me run one of John's modified motors on his 168ft Carrera six lane track, but I guarantee it would be a hoot if you could keep it on the track.

I don't see why not. The "B" motor is a major jump in performance from the original and my 50T/#29 wind may not be a huge jump up from the "B"...but I haven't tried out the "B" so I don't know how it would compare for sure. The one thing I'm not sure about is that Ed says his friend runs these @ 13V or a little more on his track and I only tested mine at 12V. Maybe he does this because the older motor is pretty weak. Anyway if you want to try one of mine, just PM me here.

-john

#459

Posted 18 July 2009 - 11:45 AM

These motors are designed for very low amp draw because of the usual home set "wall wart" power pack. A "horses for courses" thing. There is a club out of state where I am freinds with everyone, and they call for me to make the visit a lot. I have, in a certain class, dominated by using an improved RX41 in a scratchbuild. The power at the track, and the twisty nature at the track makes more powerful motors a problem for the driver.

Fate

3/6/48-1/1/12

Requiescat in Pace

#460

Posted 20 July 2009 - 07:15 AM

tks

bill harris

#461

Posted 20 July 2009 - 02:24 PM

Kevlar Thread At Amazon

I've bought it from them twice with no problems. You can get larger spools on Amazon from someone else, but one of these small spools will do a LOT of arms. Do your thing tieing the com and then epoxy. I use a round toothpick to apply the epoxy and just get a tiny bit up by the com where the thread goes over the tabs. The kevlar will "wick" the epoxy and will become saturated after a few seconds if your epoxy isn't too thick. Key to making a strong "composite" with any resin and fiber (ie...kevlar/fiberglass/carbon fiber/cotton etc.) is to be sure the kevlar is fully saturated. It will become a little darker when fully wet and any more epoxy than is needed to wet the kevlar is more than you really need. The epoxy will make the color in the kevlar thread run so you get a bit neater job if you use the light colors like yellow, but I guess the black is more "retro" looking

-john

#462

Posted 20 July 2009 - 08:47 PM

Just heard from Ed Miller and preliminary results with the little SCX motor are very encouraging...something about "blowing the rear tires off the rims".

-john

#463

Posted 21 July 2009 - 08:56 AM

bill

#464

Posted 21 July 2009 - 11:03 AM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#465

Posted 21 July 2009 - 11:39 AM

Truthfully, I don't tie the stuff at all and you get a neater job that way. I start by just wrapping the top of the stack under the com and covering up the starting end of the thread, then working my way up and over/under the tabs then down again. To finish, I use a toothpick to guide the thread between two wraps of the magnet wire and down the stack and make the turn underneath. If you wrap a bit of the thread around a piece of something straight (a toothpick, piano wire etc.) so you can tug on it without cutting yourself, you can pull the thread and cut it on the bottom edge of the stack. What's left in there will be buried between the magnet wire. Even if you have a bit of "fuzz" sticking out after snapping it, a quick hit with a match will burn it off and not hurt the magnet wire.

-john

#466

Posted 21 July 2009 - 02:03 PM

I intend to live forever! So far, so good.

#467

Posted 21 July 2009 - 02:14 PM

All I was ever able to find is the expensive 4-500 degree stuff and the regular "Devcon" type stuff. PM sent.

-john

#468

Posted 21 July 2009 - 07:23 PM

Just finish testing this SCX motor on our track, I started out with a 9/29 setup and you could not use the motor at all,so then I went to a 7/29 setup and this little motor has more then this track can handle.

This chassis with a stock motor ran around 2.90 sec. laps it now runs 1.90 and I ran it for over 500 laps and it is running cool ,this motor has more in it yet All I can say is WOW a job well done,I just wish I had longer straights to stretch its MUSCLES.

Oh on another note I have to see if they make rims for these SCX with set screws because this motor is loosening the rims on the axle and it will blow the tire off the rim on a free rev quick jolt! Talk about HP and torque. You are the BEST!

Thank you,

ED

S&E MOTORSPORTS

S&E Raceway

#469

Posted 21 July 2009 - 07:56 PM

That's good news and even better, it sounds like the motor will hold up well in the long run. Now next time you guys have a race, slip that motor in a car and don't tell anyone what's what. That should provide some good chuckles.

-john

#470

Posted 22 July 2009 - 07:09 AM

tks bill

#471

Posted 22 July 2009 - 11:45 AM

Ed, SCX uses a standard 3/32 axle. The simplist solution is to buy a SCX replacement rear axle that comes with wheels axles gears and bushings. About 20bucks.

OR just use a good 3/32 axle and use the Parma 20mm eurosport tires if you are allowed to use sponge and traction chemicals.

Fate

3/6/48-1/1/12

Requiescat in Pace

#472

Posted 22 July 2009 - 02:55 PM

Here's what I do to tie an arm.

1)Start wrapping around the bottom of the com by holding on to the end of the kevlar until the wraps hold the end in place...or you can start by putting a tiny touch of super glue on the end of the kevlar and "tacking" it to the stack. Lately, I go around and up and keep getting closer to the com tabs until I'm not far below them.

2)Once I get close to the tabs, I hop over one and go around the com alternately going over one and under the next until each tab has 3 wraps over it.

3)The I hop under neath and wrap around the part I started with under the tabs and around the shaft, getting cloe as I can to the top of the poles.

4)When I'm back down to about where I started, I stick a round toothpick point between two poles of the arm where there's normally a little space and go over the toothpick with the kevlar and make the turn straight down between the magnet wire towards the bottom of the stack.

5)When I get to the bottom of the stack, I just start to make the turn as if I was going to go around the bottom but instead yank on the kevlar to cut it off using the bottom corner of the stack as a break point. ***This is where I wrap the kevlar around something before I give it a yank to avoid having the kevlar cut into my hand.

Of course, you could just tie the arm using the first part of the kevlar left long and the last part and make a simply square hitch, but the above is neater/tidier. Plus, I've had a couple of people ask me where the knot is when I tie my arms, and how do I make it so small

Oh and i guess this slot stuff is starting to wear off on my son he wants me to show him how to wind a arm should be fun both of us at same table trying to do the same thing at same time

That's excellent!

-john

#474

Posted 24 July 2009 - 02:08 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#475

Posted 24 July 2009 - 03:42 PM

-john

This topic is locked

This topic is locked