#426

Posted 30 June 2009 - 03:29 PM

My first rewinds were fice-pole Pittmans... a failed attempt to make a high speed Pittman 704. The motor wasn't a failure, I could just get a can to go faster. In those days I did 5-7 poles, even putting Pittman arms in Mabuchi cans.

There is no real difference in winding or the approach to my mind.

One of the more interesting Mabuchis was from Tradeship in '64 or '63: a five-pole version of the Revell SP500. In parallel, Strombecker's line of Pittman 196 lookalikes included both five and seven pole versions. All of them got rewound then.

Fate

3/6/48-1/1/12

Requiescat in Pace

#427

Posted 01 July 2009 - 06:42 AM

bill

#428

Posted 01 July 2009 - 07:46 AM

Hi,

There is no real difference in winding or the approach to my mind.

One of the more interesting Mabuchis was from Tradeship in '64 or '63: a five-pole version of the Revell SP500.

Fate

Hi Rocky,

I never tried winding one of the five poles, but if I remember the period articles right, you were supposed to wind two poles at a time, and overlap them - so more complicated than a 3 pole! Maybe if Larry Shephard is around, he can remember this.

I think it was Aristo-Craft that sold the five-pole Mabuchis; very similar to the Revell SP500 can, and just about as slow, maybe slower... I always thought it was funny they would do a five pole arm in a cheapo can motor! I don't remember these from the period at all, but picked up a couple in my collecting career - and had one in a car for awhile before I realized it was the 5-pole model!

Don

#429

Posted 01 July 2009 - 08:54 AM

I was careful do make a sketch of how the wire came off so I would rewind using the same pattern. On this five-pole blank the wire "jumped" a stack. Instead of finishing a segment and then winding the next segment, the wire bypassed the closest segment to the next one. It felt pretty strange but was actually quite simple and there was plenty of room for the wire as each pole only had about 25 turns.

I'm fairly sure that Pittman wound at least some of their arms before the comms were installed, then twisted the correct wires together and welded the wires to the comm. I wound mine using only one peice of wire but when I was finished I could see that the Pittman method would be easier, if you connected the correct wires!

It's sort of hard to believe now but the Pittman style motors were faster than the Mabuchi can motors for a year or so after the "tin can" motors were released.

11/6/54-2/13/18

Requiescat in Pace

#430

Posted 01 July 2009 - 10:20 AM

Either of those sounds vaguely familiar and similar to what I was referring to, but I seem to remember the "alternate" wind thing where you wind from pole one to pole three, pole two to pole four, pole three to pole five. It could also be that there were several sequences you could do including straight "series" wind. Just looking at the arms, the space on those poles do look pretty tight though. No matter anyway, I never wound one back then and I'm not about to start now

#431

Posted 01 July 2009 - 03:28 PM

You are right, you go across two poles. I just didn't find it more tedious to do the wind.

I might be skewed in this as my dad was an electornic buff and had all the bits on hand from the beginning for me in the '50s. It was considered normal for me to wind a motor to suit my needs.

In some respects, the early Mabuchis were like the modern ones, in that Mabuchi was winding for industrial needs, usually toys, and we were just a side issue.

My first can was a 15R Mabuchi in a Stromberker in '62 that blew and I rewound it. The stock wind was ca 250t of 34 wire and "rated" at 12 volts/15,000 RPM. Again, much like the modern Ninco NC1 "S" can (FC130FC).

P will like this: I ended up putting it in the Cooper Indy so that I could beat my dad on our home track!

It wasn't really an issue, i.e. hot arms, until April '64 in the small town I was in outside of Seymour Johnson AFB. THEN it was obvious with the higher speeds that I could wind cans to beat Pittmans. So, I had no "Pittmans faster" phase. My first Mabuchis for commercial tracks started as rewinds.

On the Tradeship and Pittman five-poles, I never could find the supposed superiority others claimed. Even rewound.

Fate

3/6/48-1/1/12

Requiescat in Pace

#432

Posted 03 July 2009 - 07:21 AM

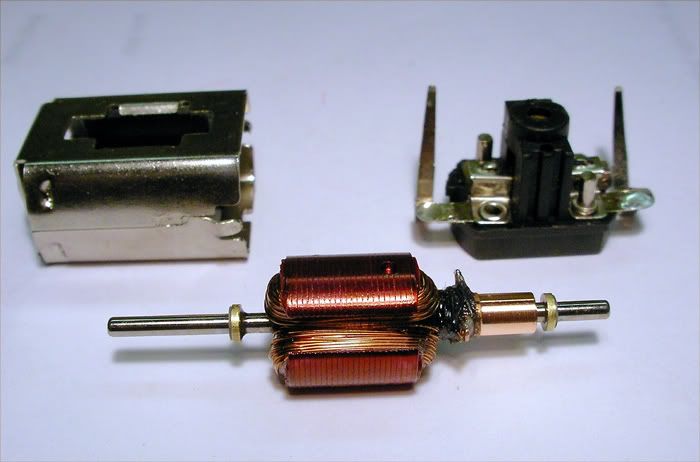

Disassembled the arm taking all the laminations off there and then did my best to flatten them and run each side of each one on a piece of 320 sandpaper stuck to my glass work surface with my fingertip.

I then reassembled them on the original shaft which was now out of true from trying to push the shaft too hard so I could slip the whole thing into my "press" (really a small vise with holes drilled horizontally through the top of the the jaws) and be sure the lams were as flat as possible by applying pressure to the assembly.

I then did the final assembly of the "new arm blank" on a new shaft, clamped it and applied high temp epoxy to the insides of the stack to act as an insulator and help hold the whole mess together.

Then I epoxied the insulators to the ends of the stack, and trimmed them flush to the stack after the epoxy was cured.

Did a polish job on the stack which took way more effort than it would have on the original stack.

I finally added a com and tail spacer as well as a Kirkwood com epoxying them all in place with the com timing set.

...all of this to get a can drive arm blank and after an embarrassing amount of time spent and I still hadn't wound the arm

I know it sounds ridiculous to spend that kind of time and effort on an arm that may not even work...but I learned some things along the way and there's value just in that! So regardless, I figure it was worth it. Anyway, here's the result:

-john

#433

Posted 03 July 2009 - 07:53 AM

When you need to move the laminations on the shaft have you tried to put the shaft under a little bit of pressure and then heat the laminations from the outside and let the heat travel towards the shaft??

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#434

Posted 03 July 2009 - 09:45 AM

Yes I have and sometimes that helps...sometimes (I suspect because of either too much heat causing them to expand or because the heat hardening/changing oxidation) it makes it worse. What I think is the best solution (assuming no machine shop tools for pressing) is to simply cut the shaft off flush with the end of the stack and press it through with a slightly smaller diameter drive pin and be done with it. It seems the most direct way as well as the one least likely to distort the laminations. I've had some luck doing that even with .007" lams...but even that is hit or miss. Thanks Don.

-john

#435

Posted 03 July 2009 - 01:26 PM

Thanks John!

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#436

Posted 03 July 2009 - 01:27 PM

-john

#437

Posted 13 July 2009 - 07:22 AM

bill

#438

Posted 13 July 2009 - 03:45 PM

From what you posted, I think we're using two different methods (and there are many). I start at a com tab and go over the next pole (either CW or CCW depending on which way I'm winding) and then drop down to start my first turn. When I have that pole copmpleted, I come up on the last turn and come over the stack I just did to the next com tab and then drop down over the stack to start winding that pole. My wires aren't broken and only the last com tab will have two loose wires to connect. So the wire is all one long unbroken piece that I strip at the place it passes over each com tab. The last turn (in this case #45) is the one that, after coming up and over the stack (a full turn), gets connected to the next com tab.

-john

#439

Posted 14 July 2009 - 06:41 AM

tks

bill harris

#440

Posted 14 July 2009 - 03:28 PM

confusion is becoming a every day occurance

Hi Bill,

Welcome to the not-very-exclusive-confusion-club...I'm a charter member. Problem over here is that I've been that way since I was young

did you recive the arms i sent you just checking to make sure the mail man is not a slot fan and keep them for him self.

...got 'em and I did reply somewhere either on a thread or a PM that they came but I can't remember where (see my answer above re: confusion)

-john

#441

Posted 16 July 2009 - 09:43 AM

bill harris

#443

Posted 16 July 2009 - 10:59 AM

#444

Posted 16 July 2009 - 02:10 PM

You're on your way!!! It really doesn't look so ugly to me, and I've seen arms that looked worse that run great. Couple of things:

1)How did you set the timing, it could be an illusion but it looks crazy-advanced?

2)2.63 ohms sounds strange and an arm done with 45T of #28 awg should be in the .3 to .4 ohm range. Maybe you meant .263 ohms and if so, you must have one heck of a nice meter to read that accurately! Did you check for continuity between the com segments and the shaft and/or stack...there should be none (one probe touching a com segment and one touching the stack or the shaft).

3)If you solder the com tabs, you should be able to give it a slight spin at low voltage with absolutely no problem. A good way to see what's what before you epoxy it.

4)The arm looks balanced, but isn't epoxied yet. Balancing should be the last thing you do to the arm...for sure it should be done after epoxying

Great work Bill, please post more pix when you get them.

-john

#445

Posted 16 July 2009 - 03:50 PM

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

#446

Posted 16 July 2009 - 04:41 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#447

Posted 16 July 2009 - 06:00 PM

-john

#448

Posted 17 July 2009 - 07:31 AM

to life it jumped humming along at delightful pace seaming content yes to borrow a line from a van helsing movie (IT'S ALIVE) so after a min or so chest puffed out with this feeling of elation victory of man over machine i basked in the glow of success. then it hit me then age long battle of good vs evil you know CRANK IT UP--- NO DON'T DOT IT FINISH IT FIRST---NO CRANK IT UP well you can guess which one won that argument. so with a twist of the wrist up went the voltage 12 volts and mother of god did the motor respond with the sweet sound of that high pitch wine ahh music to my ears well short lived it was first a little puff of smoke followed by a billowing cloud of smoke and then silence nothing it's life all be short was glorious. well needless to say the ugly duckling not resembles roast duck, duck flambé. oh well but lesson learned that yes i could rewind a 16 and get it to run now we work on improvement.

Bill harris

killer of the ugly ducking

PS stay tuned for the sequel UGLY DUCKING 2

#449

Posted 17 July 2009 - 08:00 AM

The magnets in the SCX motors are realy quite good, not sure they would work with a 25 gauge arm though but good enough for milder use.

Been fitting them into old Johnson 13uo cans [some fit, some don't!] and winding 130 x 38swg [approx 0.15mm] with only enough advance for the direction i wanted it to turn, good for 1/32 scale racing and giving them old Scalex cars extra legs!

[oneofwos]

Requiescat in Pace

#450

Posted 17 July 2009 - 08:46 AM

Thanks John Falzarano

This topic is locked

This topic is locked