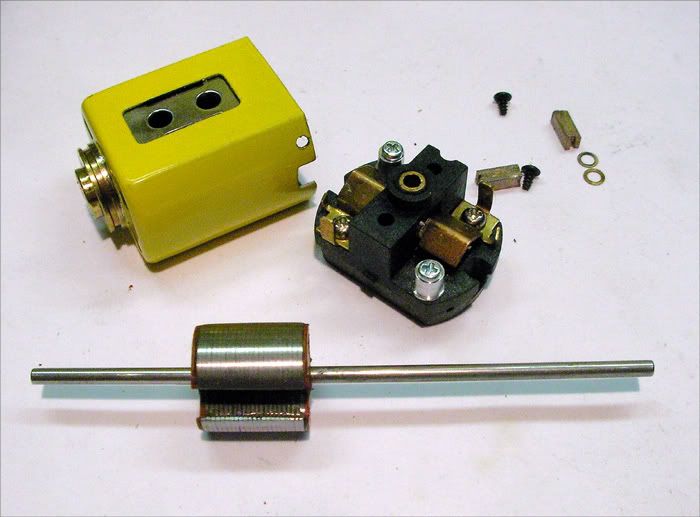

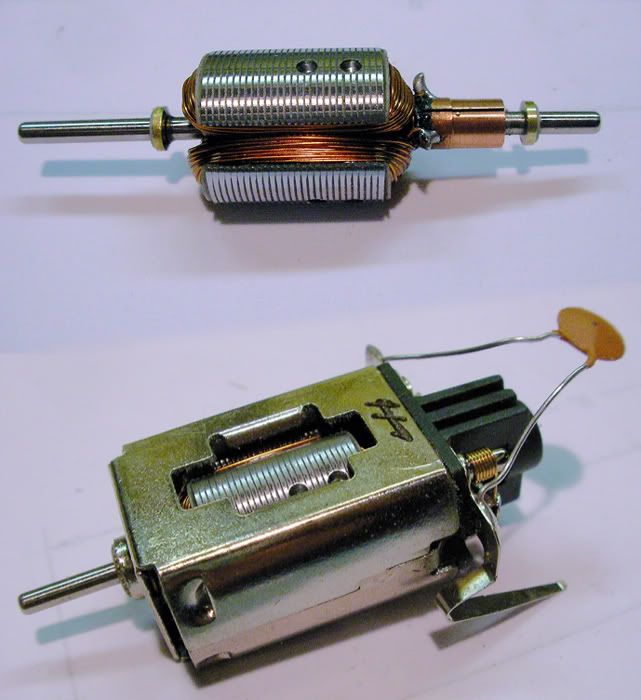

Oh... and John... armature #2 is a beauty.

Michael Rigsby

Posted 14 August 2009 - 02:42 PM

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

Posted 14 August 2009 - 05:17 PM

Looks like you took a V-8 and made a V-6 out of it.

Posted 18 August 2009 - 03:51 PM

Posted 18 August 2009 - 07:02 PM

Posted 18 August 2009 - 08:40 PM

Paul Wolcott

Posted 21 August 2009 - 03:20 PM

Posted 21 August 2009 - 06:39 PM

Of course, the shaft is just a "touch" too long still

Posted 21 August 2009 - 07:34 PM

Posted 24 August 2009 - 04:45 PM

Posted 24 August 2009 - 04:53 PM

Posted 24 August 2009 - 06:01 PM

Posted 24 August 2009 - 10:48 PM

Posted 25 August 2009 - 05:38 AM

Posted 25 August 2009 - 07:40 AM

Posted 25 August 2009 - 11:49 AM

Posted 25 August 2009 - 04:59 PM

Posted 26 August 2009 - 12:55 PM

Posted 26 August 2009 - 01:22 PM

Posted 26 August 2009 - 01:35 PM

Posted 26 August 2009 - 02:01 PM

Posted 26 August 2009 - 03:45 PM

Posted 26 August 2009 - 04:20 PM

Posted 26 August 2009 - 10:28 PM

John, this creation looks pretty nice! The endbell hardware is definitely Proslot, so good guess on the endbell. Got time for a couple questions? What diameter is the SCX blank? Any idea what size hole the magnets provide & any idea how strong they might be?

The Mura bushings are 6MM diameter. If the SCX can bushing is a 5MM one, there are plenty of quality ones of those around too. Have a look at your endbell, it's a 5MM bushing. I'm not too familiar with SCX motors, but I've heard Fate talk about their rebuildability. Any idea what their approximate retail price might be?

JH, you've done it again, buddy! Nice job of "imagineering".

Whatcha' ya' gonna wind her with?

I keep seeing you talking about your #28 wire arms and #26 wire arms, do you do #27's?

John,

As always your arm winding amazes me. Great job on the SCX arm. We here at S&E Motorsports already has a name for these motors "Little Terror".

Can't wait to do more testing ,this wind & combo should be what we need for more HP and more torque.

Thank you very much,

Ed

S&E Raceway

S&E Motorsports

Posted 27 August 2009 - 06:09 AM

What diameter is the SCX blank? Any idea what size hole the magnets provide

Posted 27 August 2009 - 10:06 AM