#851

Posted 15 December 2009 - 11:18 PM

John, what are your thoughts of this type of motor you just built, doing the things you just mentioned (shortening the can etc., to make it compact as possible) being run in a 1/24th scale chassis and providing above average performance or better? Yes/No?

Ernie

#852

Posted 16 December 2009 - 06:50 AM

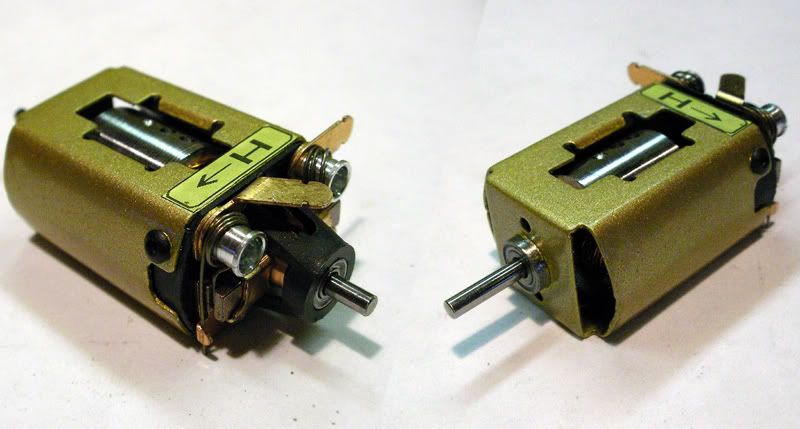

I've already done most of the work on these motors except for the can-shortening...here's an example:

It run like crazy considering how these things are from the factory. Using the C can endbell as I did in the above picture takes a considerable amount off the length and the motor would fit fine in either an anglewinder or inline car. Full-sidewinder using decent-sized tires would be the only time I think it would be necessary to cut the can down, but that wouldn't be a problem to do...of course it would then be necessary to shorten the arm stack to accomodate the shorter setup as well. I think the ideal chassis for this motor would be a piano-wire perimeter type (light) with air control on the body. There's plenty of revs, but less torque than a full size C can. On a related note, some folks are planning on running a "Frankenmotor" race using modern TSRF motors with G12 arms and replacement endbells. These are all modern equivalents to the kind of parts-swapping and motor-customization that was common in the "glory days"

-john

#853

Posted 16 December 2009 - 11:18 AM

Are you willing to give web sites that you get you arm, coms,etc. from to us? I want to experement. Took a s16d someone built(don't know who) mags, mura hood and built the can like I read on another part of the board and it flat out screams.Still learning and watching and blowing up motors.

Thanks Russell D.

I saw that you have touch on bobcats before and I did do what you said to do,how did you move you spring holders,and what is the best/easiest way to get wire off the comes?

I am only about half way through reading the arm winding section so if you have talked on any of these please tell me where.

Russell Dobbs

#854

Posted 16 December 2009 - 12:53 PM

The SCX "RX" line of motors are indeed modern Ft13uos. My favorite moder motor, though I don't know of a 1/32 club that appreciates my desire to build proper race cars with them!

In the dark ages the 13uos evolved into "P" cans for pro racing. And I think all of the few of us racing then used them one way or another. But good quality cans THEN were imports from England. These RX cans are every bit as good. For me, it was love at first sight when I bought my first RX SRS with one some decades ago.

You have seen some of the multi hinge chassis that Dennis posts from the 80s. Well, in 1/32 circles involving the ECRA in England, the cool south african guys and the Toronto group were all doing chassis with that sophistication and this can.

I did a few, but the local freeked out. So, my multi hinge 101 types have only raced a couple times, but otherwise are just play toys.

John is discovering the joy of "just cause" building. As in "I did it just cause it seemed like fun" rather than building for the next race.

Fate

3/6/48-1/1/12

Requiescat in Pace

#855

Posted 16 December 2009 - 02:13 PM

Did you ever think a string on this topic would still be going on since July 2008?

It's kind of a tribute to the amount, type and (to use the most popular phrase these days) transparency you apply to this part of the hobby. Keep it going....apparently, we haven't run out of questions or winds yet!!!

Home of Area 51 Chassis Works

Steve Vogt, Sr.

#856

Posted 16 December 2009 - 04:46 PM

HAVLICEK, I have been reading and trying to keep up with what is going on in here. I spent about 2 hrs a few nights ago reading on here. And watching you and others on here with your reports, it is neat to see how you started a few years ago to now and see a huge differents so that gave me hope that I could thy arm winding.

Hi Russel,

Then I served my purpose since, besides documenting my tortured attempts at getting back into rewinding, my whole intent was to see if others might join-in!

Now I have never took an arm all the way down,the most I ever did was take 3-5 off and put back to the com. So I decided to take a bobcat 36d all the way and experiment,well it is harder than it looks. But I got it rewinded and it atleast it works. This is what I did, took all wire off took 5 spacers off stack and put back together with 80 winds on each. What will this do? Plan on racing it this weekend.

That's freakin' excellent! If you really want to do this, just wind everything you can get your hands on (no really!). It's really cool to experiment on modern D can motors (same size arm and roughly the size ofg a Mabuchi FT16D) so you can save the old motors for when your confidence grows.

Are you willing to give web sites that you get you arm, coms,etc. from to us?

There's the rub...the only place I could get to seel me arms and coms is Mura. They have both .007" and .014" arms and very good coms, but they ain't cheap. As a consequence, I save those for special jobs and have had to learn ways to salvage coms and arms...even when they've been epoxied (but not balanced...although you can get some useable arms with extra work from those by saving as many lams as you can until you can build a full stack. I don't know why the motor manufacturers (except for Mura) won't sell this stuff, but that's the way it is. Magnet wire I get from Planet Engineers and I get hi-temp epoxy from a place in Brooklyn named "Cotronics"...but that too is VERY expensive (although it lasts for ever).

I saw that you have touch on bobcats before and I did do what you said to do,how did you move you spring holders,and what is the best/easiest way to get wire off the comes?

I don't really move the spring holders (posts?), I just either cover them to help prevent them from melting or sometimes cut them off (or just cut them down some) and use screws to attach metal spring posts to the endbell.

I want to experement. Took a s16d someone built(don't know who) mags, mura hood and built the can like I read on another part of the board and it flat out screams.Still learning and watching and blowing up motors.

Thanks Russell D.

Bingo Russel

John is discovering the joy of "just cause" building. As in "I did it just cause it seemed like fun" rather than building for the next race.

For sure Rocky, but this is mostly all I ever did as I was never a real racer...so it's more like "rediscovering"

The SCX "RX" line of motors are indeed modern Ft13uos. My favorite moder motor, though I don't know of a 1/32 club that appreciates my desire to build proper race cars with them!

They really are an excellent platform as you (and I) have noted several times. Since the motor is inexpensive and has so much potential, it would be a great motor to build a "class" around that let people tear them up and do whatever they wanted with them...just like the old days

Hey, John,

Did you ever think a string on this topic would still be going on since July 2008?

It's kind of a tribute to the amount, type and (to use the most popular phrase these days) transparency you apply to this part of the hobby. Keep it going....apparently, we haven't run out of questions or winds yet!!!

Hi Boomer. I really didn't know what was going to happen with all this. I came here like everyone else to see what was going on...built some cars and then the scarey stuff happened, I tried rewinding again

-Rick (RGEO) makes a really nice winding crank that works like the old LaGanke ones everybody used, so that part can still be had.

-Mura sells arms and coms, nobody else I tried will.

-Hi Temp epoxy can be had from Cotronics (I use their "Duralco 4461"...great stuff, but not cheap)

-Planet Engineers is a good source for magnet wire and they have it in half sizes as well as several different coatings and in 1 lb. spools.

-Modern D can motors that haven't been epoxied or balanced are a great way to experiment. See if you can get some burnt-up ones as they'll most likely be tossed anyway.

-john

#857

Posted 16 December 2009 - 05:00 PM

Your workmanship is superior,and your dedication to motor winding is endless.

Thank you,

Ed

S&E Raceway

S&E Motorsports

www.seraceway.com

S&E MOTORSPORTS

S&E Raceway

#858

Posted 16 December 2009 - 05:13 PM

Not really...anybody can do what I do with some patience and perserverence. Now Jairus, Rick Thigpen, Howmet, Steve O'Keefe etc etc etc ...what they do really can't be learned. You either got it or you don't; they "got it"! Still...thanks buddy

-john

#859

Posted 16 December 2009 - 07:02 PM

...anybody can do what I do with some patience and perserverence.....

Well, that's probably true... in theory....

But.... As I look at the various armatures that get posted here, & look the the attention to detail & the level of workmanship, I seriously doubt that you need to defer to anyone on winding armatures, John...

Plus, given the fact that the book on "how-to-do" this operation within the hobby just has never been written, it just makes it THAT much more impressive, when looking at these wonderful pieces that can produce so much speed...

For those of us who have been around a few yrs. ( decades...), it's easy to see the influence of the "major rewinders" of the day... Out here in Los Angeles, we had Zimmerman & Steube to look at, and Thorp... The East coast had Pooch & the other, lesser-known cottage-industry winders... Straight, tightly wound armatures like yours are only the work of someone who chooses to take the time to do an armature the RIGHT way... Plus, w/ the baked epoxy & tied & trued comms, plus the balancing, the armatures will run like crazy, & last a loooong time, w/ a little common sense & TLC...

So... I don't wanna hear that "anyone can do it" line... Sure, they might reach your level of expertise... But, the photos speak for themselves... You take 2nd place to no one, buddy...

Great work... Great thread... One of my favorite threads, here on Slotblog... It exemplifies the true spirit of the scratchbuilt slot racing hobby, making servicable armatures using any means possible... Even used vintage parts, when needed...

Take care, John... & good winding!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#860

Posted 16 December 2009 - 10:03 PM

Hi Ed,

Not really...anybody can do what I do with some patience and perserverence. Now Jairus, Rick Thigpen, Howmet, Steve O'Keefe etc etc etc ...what they do really can't be learned. You either got it or you don't; they "got it"! Still...thanks buddy

-john

In my day, mid 60s. My best, looks anyway, doesn't hold a candle to yours. I think you are one of very few that wind THAT well. A few looked like they were CNC done. I bow to the master.

OLPHRT

PHIL I.

#861

Posted 16 December 2009 - 10:38 PM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#862

Posted 16 December 2009 - 10:40 PM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#863

Posted 17 December 2009 - 06:36 AM

As an aside, why do they put those little caps on those motors? They can't do chit, except look trick.

???Which caps do you mean Rick. If you're looking at the SCX motor, I did tie and epoxy the top of the com as a sort of "cap" on that one. For some reason, the com needed a bit more work to true it up and I worried about it staying strong even though it's a fairly mild wind. If you mean the post protectors...the metal caps on the spring posts, they're supposed to help prevent the motor springs from melting through the posts. Of course, they won't do THAT much unless you make sure that the springs don't carry current by insulating them. Those are the only cap things I can think of...I think

-john

#864

Posted 17 December 2009 - 06:47 AM

Thanks. People need to realize that the progress I've made simply means that I have less failures (although I still have them for sure) and my failures at least look a little better

-john

#865

Posted 17 December 2009 - 10:58 AM

1st question is the machine to wind the arms is there anyway you can post pictures of it with an arm in it. I saw one on here. I have a buddy that will build one but wants to see exactly how it works. He is a machinist,and it really helps knowing someone him.

2nd question. Now what is the direction I should be going on wire? Say the arm has 28 on it should I go 23. The higher # means ? Lower # means? What should I be using.

I have two bobcats and a f7(close in size to x12 etc.) I will be tring next.Start with the cheaps one first,that way I don't get upset when it only makes a few laps.lol

THANKS FOR THE HELP.

Russell Dobbs

#866

Posted 17 December 2009 - 11:54 AM

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#867

Posted 17 December 2009 - 01:12 PM

Raw materials? Now Rick knows what I was doing when he showed me his box of cheap used arms, I would buy them in bulk!

What I do it take a dremel and cut wheel and slice through the BACK of the stack, grab the whole thing with needle nose and just rip it off.

As you wind, one thing that will happen is your sense of touch will change. You will be able to FEEL the inconsistencies in the wire down to .0001 inch. This is important because you will develop a feel for HOW the wire streaches as you wind it and make minute adjustments as the wire varies within the tolerances.

I know, I know, it seems......well.........geeky. But you really DO get a satisfaction from feeling things, doing things that most will not.

Fate

3/6/48-1/1/12

Requiescat in Pace

#868

Posted 17 December 2009 - 02:06 PM

Another "Tiny Terror" SCX RX42 rewind for Ed Miller. A #29 single wind that draws around an amp and is neutral-timed so it can go either way. The arm draws about 1 amp:

...the completed motor:

-john

What's the deal with the little brown Thorazine tab (#104) ?? Gotta have it?

-Rick (RGEO) makes a really nice winding crank that works like the old LaGanke ones everybody used, so that part can still be had.

-Mura sells arms and coms, nobody else I tried will.

-Hi Temp epoxy can be had from Cotronics (I use their "Duralco 4461"...great stuff, but not cheap)

-Planet Engineers is a good source for magnet wire and they have it in half sizes as well as several different coatings and in 1 lb. spools.

-Modern D can motors that haven't been epoxied or balanced are a great way to experiment. See if you can get some burnt-up ones as they'll most likely be tossed anyway.

-john

How significant are the differences in Temp. ratings? I'm really liking the purple but it's not the warmest of the lot. Thanks for the sources by the way!

#869

Posted 17 December 2009 - 02:23 PM

What's the deal with the little brown Thorazine tab (#104) ?? Gotta have it?

How significant are the differences in Temp. ratings? I'm really liking the purple but it's not the warmest of the lot. Thanks for the sources by the way!

Since Planet Engineers sells the stuff in 1 lb rolls that last a loooong time, I only buy the second-highest temperature rated wire from them. The highest temp stuff seems to only have a thicker coating of the same insulation (I'm guessing) and is a touch more difficult to use neatly. The nicely colored stuff is (I believe) all nylon insulated which is OK, but significantly more prone to damage from heating up so even though it looks cool, I don't mess with it. You're quite welcome for the sources of course! Some of them I got from asking right here, so I'm only returning the favor. I think it was Bill that clued me in to Planet Engineers and they're great. Service and product has never been an issue with them.

-john

#870

Posted 17 December 2009 - 02:46 PM

1st question is the machine to wind the arms is there anyway you can post pictures of it with an arm in it. I saw one on here. I have a buddy that will build one but wants to see exactly how it works. He is a machinist,and it really helps knowing someone him.

Hi Russel,

Sure...here's a picture of one of mine. I have two, one I keep set up with a clamp for FT16D sized arms, and the other I switch back and forth between FT26D and FT36D clamps. It's not a machine though as a clamp with a crank so you can hold the arm in it while you turn the crank to feed wire. I set mine up with a horizontal spool carrier so the wire doesn't go rolling around the table

Lower gauge number means bigger wire diameter...lower=bigger, just like shotguns2nd question. Now what is the direction I should be going on wire? Say the arm has 28 on it should I go 23. The higher # means ? Lower # means? What should I be using.

On Mabuchis, I think anything less than .4 ohm is really pushing things...and the Champions are probably a bity safer. The later Muras have a MUCH better ability to handle the heat and you can pretty much go nuts on those. Still...#23 wire is flirting with disaster even on those motors even if the motor is set up well and the driving is done with caution (check the motor to see how it's heating up).

Some other considerations would be how advanced the com timing is. As you advance past "neutral timing", the motor will start to run faster in the direction that you advanced the timing (up to a point) but will also generally start to run warmer...so there's a definite tradeoff. The other biggie is the actual motor setup...for example the airgap. A tighter airgap may restrict the revs a bit, but produce more torque, brakes...and heat. Opening up the airgap may let the motor rev higher and run cooler but with less torque and brakes.

Another consideration when doing this stuff is how you terminate the mnagnet wire at the com tabs. If you use regular 60/40 rosin core electronics solder on a hot wind...the motor can easily get hot enough at the com to melt the solder and throw the wire. Silver solder is only marginally better but might be worth it for mild winds. For the mild stuff, I use a paste in a syringe of silver solder and flux called "Solder It" that's good to 450 degrees F and will supposedly remelt afterwards at a significantly higher temperature. From #26 wire and thicker, I started welding (actually brazing) the wire to the com tabs a while ago as this is good to over 1000 degrees. Still, a hot #27 or #28...even a #29 could toss the com solder, so I would only go as hot as the motor can take. All the weaknesses will quickly become apparent as things get wilder...starting with the endbell

-john

#871

Posted 17 December 2009 - 02:59 PM

R/C cars use them to cut down radio interference because the cars are being controlled by... radios. If the caps weren't there and your radio picked up a big arc from the brushes, your car could suddenly do something you didn't want it to do.

A boxcar full of caps soldered to a motor won't remove lousy driving skills however.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#872

Posted 17 December 2009 - 08:20 PM

-john

#873

Posted 17 December 2009 - 09:01 PM

Dennis David

#874

Posted 17 December 2009 - 09:26 PM

Guys, you need to read what other people write...The "one-a-day" tablet is a capacitor (or cap) to reduce RF (radio frequencies) that cause interference to nearby radios and tv's caused by the brushes arcing on the comm.

#875

Posted 17 December 2009 - 09:37 PM

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

This topic is locked

This topic is locked