Can't tackle the front axle assembly until the front wheels arrive, so I turn my attention to the pan assembly. At Mike Katz' "School of heavy chassis for heavy bodies" I learned cars like this don't necessarily need lots of mechanical foof like intricate plumbing to work well. So my plan is heavy pans that fit the body sides like a glove, hung via simple hinges.

At some point this car is going to need to weigh at least 150 grams complete, and how I make the pans is going to be my last chance. It's a narrow car that needs to pack in a lot of heft in a narrow package. I'm thinking .032 pans …...

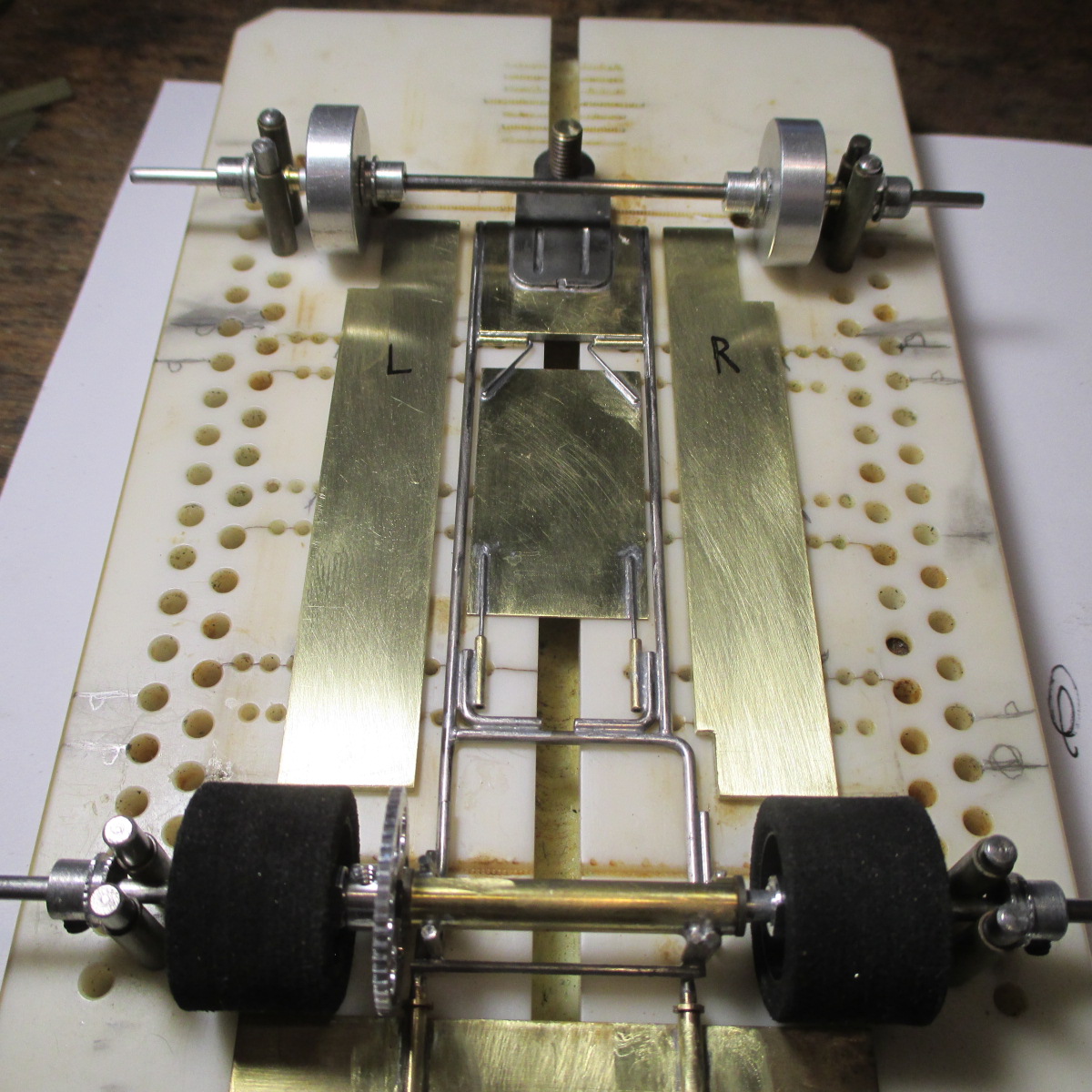

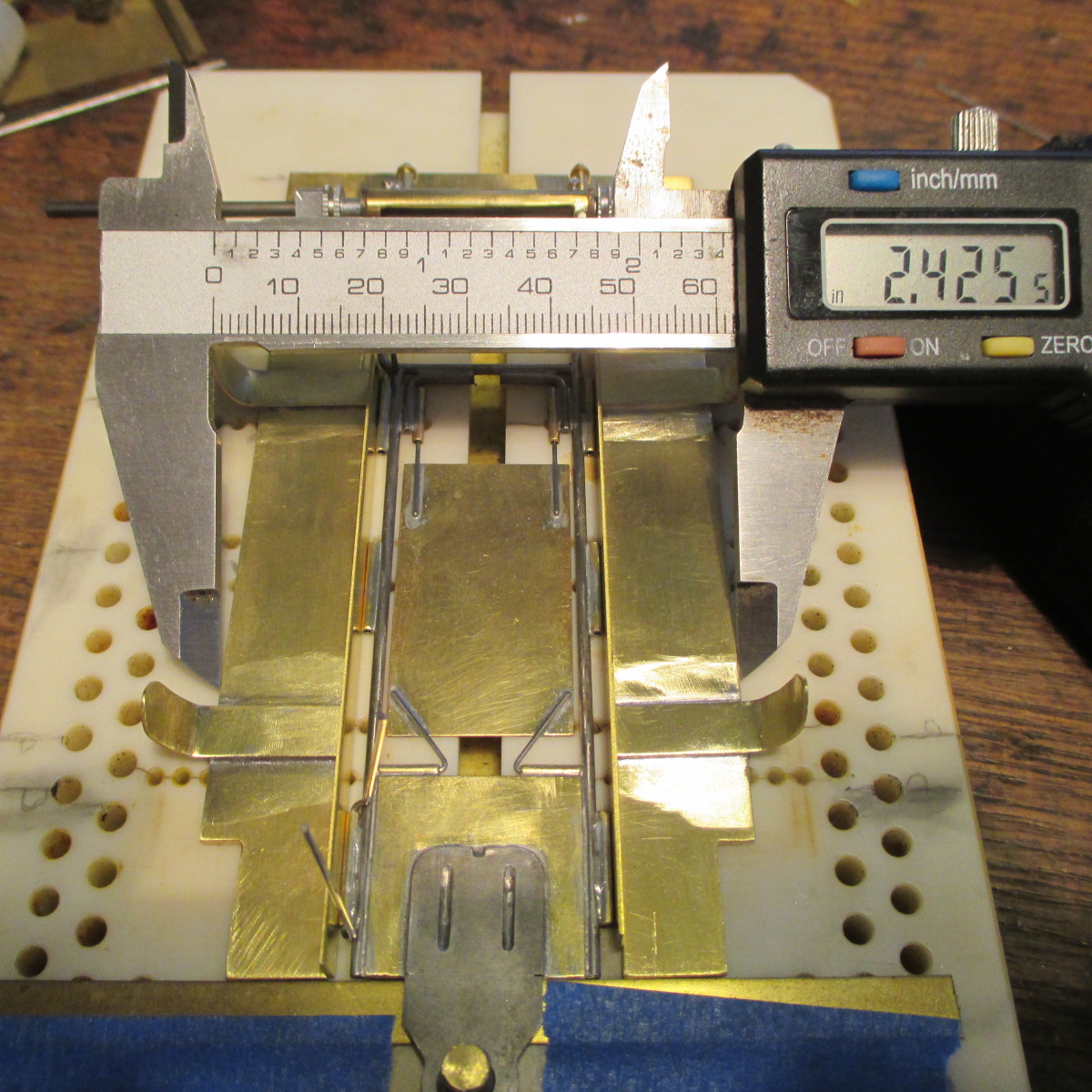

First step was mocking the chassis up with all four jig wheels and spur in their actual final resting places at the planned track widths - 2 3/4" front and rear. If I can squeeze 2 7/8" out of them during the assembly phase, super. Right now I just need to know how to cut and hang the pans. Note how I had to cut some meat off the top of the RGeo jig tongue - it was preventing the body from laying at ground zero

Pretty simple except for the elephant in the room - the body skirts on this Lola are extremely curved at the bottom. I'll bet a modeler would call it sexy. I call it a roadblock. No worries - I have a plan

![]()