Tamiya Lola T70 Hardbody scratchbuilt

#126

Posted 02 August 2019 - 01:39 PM

- Pablo and Rotorranch like this

#127

Posted 02 August 2019 - 05:34 PM

Hey Paul, I do not understand the advantage of putting weight behind the rear axle. Is there a theory for this design.

I have always thought less weight swinging around make's for a better handling car.

Looks like you guys enjoy discussing the theories and reasoning, so I'll go ahead and give you some long answers and share my reasoning. Just some random things that scroll through my head when designing:

-I'm a copycat. At some point, somebody tried that aft weight platform on a hardbody on the flat track and it worked. Now I see a lot of guys using it there. Marco's car has one, so it must be working ![]()

-"weight swinging around" isn't an accurate description. Look at a pro-era lead sled fully plumbered with tilting mounts - lots of parts de-coupled from the main rails and it's all as low down as possible. The secret of handling is in the de-coupling of components. Look at a Cheetah running at full speed in the wilds of Africa - absolutely everything on that animal is moving. Same as a Top Fuel dragster going down the strip - the only things on that car that aren't flexing every which way is the engine and axle assembly.

-De-coupling sections of a chassis lessens the likelihood of crash damage - instead of the force transferring throughout the car, it's diminished and absorbed.

-Weight high up is always bad. My BP Platform is not only de-coupled, it's only .025 thick, doesn't weigh much, and it's down low. What Eddie will probably do is start adding lead one piece at a time and watch lap times. As they continue to go down, he will keep adding more until it levels off. We won't know how much the car likes until it's on the track. It may be best without any weight. In that case he could even consider removing it. It will come right off by hitting the rear keepers with a hot iron.

-One heavy hitter chassis builder out there who builds a lot of hardbodies suggested several sub-assemblies, all de-coupled. That has been one of my main themes on this build. Hopefully every piece contributes to the goal of making laps.

-My favorite from Danny Zona:

"There is only one truth - lap times. Everything else is just theory".

-The Laws of Physics were on Earth long before slot cars were invented. We all know these things defy common logic sometimes ![]()

-dc-65x: "Onward. Wheeeeeeeeeeeeeeeee" ![]()

- MattD likes this

Paul Wolcott

#128

Posted 02 August 2019 - 06:41 PM

I'll add one thing. That back plate was first used on BPR hard body cars about about a year ago & the idea originateds from Brazil. Some place on here, is the sports car (LMP?) chassis Marco C. rebuilt for Ed Shorer & the first time out, Eddie with that car was untouchable. I believe that race coverage article had an explanation how the plate works. I know there were numerous Keith Tanaka photos of the chassis..

I intend to live forever! So far, so good.

#129

Posted 02 August 2019 - 06:59 PM

People have been adding weight behind the rear axle at BPR for quite some time before Marco did the rebuild. He certainly improved on it. And it was a GTP car. A Tamiya Porsche 962c.

I'm really enjoying seeing how the Lola is shaping up.

Eddie

Team Boola (circa the '60s)

#130

Posted 02 August 2019 - 07:56 PM

Thanks for the corrections Eddie. I must have overlooked the previous plates/weights being used. Did they originate in Brazil as I had thought? Some of those BPR hard body cars are build with innovative engineering.

I intend to live forever! So far, so good.

#131

Posted 02 August 2019 - 08:02 PM

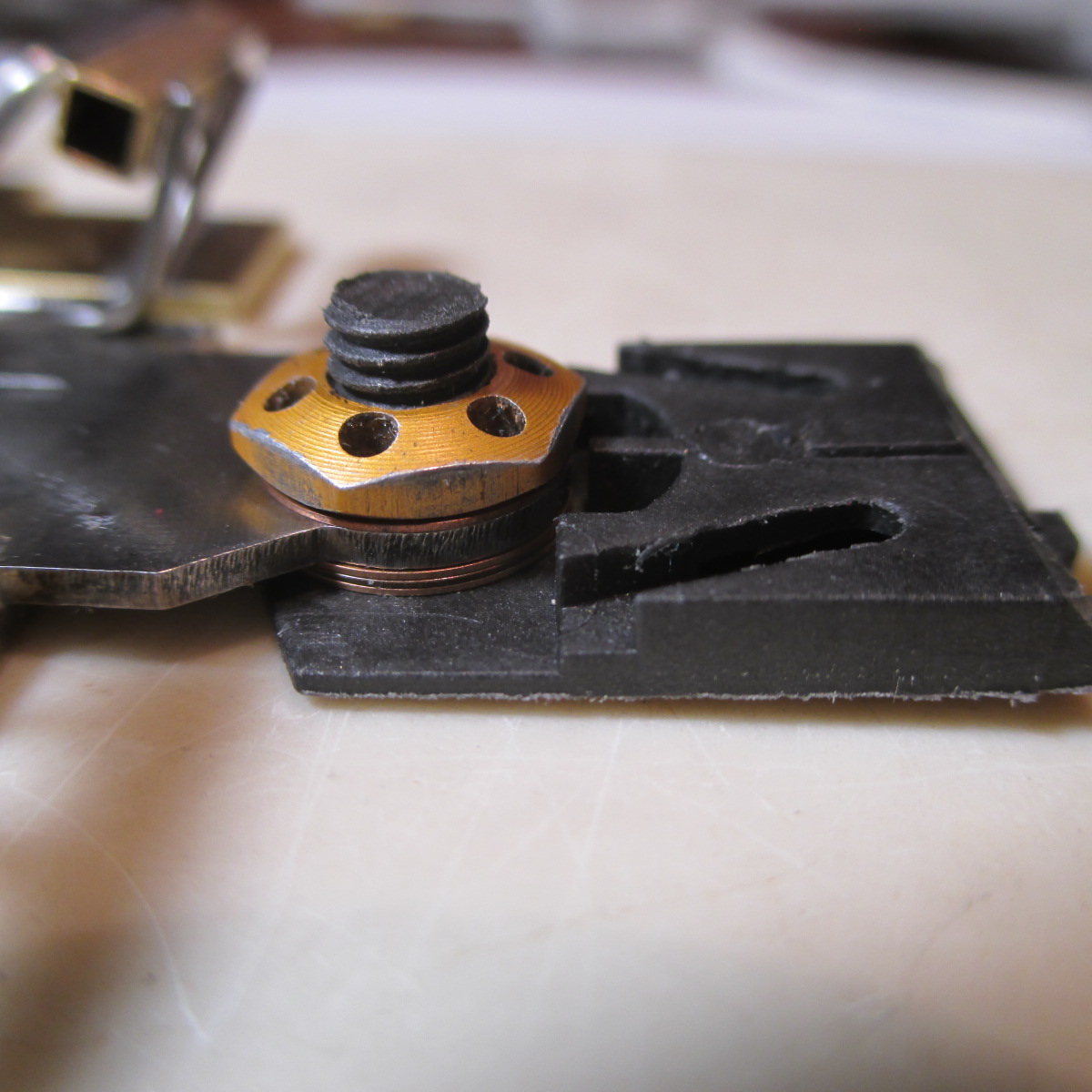

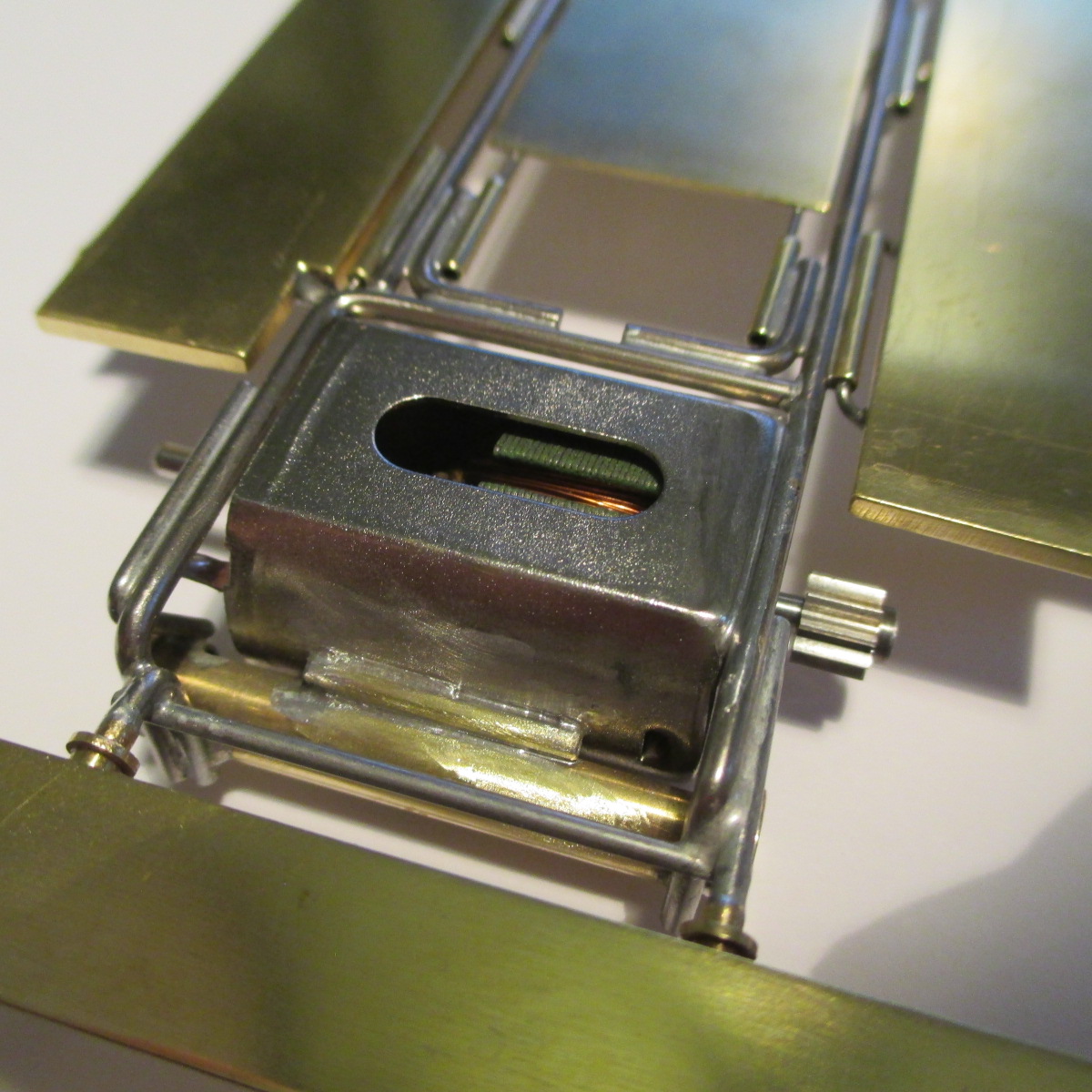

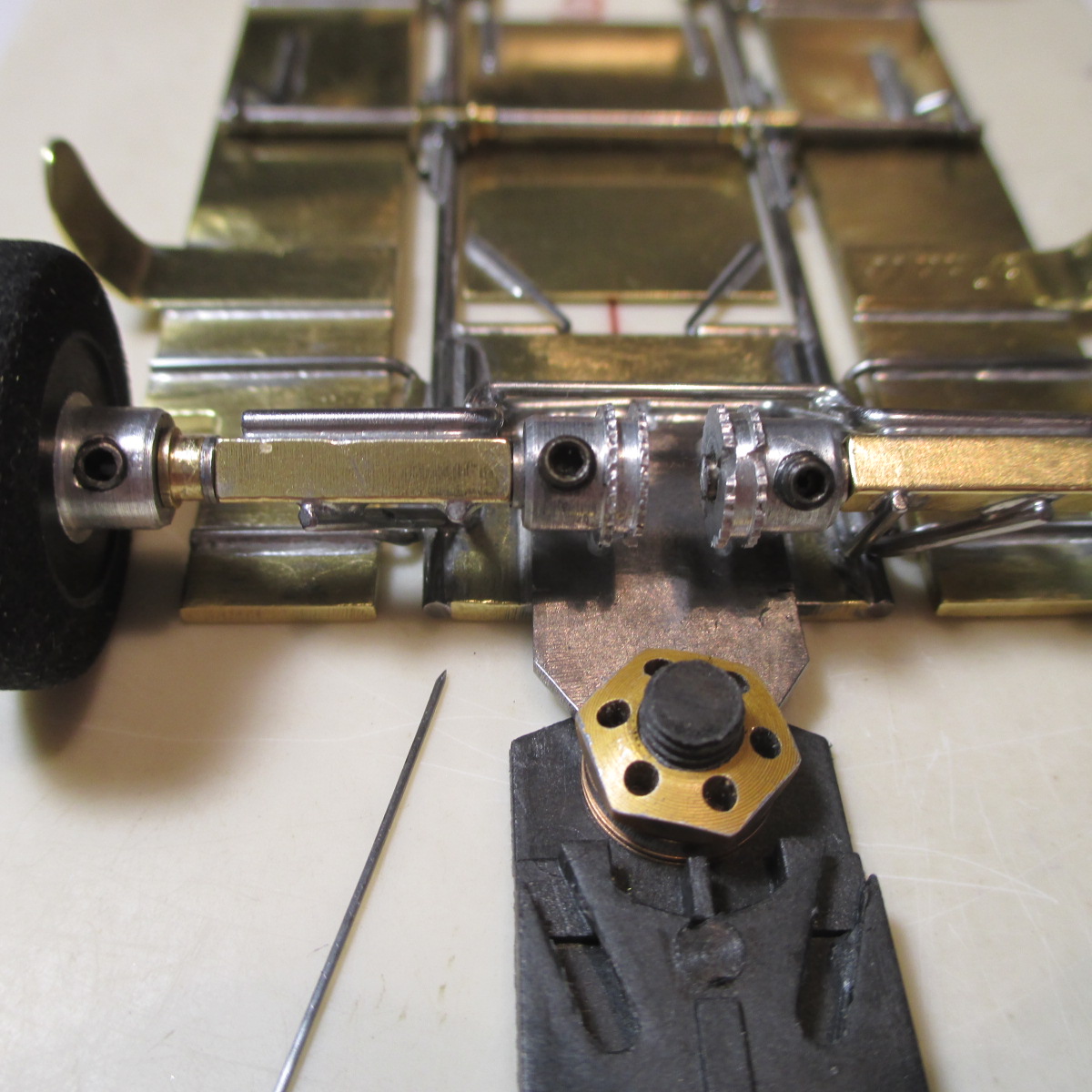

Red Fox flag blueprinted (didn't take much, it's perfect), all rotating surfaces faced with Magnehone, ChiTown tongue hole hogged out slightly with a chainsaw file, three 10 thou Koford bronze spacers under, one over (Eddie, the one over is in case it needs more, simply remove the nut, swap it from above to below) and a Koford aluminum nut

Koford rear axle has a single 20 thou steel spacer between gear and bushing

Hawk Retro had some acid/60/40 work - 10T 64P steel pinion, three chassis attachment points tinned, and wire tabs with a mini-dollop. Then washed, rinsed, blow dried, and heated on the solder station until dry ![]()

- Jencar17 likes this

Paul Wolcott

#132

Posted 02 August 2019 - 11:05 PM

"There is only one truth - lap times. Everything else is just theory".

-The Laws of Physics were on Earth long before slot cars were invented. We all know these things defy common logic sometimes ![]()

Agreed.

One more thought. While we are talking physics. The weight you put behind the rear axle has a negative and lifting effect on acceleration. If you want to lift the guide out of the slot on acceleration, just keep adding weight, physics.

Cannot see how this added weight helps cornering or acceleration. Is it more traction you are after ? got to be a better way.

Lap times will tell the truth. Please add the same amount of weight ahead of the rear wheels for a good track test. ![]()

#134

Posted 03 August 2019 - 03:49 PM

Martin, you should contact some of the BPR hard body racers to find their opinions why they think the weight back there works or doesn't. I certainly don't know & it seems that most Slotblog members here don't either. Eddie Shorer would be the exception. I might be wrong, but I seem to recall some of the brass back weights on stock car chassis had lead weight added on them too.

In the photo above, had the driver used a 4-wheeled cart, the donkey could have easily pulled the load. ![]()

- Pablo likes this

I intend to live forever! So far, so good.

#135

Posted 03 August 2019 - 05:24 PM

The rear weight concept was used in 2014 at BPR. I drove a rear weighted hardbody NASCAR in the 2014 D3 Hardbody Nats at Buena Park Raceway.

The idea for the rear weight actually originated with a hardbody Jalopy which Bryan Warmack built/raced to victory in the 2011 and 2012 D3 Hardbody Nats. I copied Bryan's jalopy design and built a similar Jalopy car (different body) which I won the 2013 D3 Hardbody Nats at BPR. To this day, this particular Jalopy still holds the total lap record for the Jalopy class at BPR.

Bryan Warmack's D3 Hardbody Nats "Jalopy" winner for 2011 and 2012.

Keith Tanaka's 2013 D3 Hardbody Nats "Jalopy" winner. Notice how similar it is to Warmack's Jalopy design. Fortunately for me, my copy of Bryan's car handles very well. It still holds the total lap record for the hardbody Jalopy class at BPR.

Because this Jalopy handles so well (for a Jalopy) and is easy to drive, I wanted to find out "what" makes it handle. At the time, I thought the rear bumper on the Jalopy added significant rear weight to the chassis since the rear bumper is far from the rear of the chassis. The long distance provides "leverage" as far as rear weight is concerned without adding a lot of weight to the rear. Using wider rear tires (Protrack drag tires, .700" before trimming versus the standard .500" wide Protrack tires) probably helped to stabilize the traction. Another factor is the body mounting. I managed to build the Jalopy body mount so it "floats" on the chassis side pans (again, similar to the Warmack design). If you ever wonder how much the body mounting affects the handling of these top heavy cars, take some laps without the body, then add the body and notice the big difference in handling and lap times. Mounting the body with little or no stress on the chassis helps the handling significantly.

Anyway, I built a NASCAR adding "rear weight" to the chassis. Here's a photo of the car I built/raced in the 2014 hardbody Nats at BPR:

Adding the rear weight improved the handling by stabilizing the traction of the car thru turns. I added rear weight to several other hardbody cars (different racing class cars) and saw improved handling again with different types of hardbody cars. Other racers at BPR began adding rear weight to their cars and for most of them they experienced improved handling of their cars.

Later, I decided to try the "rear weight" concept by building a Porsche 934 with the motor "behind" the rear axle. Instead of adding rear weight, why not mount the motor behind the rear axle?

Just like the 1/1 Porsche, this particular car (flat brass pan type) resulted in an excellent handling car. It's not faster thru the turns but is much more difficult to deslot, thus it's much easier to drive consistently fast thru turns.

The last rear motor car I built was a Porsche 962. This particular car won the 2017 D3 Hardbody Nats "GTP" race driven by Victor Dubrowsky. Again, this car handled very well and easy to drive consistently fast.

Here's a link to photos and more info on the Porsche 934 and 962 rear motor cars: https://socald3.smug...-cars/i-FXm2HkS

After building/racing rear weighted and rear motor cars since 2014 at BPR, I can say these type of cars handle very well as they are more difficult to deslot than the typical sidewinder/anglewinder hardbody car. They are not faster thru the turns, but are easier to drive for most racers.

Of course, there's other ways to building/racing hardbody cars which can be better, that's what' so fun about scratchbuilding these cars.

Keith ![]()

- slotbaker, Pablo and Jencar17 like this

Team Rolling Hills circa '66-'68

#136

Posted 03 August 2019 - 05:28 PM

Nice mags on the cart, Martin ![]()

Motor is soldered in 3 places. Eddie, when you need to remove the motor, I'd first slice the top 3/32 brass tube piece off athwartships, sacrificing it, with a thin 409 Dremel wheel

Then heat the side rail and .063 tube joints from below

- Jencar17 and justDave like this

Paul Wolcott

#137

Posted 03 August 2019 - 05:33 PM

Keith, those Jalopies are ultra keen ![]()

![]()

![]()

Paul Wolcott

#138

Posted 03 August 2019 - 06:27 PM

Thanks Kieth for your in-site and experiences.

There is something going on here. A dynamic that is counter intuitive. But if it working, carry on.

#139

Posted 03 August 2019 - 06:37 PM

It is counter intuitive (rear weight or rear motor). You do need to use wider, firmer tires (Protrack drag tires .700" wide before trimming, treated rather than natural) to balance the rear weight. This combo seems to work very well. It's not faster thru turns, but provides a smoother, more stable handling thru turns than the standard setup.

Keith

Team Rolling Hills circa '66-'68

#140

Posted 03 August 2019 - 08:19 PM

Martin, what took me several posts to convince you, took Keith Tanaka one.

I'm getting the impression I'm still a newbie builder here in your mind ………. ![]()

Paul Wolcott

#141

Posted 03 August 2019 - 09:19 PM

Hmmm.... No adjustable motor bracket with screws? What do you usually do to adjust gears? This is getting above my pay grade! ![]()

Eddie

Team Boola (circa the '60s)

#142

Posted 03 August 2019 - 11:11 PM

Paul, I'm the newbie, learning something everyday, and I love it. Dont take it personal and did not see "several posts" with you trying to convince me? Just looking for the reason or theory behind the design.I did quote you and agreed with your post #127

Kieth presented data. You are not there yet with this beauty.

Look forward to your track testing though.

But you may have the motor on the wrong side of the rear axle ![]()

Did you check out those rear engined jobs? that's a new one on me.

#143

Posted 04 August 2019 - 01:31 AM

I’m happy to say that Keith’s observations/explanations fall well within the laws of physics. That is a good thing because violating these laws carries with it severe penalties.

Starting with a simple equation:

Ff = µ X Fn

Where Ff equals the frictional force at the rear tires i.e. the force that will resist sliding and

µ is the coefficient of friction, a property of the tires and the surface and

Fn is the normal (downward) force on the tires we would expect the following:

Holding the amount of weight constant, weight behind the rear axle will exert a greater downward force than weight in front of the rear axle and the frictional force will increase. Moreover as the weight is move farther and farther behind the axle that force will increase further.

There is a bit more to it than that however.

There exists also an inertial moment between the pivot point (guide) and the rear of the car. This is a function of the position of the center of mass of the car and the distance between that center and the pivot point. (Think about the effort required to swing a heavy weight at the end of a long versus a short stick) The greater that moment, mass X distance squared, the greater the resistance to the beginning of the slide however, once the slide has started, it is harder to stop.

So, putting aside issues like front end problems (lifting donkeys) the greater the effective weight on the rear end the less likely it is to start to slide but, (physics giveth and physics taketh away) once a slight starts, the margin for error in stopping it shrinks. (Porsche drivers are familiar with this phenomenon)

EM

#144

Posted 04 August 2019 - 05:22 AM

Martin, what took me several posts to convince you, took Keith Tanaka one.

I'm getting the impression I'm still a newbie builder here in your mind ……….

I don't think we/anyone considers you to be a newbie builder on here. In this situation, it's just a case of Keith having more experience building & racing hard body cars. The west coast has many talented hard body racers, but I doubt any of them is more experienced than Keith when it comes to racing hard body cars with scratchbuilt chassis.

I intend to live forever! So far, so good.

#145

Posted 04 August 2019 - 09:06 AM

"...… did not see "several posts" with you trying to convince me?"

Re-read posts 120,122,124,127,128,129

"But you may have the motor on the wrong side of the rear axle ![]() Did you check out those rear engined jobs? that's a new one on me."

Did you check out those rear engined jobs? that's a new one on me."

I did actually consider the motor aft of the axle instead of a rear platform, and the driver convinced me that was a little too radical. I agreed. If I was in LA and could test every day I'd probably try it. But I don't and I have one chance to present Eddie with a competitive car. So I stuck with what we all know will work - full sidewinder forward of the axle and a light decoupled sheet platform aft to add weight if needed. Again, if the car works fine without any weight there, it's certainly not hurting anything. Not to mention, once again, two touches with a hot iron and it comes right off.

Every detail is given considerable thought here at The Wolcott Twisted Physics Ranch ![]()

Paul Wolcott

#146

Posted 04 August 2019 - 09:12 AM

Hmmm.... No adjustable motor bracket with screws? What do you usually do to adjust gears? This is getting above my pay grade!

Eddie

See post #136, piece of cake. Or send it back to me here at The Ranch and I'll do it.

Paul Wolcott

#147

Posted 04 August 2019 - 11:38 AM

I don't think we/anyone considers you to be a newbie builder on here. In this situation, it's just a case of Keith having more experience building & racing hard body cars. The west coast has many talented hard body racers, but I doubt any of them is more experienced than Keith when it comes to racing hard body cars with scratchbuilt chassis.

Well said Bill.

Paul, please do not make it uncomfortable to enjoy your builds, if you do NOT like questions or input on your builds just say so and I will go. I was assuming (and feel) this was an open forum where we all have respect for each other and there comments. I feel like we all contribute to the conversation, this has always added to my interest. This is your sand box and I respect that. No put downs, only an interest in designs I had no knowledge of

Liked your explanation Alan and Keith's post #139 makes sense.

Look forward to track testing with weight moved front and rear of the rear wheels. Drive ability and lap times as Paul has said will say it all.

#148

Posted 04 August 2019 - 02:00 PM

A lot of things defy logic in slot racing.

Maybe for the particular traction level, and configuration of the track, at BP, the motor in back is indeed the ticket.

But for a real scientific test, you would build the chassis with a motor bracket like the below, and try it both ways, on the same day, obviously under the same conditions.

- Pablo, Jencar17, Rotorranch and 1 other like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#149

Posted 04 August 2019 - 02:39 PM

Now you show us ![]()

- Rotorranch likes this

Paul Wolcott

#150

Posted 04 August 2019 - 04:09 PM

Front clearance check:

With a piece of .055 under rear axle and front end resting on front wheels, a piece of .020 wire is no-go. My first thought was, uh oh, I missed the math on front jig wheels. Nope. The culprit is, 3/32 axles riding loose in 1/8 square tubes are very sloppy. So the wheels let the chassis droop

You may recall I wanted to have independently rotating fronts and allow the axles to rotate within the tubes. That was flawed thinking, and I'm simply going to solder the wires inside the tubes solid. Simpler is usually better and I don't feel I'm losing anything.

So the temp collars come off, axles come out, and it's time for two coats of nail polish to harden and anneal the JK firm rubber ![]()

- Jencar17 likes this

Paul Wolcott