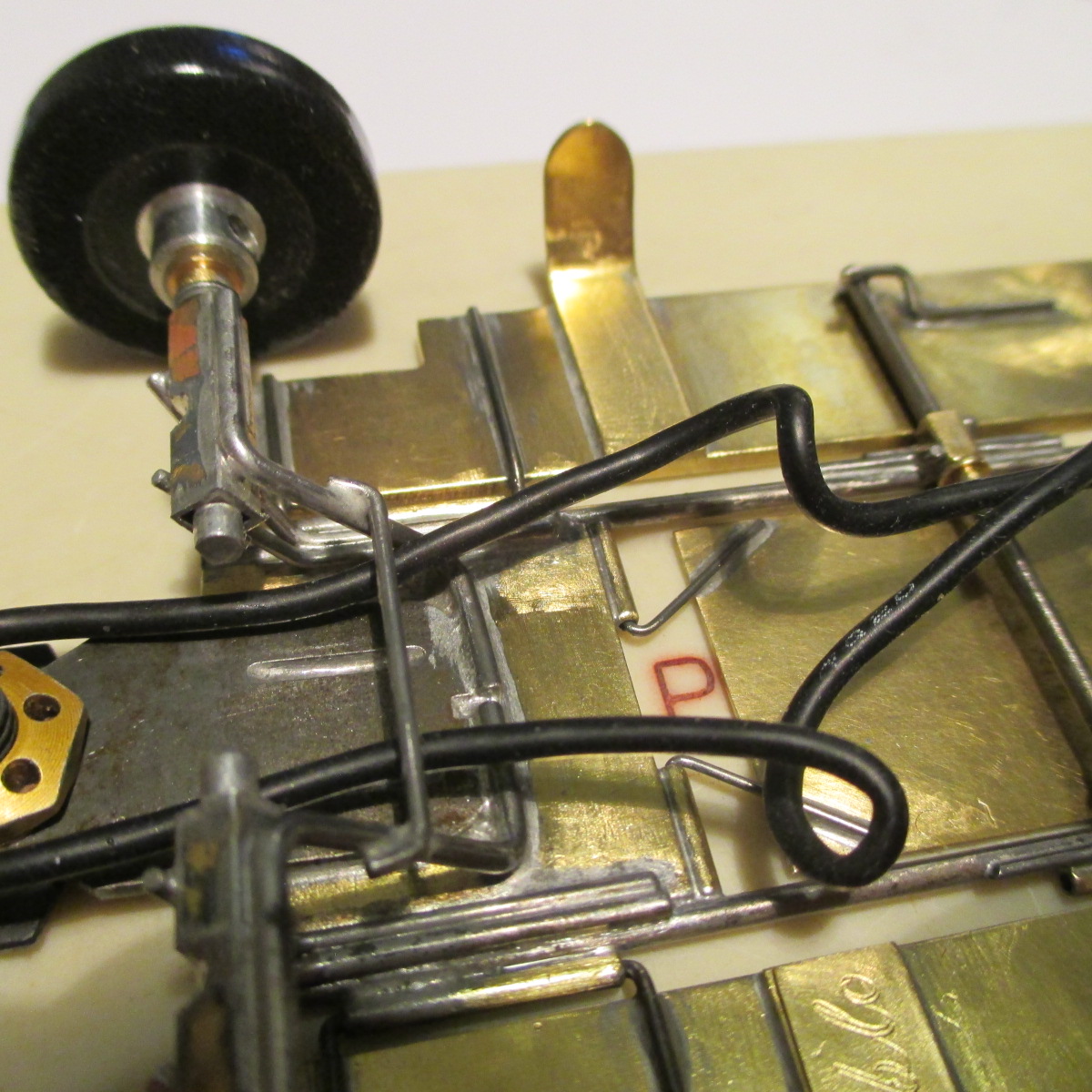

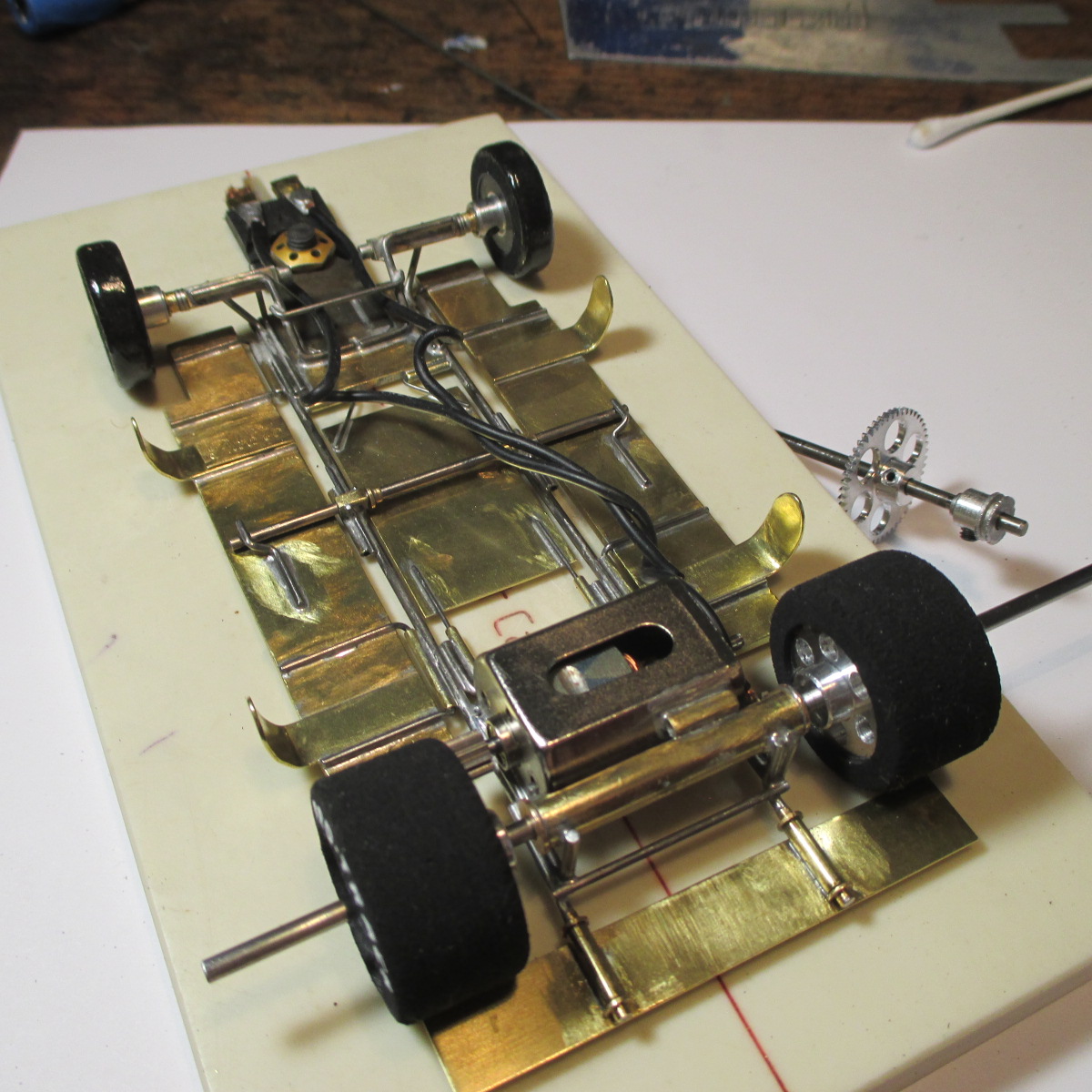

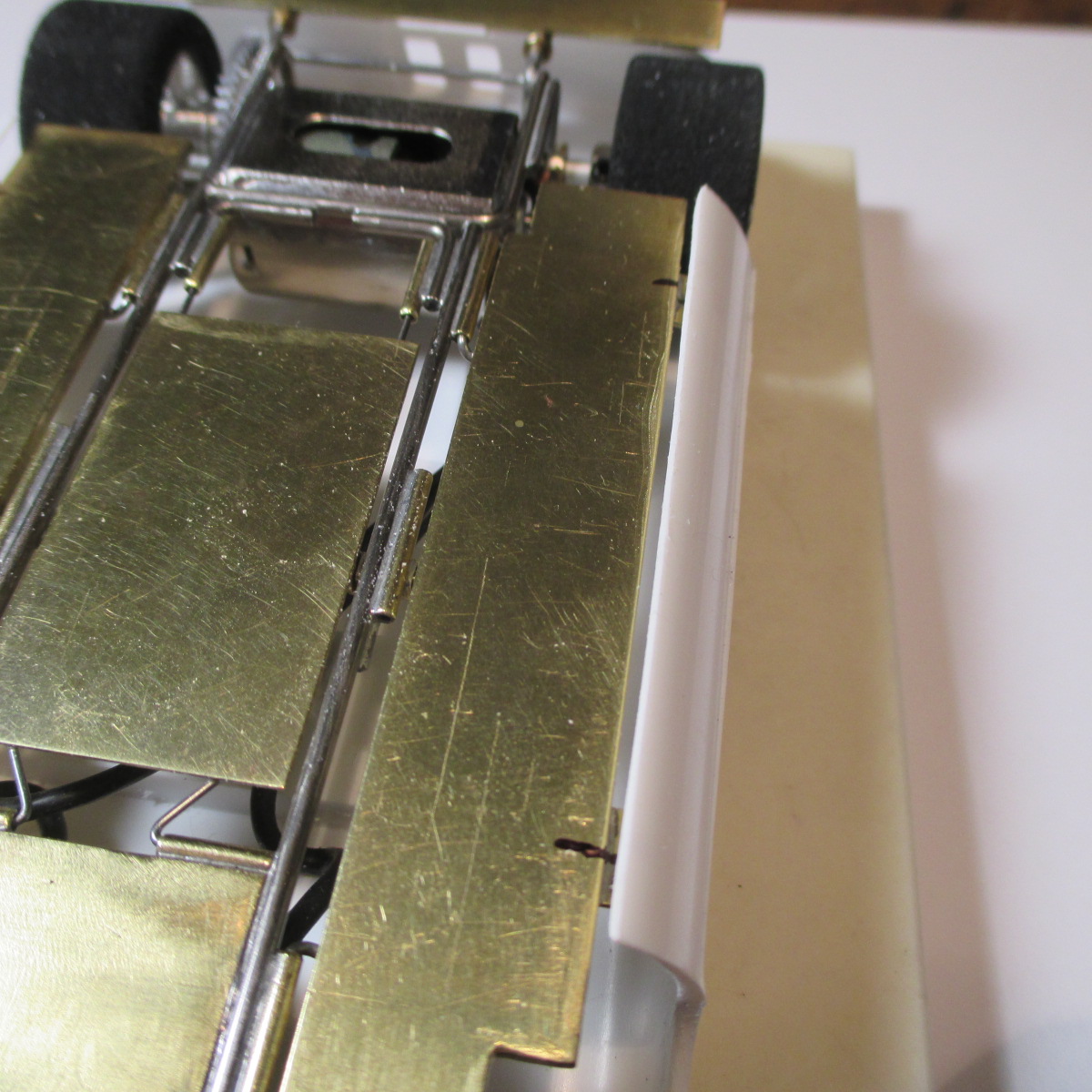

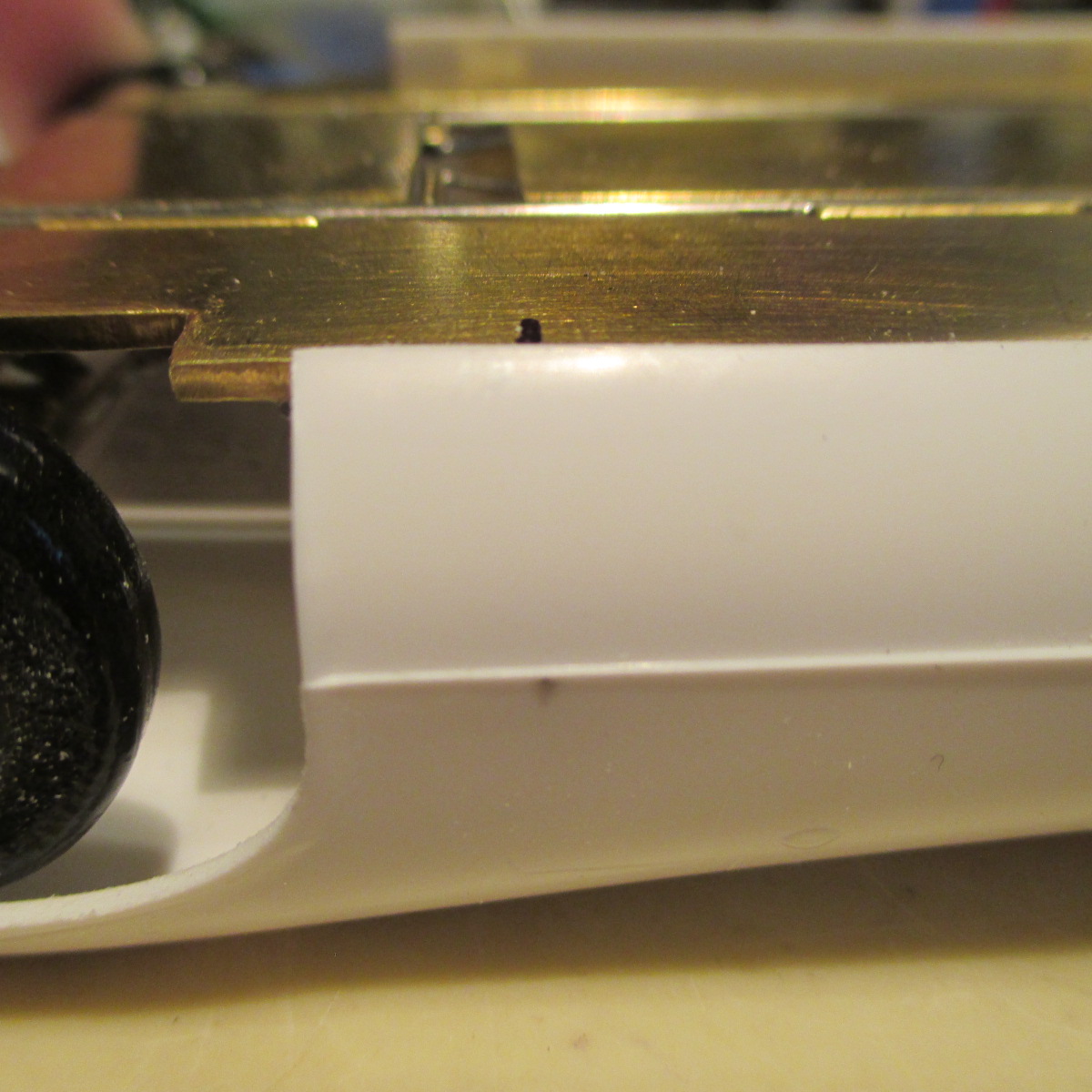

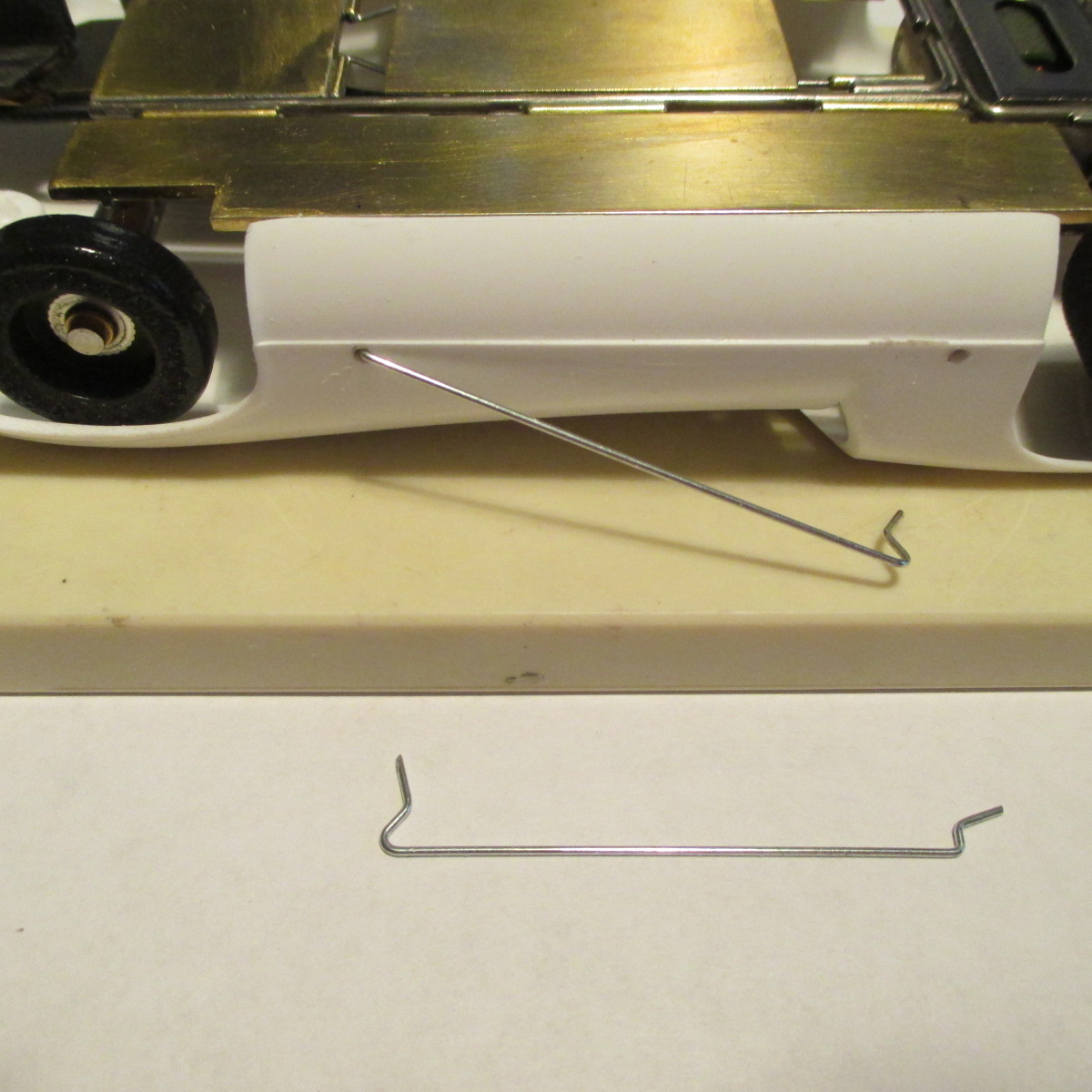

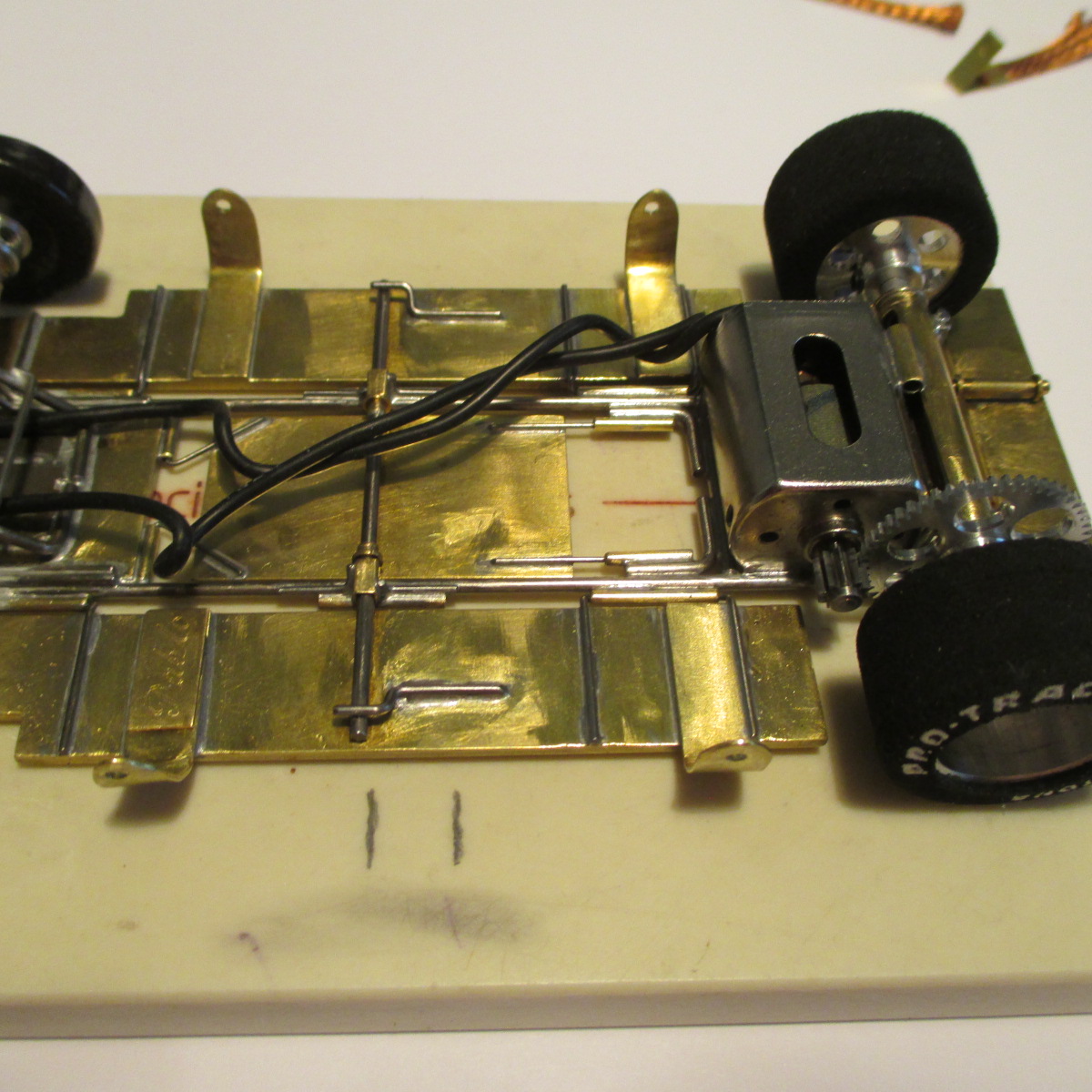

To check my balance point fore/aft, I use a piece of whatever rod or tube is handy, like a 3/32 tube, hold it under the chassis and cradle the car. No science here, just seat of pants, and my educated fingers. All my best handling anglewinder/sidewinder cars seem to balance about midway between rear axle and flag shaft. I usually use that as a starting point, and adjust from there.....

You say your 1/32 cars have the balance point further aft. The "BP Platform" will be your answer to that ……...

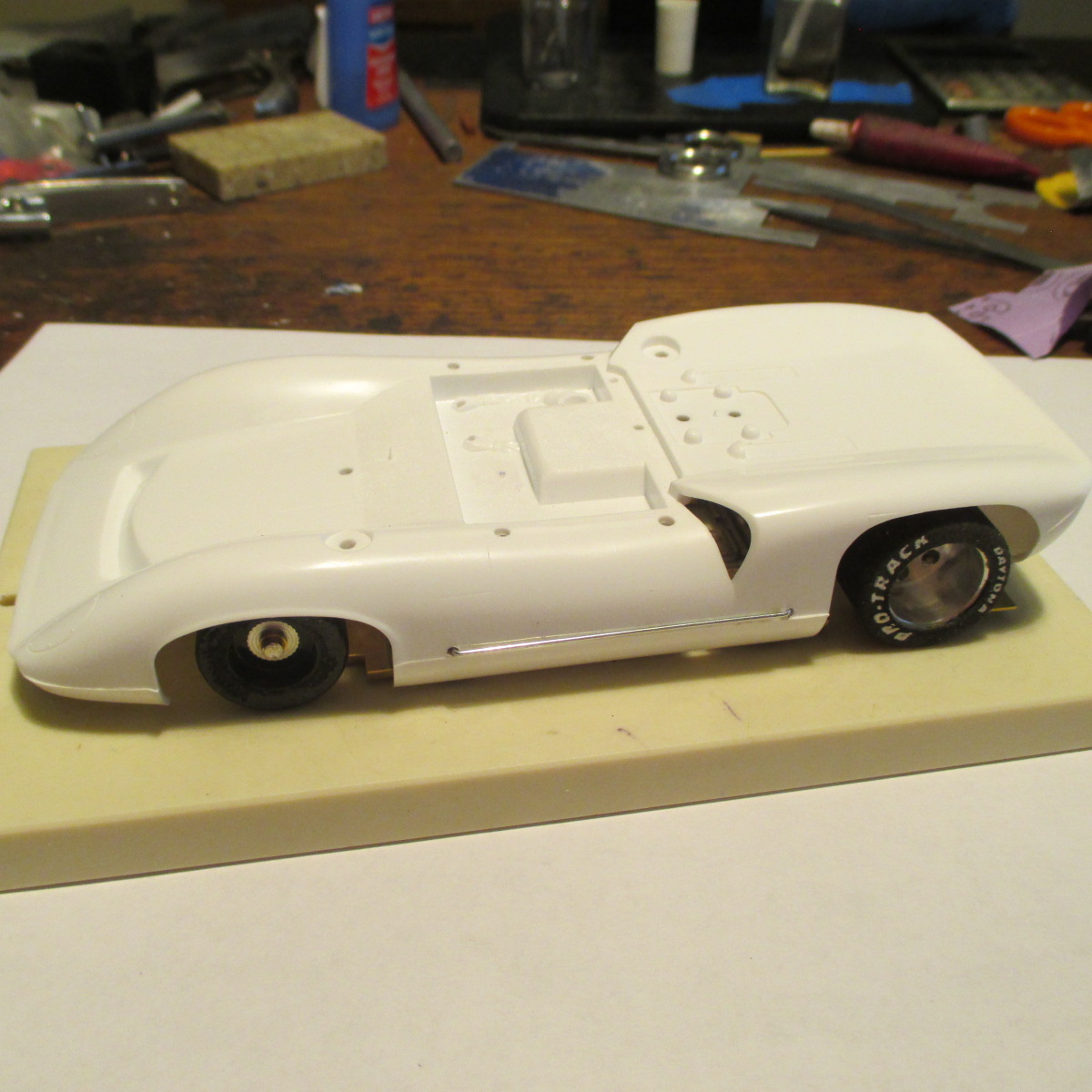

The body as is, weighs 23. But I haven't cut the interior out yet. Stand by for body work.

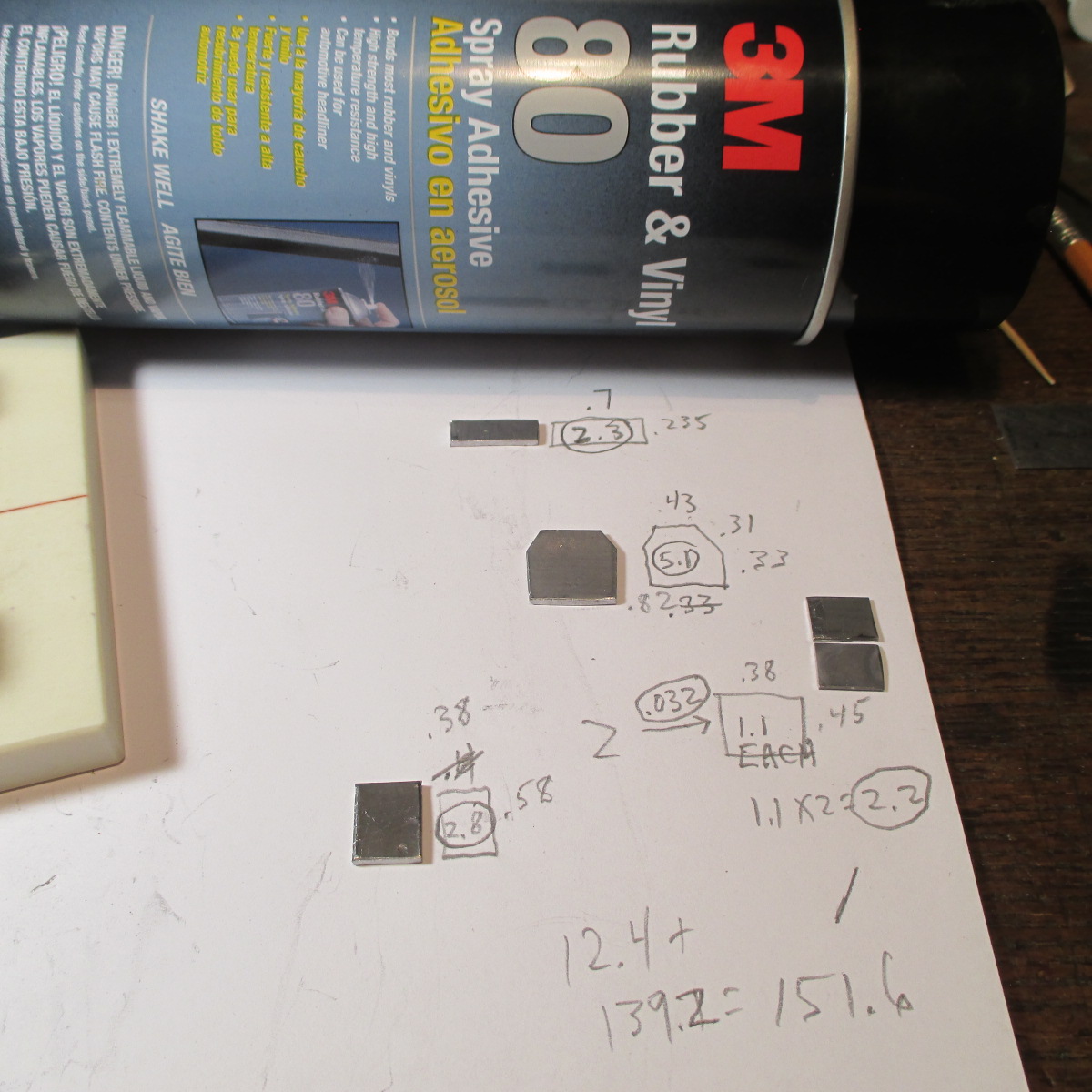

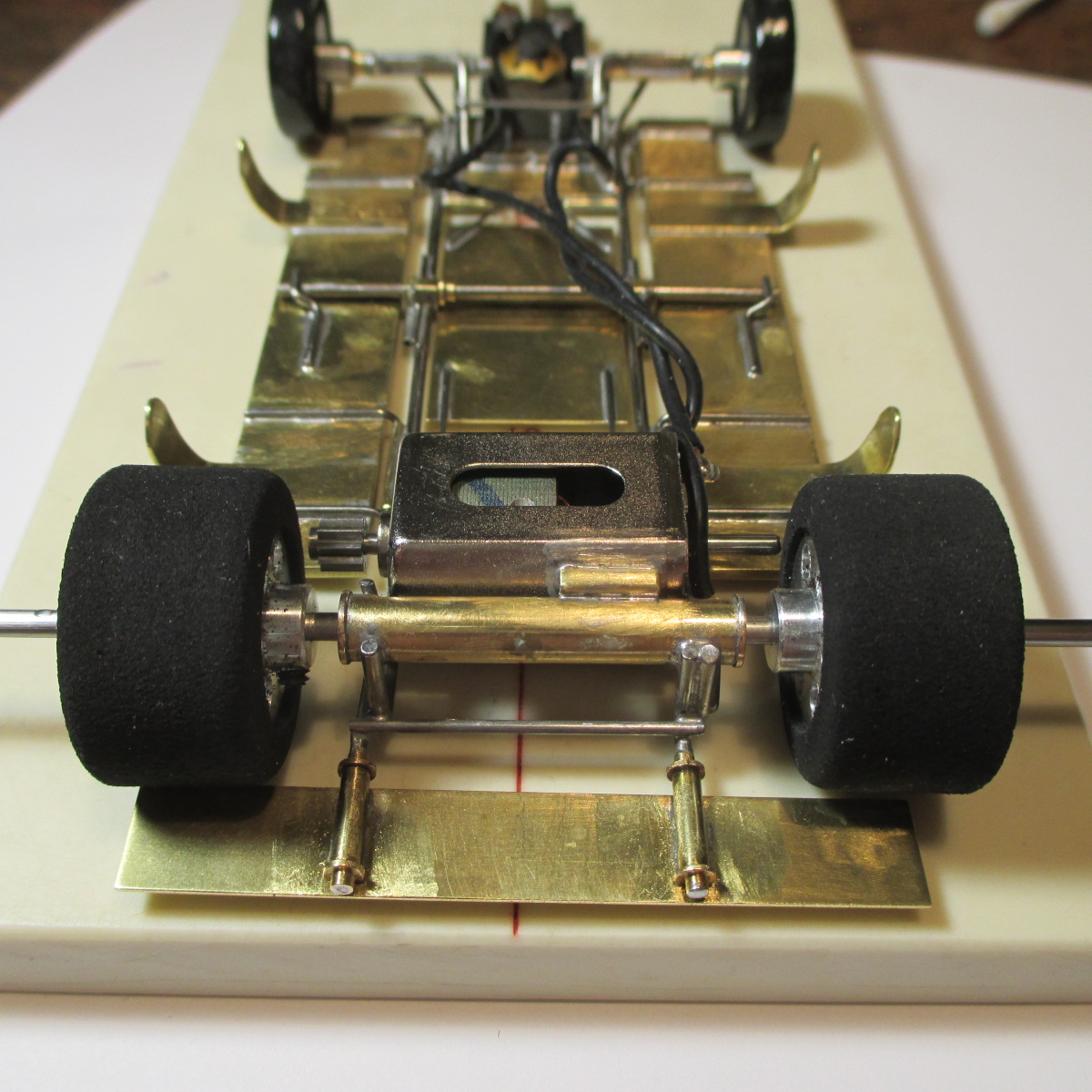

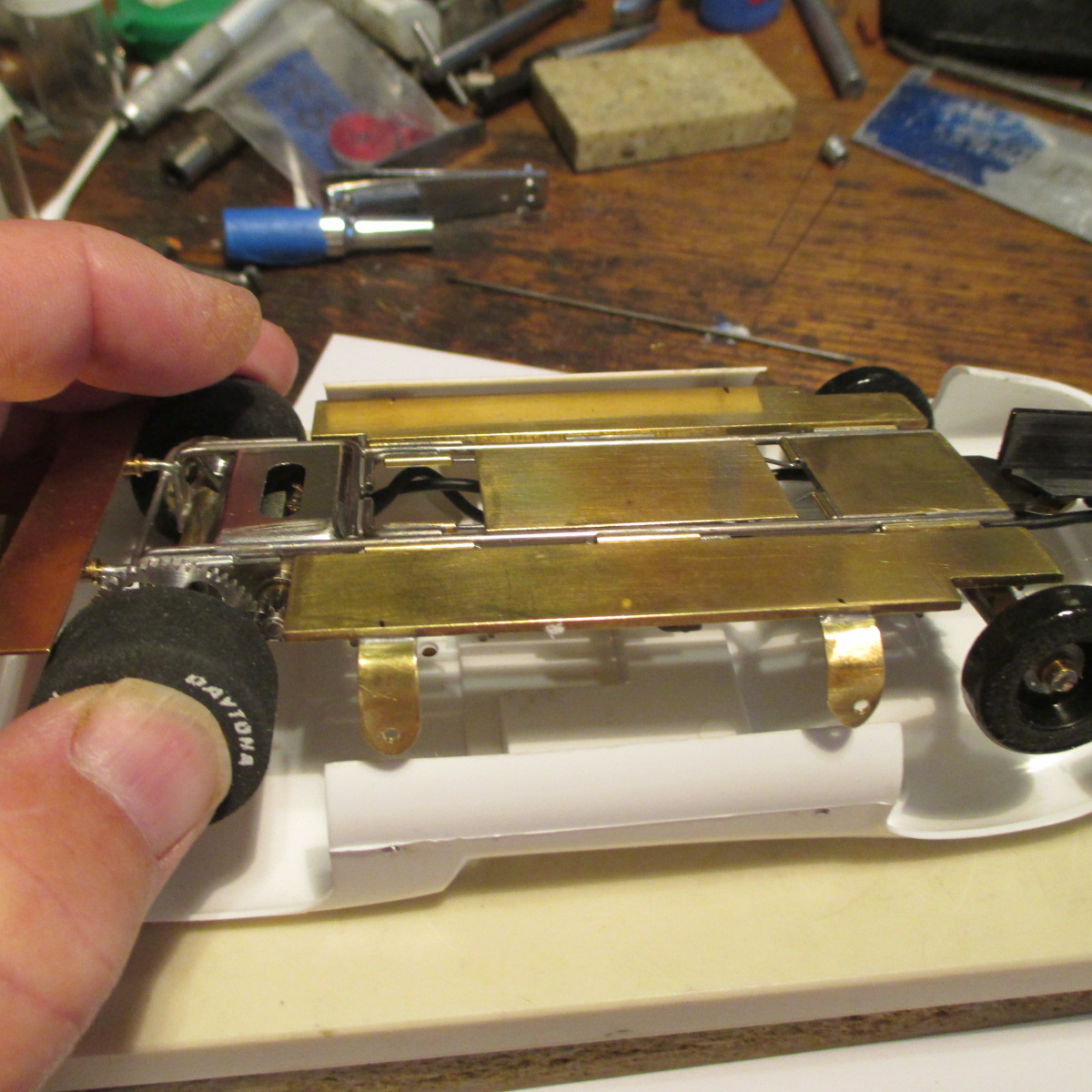

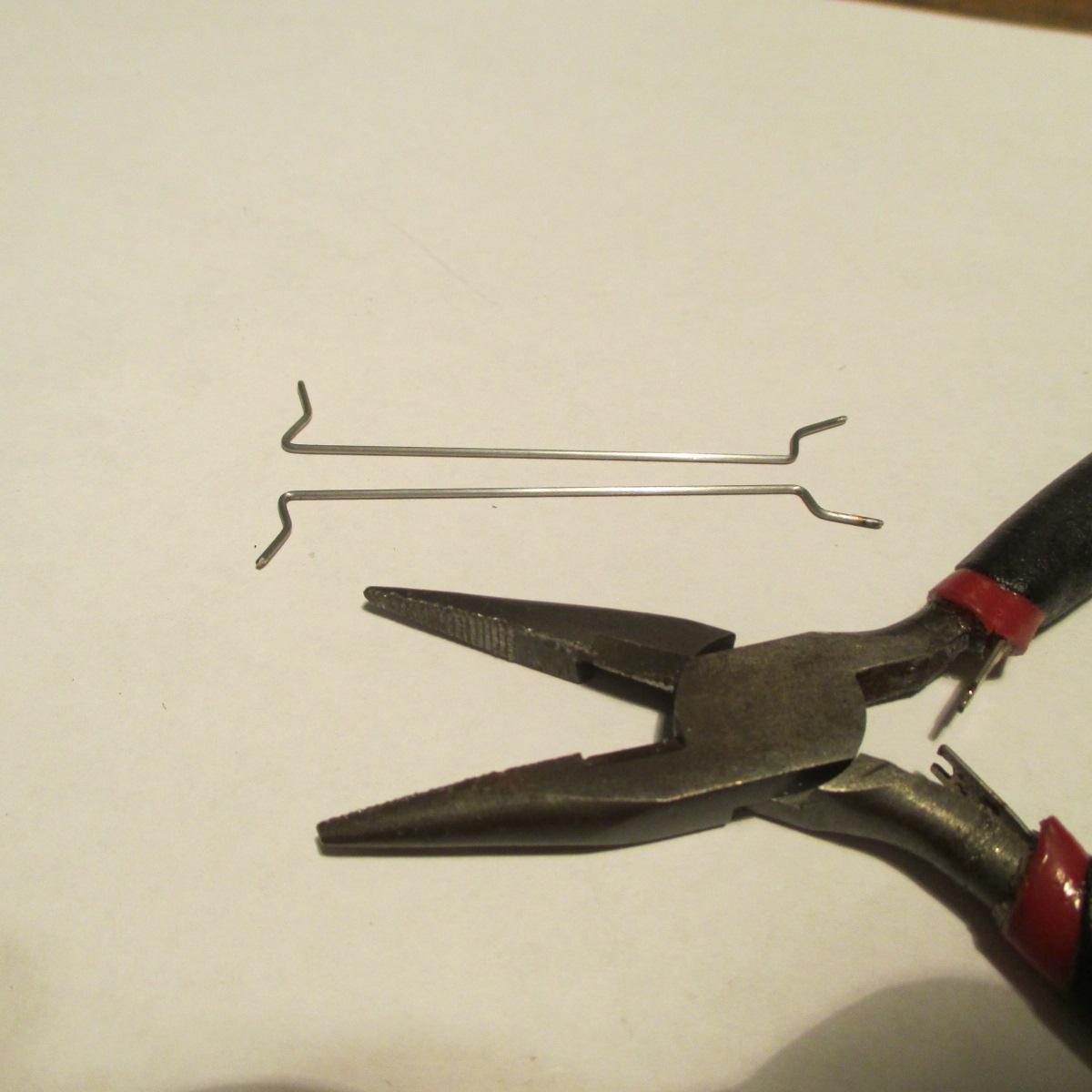

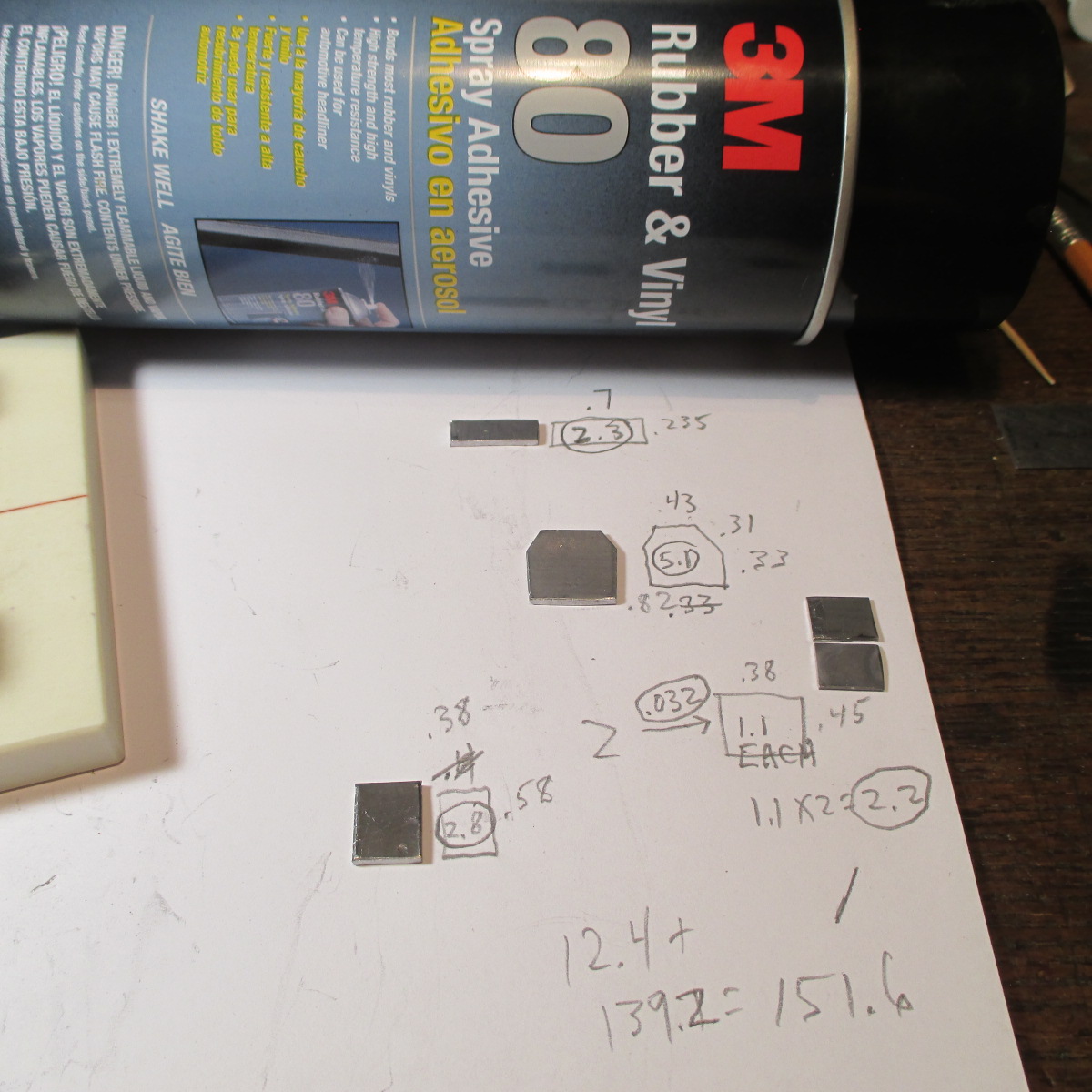

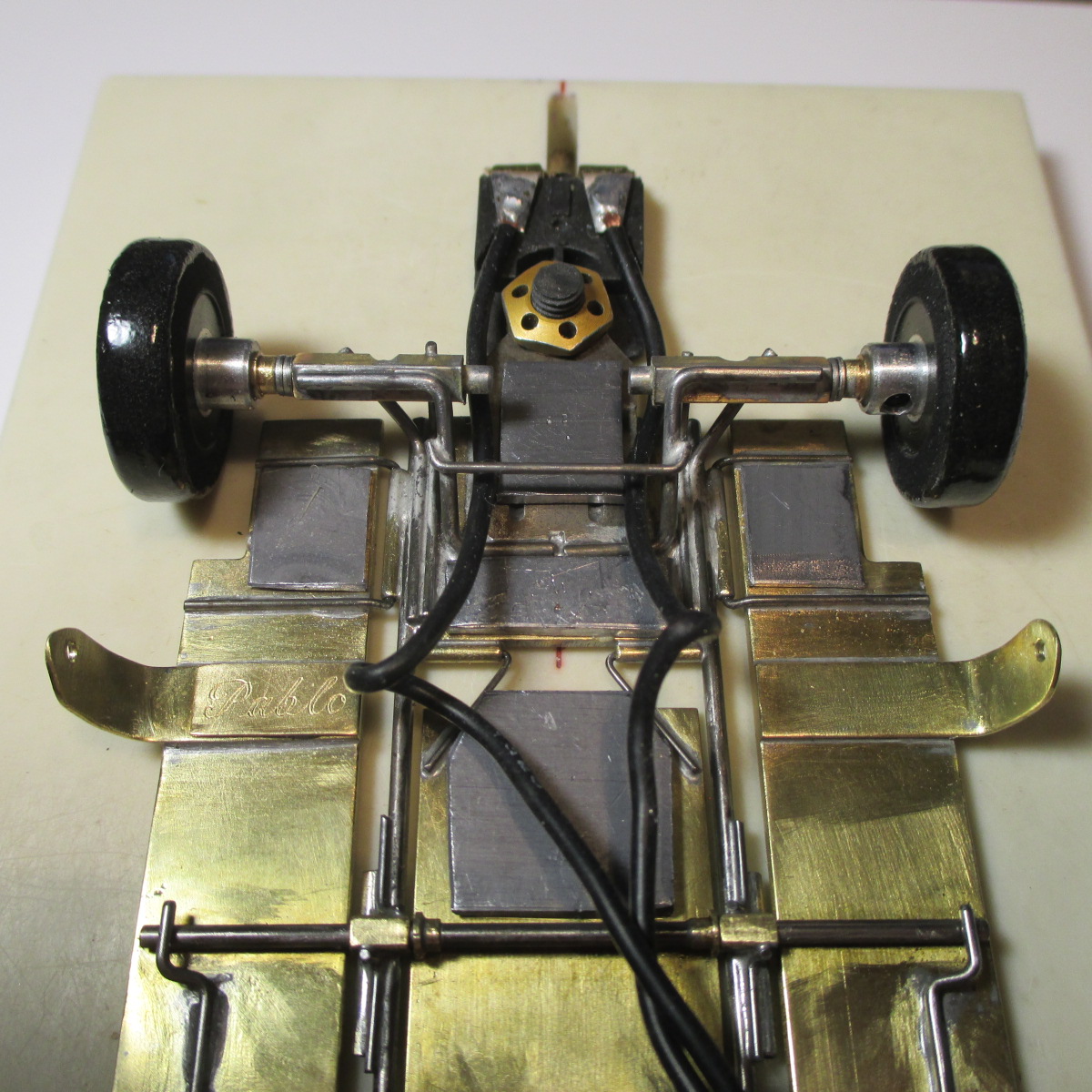

Just to show there actually is a method to my simple "pencil and ruler" madness, here is the simple math, dimensions and weights of those I consider permanent. As I said in my previous post, the goal is to add overall weight, and change the balance point forward a little. Once attached, the car plus body should weigh about 152 and the balance point should be very close to the bite bar.

Tony P. says the best attachment method for weights is contact cement. So I went crazy, found every single weight I could find here at The Ranch and those that still have factory glue residue and self adhesive tape got soaked in Lac thinner for a while. That way they all sit as low as possible and will be attached with 3M #80, or sometimes double sided wing tape. Eddie, if you want to remove them, just a touch of lac thinner will release them