You were right about it taking overnight before my vision would clear up Bill.

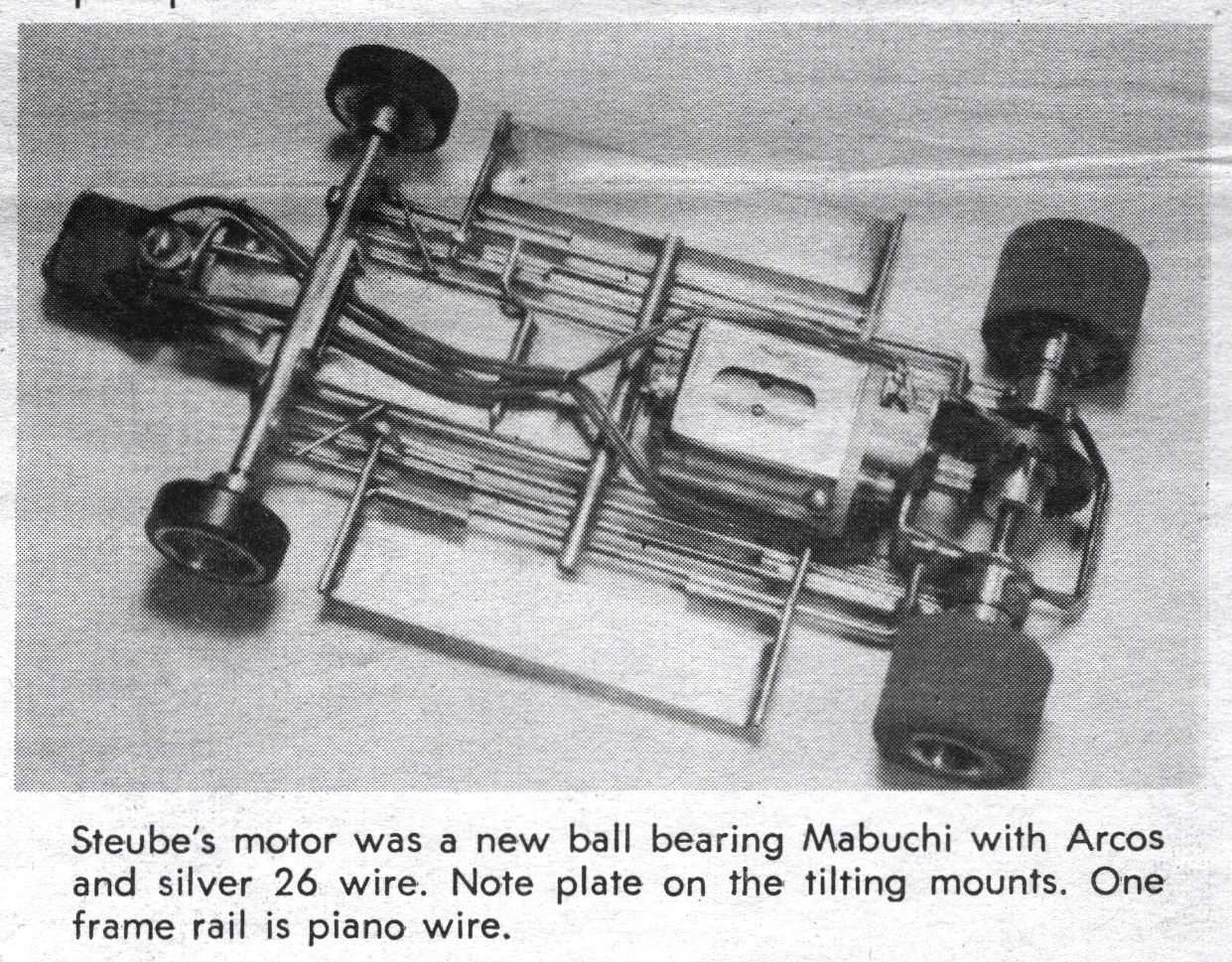

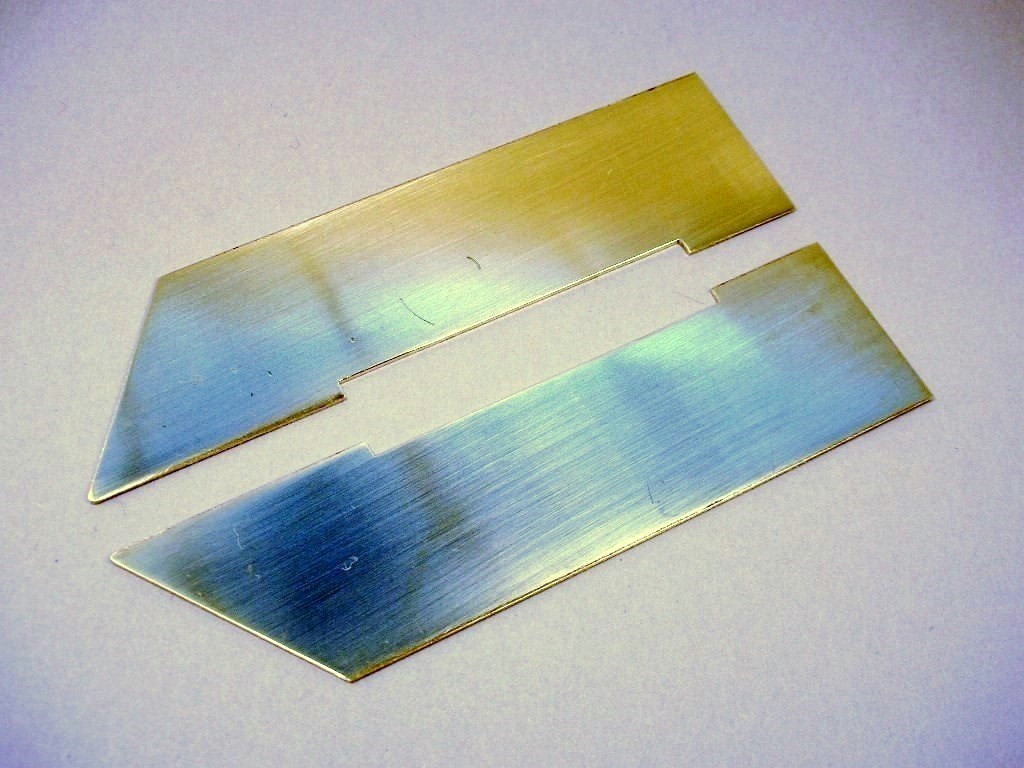

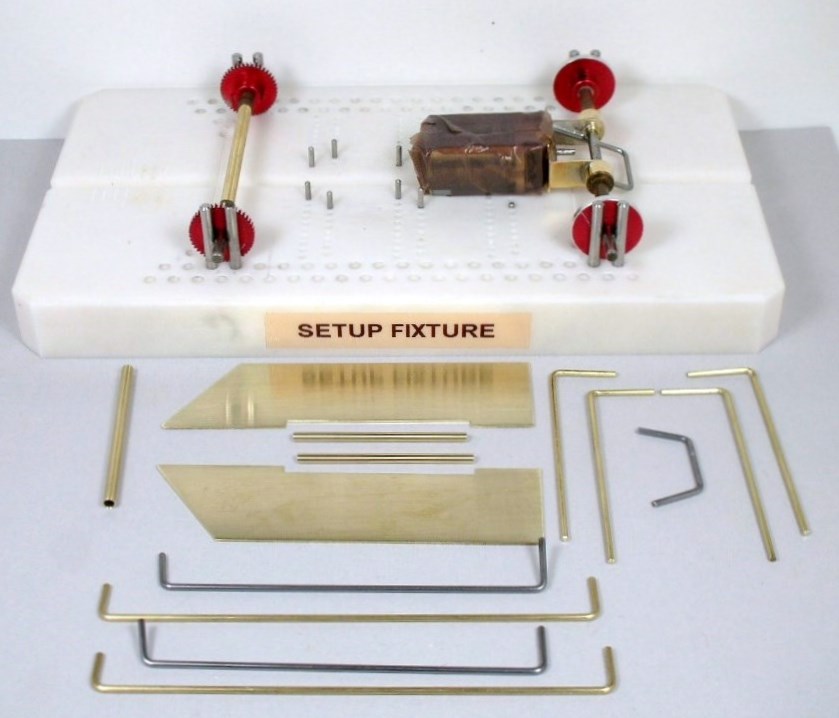

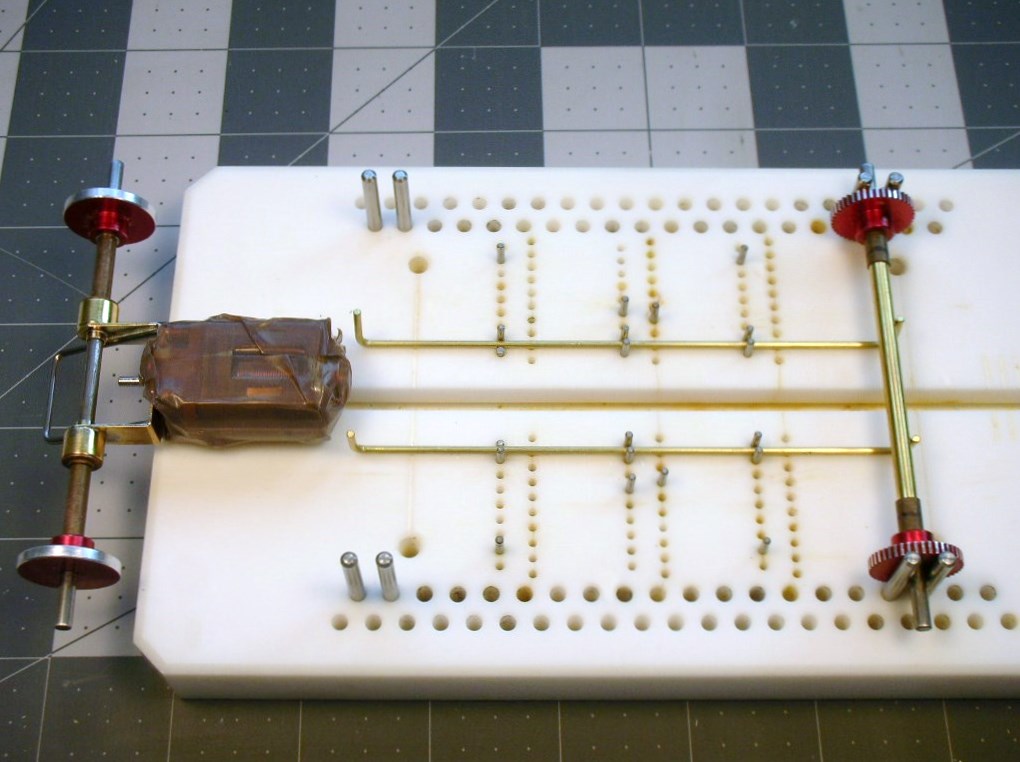

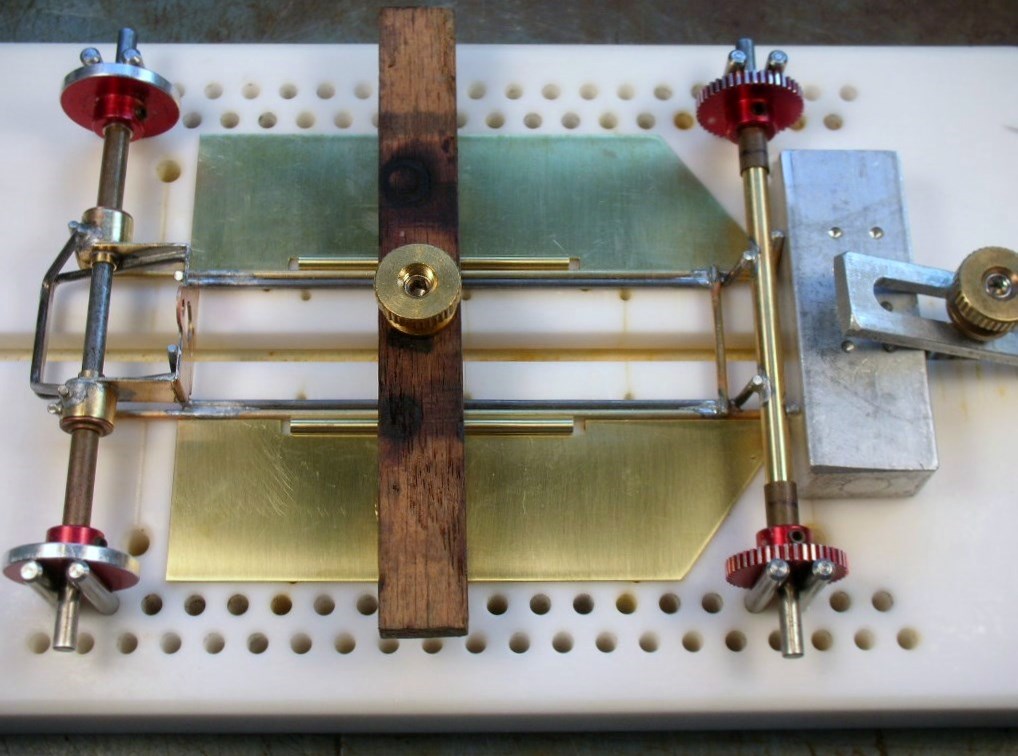

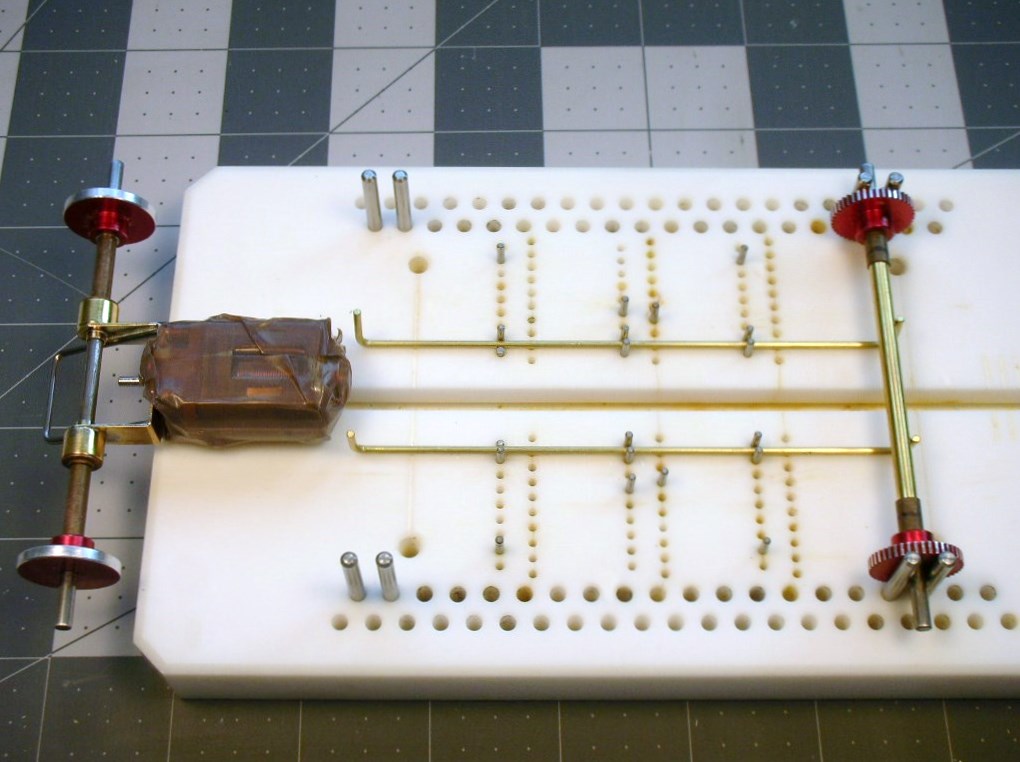

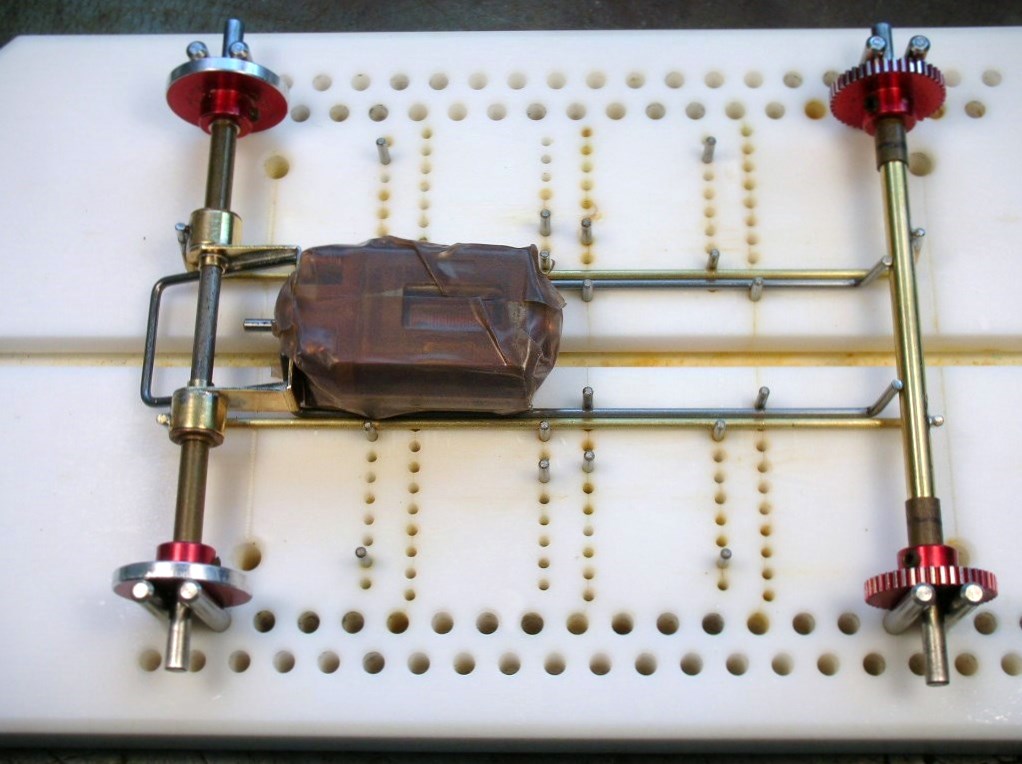

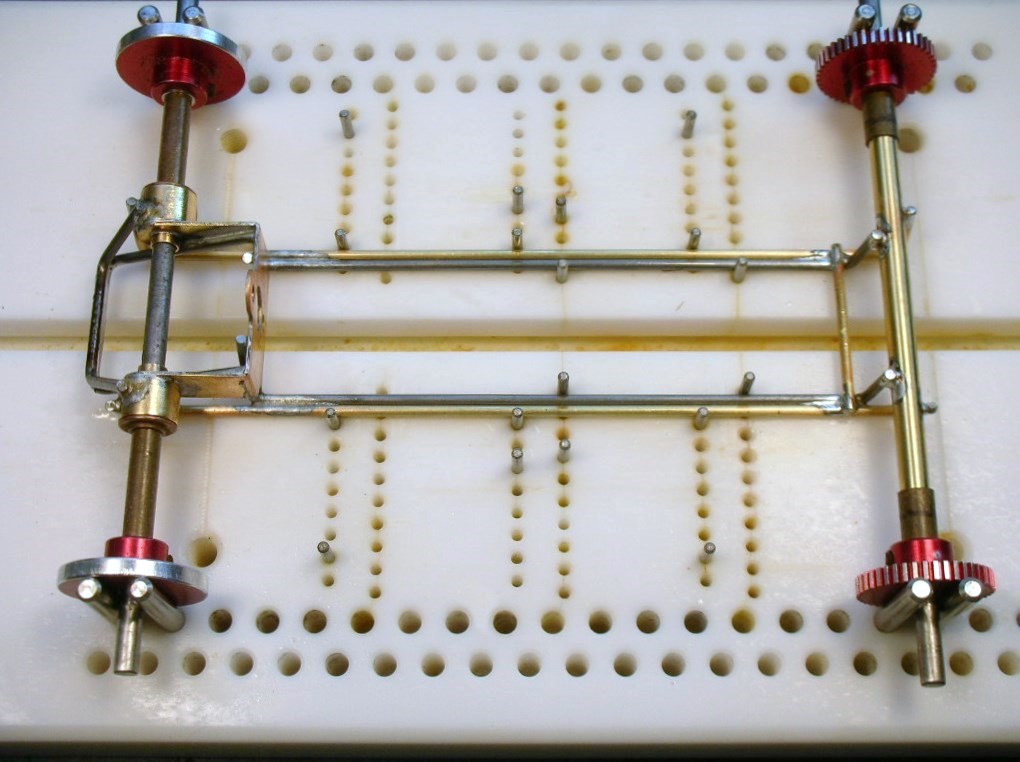

The motor is all covered with tape to protect it. The motor bracket has a U-brace installed. The outer brass rails are held in the jig with 3 pairs of pins for alignment and ready to solder:

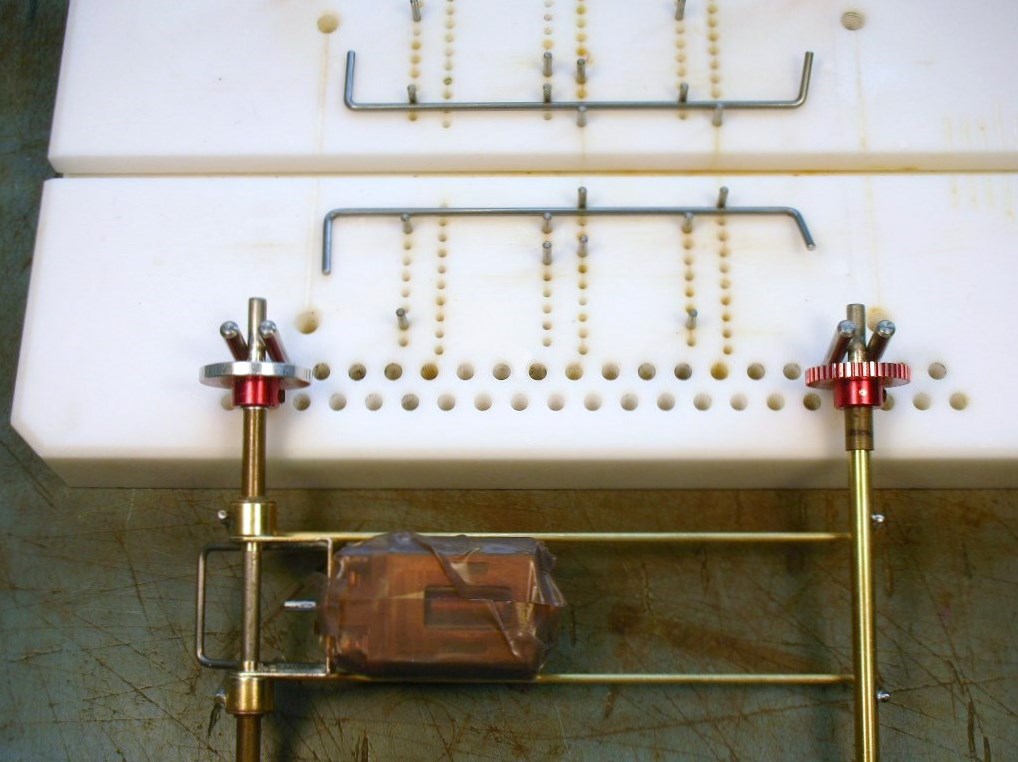

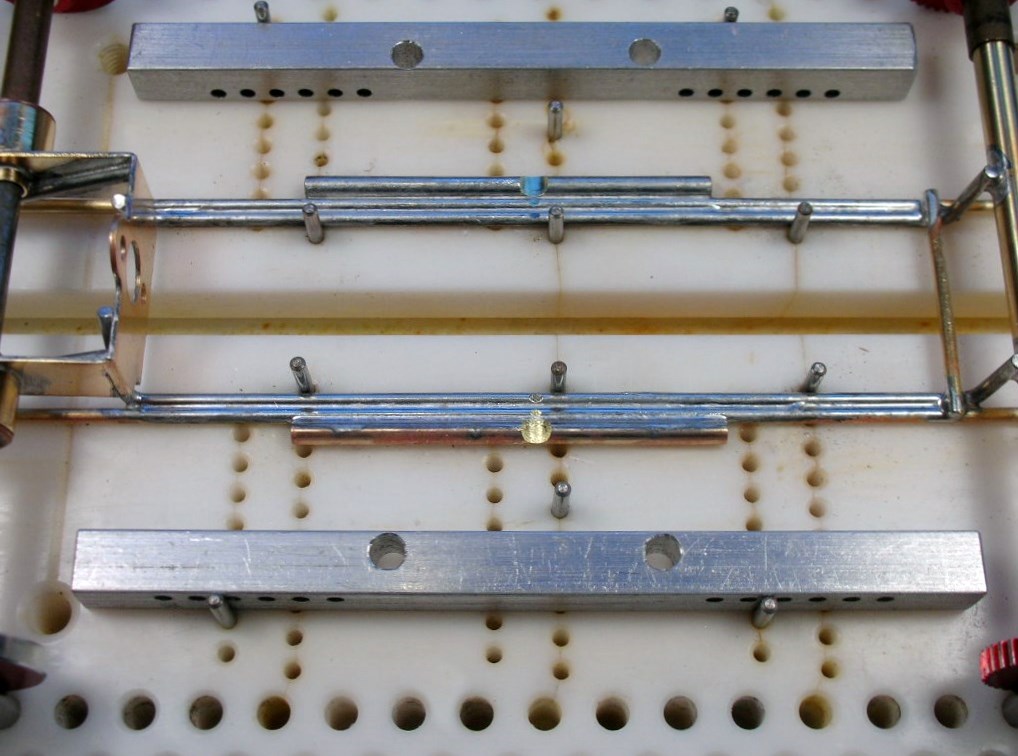

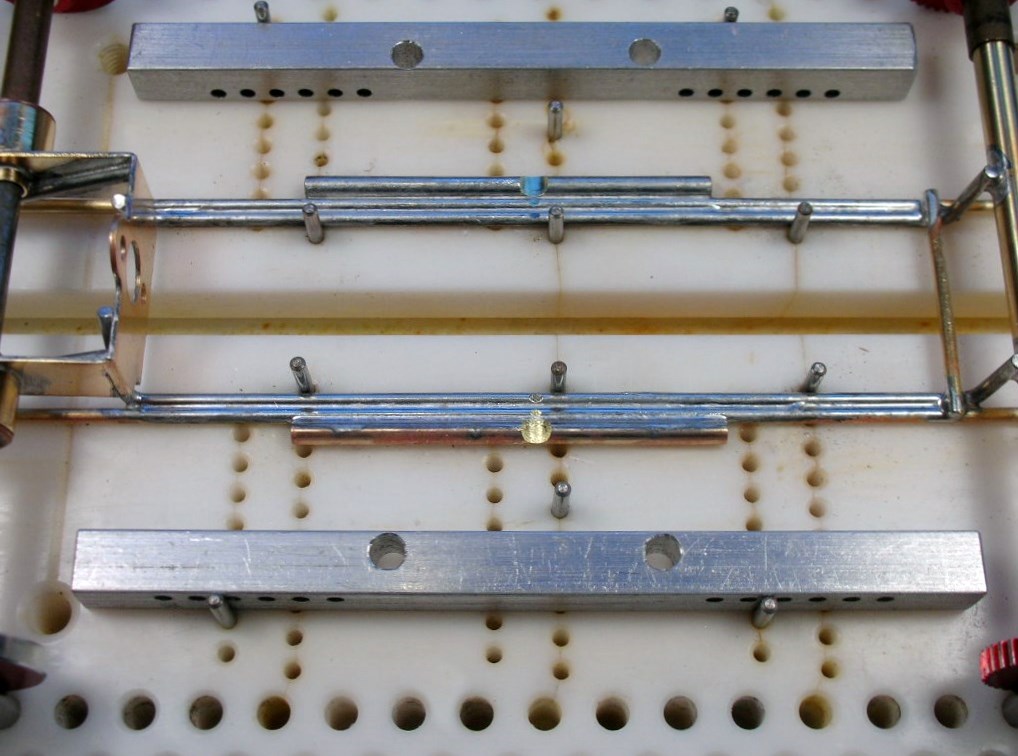

Next the inner rails go in the jig:

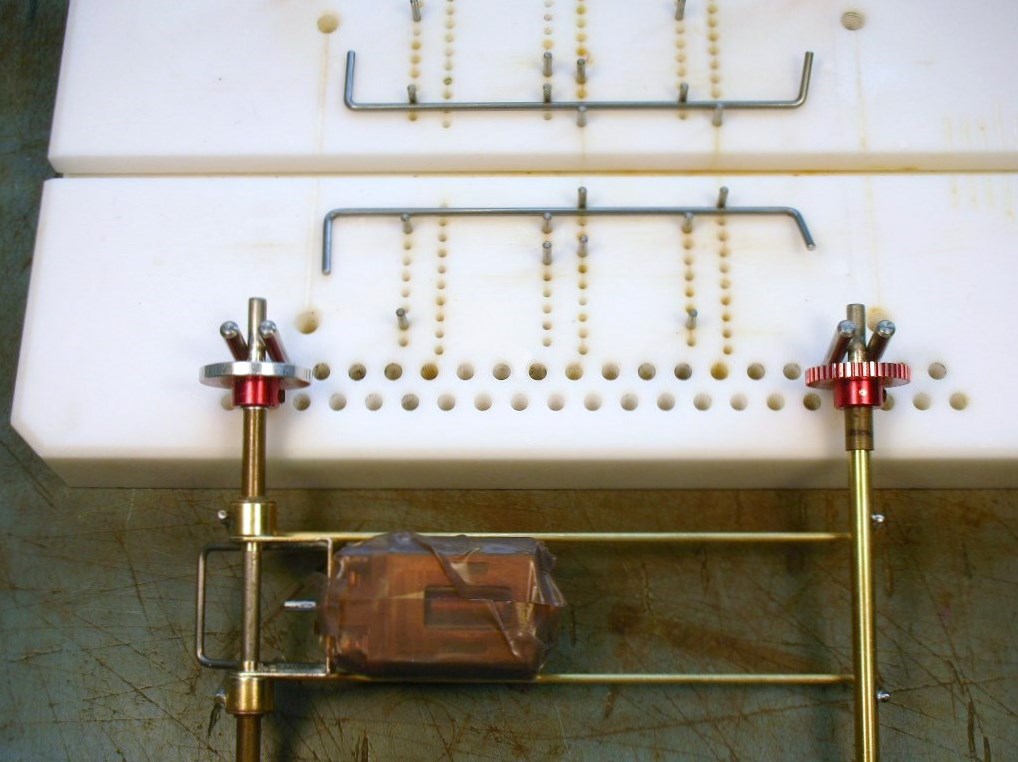

The inner rails are just lightly tacked in place on the motor bracket so I don't melt the endbell:

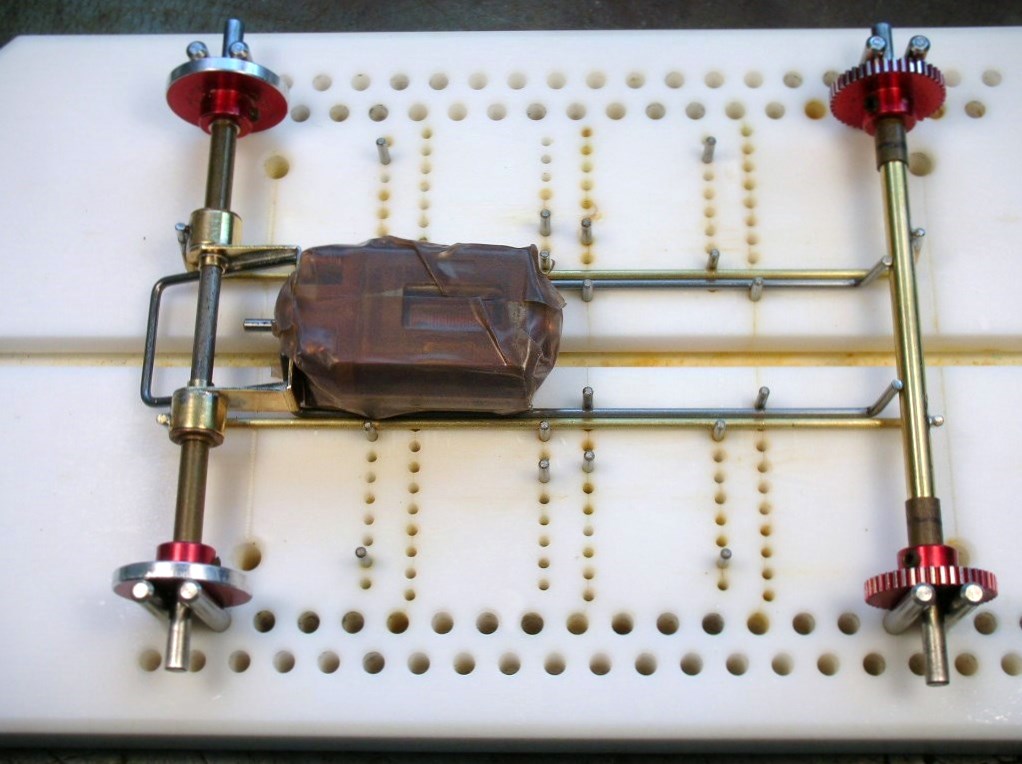

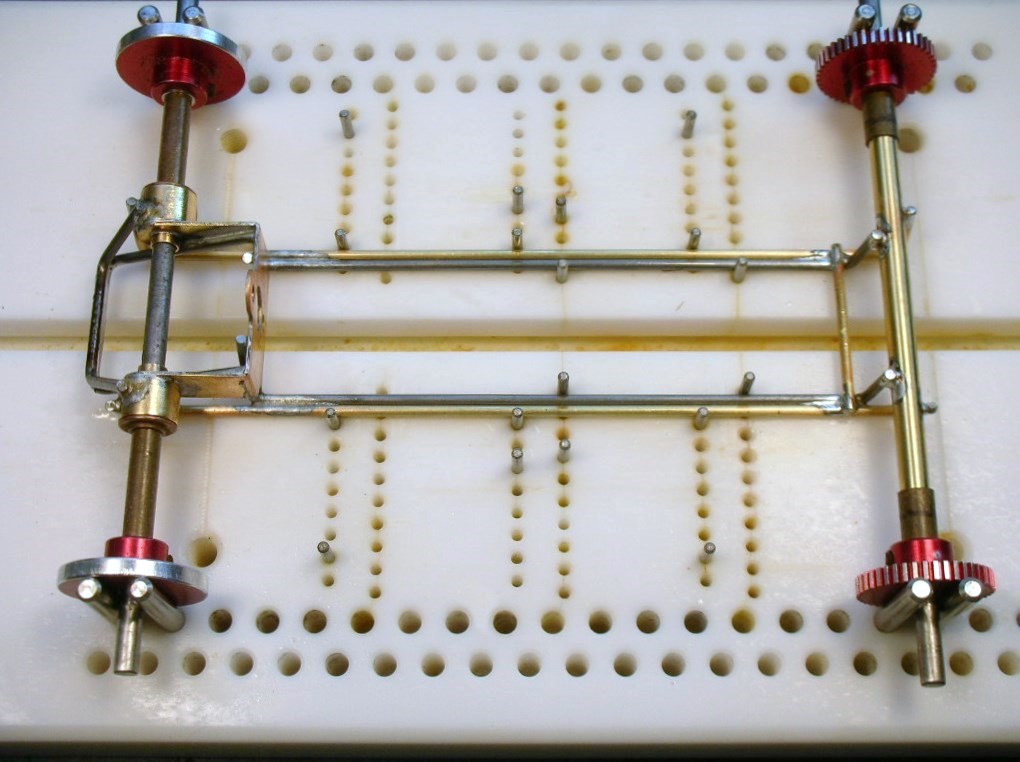

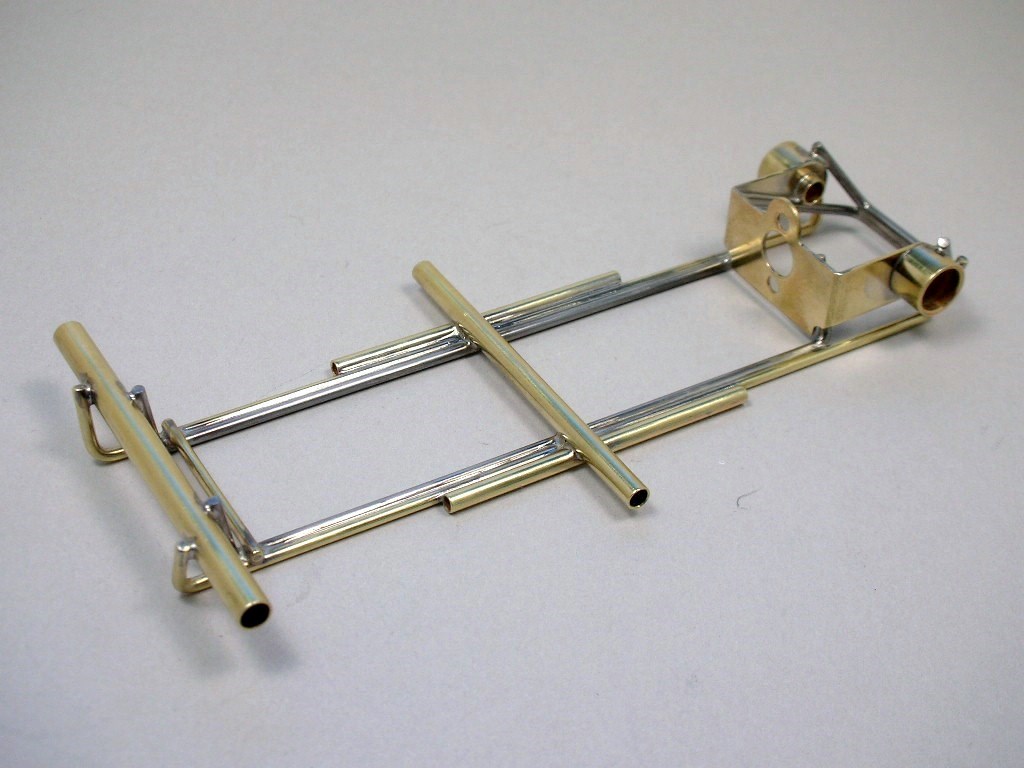

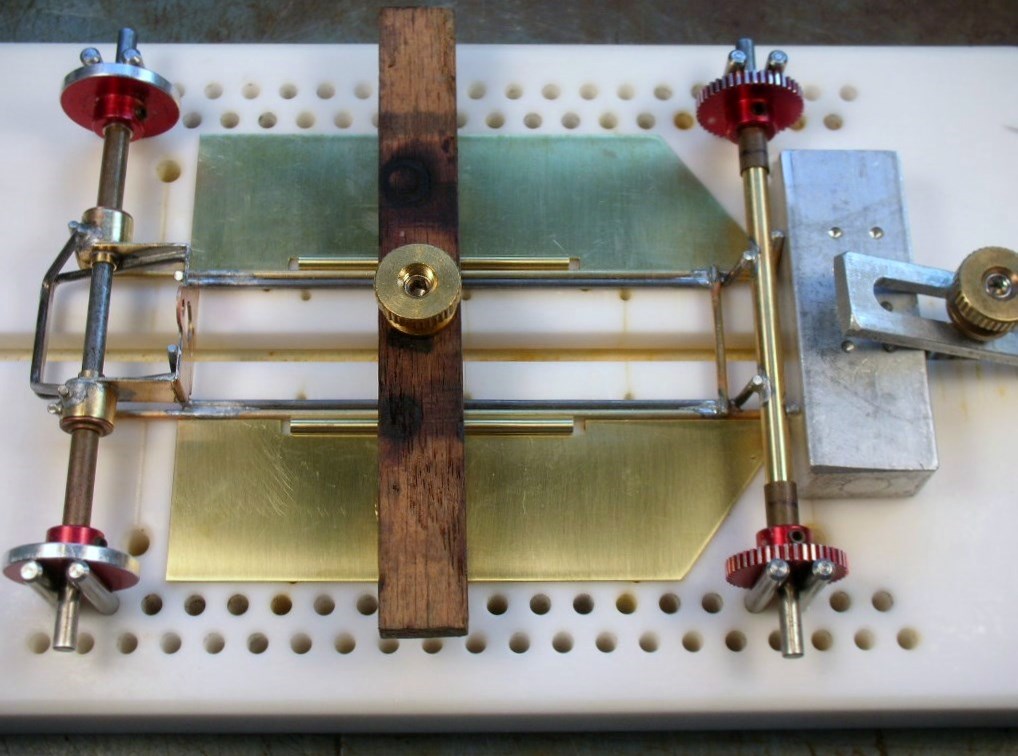

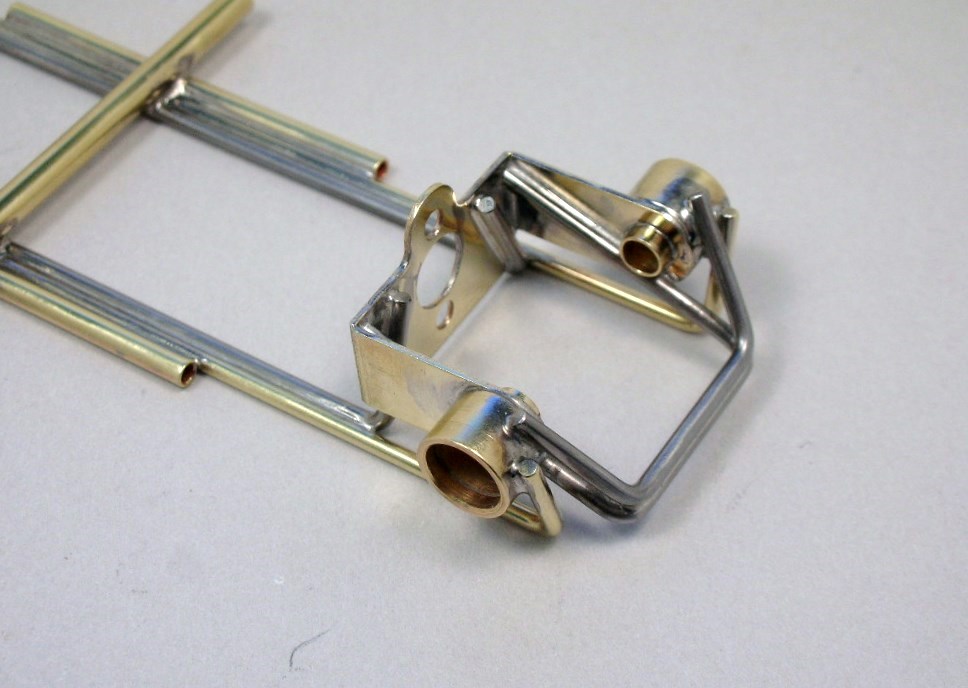

Out comes the motor and all the soldering is completed including the drop arm up-stop and another rear bracket brace:

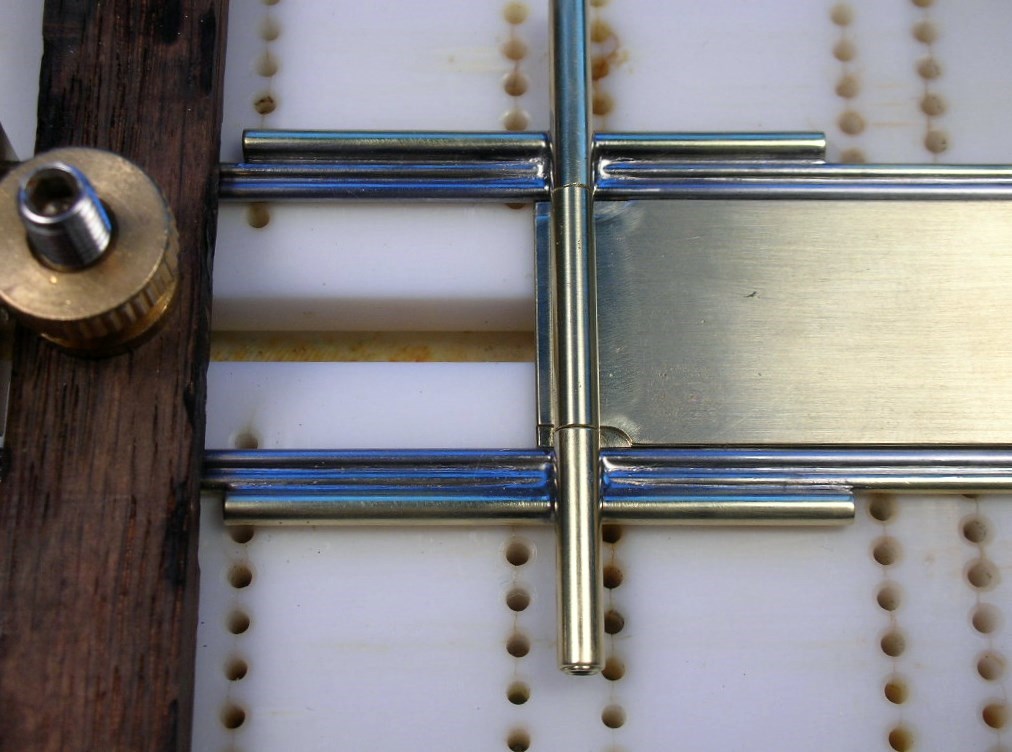

The pan hinge tube are next. They get tacked in place:

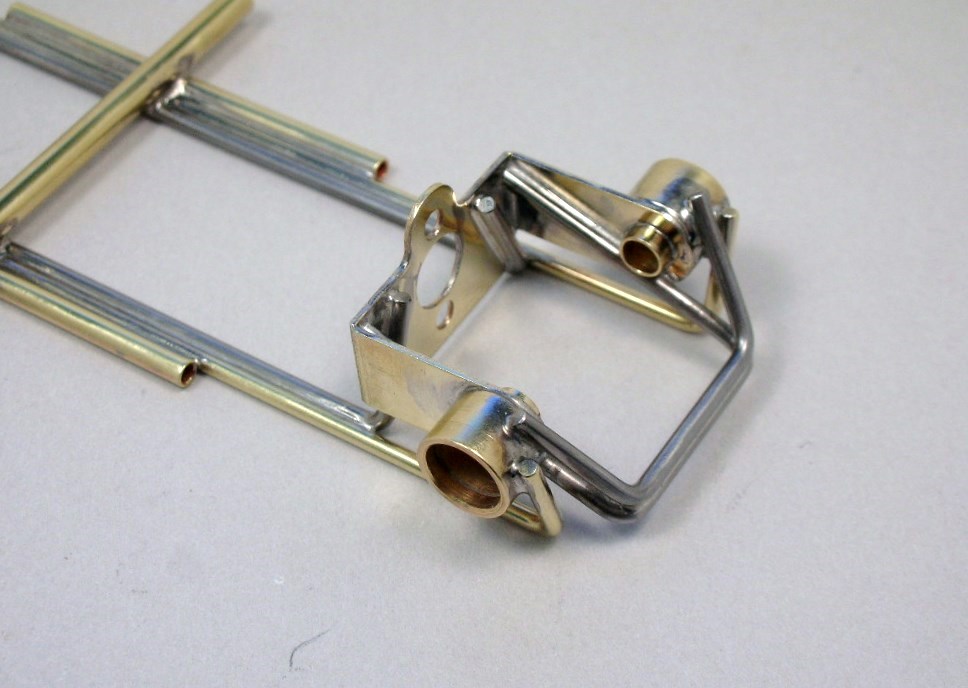

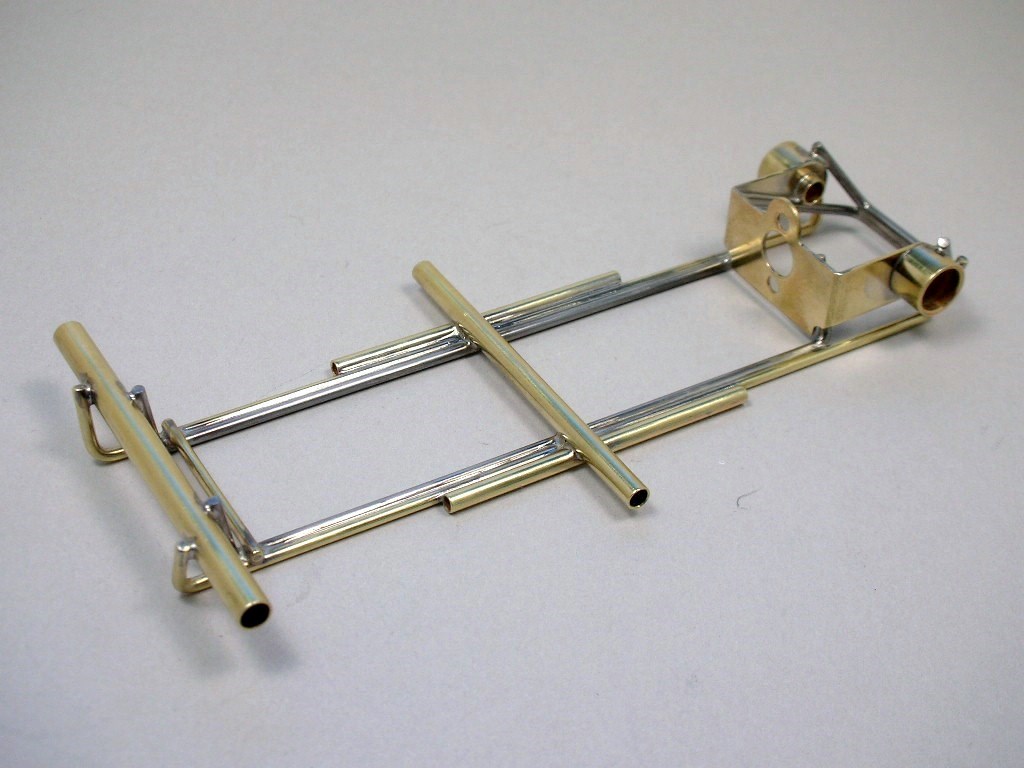

The hinge tubes and the full length of the rails are soldered. They warped like crazy into an hour glass shape.

Quite a project to straighten things out.

A notch needed to be filed into the pan hinge tubes for the drop arm pivot tube.......

........and it is soldered in place:

Here's the center section:

The drop arm is next.........