Parma Flexi and International 32 instruction/setup sheets

#51

Posted 04 May 2021 - 11:26 AM

#52

Posted 04 May 2021 - 11:28 AM

http://slotblog.net/...-parma-intl-32/

Sorry, my phone didn't look like that comment had posted the first time.

#53

Posted 04 May 2021 - 11:43 AM

The JK chassis appear to be stainless steel, and not plated(as far as I can tell).

In any area's you want to solder, grind away the outer layer of metal, with something like a Dremel 409 disc, and immediately flux with a strong acid flux, advertised for stainless steel, and tin that area.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#54

Posted 04 May 2021 - 12:33 PM

Thank you both, and pardon my ignorance. Before the last few months, I've only ever soldered wiring, so this a bit of a new world for me. My first experience soldering something structural on a slot car was soldering a brace back in place on an old wing car with a brass and wire shuttle chassis, and that was almost too easy. But if those chassis are stainless, and I'm not using the right stuff...

Both of those use screw-in motors, so it hasn't been a big deal, but going forward, I am going to need to need to be soldering motors in.

#55

Posted 04 May 2021 - 02:46 PM

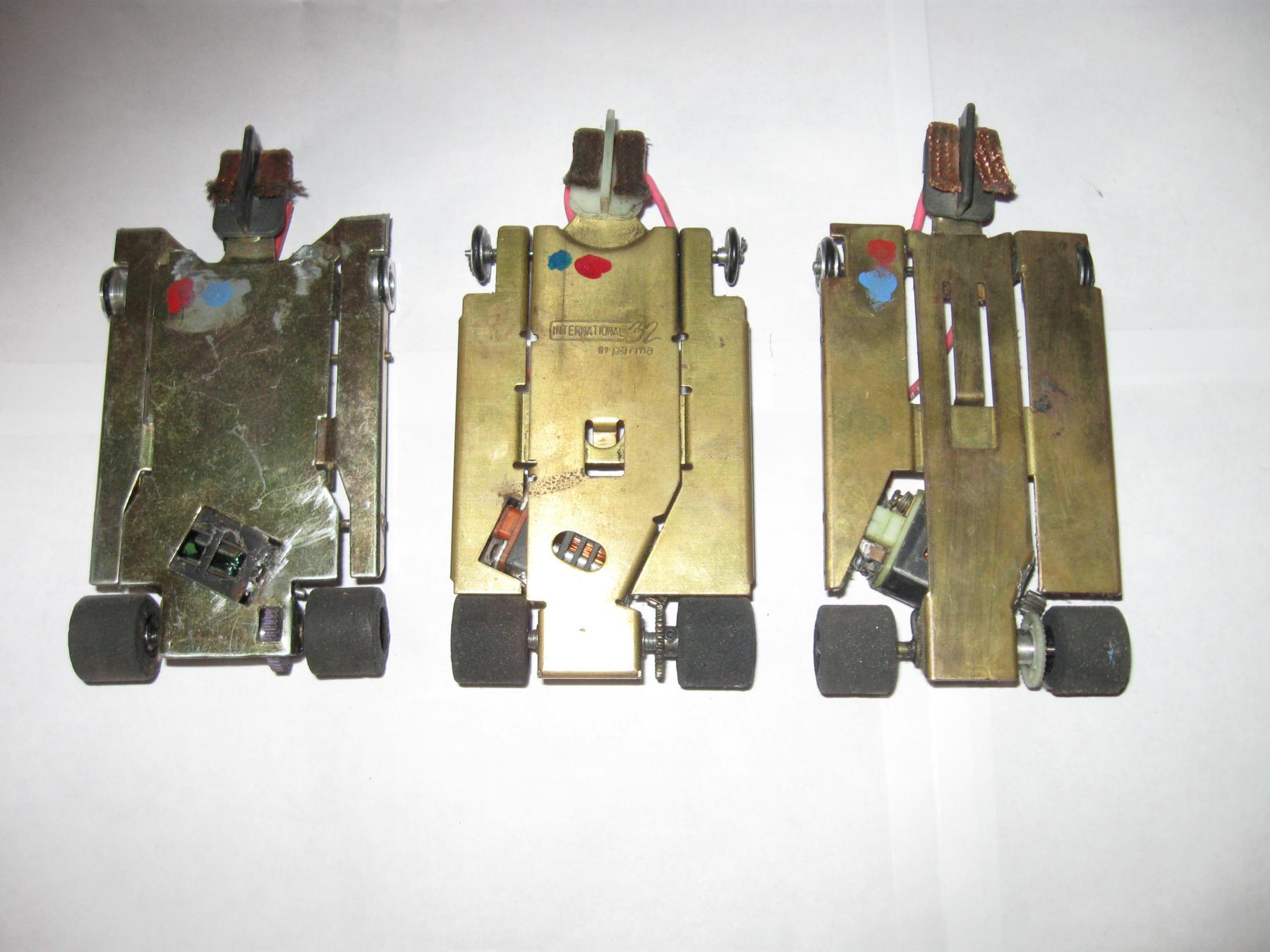

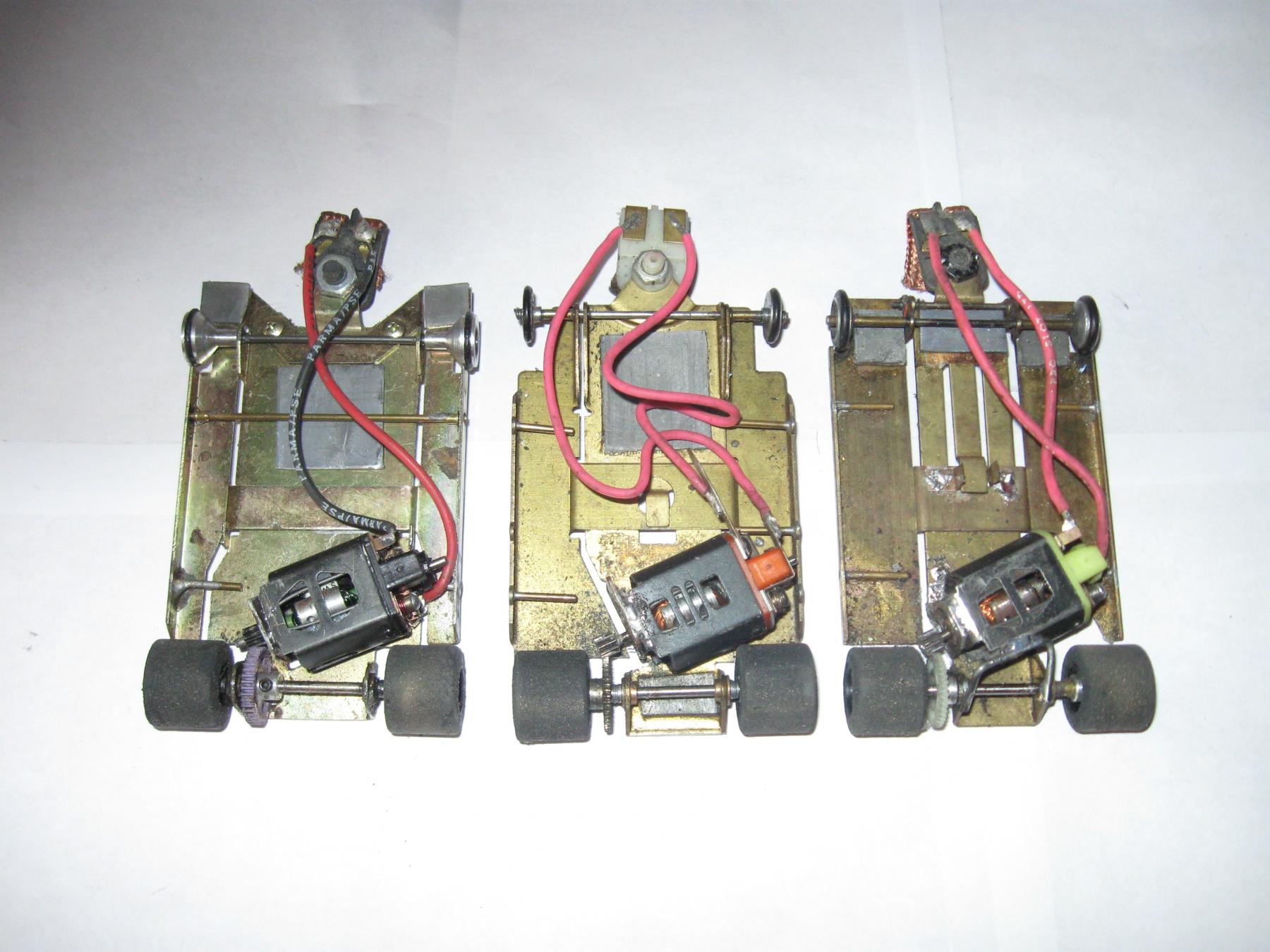

The Proslot Demon, which I could not find, is the far right chassis in the following two photos. Jason, thanks for posting the Int. 32 link. I found them in there.

Acid fluxes I'm aware of that works for soldering stainless are: Oatey's Liquid Flux, Chicagoland, Stay-Clean, & Lucky Bob's. There may be others available too.

There used to be several setup articles online for the Parma International 32 chassis. I don't know if they still exist. I have limited experience myself with them. Yes, I built a couple cars for others in the early 2000s, but my own car was never completed & still isn't.. The one thing I can remember about them, it was then legal to cut off the motor mount plate. That allowed the motor to be slid over to the left of the chassis for better balance. The rest was to make sure the chassis was flat & straight. The rear of the chassis could be reinforced in a number of different ways using brass strips or piano wire. A simple way was to solder in a piece of 7/64"(?) brass tube between the uprights.

I intend to live forever! So far, so good.

#56

Posted 04 May 2021 - 03:01 PM

I've raced International 32's a couple of times and found the thing that improved the handling the most was to put a big piece of lead on the back of the pan opposite the end bell side of the motor to achieve a basic left-right balance. Then start your usual tuning from that point.

- rmjlmartin likes this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#57

Posted 14 May 2021 - 12:12 AM

I've raced International 32's a couple of times and found the thing that improved the handling the most was to put a big piece of lead on the back of the pan opposite the end bell side of the motor to achieve a basic left-right balance. Then start your usual tuning from that point.

The only International 32 that I've run any amount has a Falcon minican motor in it, and seems fairly balanced like that. Maybe the minicans are enough smaller than a 16D that it doesn't need as much compensation? Just looking at it, it appears that the magnets and armature are about in the center of the car. I'll try a weight, too, though.

Does flux go bad with age? The flux I was using says it's supposed to work with stainless steel, but it's a very old bottle that I borrowed from work from the days when we used to repair all-metal car radiators. (I'm an automotive technician by trade.) I picked up a Ralph Thorne acid flux pen though, and it seems to work better, at least soldering the pinion gear that I did the other night.

#58

Posted 14 May 2021 - 08:30 AM

Flux is cheap enough that I wouldn't bother using an old bottle. Jason, I have a new 50 yr. old bottle of Cobra acid flux I don't plan to use. ![]()

I intend to live forever! So far, so good.

#59

Posted 14 May 2021 - 11:33 AM

Jason:

The strongest fluxes (often used in radiator work) will usually have zinc chloride and hydrochloric acid in them, just google "tinning flux" and you should find several possibilities. These type fluxes work very well with stainless steel, mild steel, and all copper based alloys. In fact with proper preparation you can even solder directly onto a zinc plated chassis, even though most will tell you can't. When you use this kind of flux be sure to clean what you soldered very well after use as it will start to rust anything it has touched very quickly. I usually take a soldered-in motor out right after a race to clean the motor and the chassis as this flux is very thin and gets in everywhere.

- Rotorranch likes this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#60

Posted 23 May 2021 - 05:33 PM

Gotcha, yeah, I just used that bottle some because that's what I had on hand without going and buying some. I actually only used it to solder a pinion or two, and to try to tack a couple of motors in place after screwing them in place, and I cleaned things afterwards with QD Electronics Cleaner, so hopefully that cleaned everything up ok. I don't see any obvious signs of rust, so I must not have got enough on it to be a problem, or I cleaned it up well enough.

You're right Jay, it does have zinc chloride and hydrochloric acid in it. So I won't try that again, especially since I have the Ralph Thorne flux pen. I used that to solder in a motor for the first time on a JK Cheetah 11 chassis, and it worked fine, so it would appear that it was probably just the wrong flux. Assuming the Cheetah 11 is stainless like the Indy car and the Cheetah 21.

On another note, I've taken that Ferret Humdinger (1/32 scale wing car) to the track a couple of times, and it's pretty cool. Everyone loves it and thinks it's cute! They also think it's a Womp, though I guess I can't blame them. After I replaced the stock 8/32 gears with 10/30, it's decently fast with the old Super Wasp motor that's in it. I was able to pretty consistently run sub-5 second laps with it on the 155 foot King track. I'm planning to convert it to a 3/32 axle and put 64 pitch gears in it, which should help smooth it out a bit.