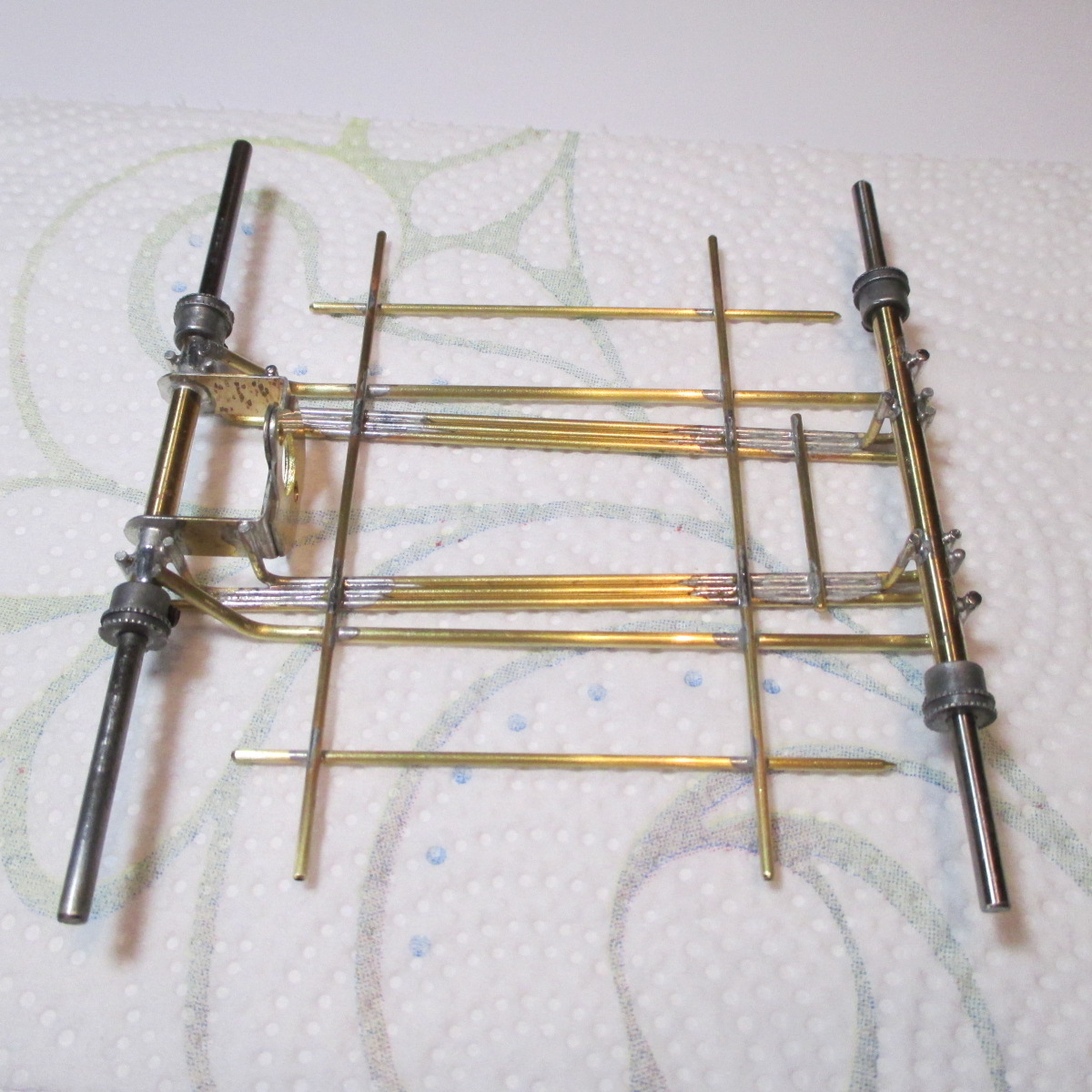

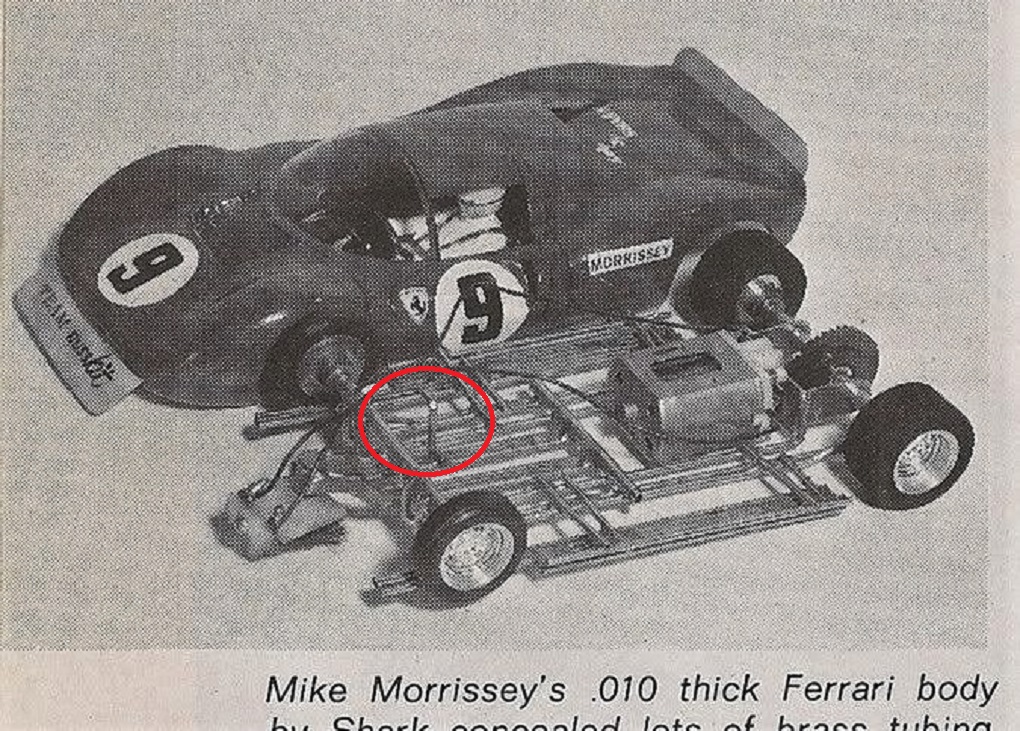

"Hey Bunky, I wonder if 13/16 Briggs Jig wheels will provide 1/16 clearance with 15/16 wheels on my RGeo jig?" No way, he says, "Apples and Oranges don't mix". So I showed him the math and with a scowled face he retreated back to his trailer ![]()

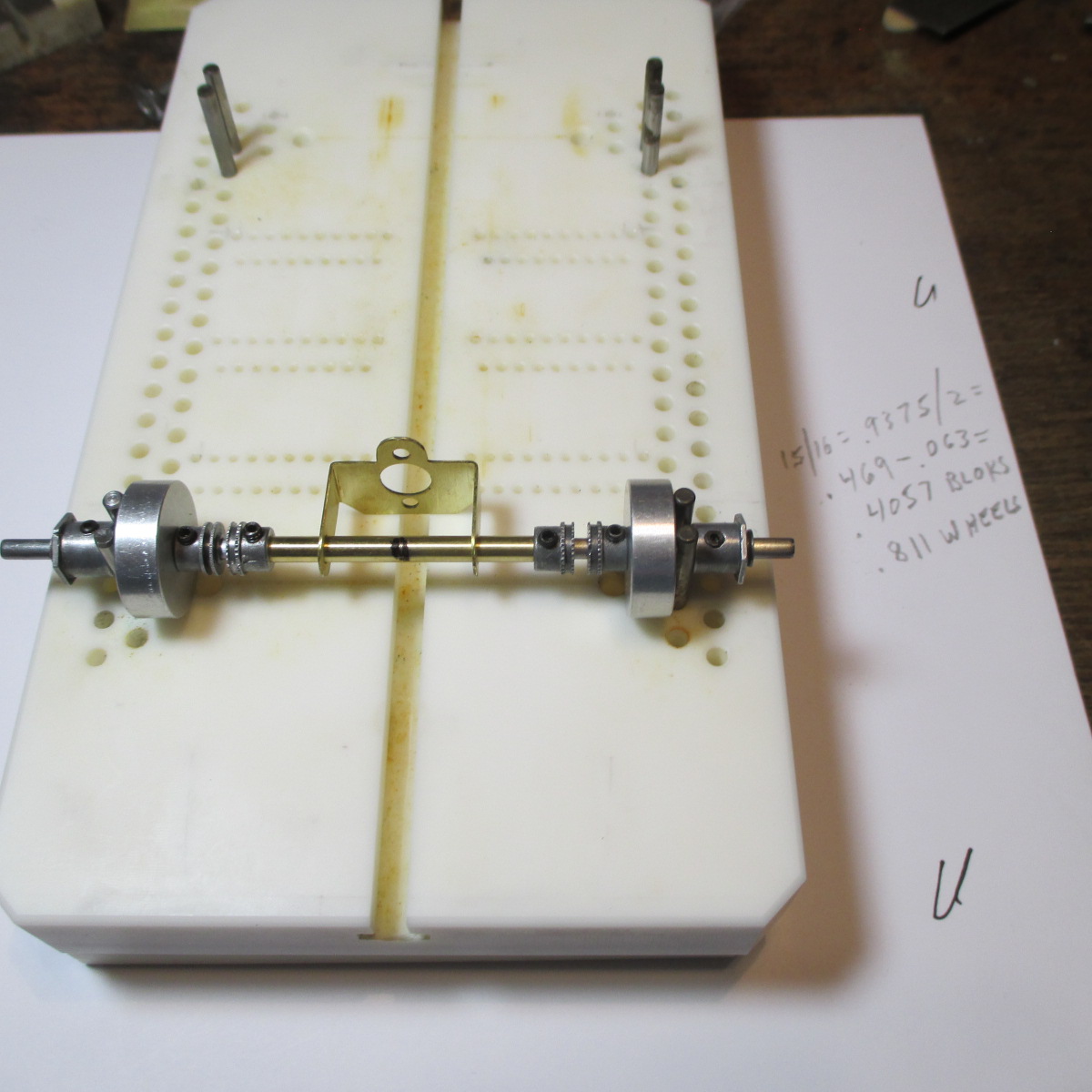

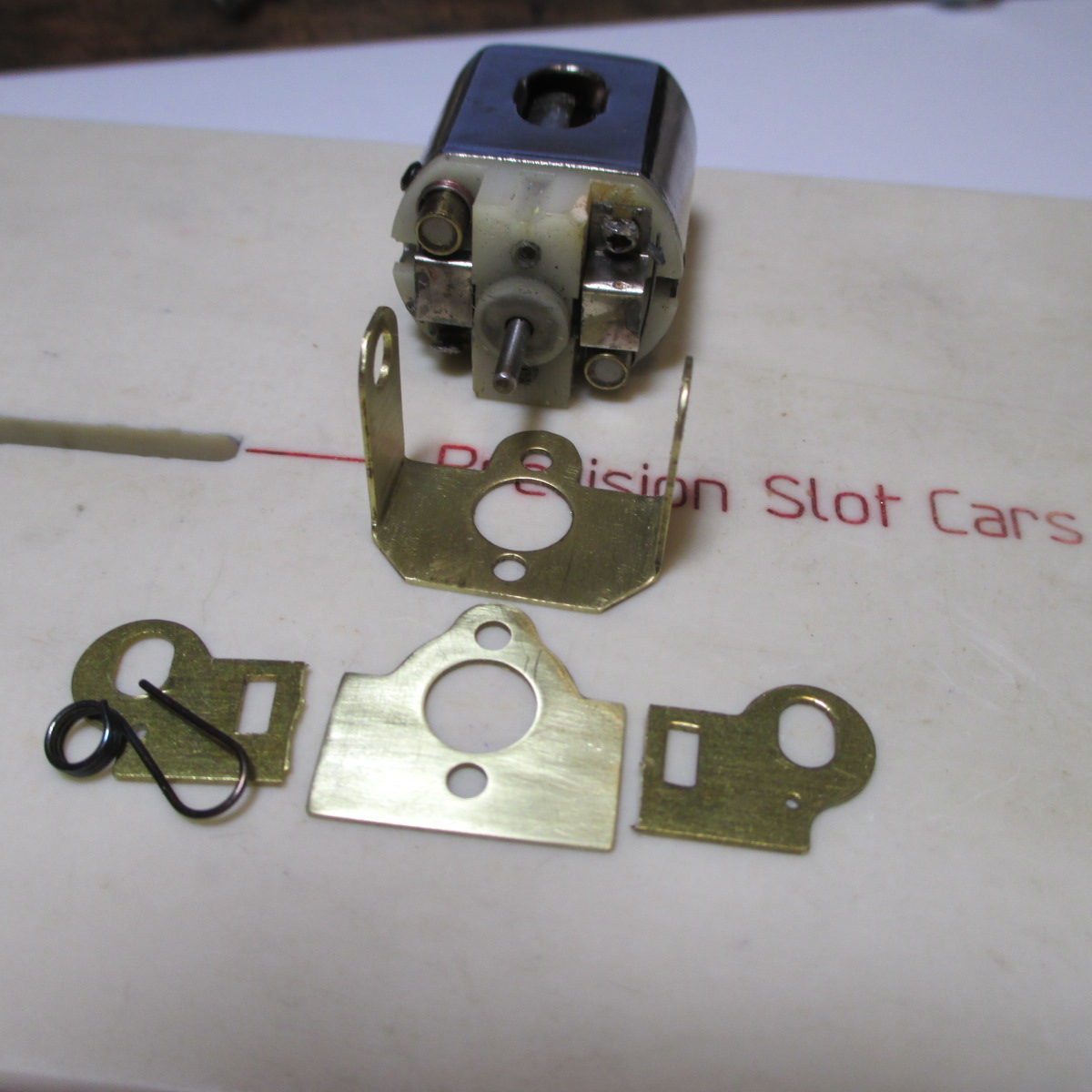

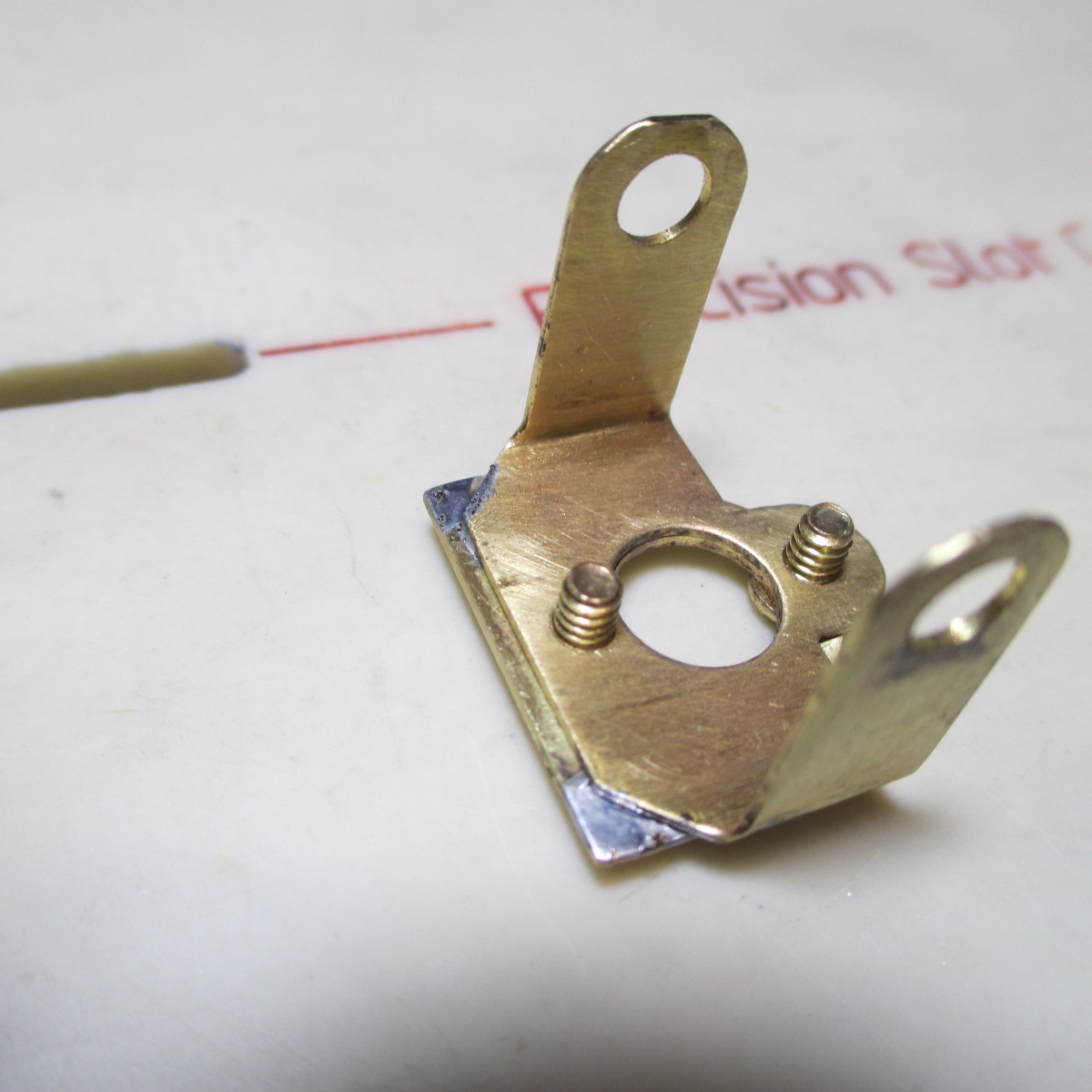

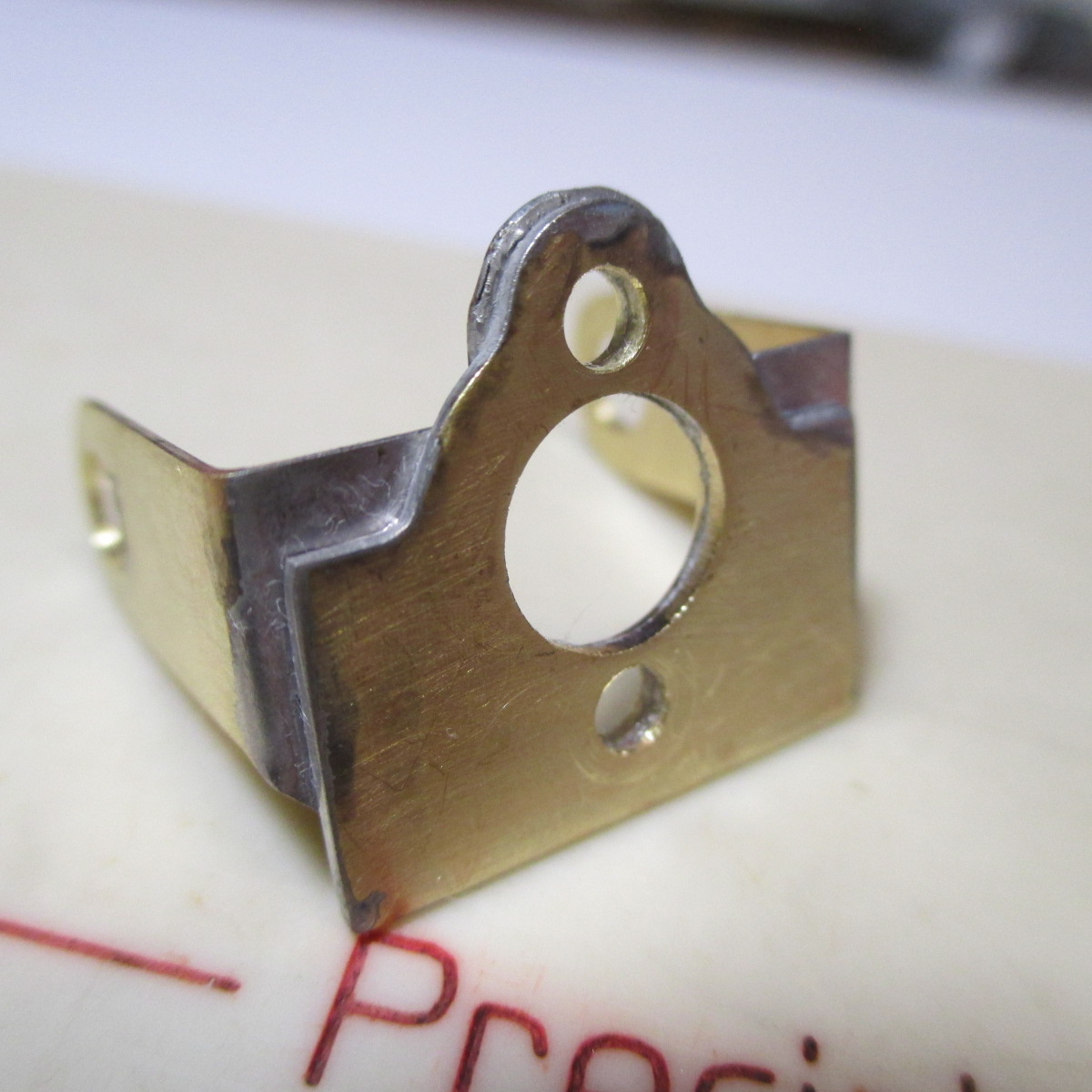

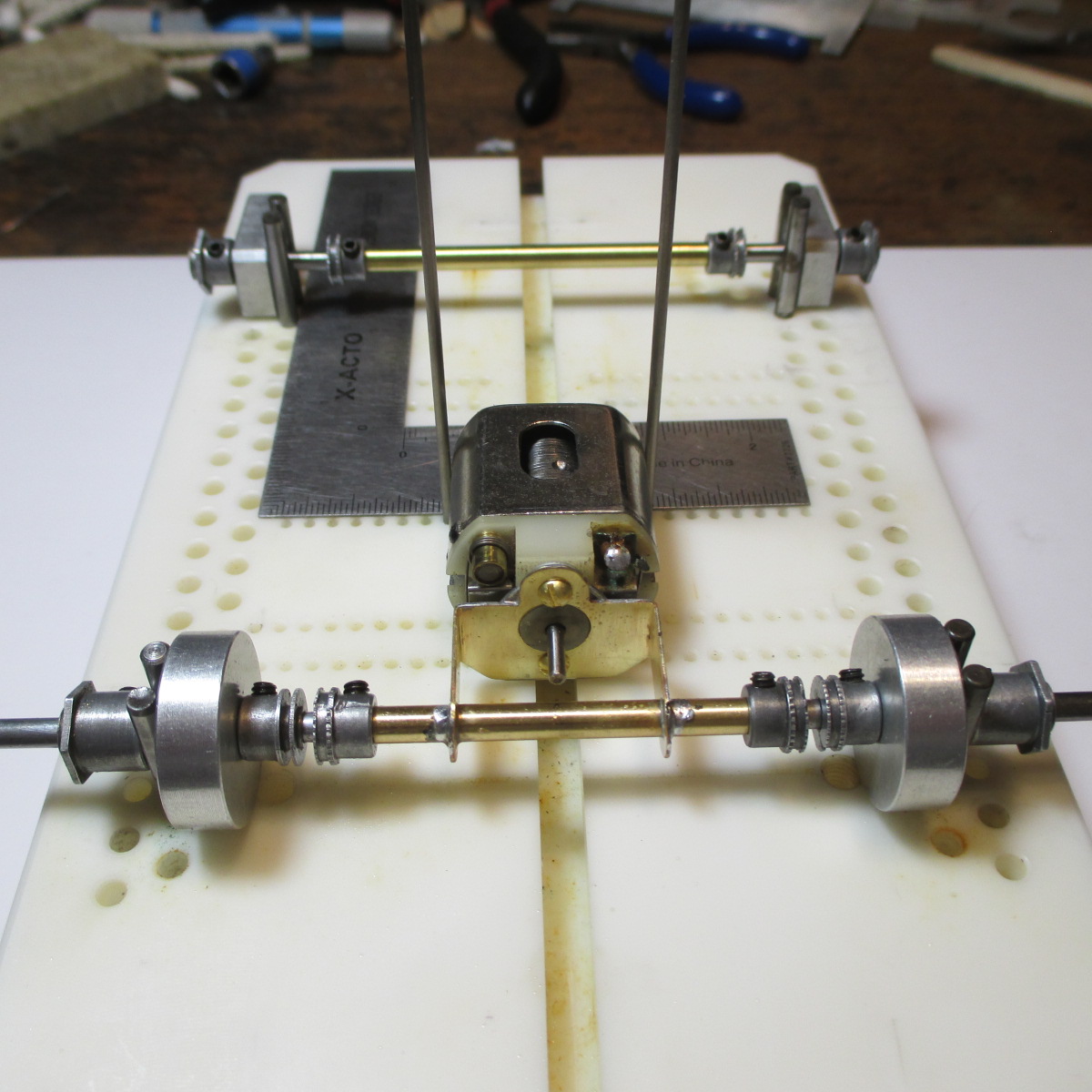

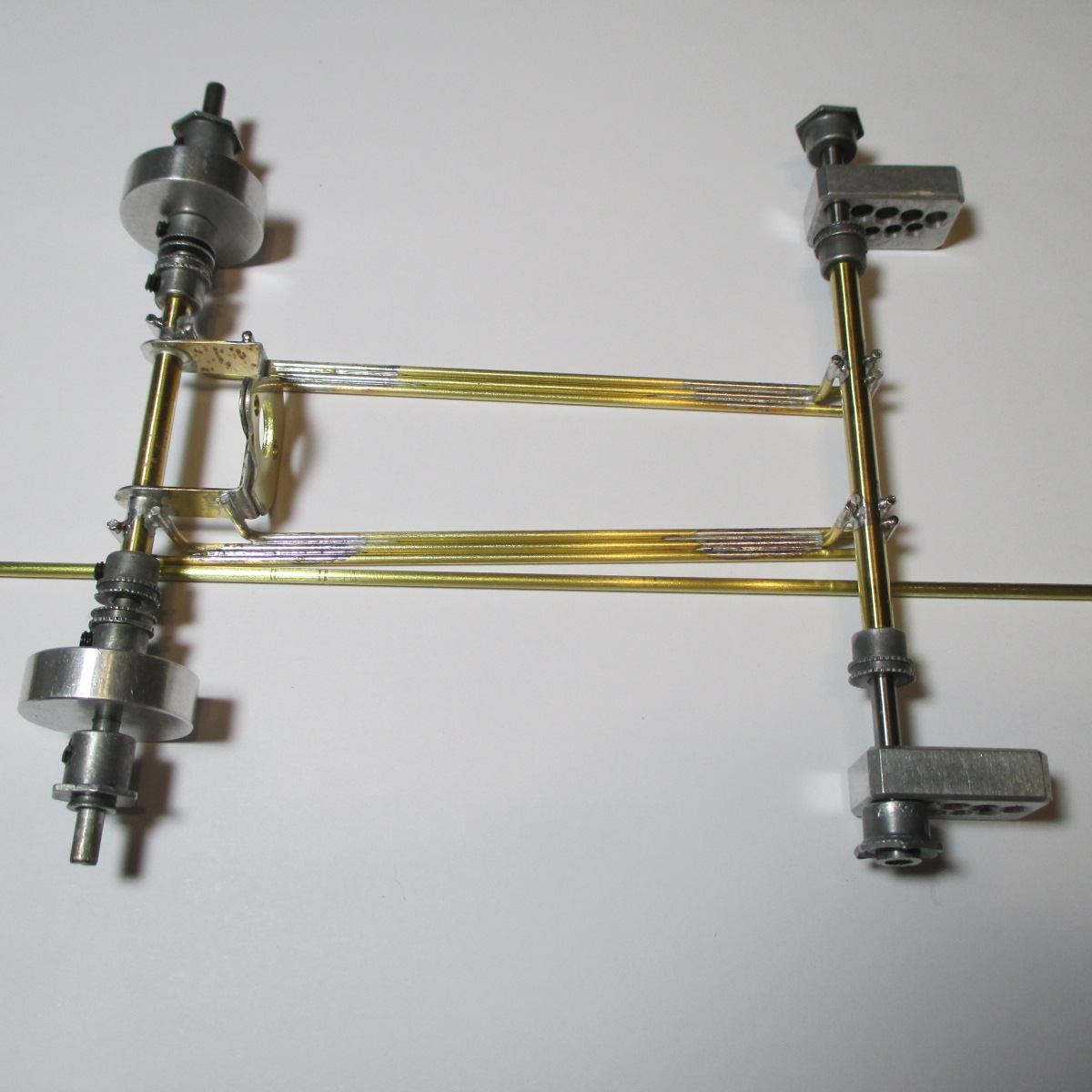

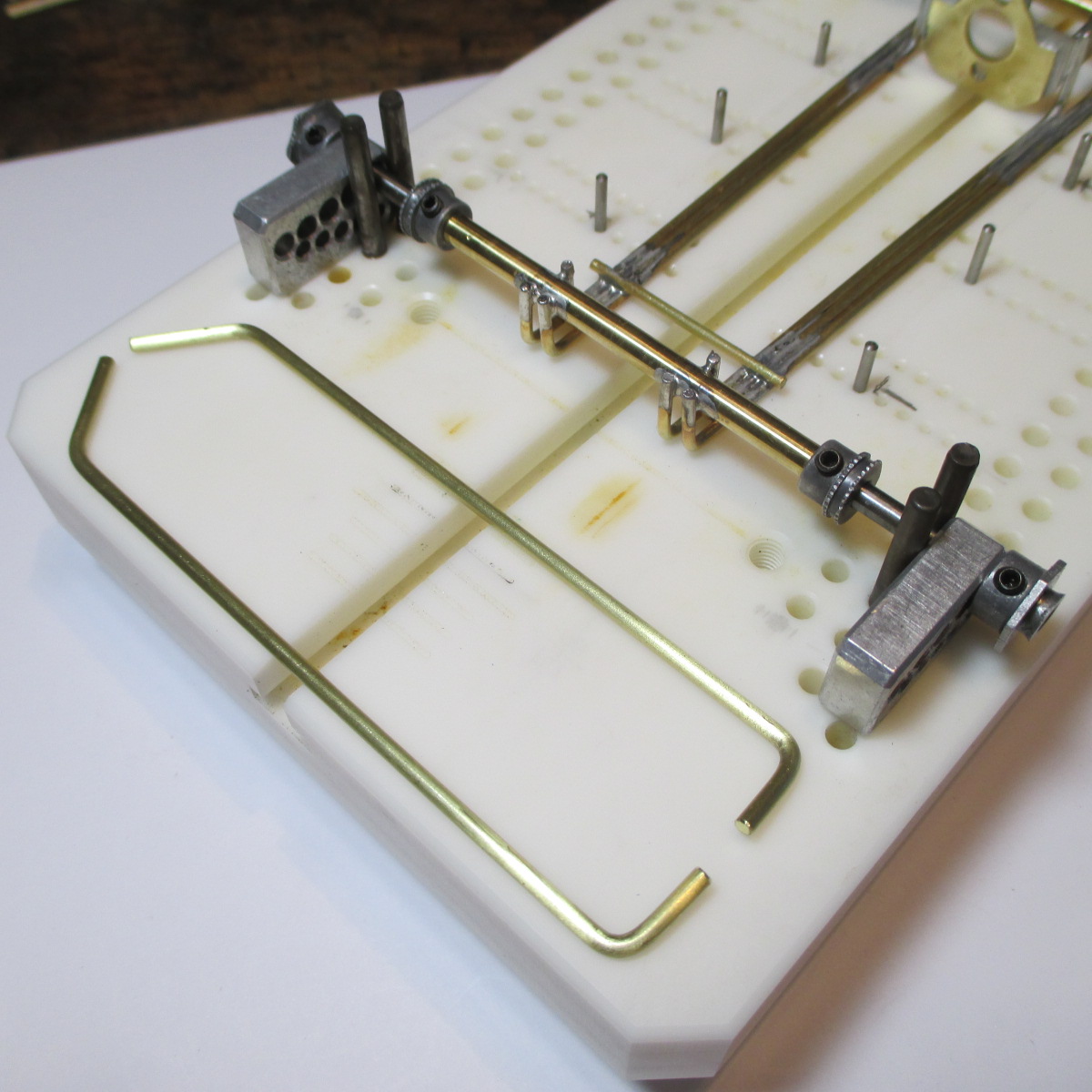

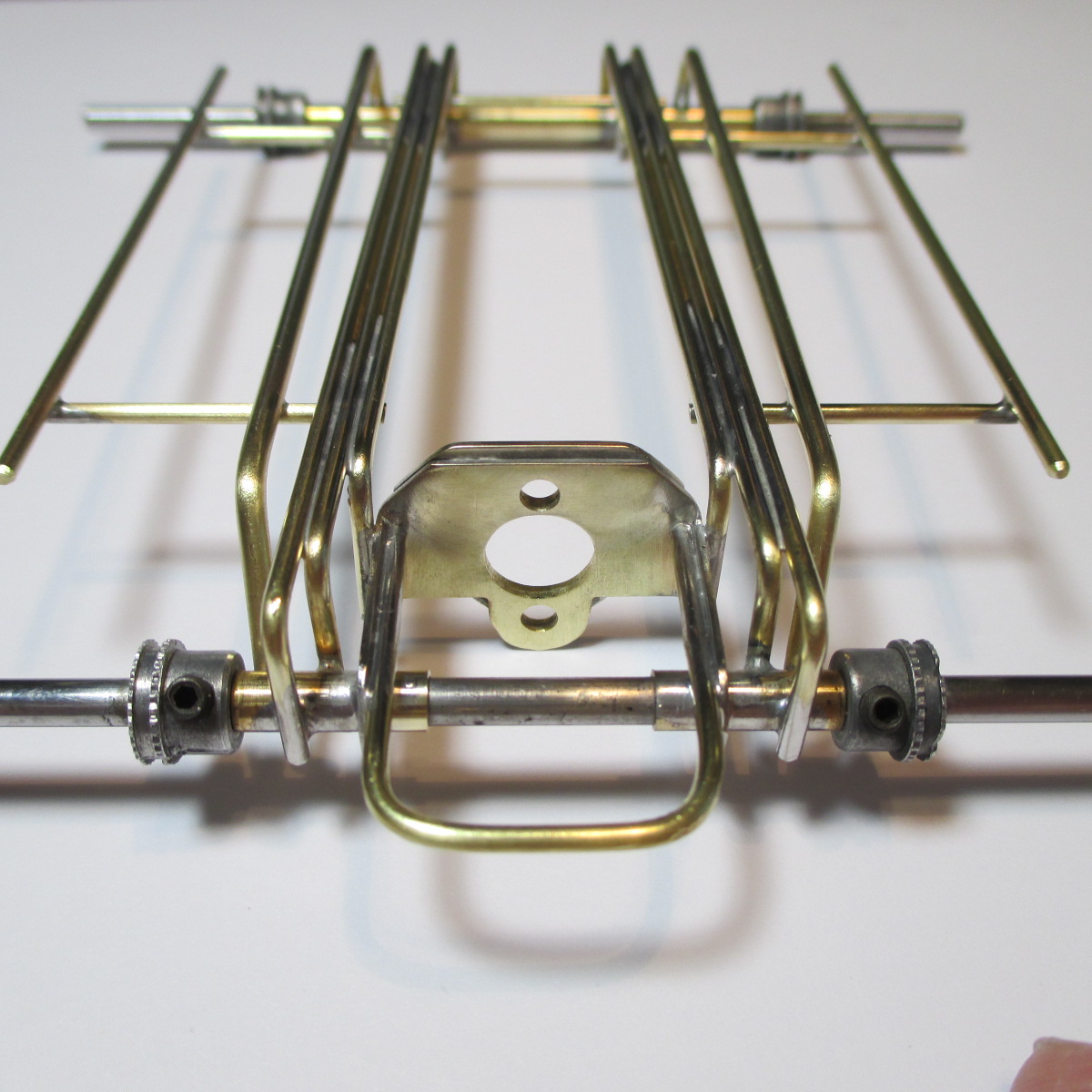

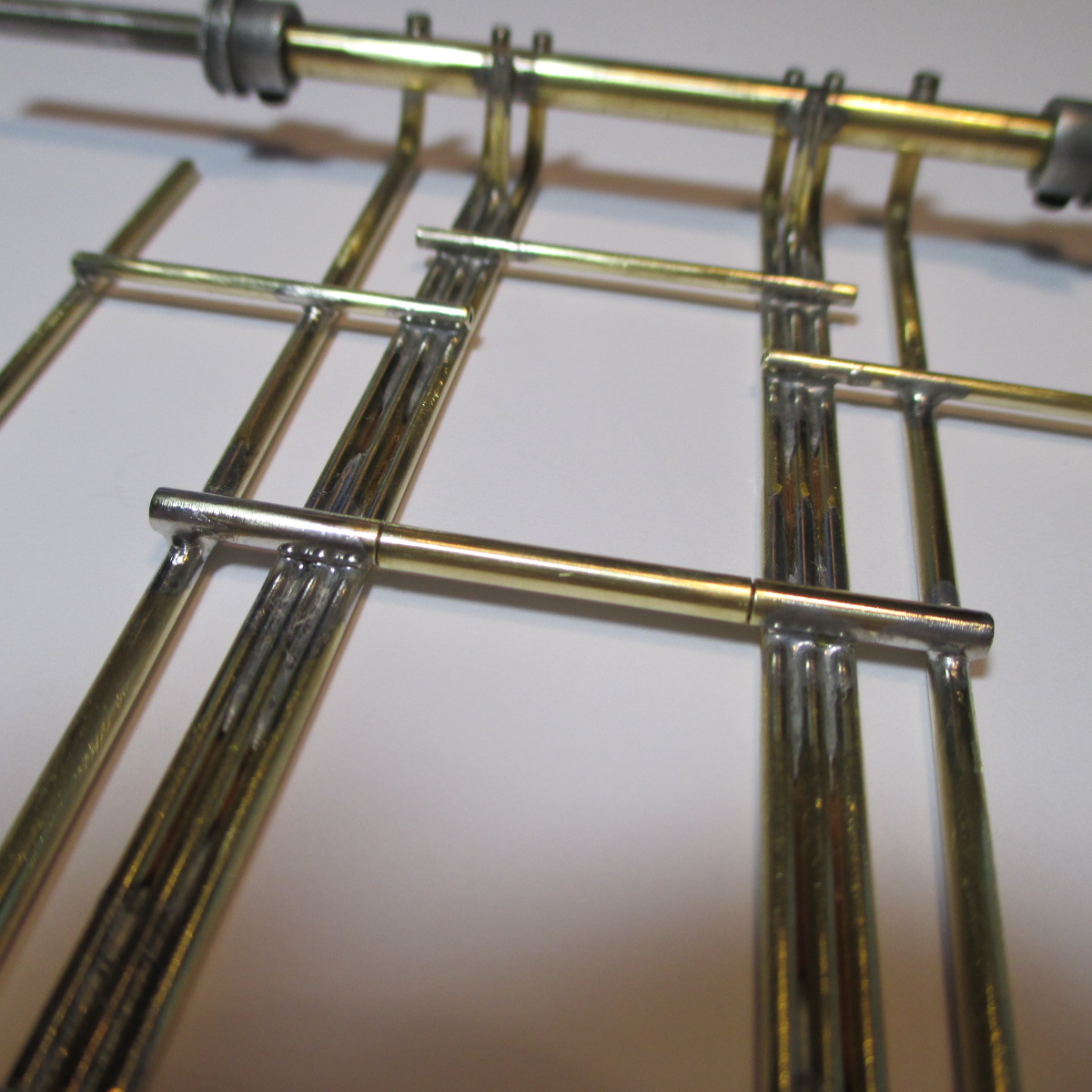

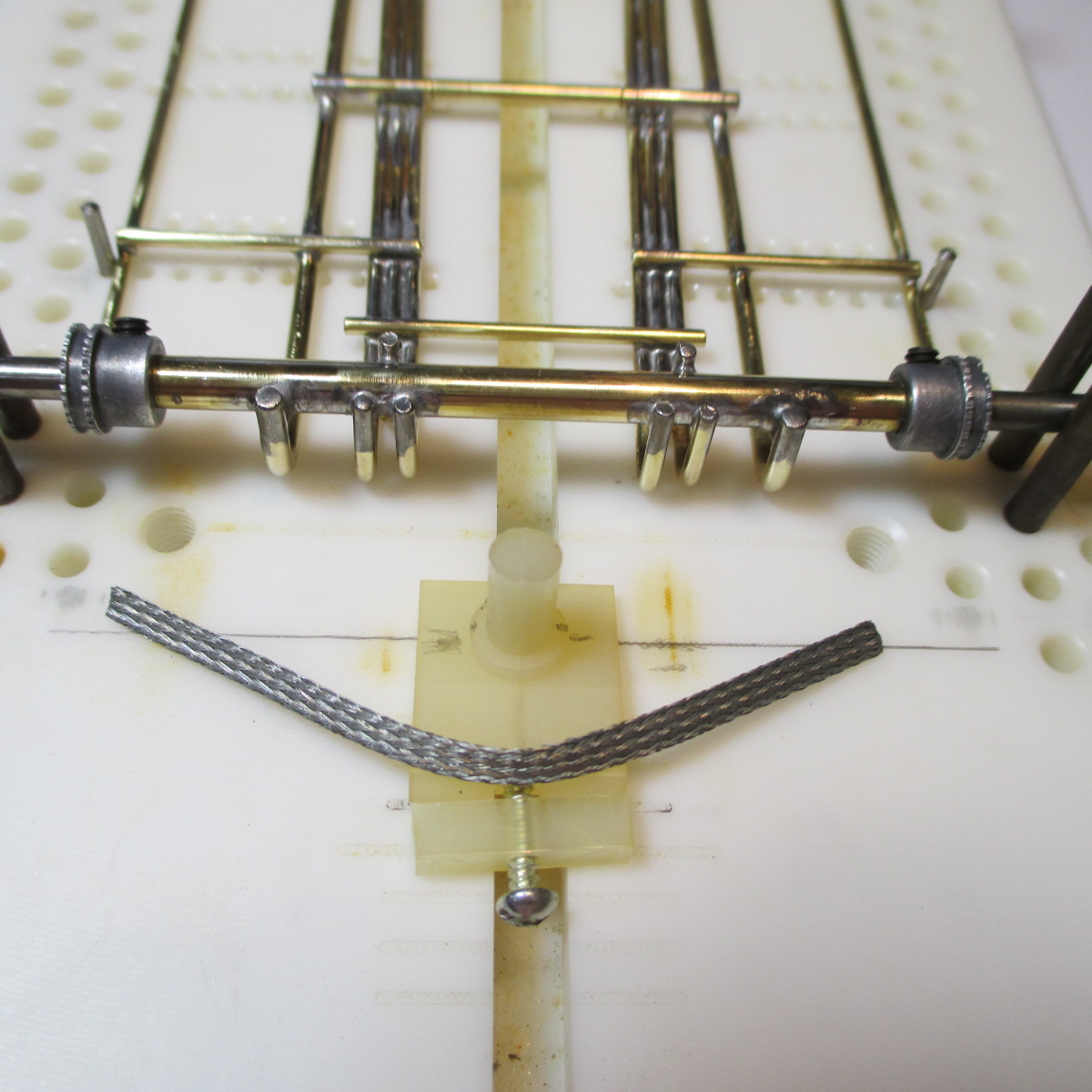

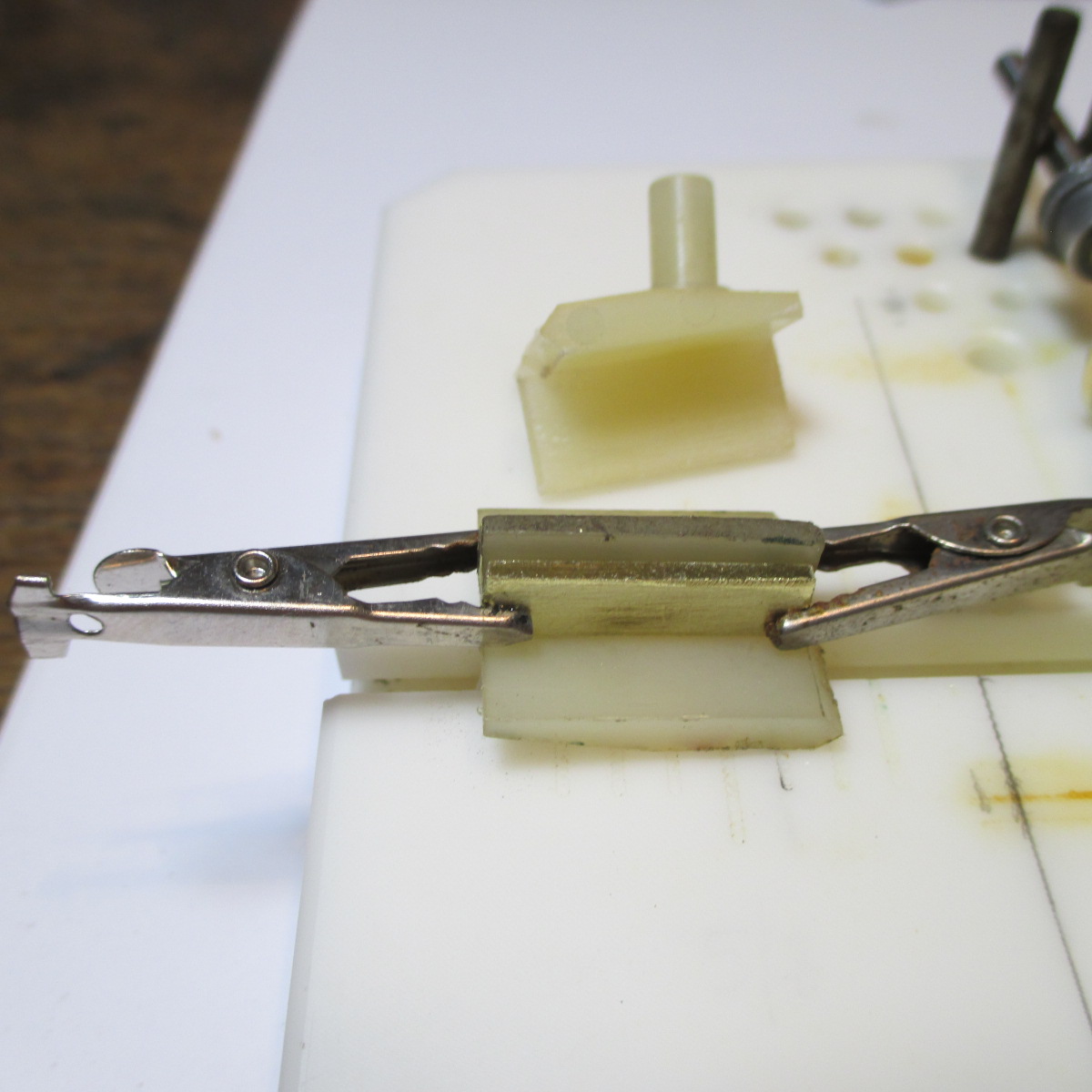

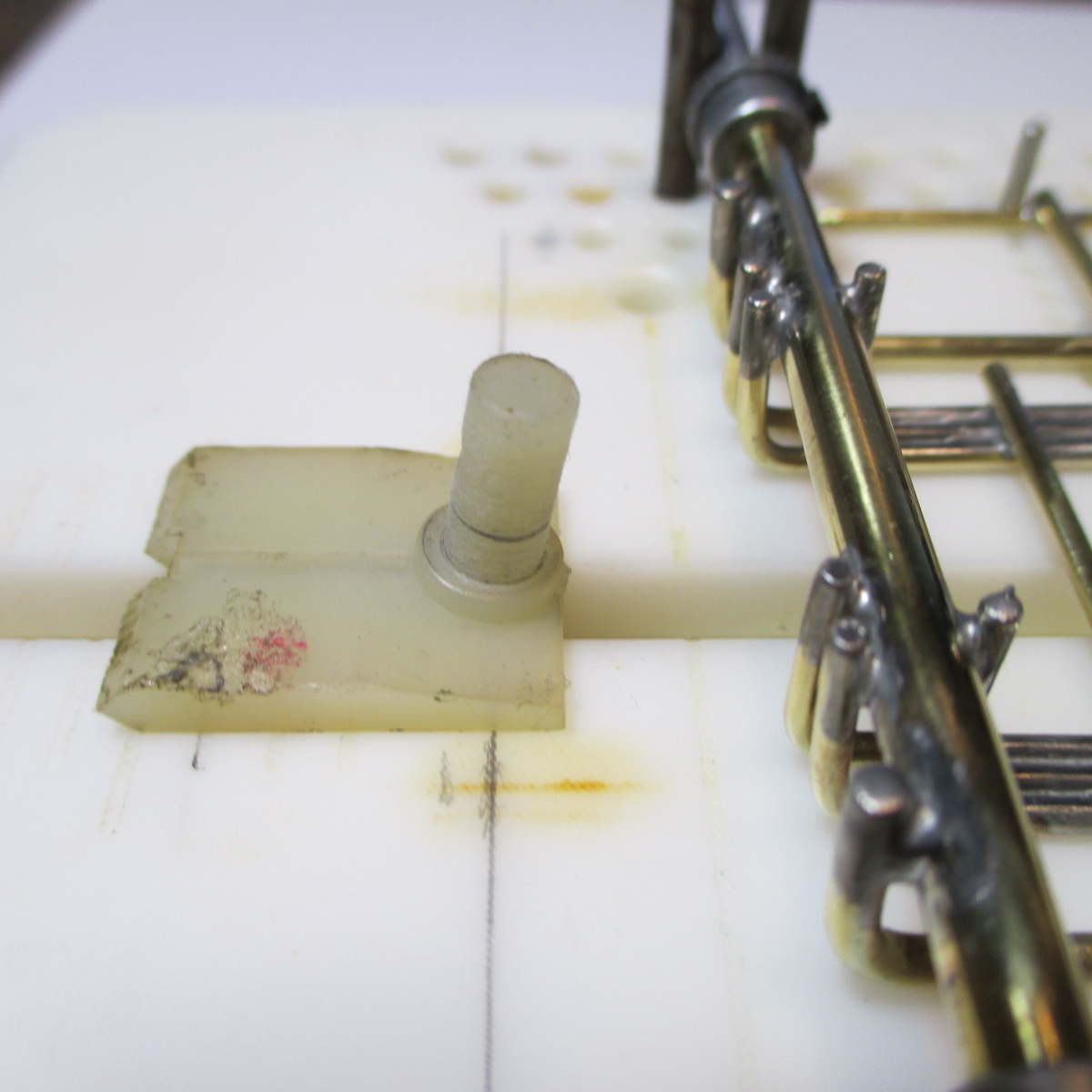

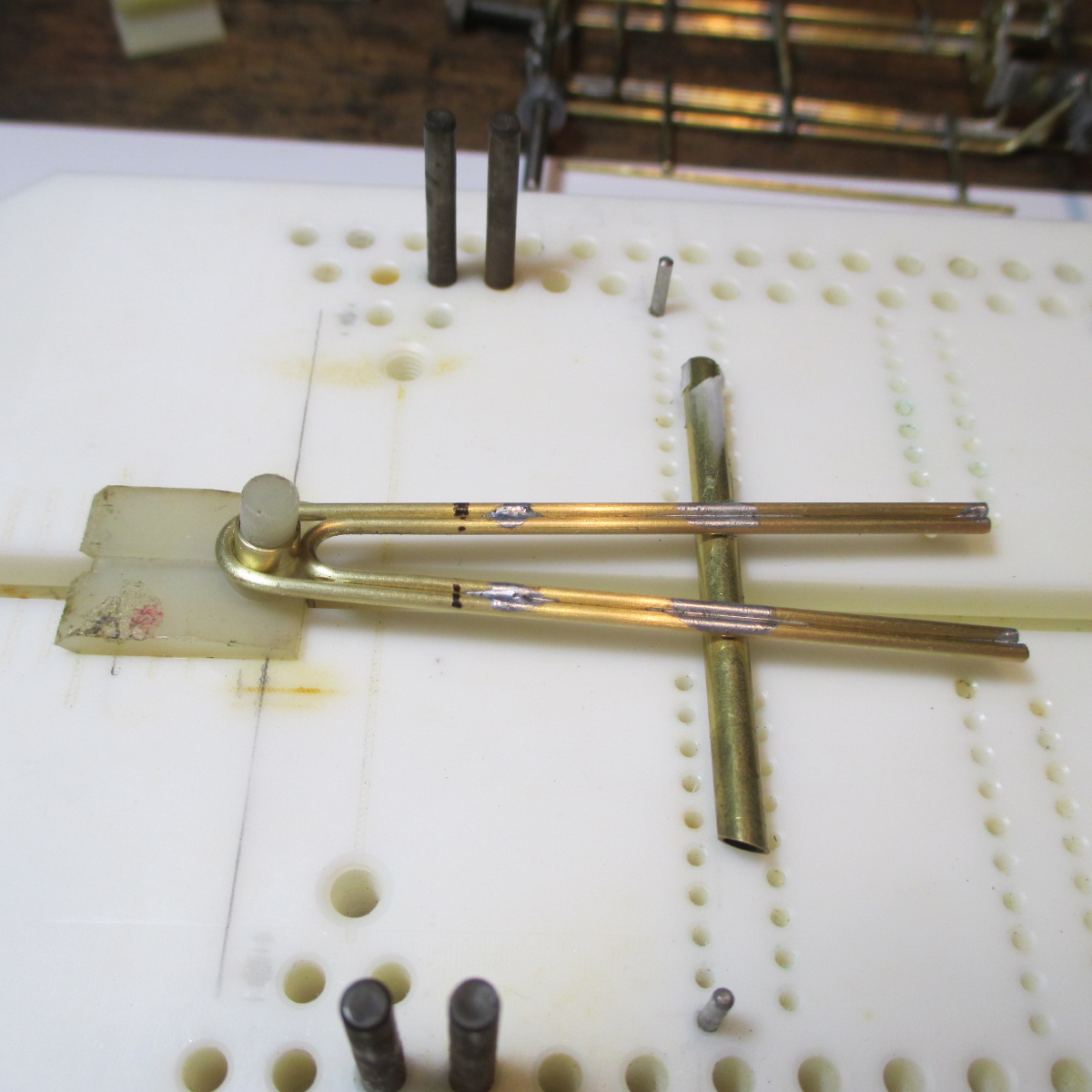

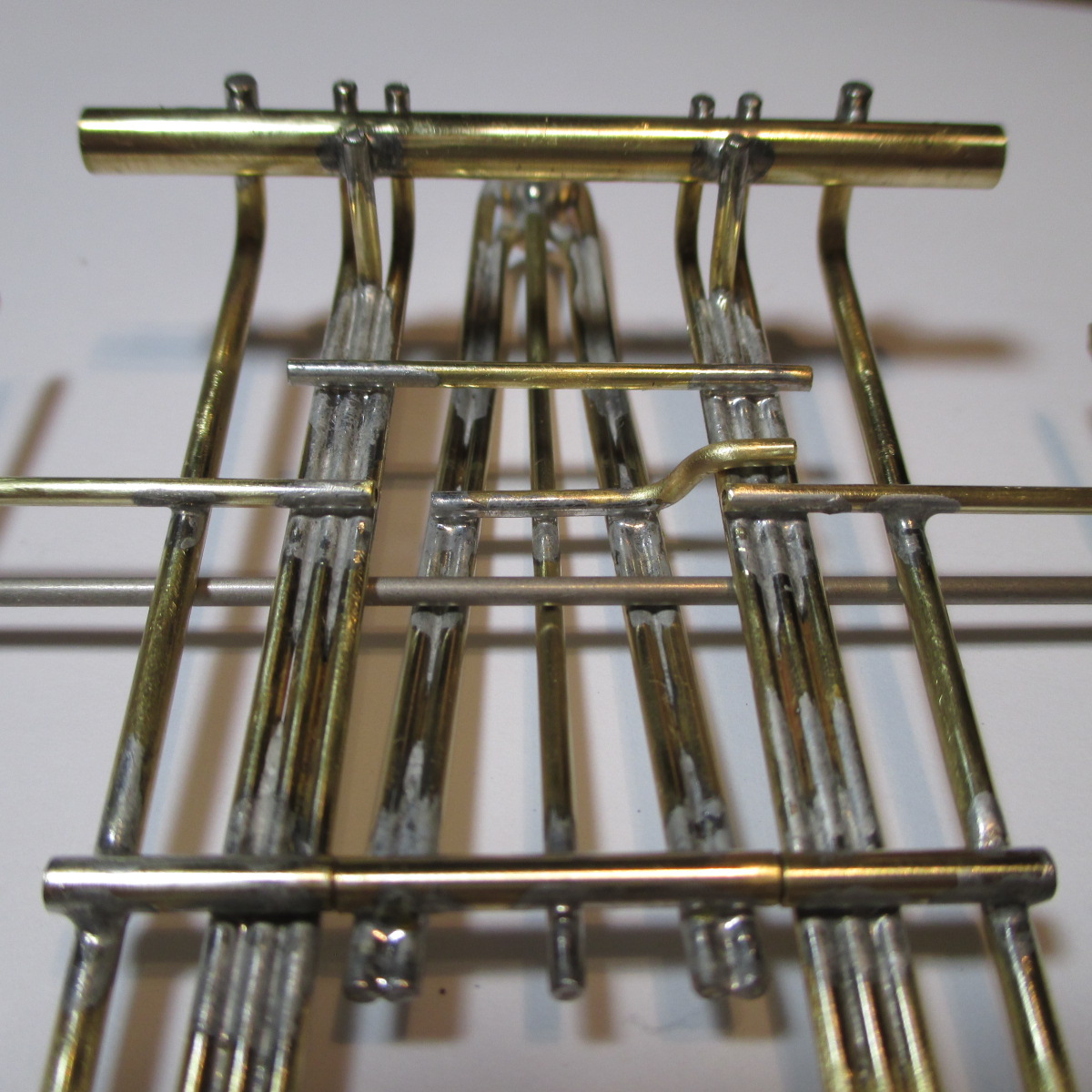

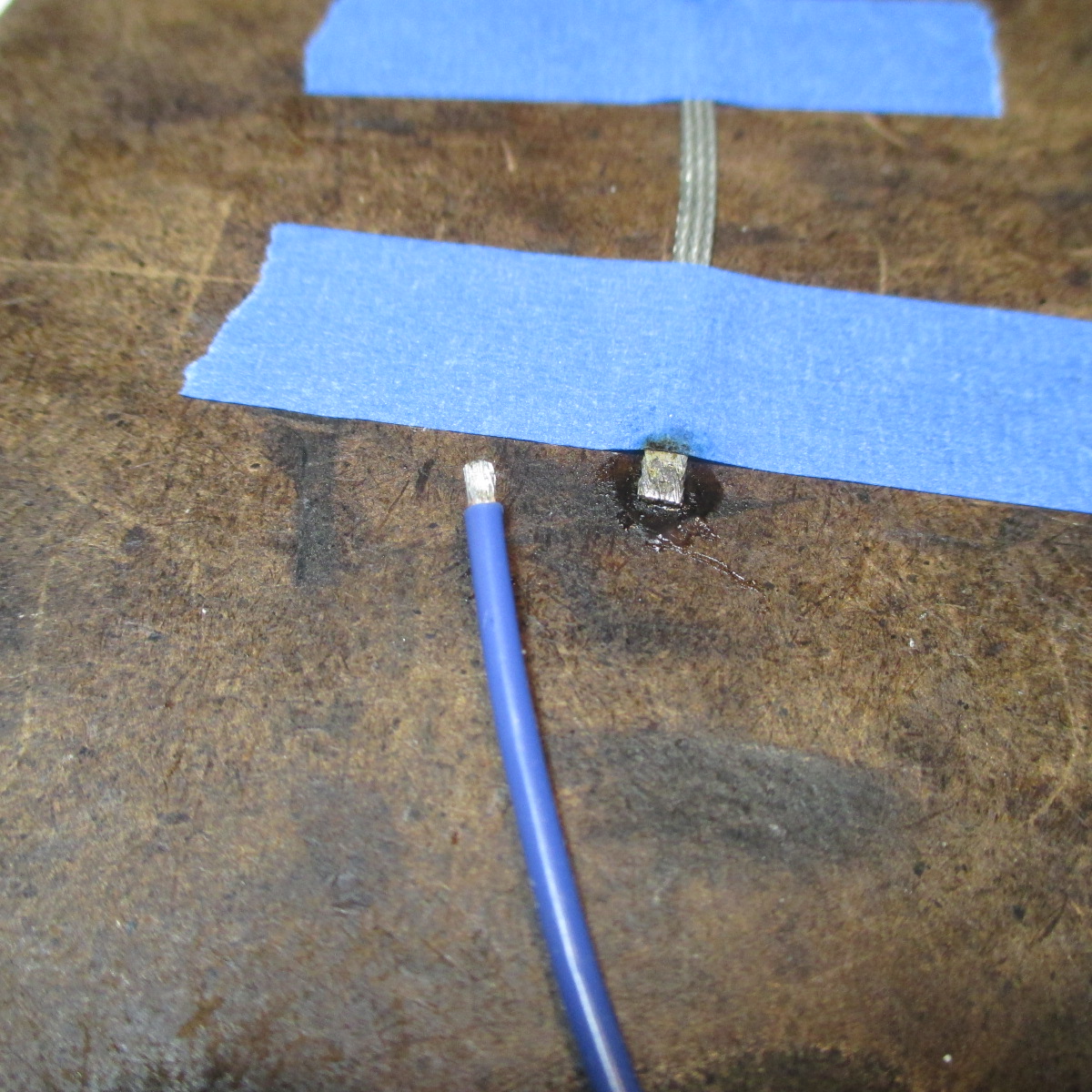

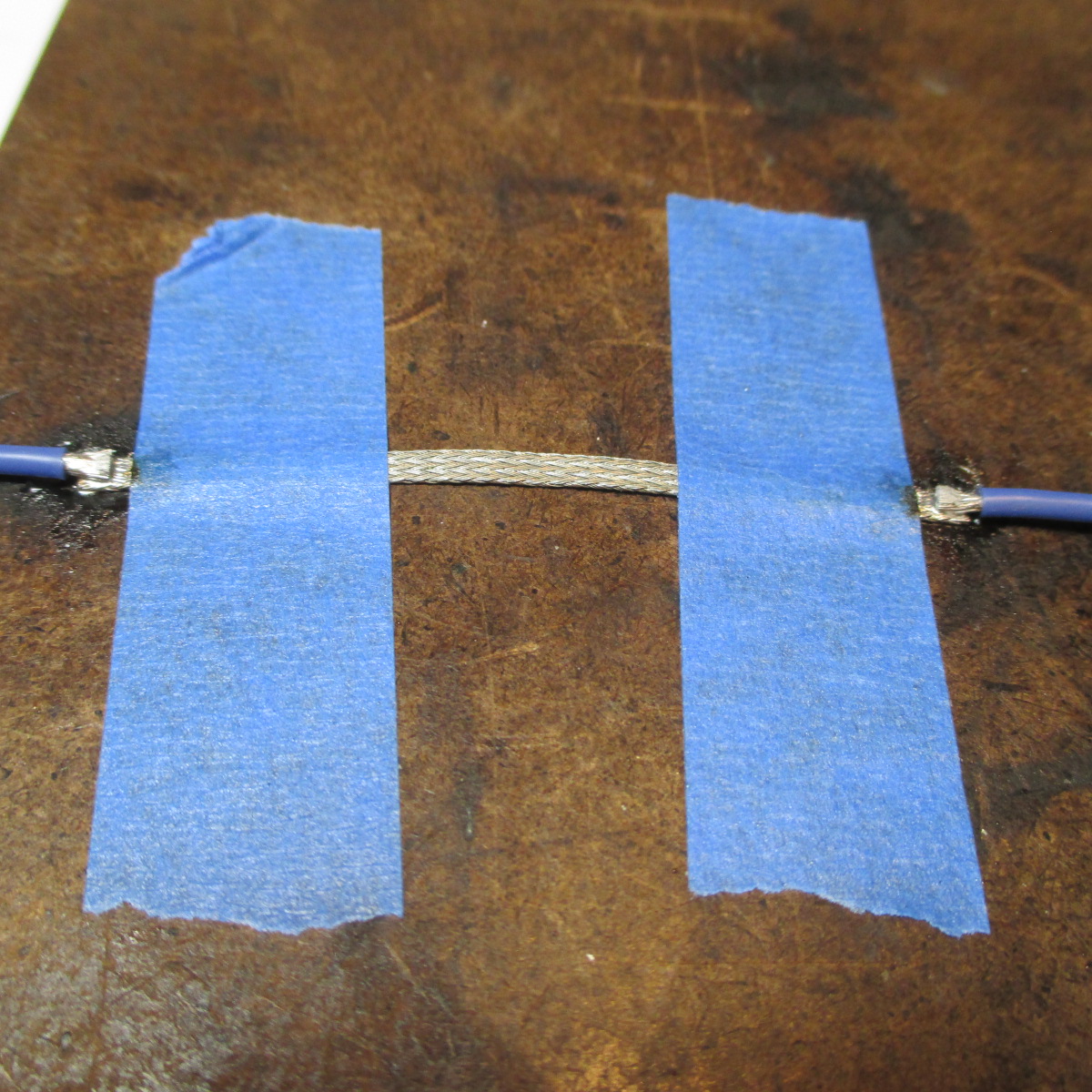

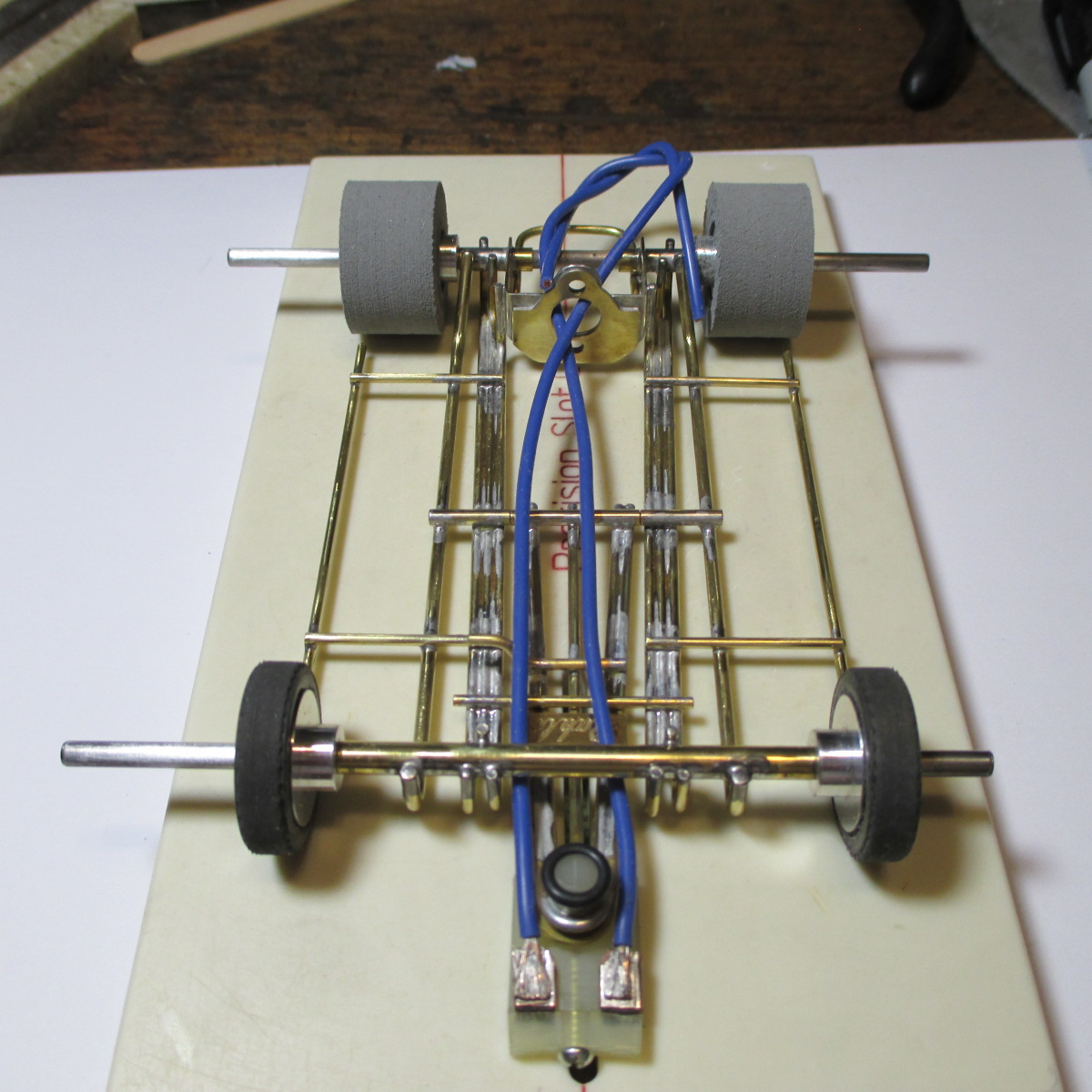

Rear axle setup is ready for tack soldering the bracket in place. Jig motor is ready, and I'm setting my jig pins to mimic Capt. Rick's tapered setup. It's approximate because my jig is a different version, and I'm learning Rick moves his .063 pin alignment wires around as needed