i might have to private message you and pick your brain about making molds and what products you use. i tried just recently with copying revell wheel inserts with kneeded eraser as a mold and jb plastic weld! didn’t come out to good to say the least but was using what I had laying around.

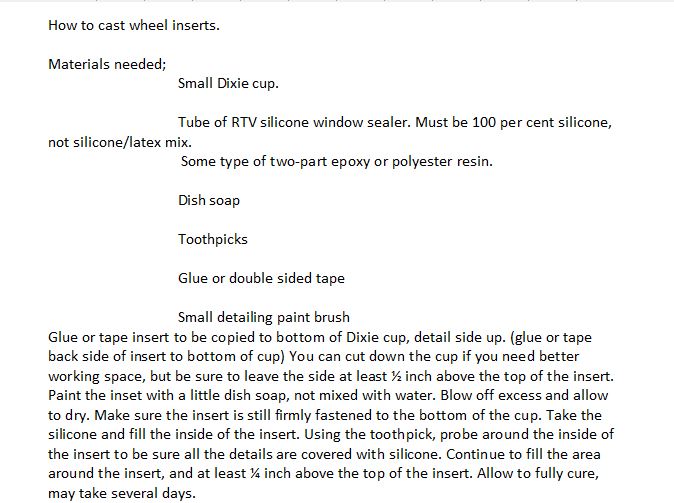

I can post the same instructions I gave to Paul;

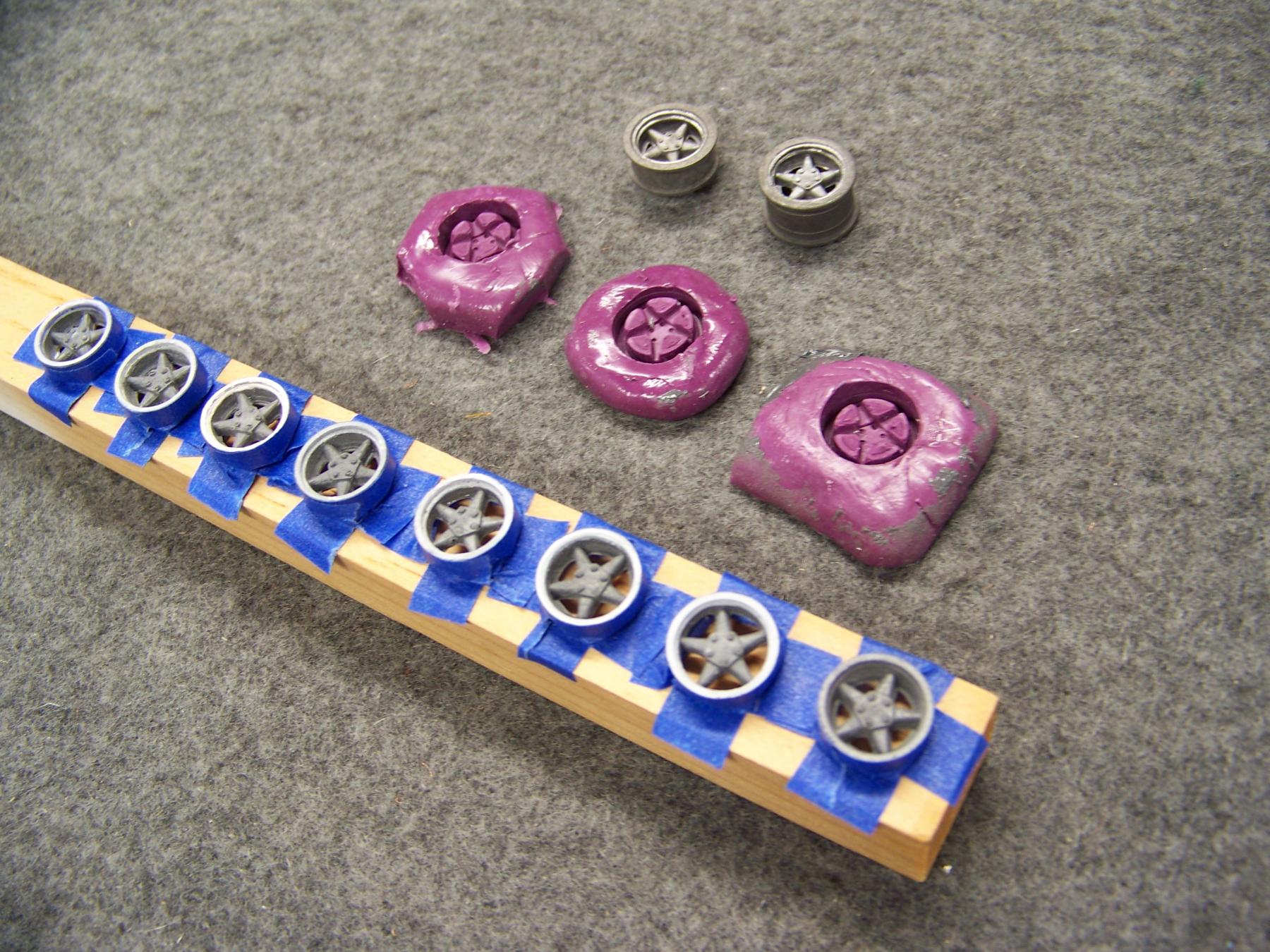

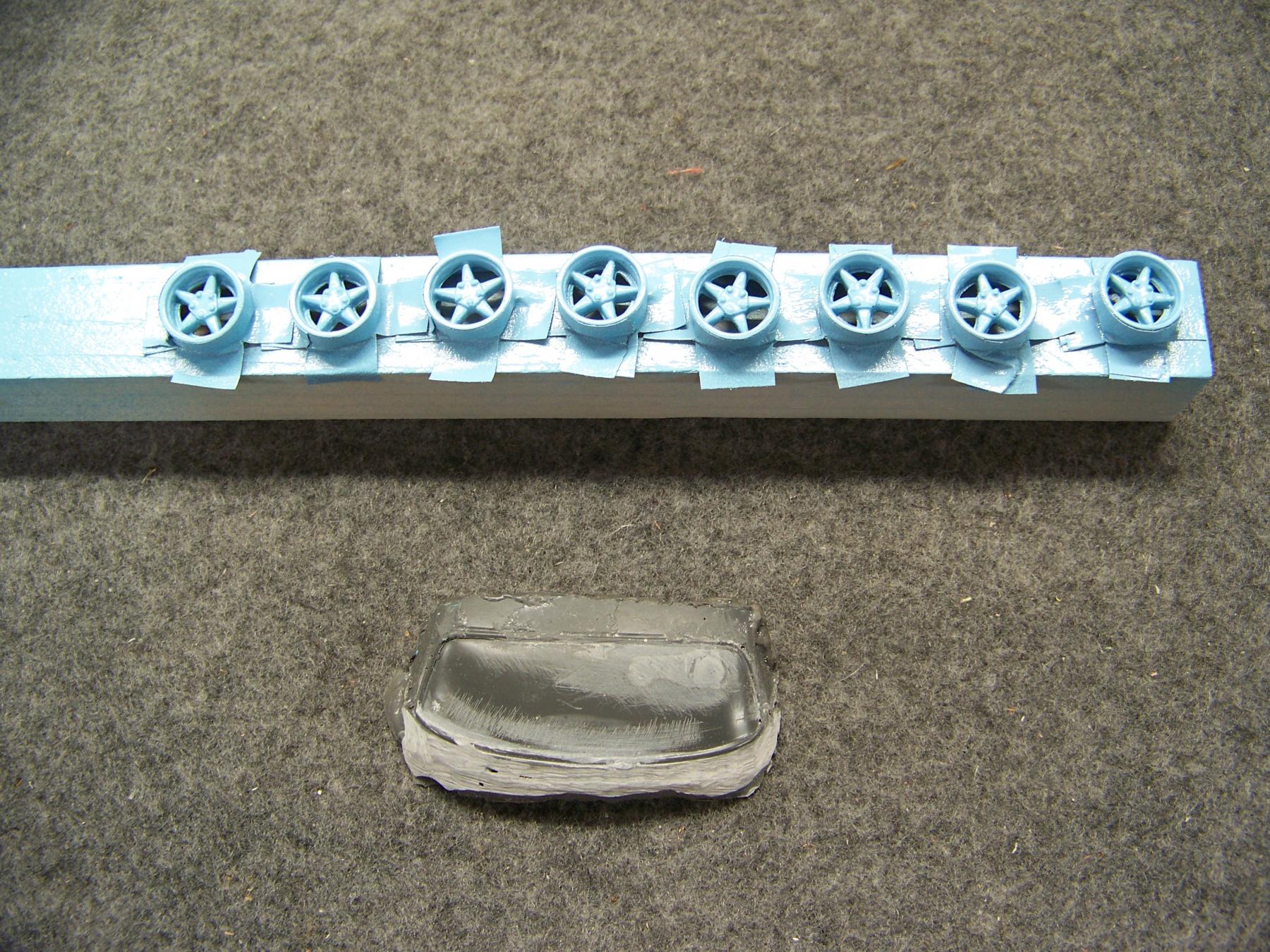

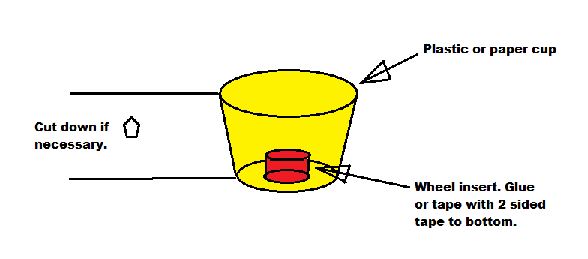

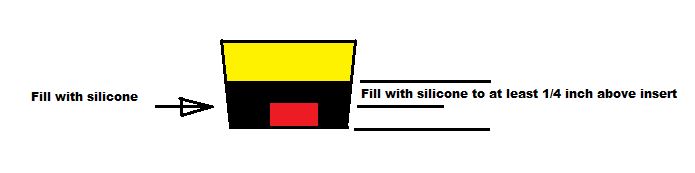

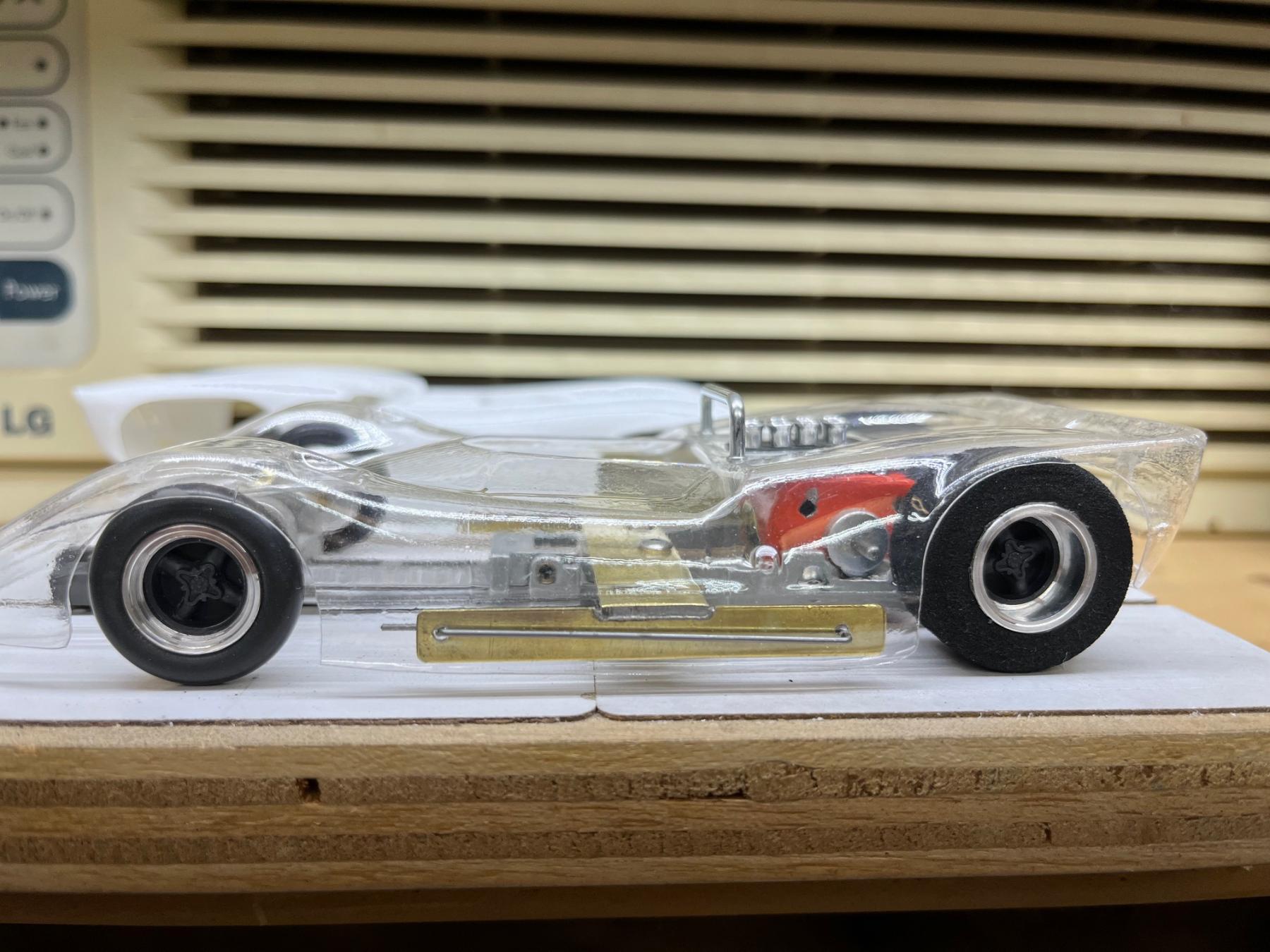

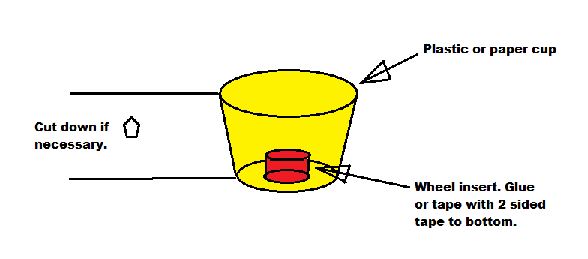

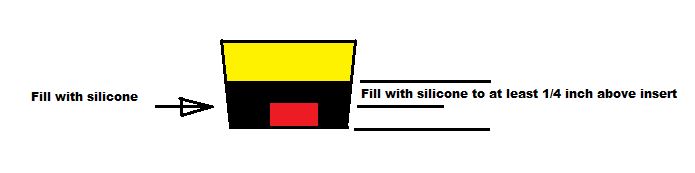

This is what it should look like at this point before pouring the silicone.

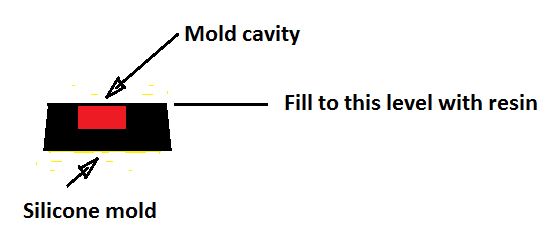

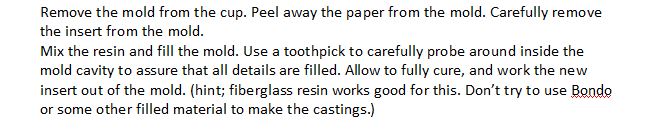

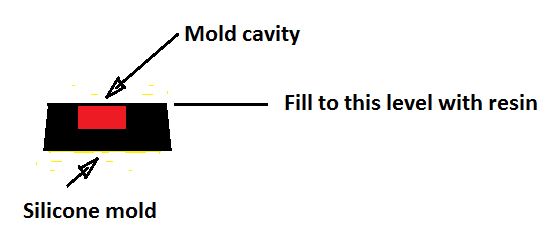

A couple of hints to make all this easier; After the mold is filled with resin, before it starts to cure you can use a ruler or some other straight edge to level the resin to the top of the mold. This will make less sanding of the back of the finished insert to fit in the wheel.

Making multiple molds makes casting quicker and wastes less resin. (More often than not, you will need different molds for front and rear inserts)

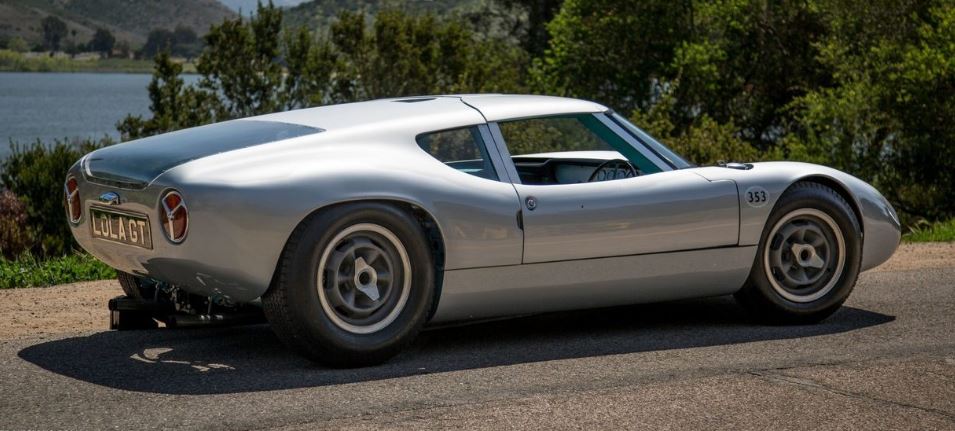

Make sure the master part fits in the wheel the way you want it to. Otherwise you will have a lot of fitting after molding.

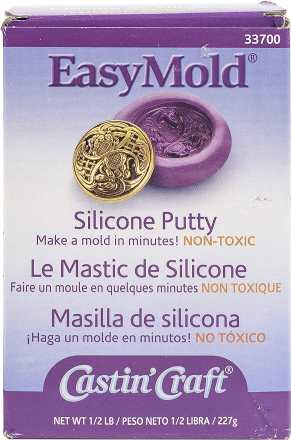

If you are only going to make one or two inserts, you can use whatever materials are handy. But if you need a lot of inserts, use a quality mold rubber and resin. I buy my materials from Eager Plastics, but since they are only sold in 5 gallon buckets, I would gues that is not an option for slot racers. The Alumilite kits sold at Hobby Lobby and Michael's are very good. A little pricey, but if you don't waste much, you can probably make 5 or 6 molds and get 25 or so inserts. Smooth-on is another good supplier, but since they are also an industrial supplier, you may end up having to buy more than you need. Fiberglass resin works for the castings, but the catalyst attacks the silicone rubber, so you won't get many casting out before the mold falls apart. I found that the mold putties don't always pick up the detail I want.

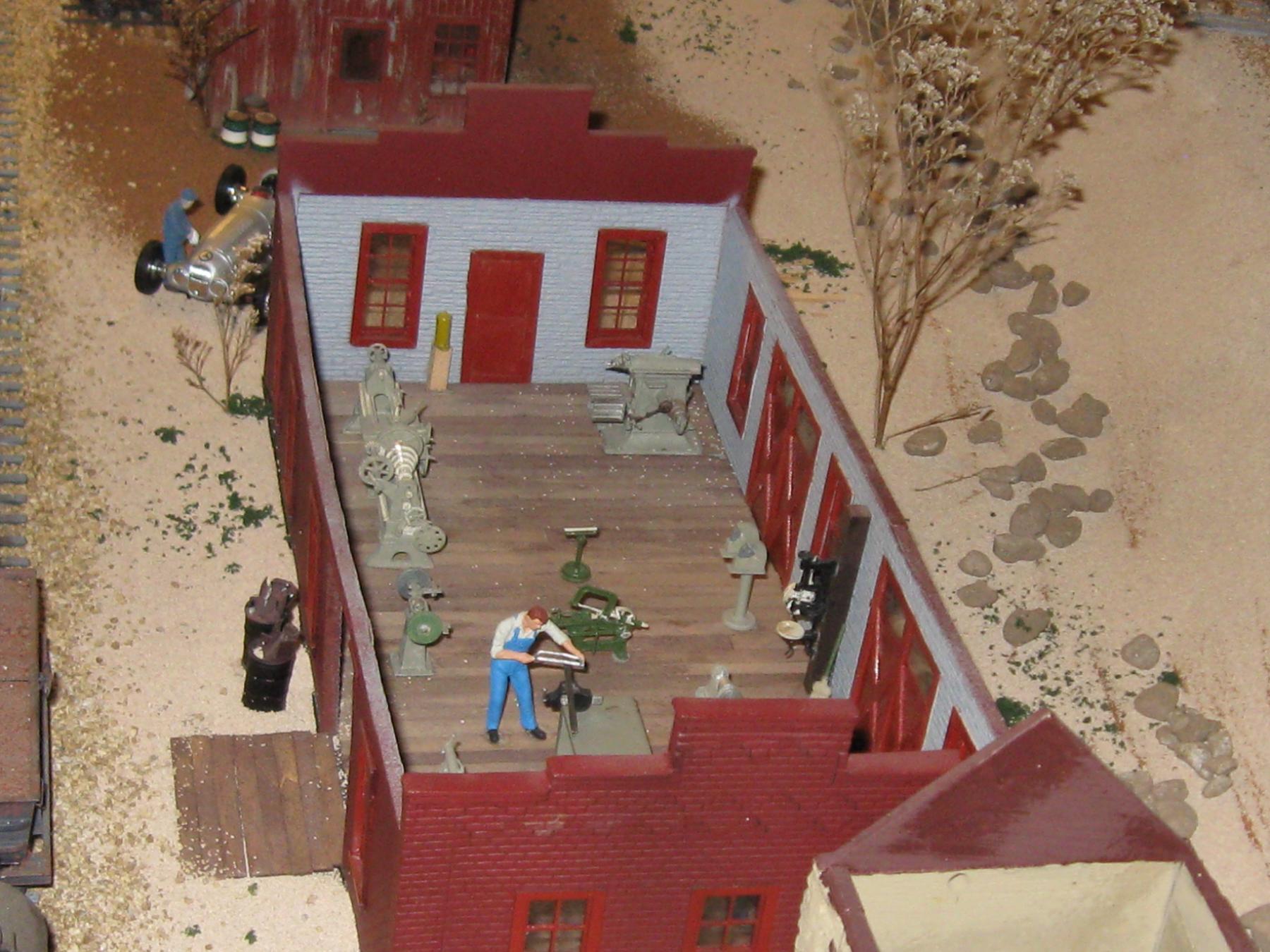

For masters, you can use the wheels from plastic kits. Most likely you will have to cut them down to fit the slot car wheels you are going to use. Again, make sure that they fit before making the mold. Some of the masters I had to make from scratch. I used Nyrod nylon rod for this, and used a lathe to machine the outside to fit the wheel. The inside details were done in a high-speed CNC router. I did my own 3D models at 10 to one, then reduced them to make the CNC program.

I have been making resin parts since the late 1960's, starting with model railroad products. I learned a lot from a friend who worked for Arrem Plastics, making resin castings. For many years he had a small side business making resin bodies and parts for the car model market.