that's awesome Jairus!

My small Dynamic collection

#26

Posted 15 December 2022 - 02:17 PM

???-2/31/23

Requiescat in Pace

#27

Posted 15 December 2022 - 03:25 PM

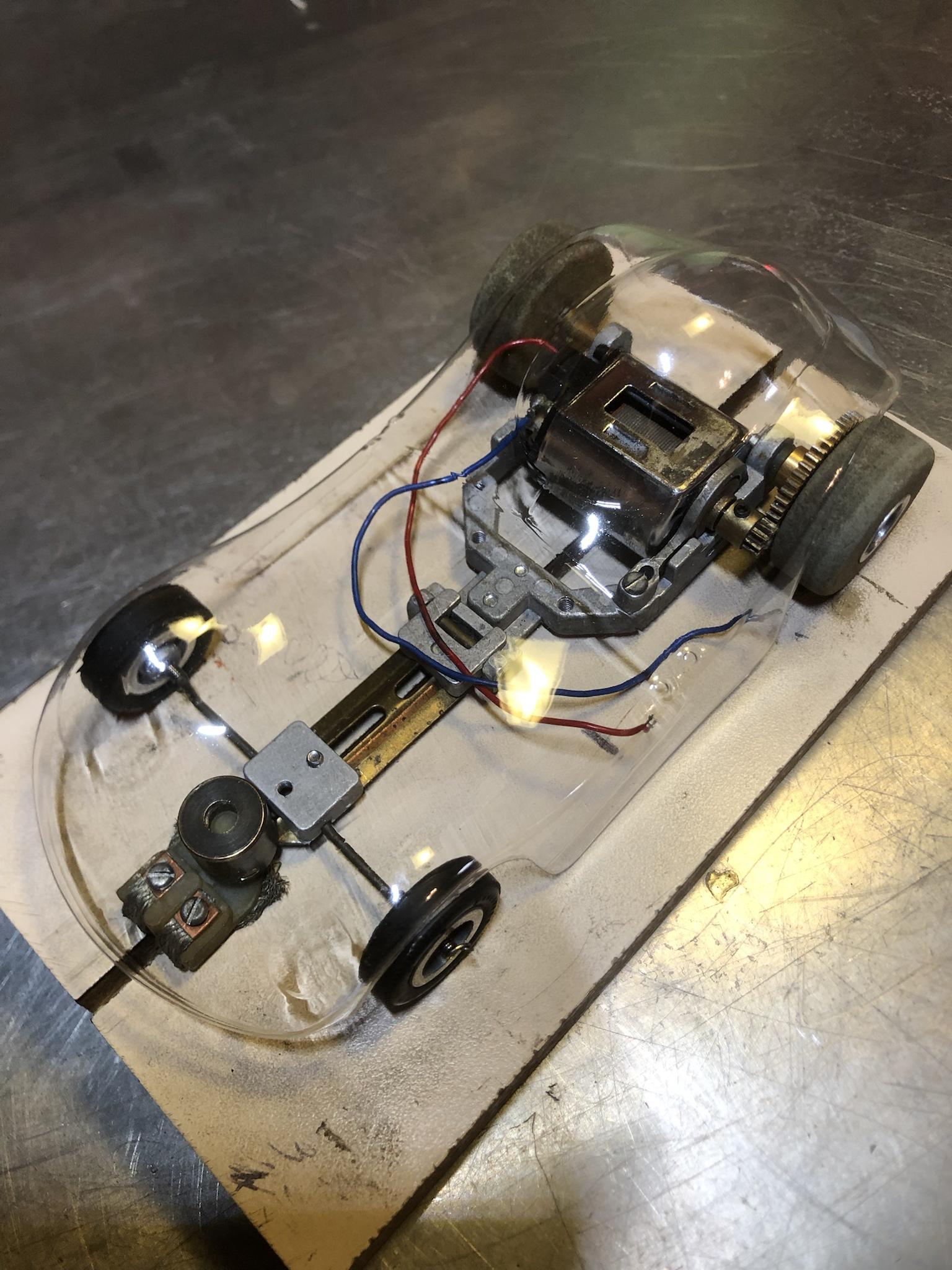

This is the only photo I have of my Dynamics cars. I ran them a lot back before adding pans was popular. Still have some of them. They were very competitive cars. One has a Pittman 403 type motor and a Ford GT-40 roadster body. The armature is one of my re-winds, and still turns pretty good lap times on a flat track.

The die casting tooling for the Dynamics parts is real simple. If I was still working I could turn it out on my lunch hours and after work. Much of the machine work to do it could be done in my basement. The EDM burning I would have to do using company equipment. I sense the popularity of the cars is getting such that the low volume of 3-D printing doesn't make sense. Once the die casting tooling is proved out, you can cast thousands of parts per hour. The different versions would be made using interchangeable inserts, so only one mold base is needed. I could do any finish machining of the castings in my basement.

#28

Posted 15 December 2022 - 03:44 PM

If there is the demand to recreate the vintage parts in volume, I will add to Dave's comments by pointing out that 3D printing in aluminum is both expensive and the finished piece has a pretty rough texture as opposed to the smooth mat finish of the original die cast parts. I found that I could sand and polish the printed aluminum and then soda blast it to achieve the same finish but that just added to the cost and production time. Don't get me wrong, I love 3D printing for both one offs and prototyping but its not a good way to make these parts in volume.

#29

Posted 15 December 2022 - 03:56 PM

I think we need Dynamic kits again.

Why even think about repo parts

makes no sense to me. There are so many Dynamic cars and parts still for sale. Must be plenty of original parts for everyone that wants some.

Because "everyone" wants to build with mini can motors. /s

By the way beautiful stuff, I wish I had used it back in the day.

Martin,

Knowing him real well, I think Nelson meant easily available to all, where you don't have to scour Ebay or swap meets.

So you could run a weekly or monthly race class, and even better, where a raceway owner who pays rent, can make a few $$, also selling them.

Dave,

I ran it by Grider probably back when we called all throwaway motors "Falcons", and he made me aware that in aluminum, it wouldn't be cheap to 3D print them.

Just like you mentioned, this had "government work", written all over it.

- NSwanberg likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#30

Posted 15 December 2022 - 04:07 PM

I don't do 3D printing, I mentioned it only as a technology that was not available when Dynamic chassis were cast, The secondary market wants outrageous prices for anything labeled Dynamic. I have a few Dynamic parts from the 60s but they were never very popular for racing in New England.

I intend to live forever! So far, so good.

#32

Posted 15 December 2022 - 07:40 PM

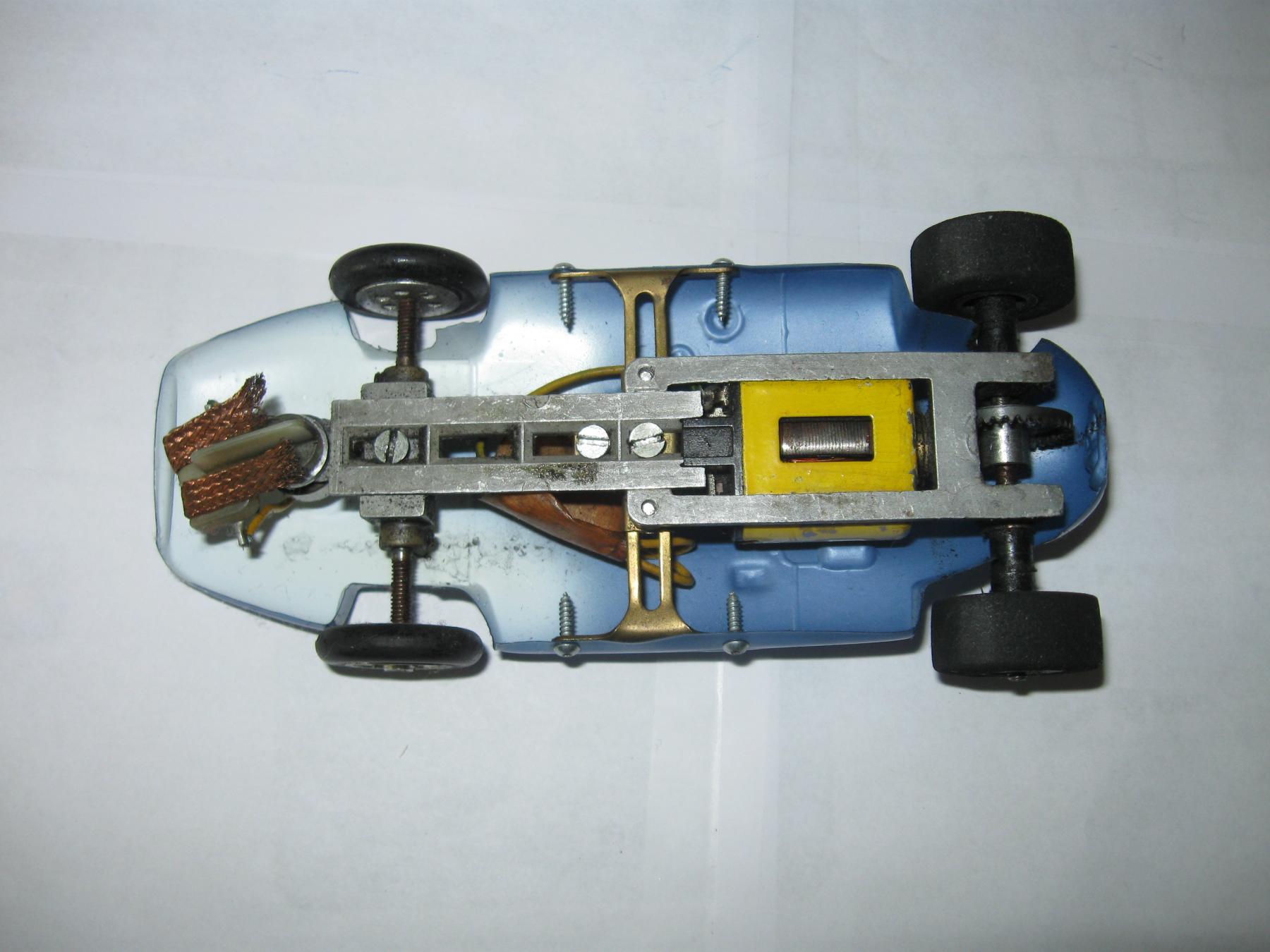

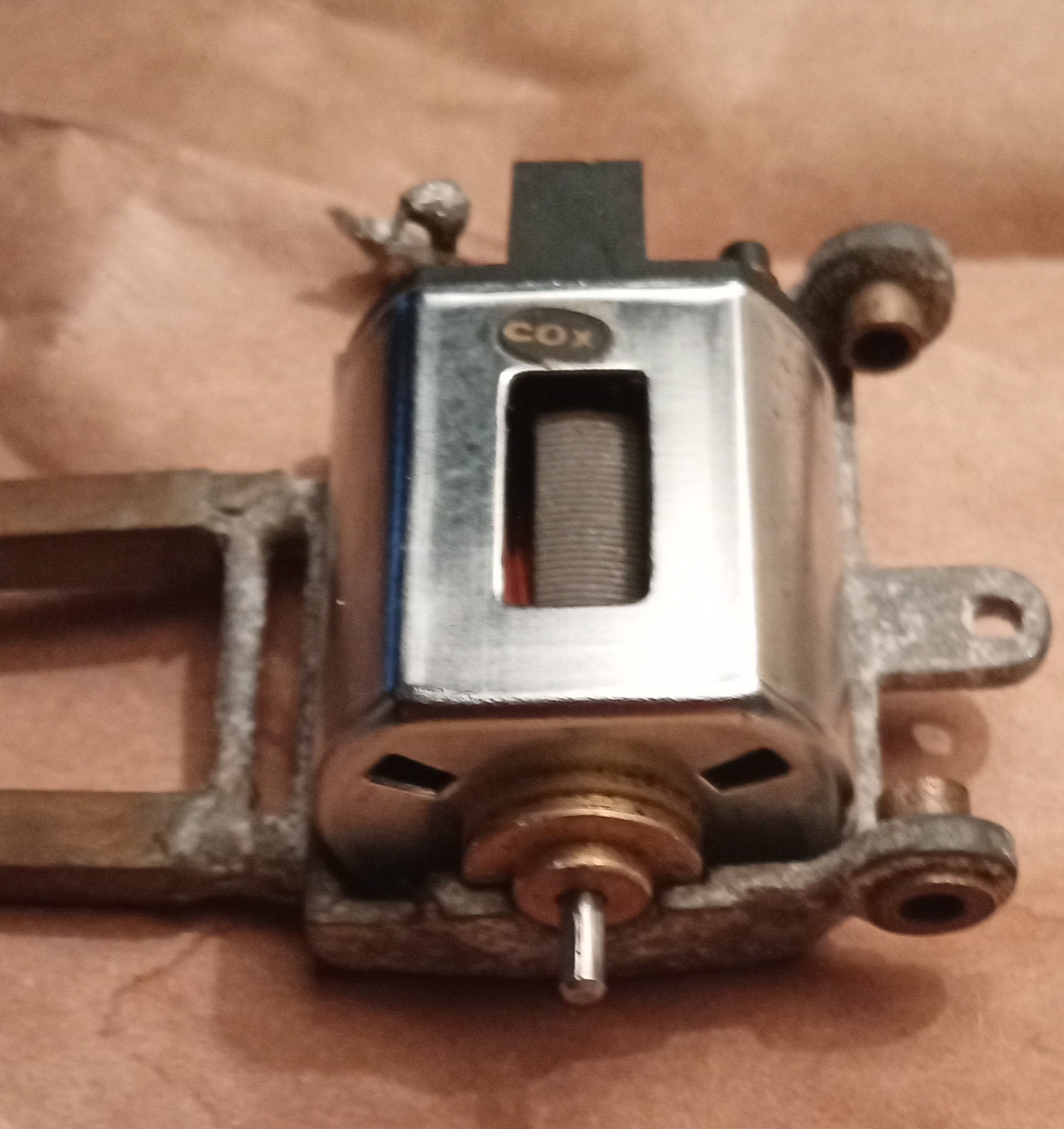

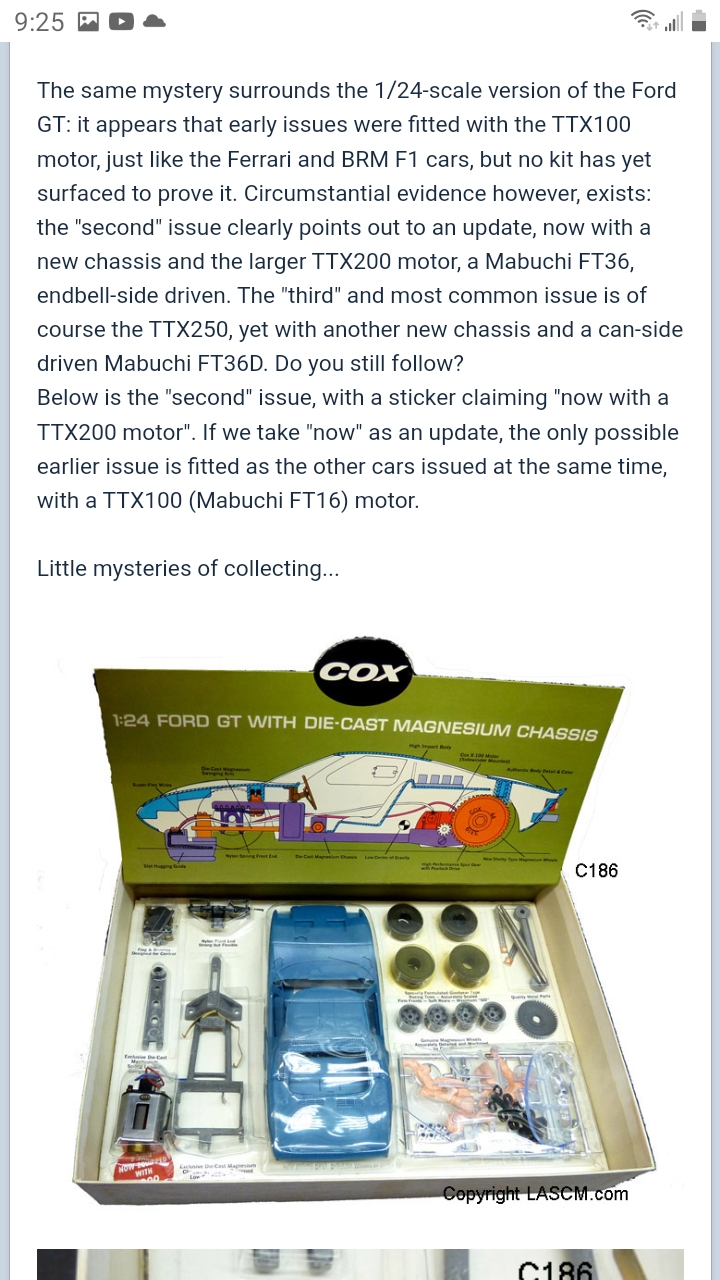

Mark, that doesn't look like a Dynamic chassis piece. It looks more like Cox. They used a series of brass strip clamps to hold motors in.

I intend to live forever! So far, so good.

#33

Posted 15 December 2022 - 08:15 PM

Thank you Bill, yes Cox use a brass clip. I have extras if you need one Mark? Or here are some. Make sure your chassis is for a 36D.

The 16D chassis looks very similar.

https://www.ebay.com...:Bk9SR7zEh4ijYQ

P.S. found a better shot of the Dynamic hooks Larry had made. As printed and then surface finished compared to factory.

- Larry Horner likes this

#34

Posted 15 December 2022 - 09:16 PM

#36

Posted 15 December 2022 - 09:32 PM

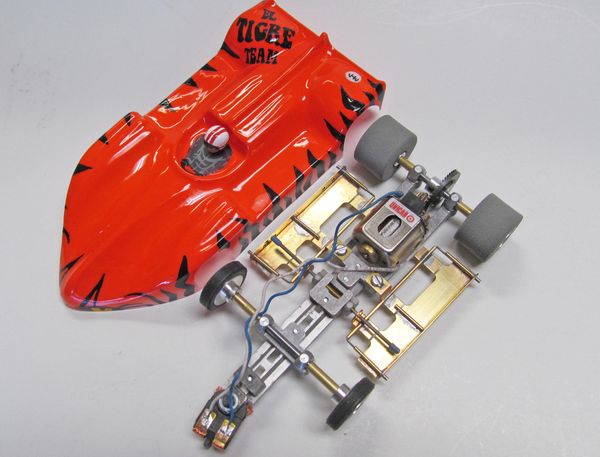

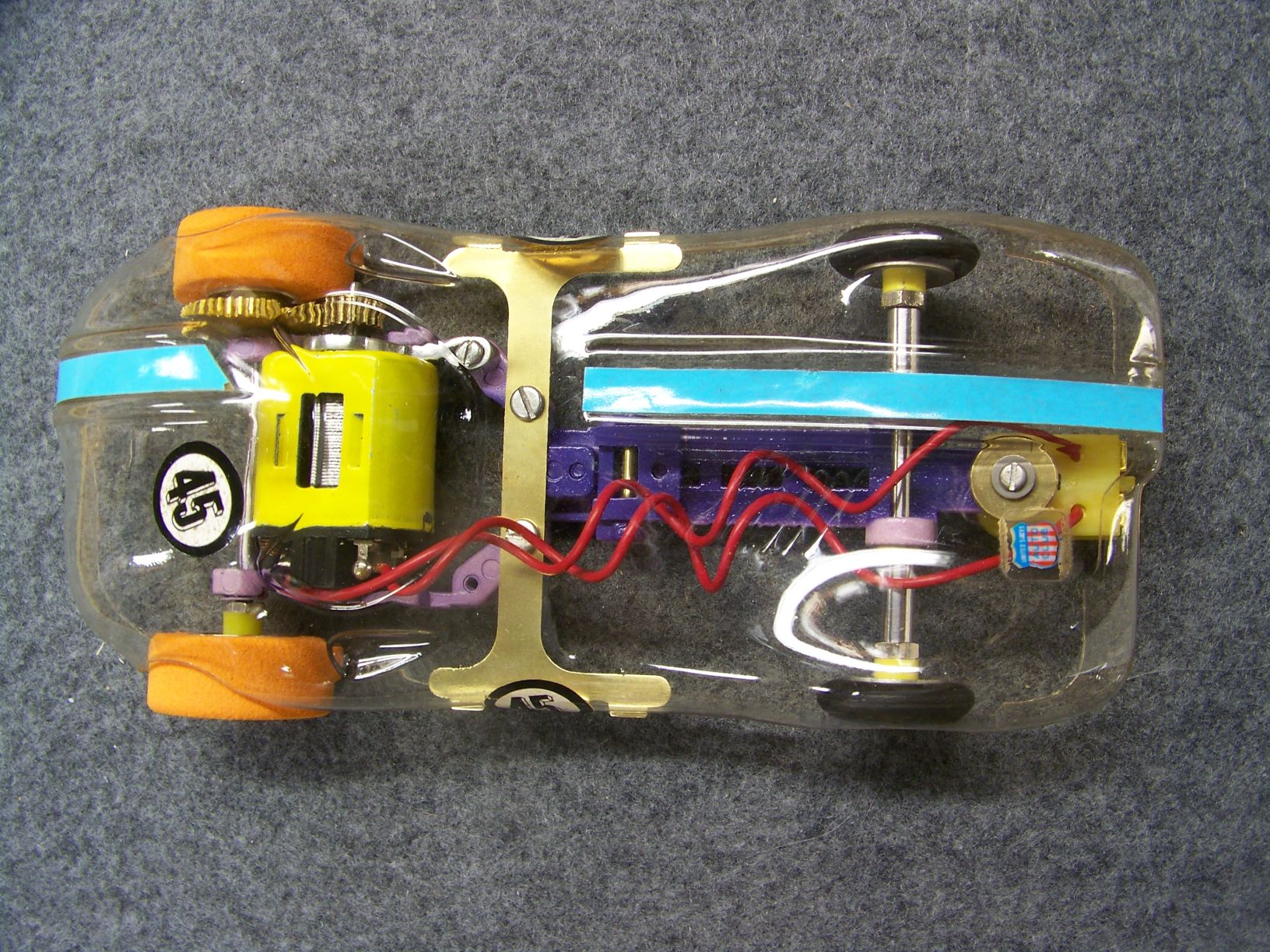

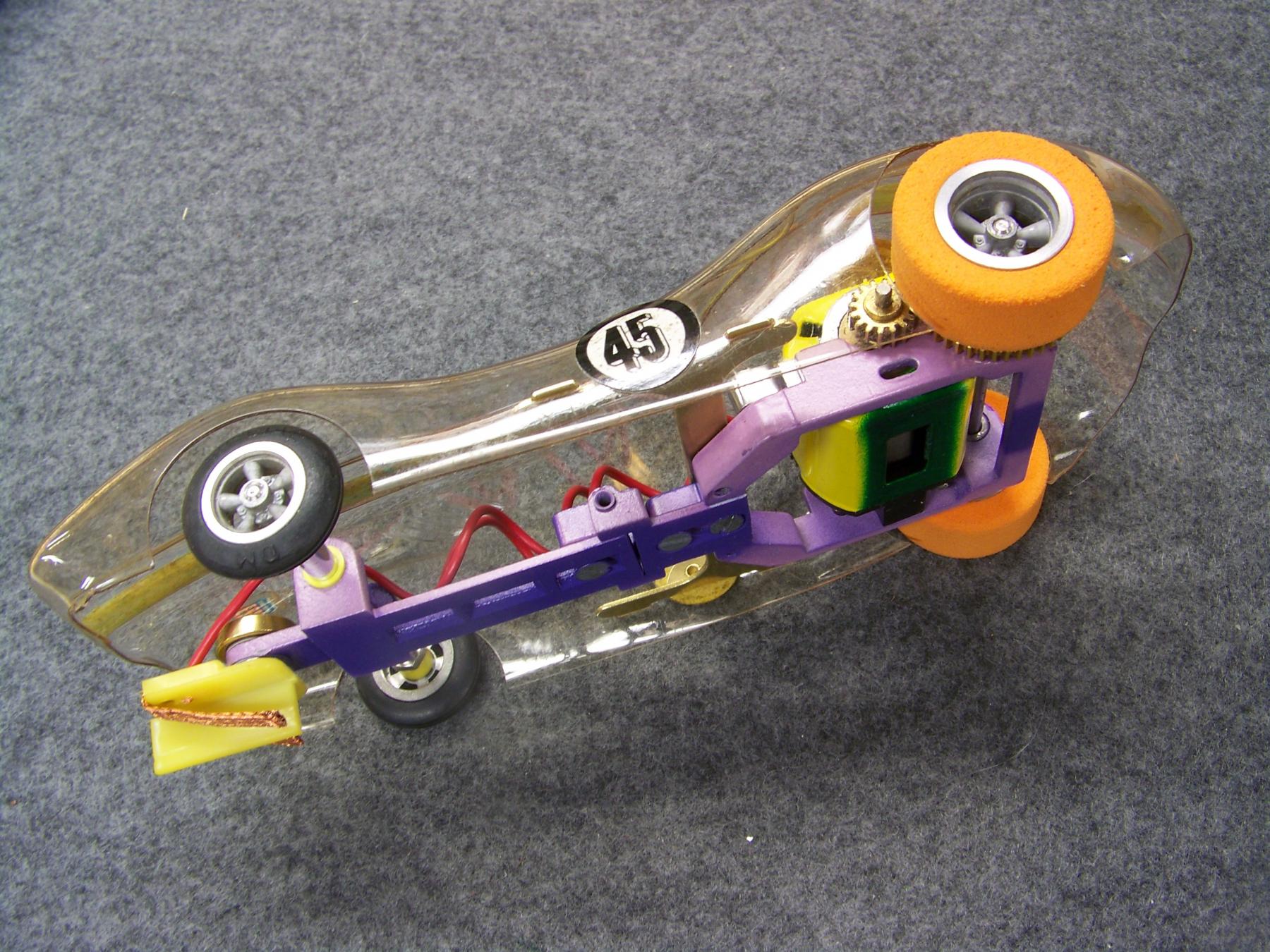

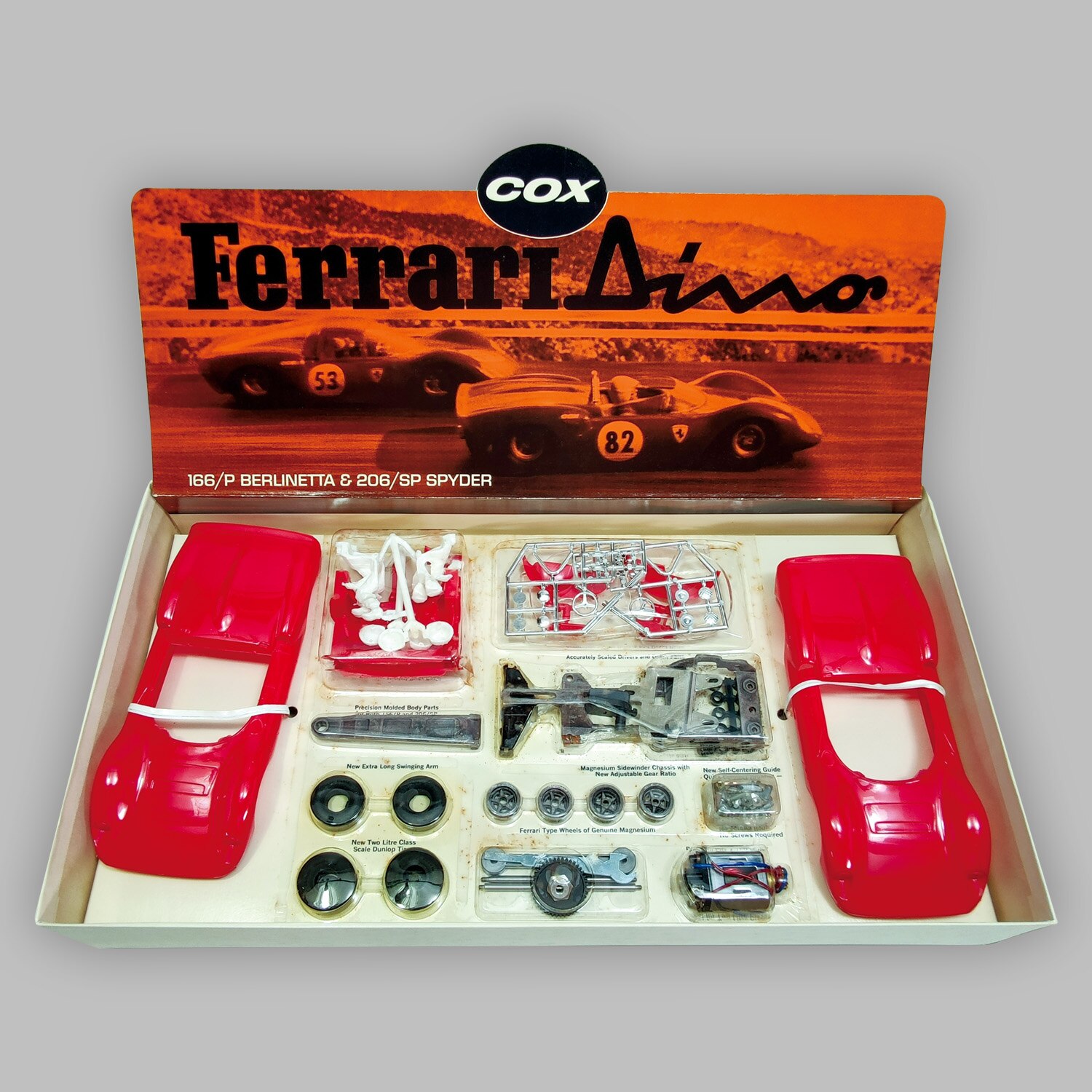

I'm pretty sure this Ferrari kit had the mag frame, but with a 16D.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#38

Posted 15 December 2022 - 09:42 PM

Different again Mike. The Dino chassis is for a 16D but gearing is adjustable.

Mark, whats going on with the square tubing, looks like a JB repair?

#39

Posted 15 December 2022 - 09:58 PM

#41

Posted 15 December 2022 - 10:24 PM

O.K. then, that is for a 36D.

Lets get back to Dynamic, stuff. You got me off on a tangent. ![]()

#42

Posted 15 December 2022 - 10:34 PM

Yes, the Ferrari in the pic has the style of chassis like the Chaparral 2D.Different again Mike. The Dino chassis is for a 16D but gearing is adjustable.

Mark, whats going on with the square tubing, looks like a JB repair?

I wasn't sure if it ever came with the older chassis.

I just associated the double Ferrari with a 16D.

The 16D old style chassis would of been in the Ford GT kit, if it indeed exists.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#43

Posted 15 December 2022 - 10:54 PM

#45

Posted 16 December 2022 - 10:44 AM

Dave,

I ran it by Grider probably back when we called all throwaway motors "Falcons", and he made me aware that in aluminum, it wouldn't be cheap to 3D print them.

Just like you mentioned, this had "government work", written all over it.

3D printing has improved over the years, but still not cost effective in a production sense. Even if you could get the cost of a 3D printed part under $1.00 each, it still can't compete with the high volume capabilities of die casting or injection molding. Taking my time out of the equasion, it would have cost me roughly $1,000 in materials and to pay for heat treating. (I actually figured this out on a different but similar project) Run time on a 40 ton die cast machine was charged out at $600/hour at the time. Add $675 for A380 aluminum (far better than the the white aluminum Dynamics used) and we come up with $2275/hour. I calculated 500 shots per hour, a bit conservative. That means that each part would cost $4.55 for one hour of production. Naturally, the cost of the tooling could be amortized over hours of production. So let's assume we could sell 2000 of each style part. That now reduces the cost of each part to $1.137 per piece. Now, if I were designing this die, I would design it to run two parts per shot, easily doable in an 8 X 10 unit die. That cuts the cost in half, although there would be additional tooling cost in making the second set of inserts. So just guesstimating (I'm getting tired of doing math this morning) that the cost of each part is reduced by an additional 35%, that brings us down to around 75 cents per part. Some parts will need secondary machining, so let's add 20 cents per part for that. All told, we would be at about 95 cents per part.

(Yes, I know this price does not include my labor. You could double the price if you had to pay someone to build the tooling)

In reality, even the best 3D printer is not going to produce 500 parts per hour, so the price is going to be considerable higher than $1.00 per part. Plus the parts won't have the impact resistance of the better alloy of aluminum.

#46

Posted 16 December 2022 - 12:08 PM

We just need to get them CNC'd out of billet. Problem solved! ![]()

???-2/31/23

Requiescat in Pace

#47

Posted 16 December 2022 - 12:18 PM

That would be fine for yourself and a few friends. Definitely not cost effective in higher numbers. Don't know where you think you can get them machined for under $10.00 each. For the usual three parts, that's $30.00 per chassis. More for a drop front end.

#50

Posted 17 December 2022 - 12:55 AM

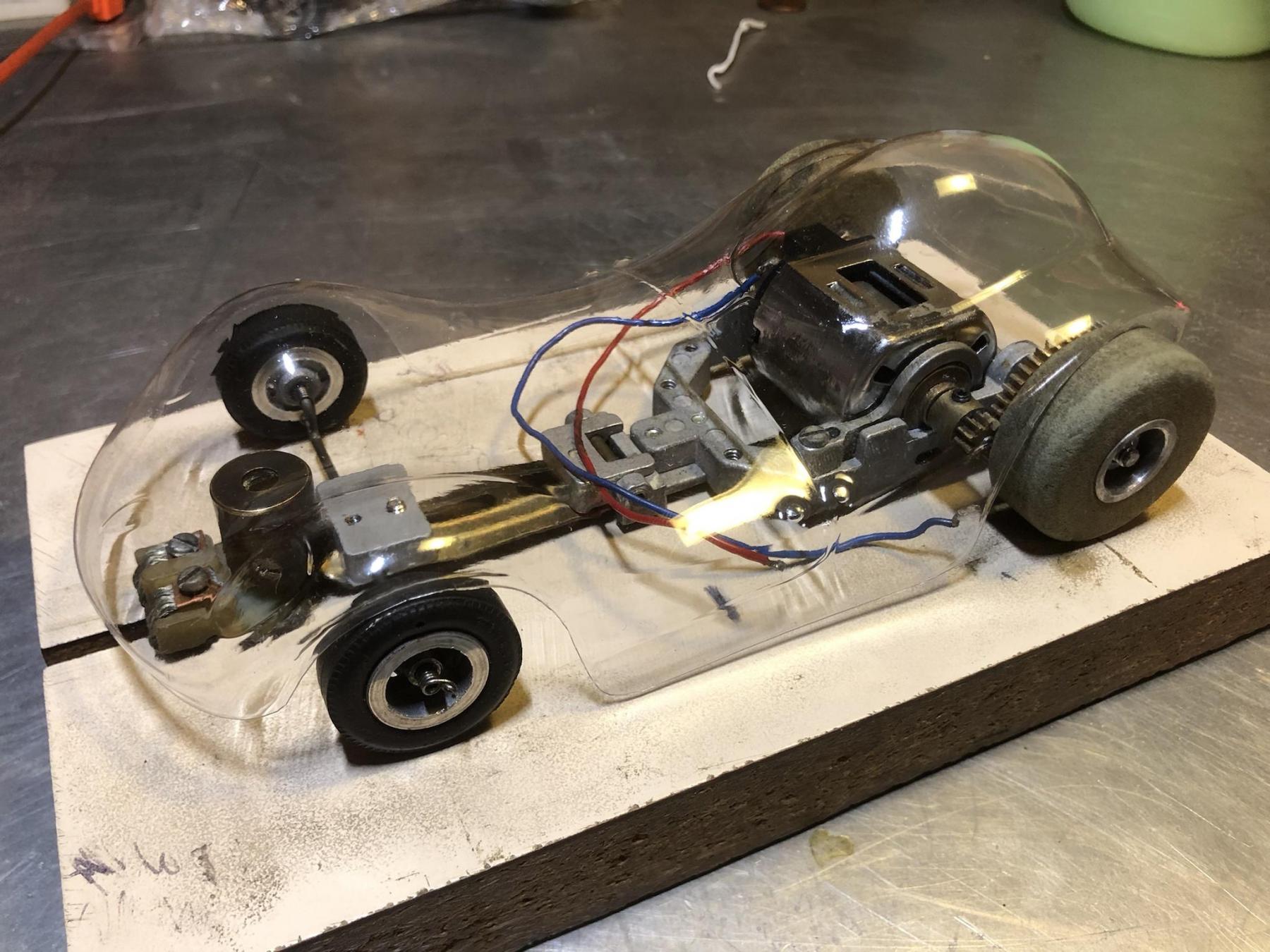

Kinda reminds me of this Dynamic Renegade I put together with a NOS unpainted body. I left it clear to show off the painted 3D printed front end. I was experimenting with unpainted bodies and painted chassis.

- Jencar17, Phil Smith, olescratch and 2 others like this