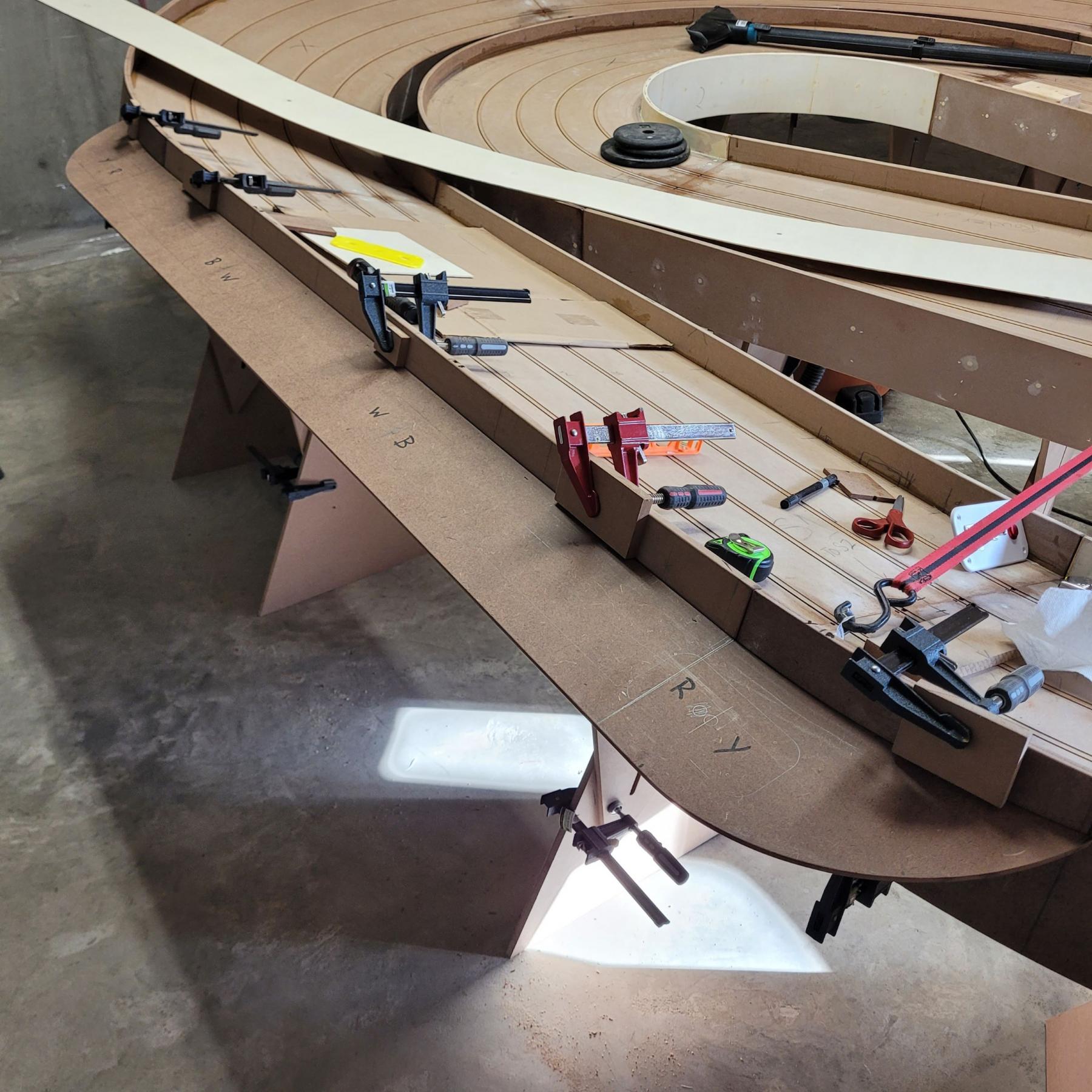

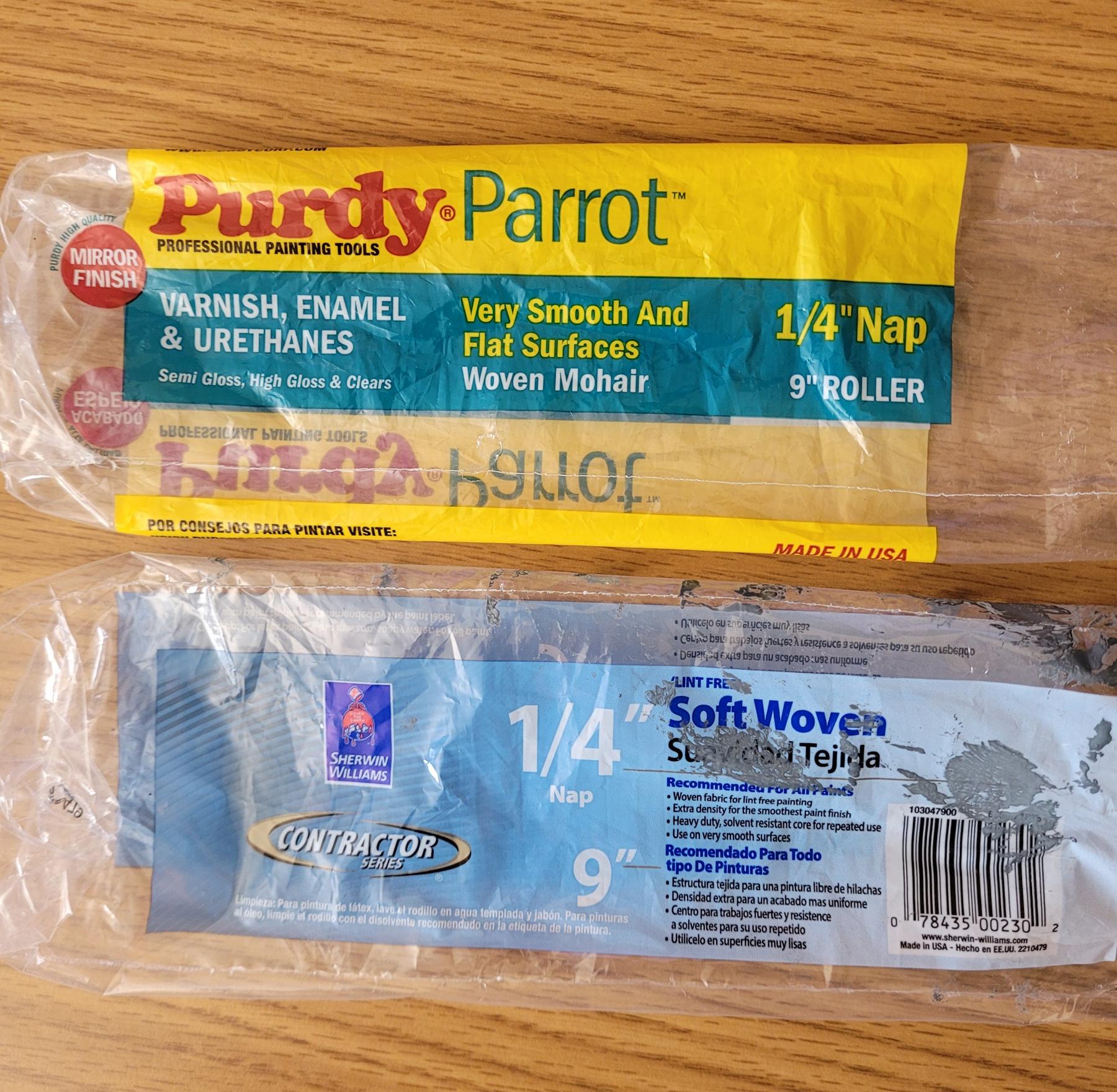

Well I finally got to the first coat of the 2-part water based epoxy top coat. The entire track was hand sanded and prepped for paint and yesterday the anxiety was low enough to attempt the topcoat. Pre-stiring all the components separately then measuring and mixing the parts A&B together. I mixed 2 quarts A to one pint B 4:1 and power agitated with a drill motor mixer. I poured what I needed into the metal roller tray and covered the remainder in the mixing tub. I used a 1/4" Purdy Parrot Mohair 9" roller which I defuzzed with Duct tape but trashed it as it was putting down roller filaments into the paint so I switched to a Sherwin Williams Contractor Series 1/4" nap.

The Sherwin Williams roller worked very well with a smoother finish and no nap residue. I will need to sand the small bad area (fuzzed) with some 240 to 400 grit to get the fuzz knocked off before the second coat. I had nearly a quart of mixed paint left over but not knowing what the coverage would be I didn't want to be mixing more during the application process because this waterbase epoxy will tac up in 10 minutes. So you don't want to re-roll to far back but keep a wet edge as you go around.

The Sherwin Williams material is similar to a medium thichness latex and rolls on and levels out nicely. I started under the bridge then around the loop then over the bridge to the lead-on turn to the back straight where I paused to raise the brigde section onto three five gallon buckets. I did that so I can get under the bridge properly on the return. I had to roll and work in the paint into the gains groove with the edge of the roller to get them covered completely and checked that I haven't left any paint blobs down in the slot groove. The slot groove has about a 1/16" of paint film down each inner wall of the groove which is fine by me.

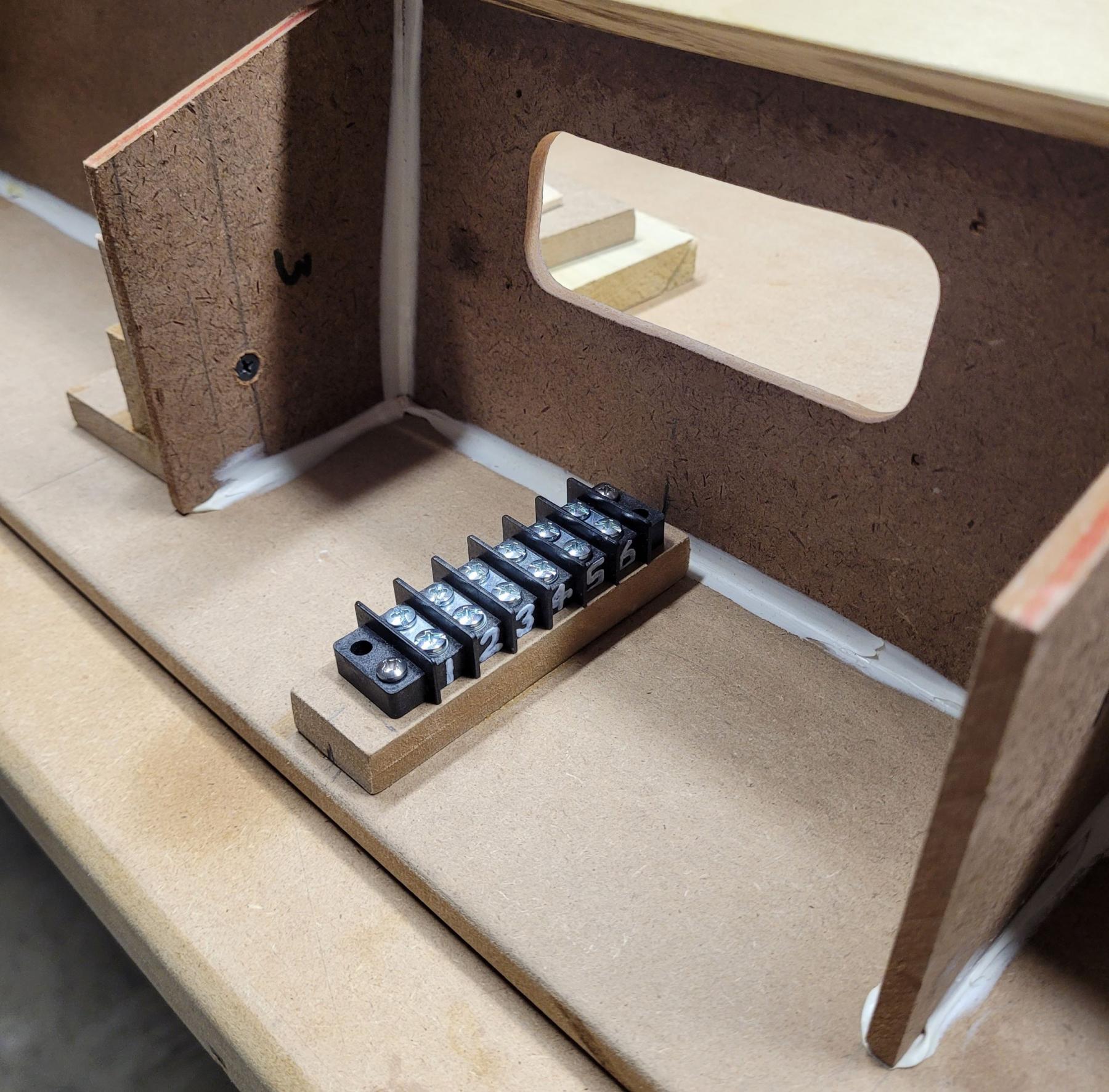

The Polyurethane was previously applied into the groove slots to harden the MDF. After applying the initial layer of paint and working the gains I rolled the sidewall gutter lanes and did a final smooth out of the surface. I also raised the roller off the surface as I rolled into the previous painted surface to help blend the wet coat overlap. This material flowed out nicely! I must say the fumes from this product are similar to painting with wall latex but I still wore my 3M respirator mask for safety.

You can see the wet and dryer areas of the fresh paint on the banked turn and other places. The material went on a bit lighter then dried to the darker chossen color.

I used a 2" wide foam sitck brush to apply material into the sidewall corners and onto the track surface with good coverage. I made sure there wasn't any heavy smudges and runs on the sidewalls and the track. The V-point of the brush worked well for this because I only wanted about 1/2" of paint on either side of the sidewall corner.

I didn't want roller spin marks on the sidewalls. I rolled the loaded roller down one side the return on another path to help initially spread out the material before rolling and covering the entire surface. One cleaver thing I thought of before I started rolling was a 3D printed plastic dome button .150" high that I glued onto the end of the roller to bump against the sidewall. This dome helped me keep the roller edge from rubbing paint on the inside of the sidewall and making a paint mess but got me close enough to cover the foam brushed area.

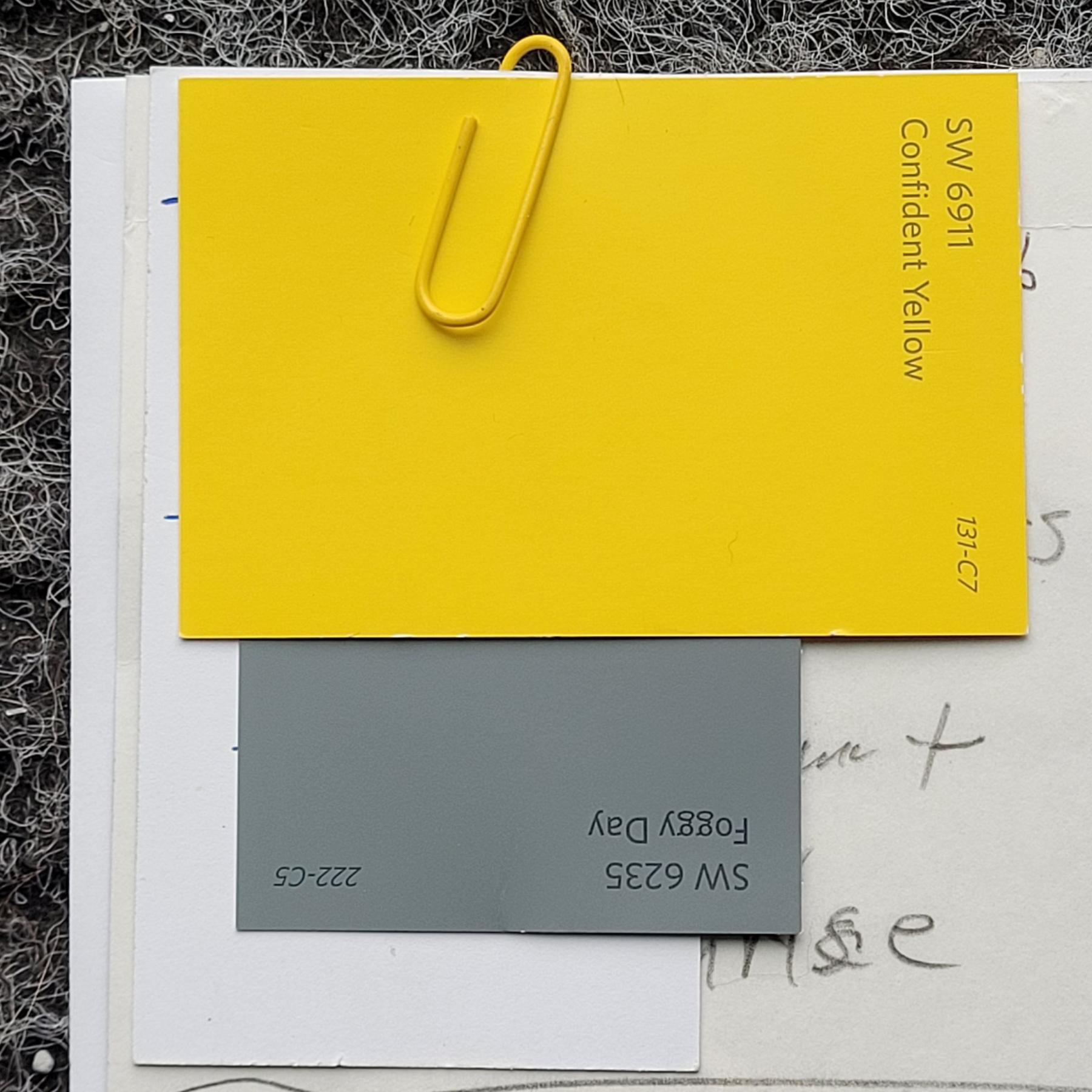

I didn't paint the inside sidewalls with epoxy as originally planned because I was unsure of the amount of paint needed. I decided to paint the inner sidewalls with primer and the track colored latex I used on the console. If I do need touch-up on the inner sidewalls I will use the latex paint which is much easier to deal with. I will paint all the sidewalls in and out once the track sections are separated so as not to fill the sidewall section gaps with excess paint. The shelf life on the epoxy components is one year.

I might do a second final coat on Monday depending on how hard the epoxy is after 48 hours to sand the fuzz out. I had high anxiety on this portion of the build so I wanted to let any fellow builders know what I did and why.

Happy Fathers Day those of you that matter.

Rob