The two-rail chassis revolution

#76

Posted 30 January 2011 - 07:08 PM

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#77

Posted 30 January 2011 - 07:13 PM

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#78

Posted 30 January 2011 - 07:31 PM

....Rhennius Machine

"Device of alien manufacture, which will reverse, or turn inside out, any object passed through its mobilator"

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#80

Posted 30 January 2011 - 08:34 PM

Duffy's CMM and Rhennius Machine,

Well Duffy finally stumped me and I had to google "Rhennius Machine". I should have seen the clue with 15 year old Duffy?

I know I'm probably going to give you a heart attack with this one, but one random thought was to CMM a slot car body, make modifications and do a rapid wax prototype to create a new slot car body mold

#81

Posted 30 January 2011 - 09:33 PM

I'm a monster Roger Zelazny fan. 'Nuff said.Well Duffy finally stumped me and I had to google "Rhennius Machine".

Oh .The Old School name for this is "Backpour" and was done with cheaper equipment than SLS. Maybe we don't need higher tech here.I know I'm probably going to give you a heart attack with this one, but one random thought was to CMM a slot car body, make modifications and do a rapid wax prototype to create a new slot car body mold

Now'days , stereolithography is done in several very-useful engineering plastics, including composites. Properly programmed, you can do pretty impressive stuff. Here's a show-off project gone horribly wrong, a FLUTE built in a SLS tank and using several disparate materials--impressive for the accomplishment, wrong because the engineers didn't do basic homework up front like asking a MUSICIAN first. We often go off on a project with similar prep.

But, yah, if someone took the time to become versed in 3D CAD, he could draw a solid model of a given car and send that file to the prototyper, who'd make the plug. Or we could just carve the thing the Old Good Way and save some time and money. I do not know which would be the better expenditure of resources.

A lot comes down to What your Hobby Is.

In my other hobby, flying models, some guys would get caught up in the perceived excellence of graphing up colors & markings on their computer, then printing out whole model airplanes' worth of tissue covering, all complete. --And I noticed they'd often get so involved in the imaging, they no longer built and flew. Their Hobby would shifted. This can happen, if you're not watching. It's why I react with some reserve whenever we talk about applying New Tech to Old School. Might work, but it's worth cautiously considering.

I sometimes worry that guys take what I say as somehow extolling the virtues of my way of doing things, as if I expect my exigencies to be instantly universal; or that someone's having a go at me when I don't instantly see the inherent reason of their particular hobby niche. I say here,neither's important. We talk. That's all.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#82

Posted 31 January 2011 - 03:01 AM

John Dilworth

#83

Posted 31 January 2011 - 08:26 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#84

Posted 31 January 2011 - 10:51 AM

But for me a vintage car should be built with vintage techniques and vintage hand tools just as it was "back in the day". (always hated that expression)

J

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#85

Posted 31 January 2011 - 12:42 PM

I don't know that I have ever had a Nutley! Or even seen one in person. Very cool.

I do have a small bin of drop arm parts but I think that they are all dubro, associated, parma and a few champion. But, IN THE DAY(grin), I don't think any of us even thought about the way the things get broken with the bends. The first I remember being conscious of it was listening to Philippe rant about bad bends a long time ago. I think we did commonly reinforce the bend with bits. I still do that with my flexi chassis as well, but no one articulated it that I remember.

Fate

3/6/48-1/1/12

Requiescat in Pace

#86

Posted 31 January 2011 - 08:06 PM

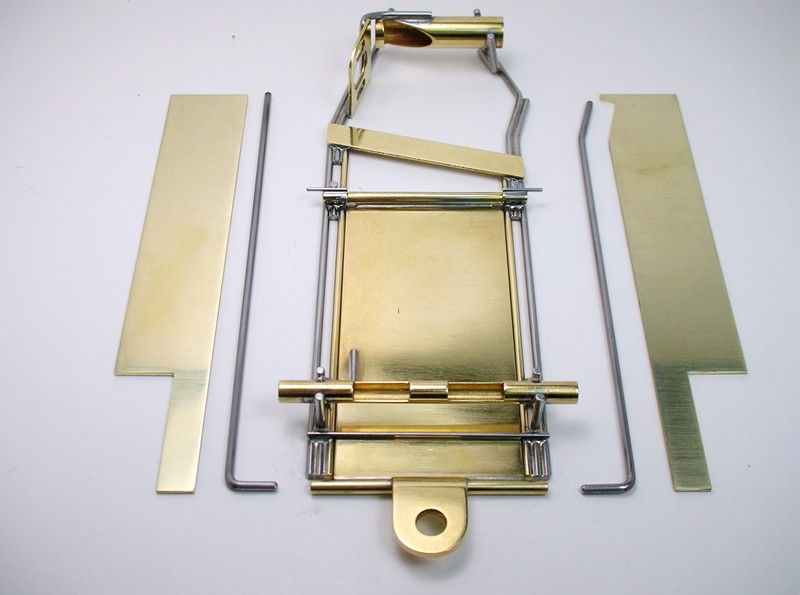

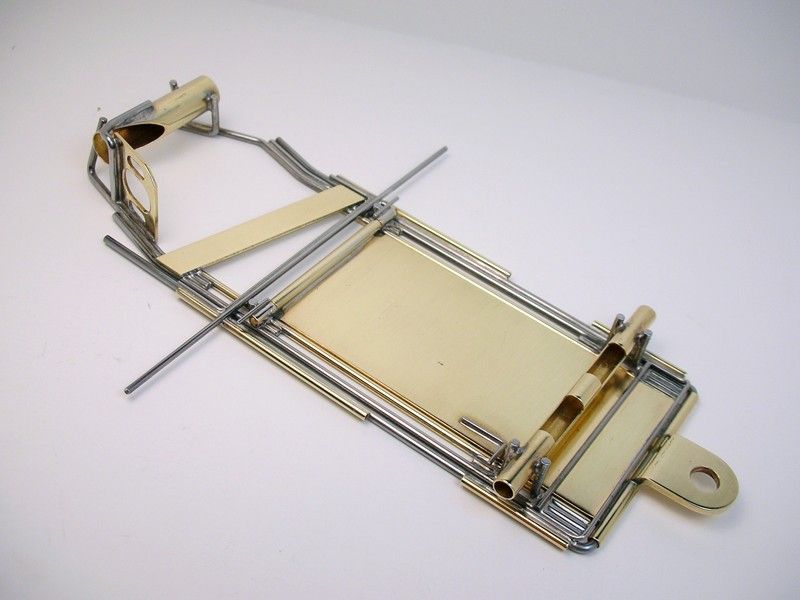

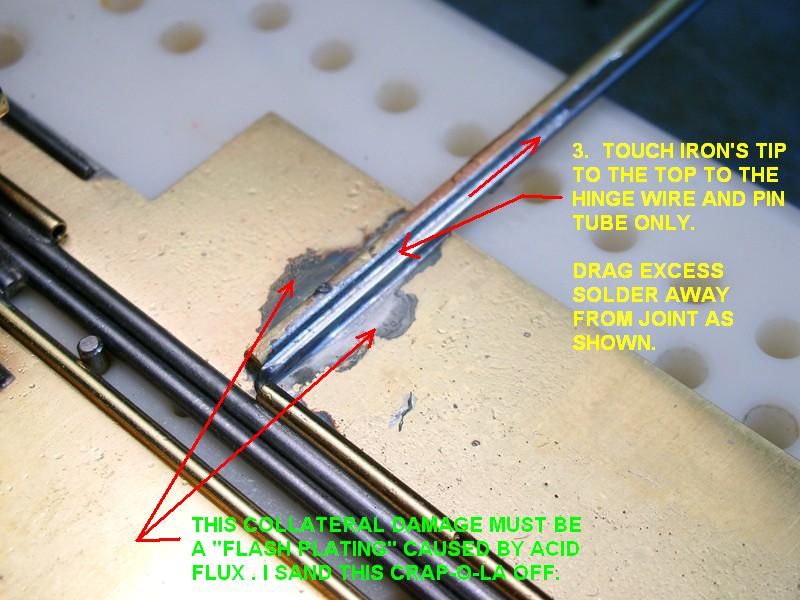

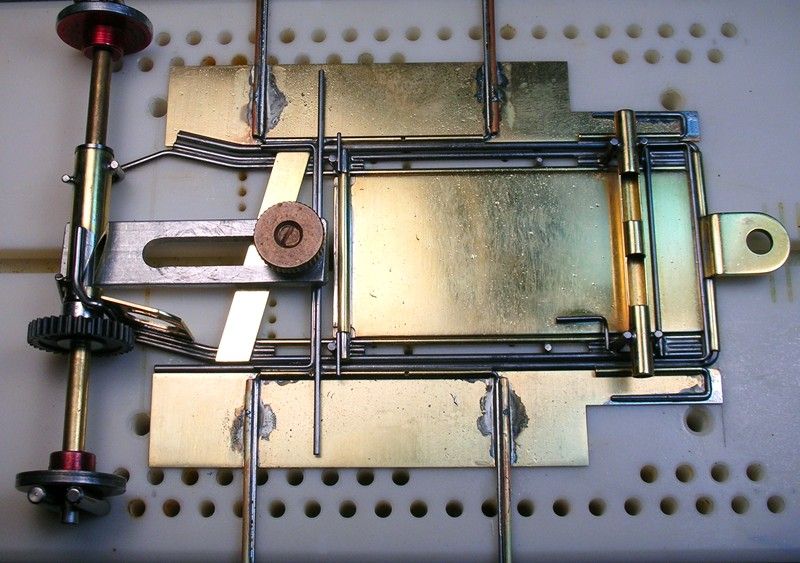

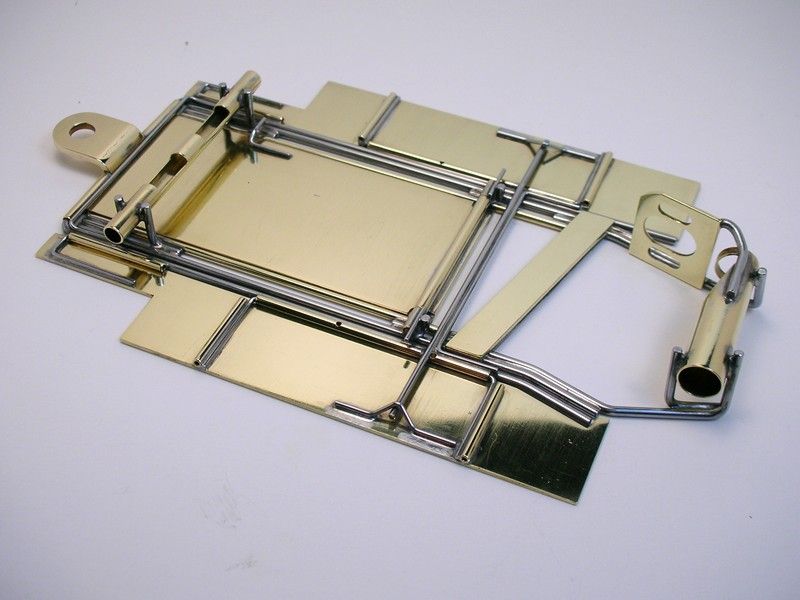

Here the pans and plumber rails are laid out. I made the plumbers out of 1/16" wire. I'm not sure if Bob was using .055" yet:

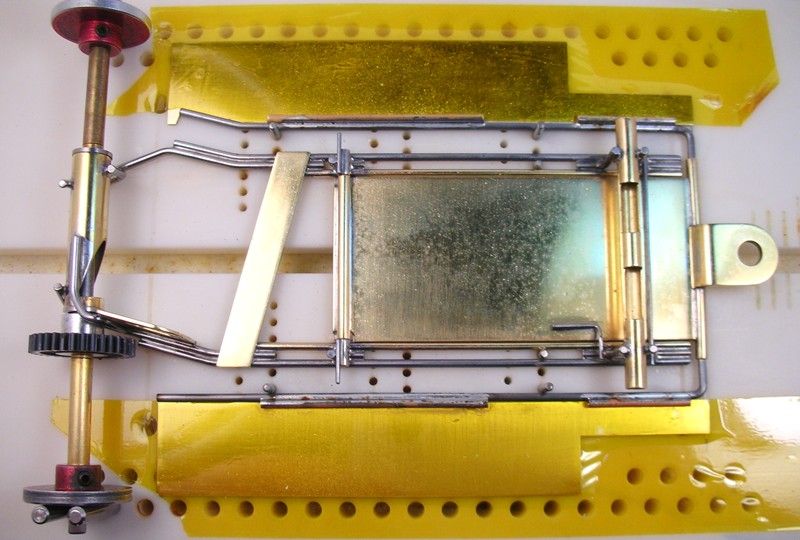

My Rick's Jig allowed me to use the many pin locations to space the plumber rails away from the main rails so as not to solder the whole mess up solid

But for me a vintage car should be built with vintage techniques and vintage hand tools just as it was "back in the day".

I hear ya Jairus....but if I couldn't build on my Rick's Jig, I think I'd change hobbies!

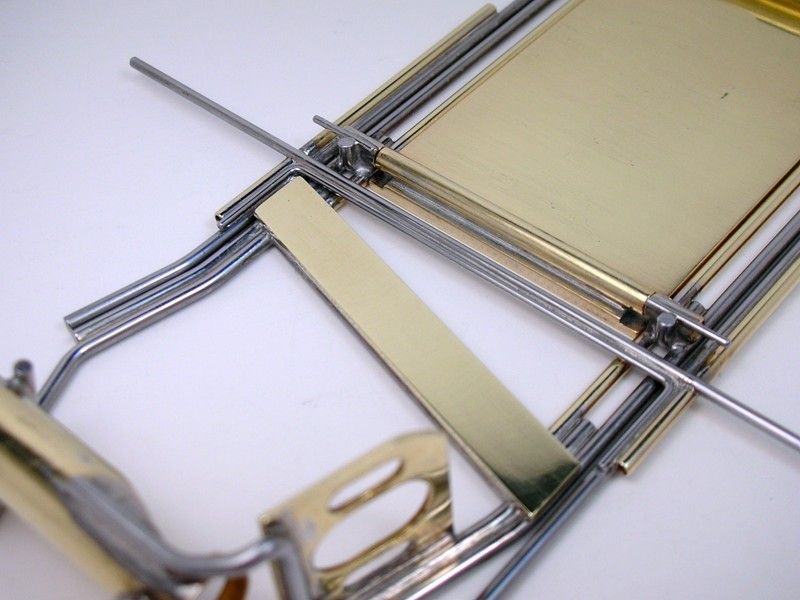

A U-shaped .03" wire holds the front of the plumber rails together. I used some tiny strips of 600 grit sandpaper to space the plumber rails away from the main rails for a little side to side "slopski":

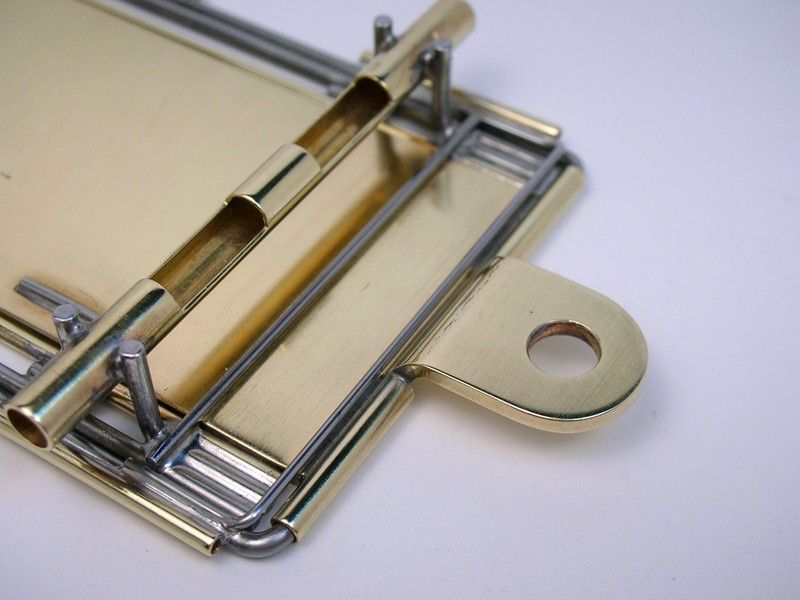

Another U-shaped .03" wire holds the rear of the plumber rails together. The .047" wire cross piece is cut into the pan hinge tubes so it sits down flat on the plumber rail:

I lucked out and got the plumber to work nice and "smoof":

Pan hang'n time

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#87

Posted 06 February 2011 - 05:30 PM

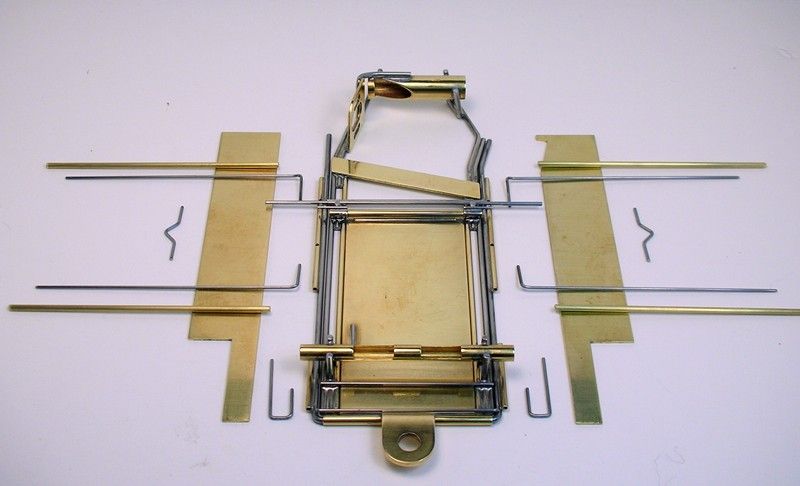

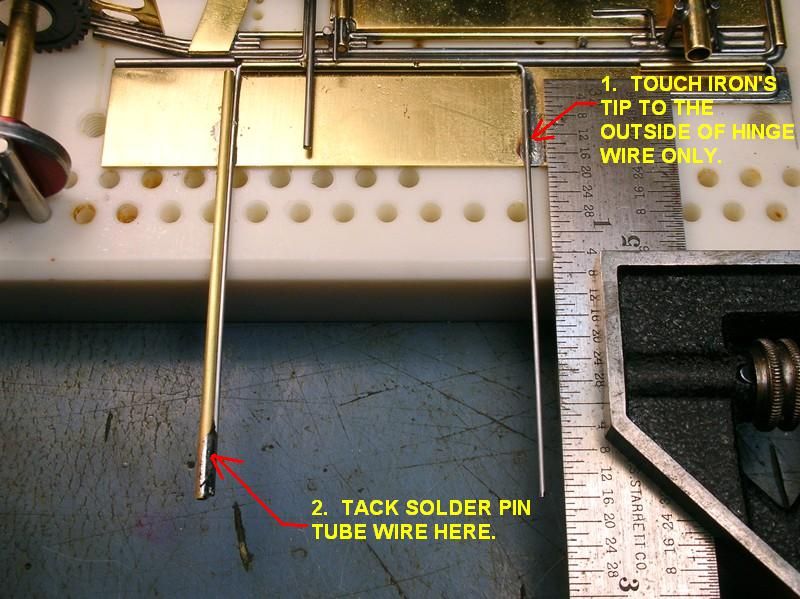

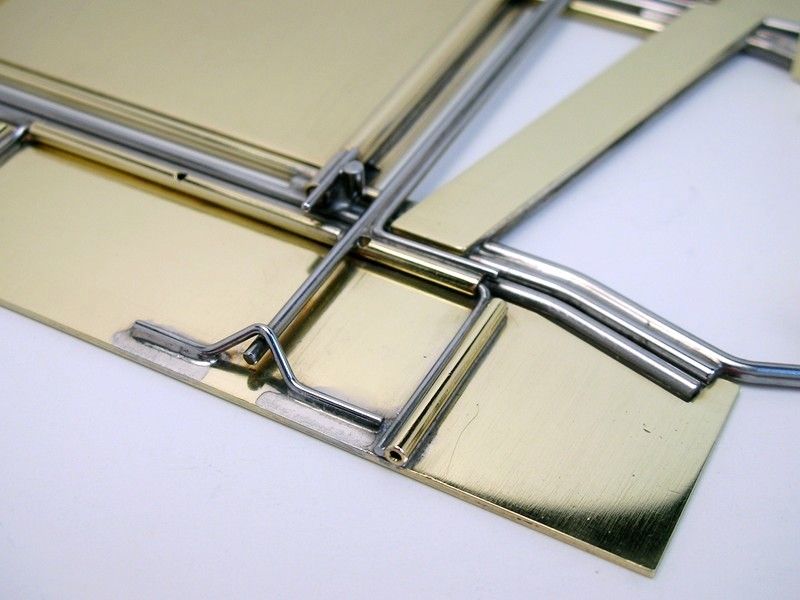

A square lines up the extra long hinges nicely:

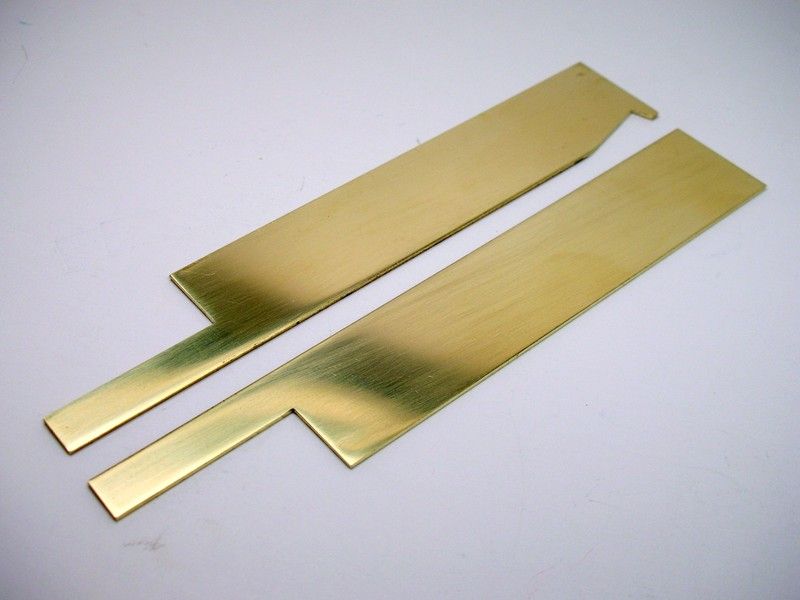

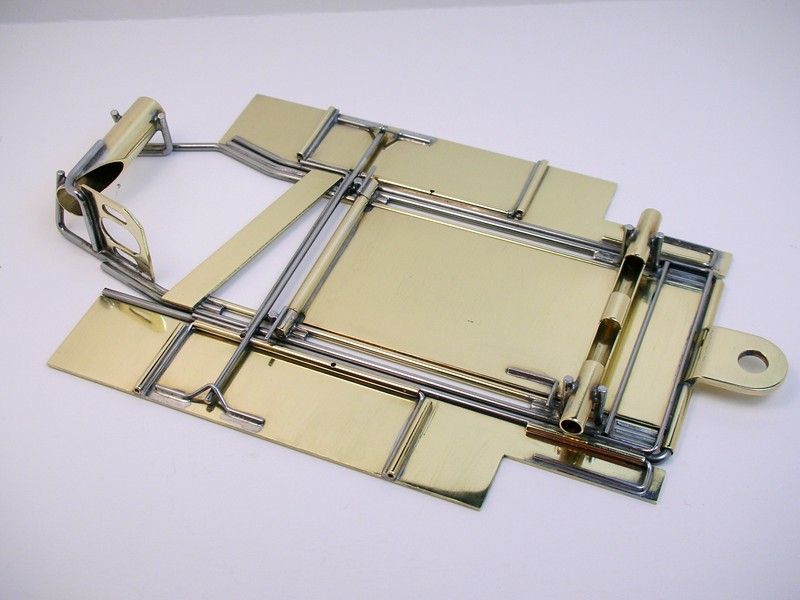

The finished pans:

I tried to do well by this chassis and get rid of any acid flux left in the hinge tubes. I drilled "Blow-holes" in the pin tubes to help flush out and blow out the flux. I treated it to a 5 minute ultra sonic bath with tap water and baking soda followed by a soap and water wash. Finally a 5 minute ultra sonic bath with plain tap water finished up the cleaning process. Then blowing it dry and placing it in a oven at 150 degrees for a half hour.

What did I get for all my efforts......RUST!

A couple of 5 minute washings and the thing rusts

I took the time to polish out the chassis after each step. It's hard to polish out a finished chassis and get in all the tight spaces. Now I had a brand new RUSTED chassis to deal with

A few hours with sandpaper, a wire wheel in a Dremel and metal polish saved the day:

Time to assemble.....

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#88

Posted 06 February 2011 - 05:54 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#89

Posted 06 February 2011 - 06:09 PM

...I suggest you try using a "sharpie" brand marker to "mask" where the solder should not go. This is a fantastic way to control the solder because it WILL NOT flow where there are markings.

I LOVE these tidbits!

Rick, the chassis is a thing of beauty... the things that excite an old man.

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#90

Posted 06 February 2011 - 06:17 PM

I LOVE these tidbits!

I do too Tex.

Thanks Jairus, I'll give it a try

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#91

Posted 06 February 2011 - 06:26 PM

I intend to live forever! So far, so good.

#92

Posted 06 February 2011 - 06:27 PM

My thought: wash, scrub, tumble, polish, wirebrush, Scotchbrite & Whatever at every stage of the build, or at the end of a work session. Shiny? NOW HIT IT WITH A FLOOD OF WD-40.

That keeps the rust off 'til your next build&clean session. Then, at last assembly, go through the whole ringamijing, NOW RIGHT NOW take your Sparkle Shots of the dry perfect high-Albedo rig, and then HIT IT WITH A FLOOD OF WD-40.

That'll keep it nice--

--'til you hang the gear on and take it to the track.

It'll all be downhill from there.

Think of it like the Prom Pics you paid that fortune for: she's scrubbed and fresh, dressed to the 6.5s (this is The Hipster Age, after all), happy like she's got the world by the throat, then into the Limo and away. You don't want to see her tomorrow morning. And SHE doesn't want to think about the next 60 years, either.

Yah. Slot Cars are a little like that. Get the shot now.

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#93

Posted 06 February 2011 - 07:25 PM

'til you hang the gear on and take it to the track.

It'll all be downhill from there.

Duffy, Duffy, Duffy......."Don't hit me with those negative waves so early in the morning."

Auto spray wax helps too....(thanks Dokk

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#94

Posted 06 February 2011 - 07:50 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#95

Posted 06 February 2011 - 08:08 PM

Or did I dream that ?

Paul Wolcott

#96

Posted 06 February 2011 - 08:18 PM

Once you get the " money shot" let her age gracefully...

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#97

Posted 06 February 2011 - 08:37 PM

Didn't we already know your tap water was doing bad things ?

Or did I dream that ?

I know Pablo, I know.....I'm a slow learner I guess

I promise, never again will I use my tap water

....let her age gracefully...

Yup!

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#98

Posted 06 February 2011 - 08:45 PM

"You Will Be Assimilated. Resistance is Futile."

Philippe de Lespinay

#99

Posted 06 February 2011 - 08:53 PM

Don't you put the term "Money Shot" that close to my daughter's Prom pics. I'm a FATHER, dammit.Once you get the " money shot" let her age gracefully...

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#100

Posted 08 February 2011 - 01:04 AM

but you might be doing yourself a disservice by continually cleaning as you go.

A little oil from your fingers might help protect the wire and brass.

Also the final step might be a little too much, baking soda, ultra sonic cleaner,

oven, etc.

Especially an ultra sonic cleaner. I've heard of and witnessed too many horror stories with them

to ever use one again. Guys would send in good arms to armature reconditioners and would get

them back with "opens" where the brazes connecting the wire to the com were eroded/ultra soniced away.

I would just keep a bucket of soapy(Dawn is fine)water near your work bench and periodically

dunk the jig with the chassis on it into it. Dab it 95% dry with some paper towels and move on.

If you think your tap water is funky, certainly go to distilled.

Last, but not least, you probably already do it, but don't leave any quantity of flux out

on your work bench. Just pour a tiny bit in a tire tube cap and refill as needed.

BTW, nice bend on the top, gear side brace wire.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559