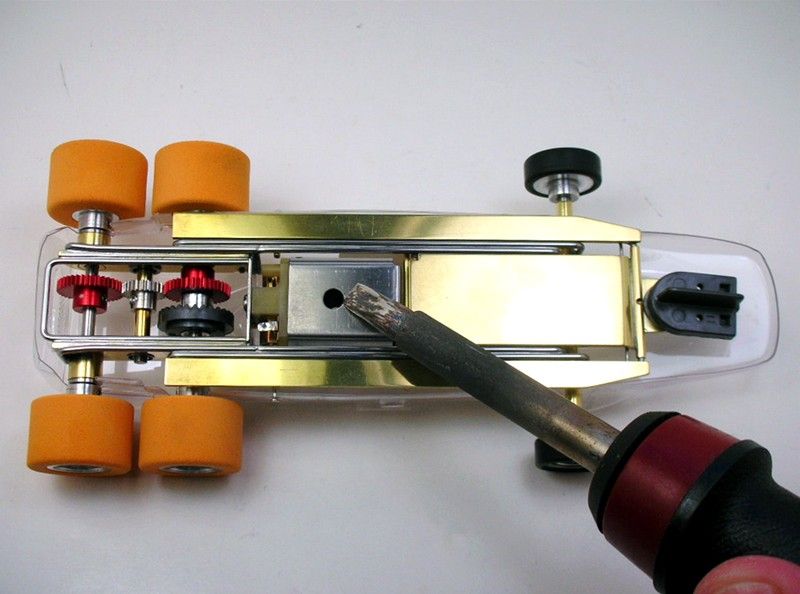

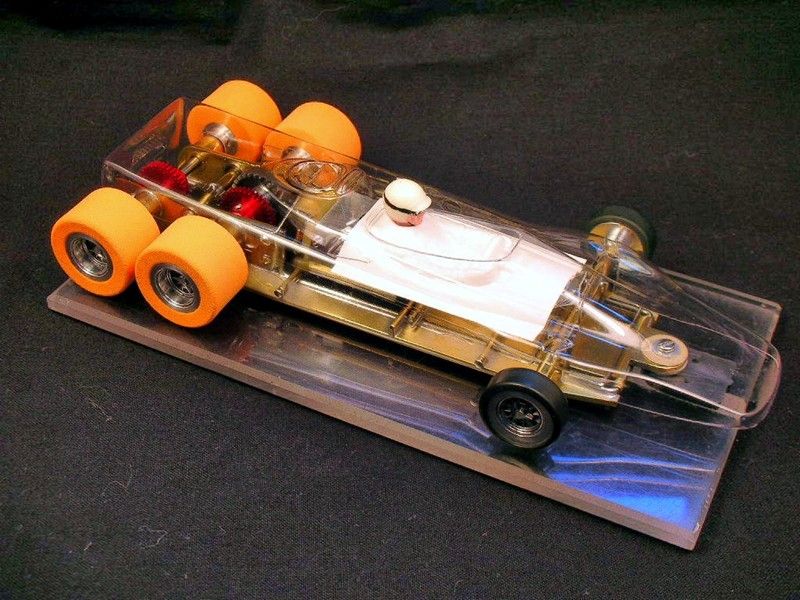

this thing is going to be crazy! i dont know why but i imagined this with orange foam, guess i was right.

Six-wheel racer

#101

Posted 27 June 2013 - 06:40 PM

#102

Posted 27 June 2013 - 07:30 PM

Awsome trucks!!!

#103

Posted 27 June 2013 - 08:07 PM

Long live ridiculous behavior! ![]()

- Gator Bob likes this

Steve Okeefe

I build what I likes, and I likes what I build

#104

Posted 27 June 2013 - 09:05 PM

Long live ridiculous behavior!

Couldn't agree more!

#105

Posted 29 June 2013 - 05:46 PM

I resemble that ![]()

![]()

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#106

Posted 02 July 2013 - 06:01 PM

Okie Dokie, time for a body for my 6-wheeler. In my research I discovered a rare prototype 6-wheel race car from 1968. Most of us are familiar with the Lotus Type 56 Turbine racer that competed at Indy:

There is a little known and even less photographed prototype version of the car called the Lotus Type 56-6. Yup, it was a 6-wheel prototype version of the Turbine car that Lotus experimented with in 1968. Here it is with World Champion Graham Hill behind the wheel and its designer Colin Chapman and others standing in front of the dual rear wheels:

Here are a couple of shots of Hill testing the prototype:

What?

I know you can’t see the dual rear wheels in the pictures but….. ![]()

What?

You’re not buying any of this? ![]()

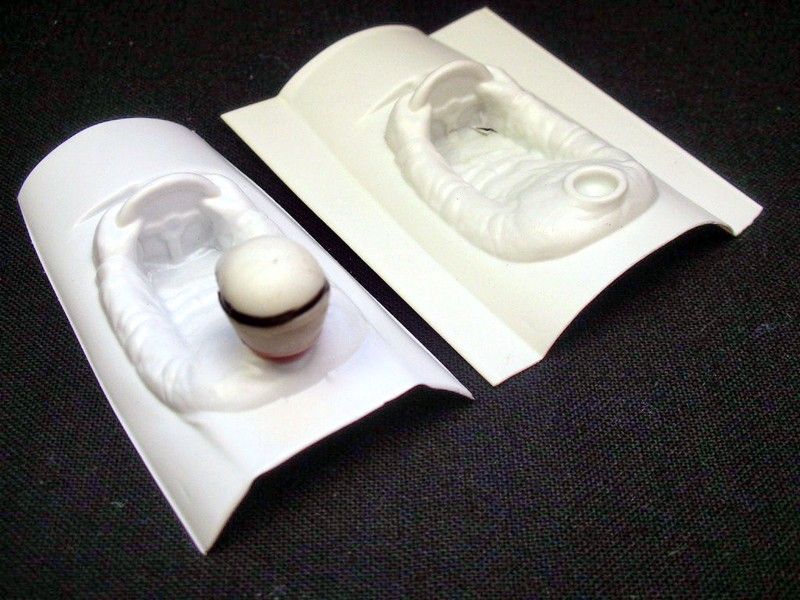

OK…OK…there wasn’t really a 6-wheel type 56 Lotus Turbine but there should have been so I took the challenge of building one in 1/24 scale. I’m using a True Scale repop of the Lancer body:

The motor is pushed pretty far forward with the extra set of rear wheels. It intrudes into the drivers compartment. I used a Lancer GP driver figure and heat formed it around the motor. Heating the can with a soldering iron and pressing the driver against it did the trick:

The modified driver is on the left:

I think it's going to make a cool 6-wheeler:

Lotus should have built this car! ![]()

- slotbaker, MSwiss, Maximo and 3 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#107

Posted 02 July 2013 - 06:20 PM

![]()

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#108

Posted 02 July 2013 - 06:25 PM

Loving this Rick ![]() Such a neat idea to make the Lotus Mr Chapman should of made! Just look at all that Orange sponge

Such a neat idea to make the Lotus Mr Chapman should of made! Just look at all that Orange sponge ![]()

#109

Posted 02 July 2013 - 10:13 PM

Rick said:

"Heating the can with a soldering iron and pressing the driver against it did the trick".

I bet the driver was "hot" about that ![]()

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#110

Posted 02 July 2013 - 10:19 PM

You know... I think it works! ![]()

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#111

Posted 02 July 2013 - 11:22 PM

Thanks guys ![]()

You know Jairus, I stared at dozens of bodies for this project for weeks. The Lotus Turbine just looked "right" to me. We'll see when she's painted up........

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#112

Posted 02 July 2013 - 11:26 PM

I think you made the perfect choice.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#113

Posted 03 July 2013 - 01:22 AM

Looks great.

![]()

Steve King

#114

Posted 03 July 2013 - 04:09 AM

Thanks for my morning chuckle Rick - looks perfect too!

Don

PS: hate to admit it, but you really had me going for a couple seconds.

#116

Posted 03 July 2013 - 12:04 PM

#117

Posted 03 July 2013 - 02:32 PM

Rick, I thought you might get a laugh out of this thing I built some years back. I went the anglewinder route, but from the onset I was building a “dualie truck”. Couldn’t make up my mind on the body either, so I went with both (each with its own sissy bar). The first time I spun those rear gears was a Zen-kinda moment. This thing is fast and corners like it’s on rails. Scares the heck out of people… at least when they’re not laughing. The drawback is having to true two pairs of rear tires!

In any case, I’m sure you’ll have a blast with yours too! Have fun!!

Rick / CMF3

Very NICE !!!

I liiike truuucks.

Bob Israelite

#118

Posted 03 July 2013 - 02:54 PM

OH MY GOSH! Steve, you found a picture of the "rare Indy prototype"! Awesome!!!! ![]()

![]()

![]()

Now if we could just find a picture of the "rare GP prototype" in the bitch'n red white and gold livery of the 1968 Lotus Grand Prix team.

Here's a Lotus 56-6 at Goodwood....

It does look good. They should have built it! ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#119

Posted 03 July 2013 - 03:11 PM

![]()

A pair of Ricks show us their tricks.

One in line, the other in angle

All six wheelers and none of them dangle

Spurs and crowns, so back off clowns

Get off the track and don't make a sound

Kick back and listen as the gears go round

Bob Israelite

#120

Posted 03 July 2013 - 03:53 PM

my poor attempt at haiku:

building cars from scratch

we see the beauty in them

from two Ricks they come

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#121

Posted 09 July 2013 - 02:42 AM

Bob, are you also a member of a poetry blog out here somewhere? That was pretty good.

Steve, ![]()

![]()

![]()

![]()

![]() EXCELLENT!

EXCELLENT!

Andy Granatelli would be proud.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#122

Posted 09 July 2013 - 10:30 AM

Roses are red violets are blue

Four drive wheels are better than two.

![]()

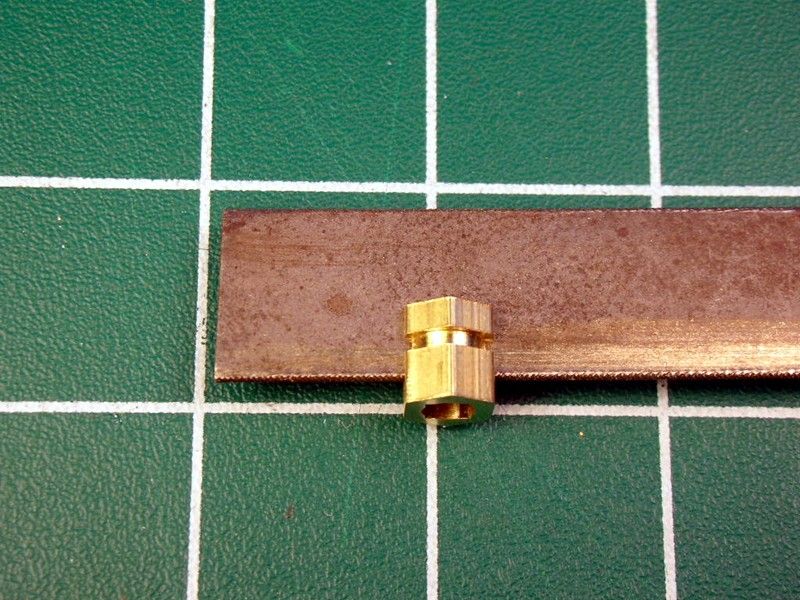

Well, maybe not.....anywho.....my new "toys" showed up and my motor build can begin soon ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#123

Posted 09 July 2013 - 10:46 AM

#124

Posted 18 July 2013 - 05:29 PM

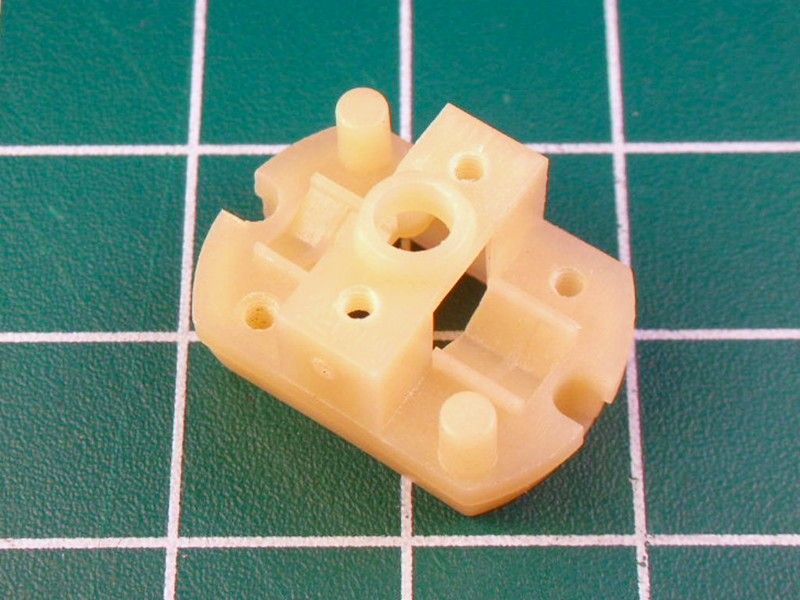

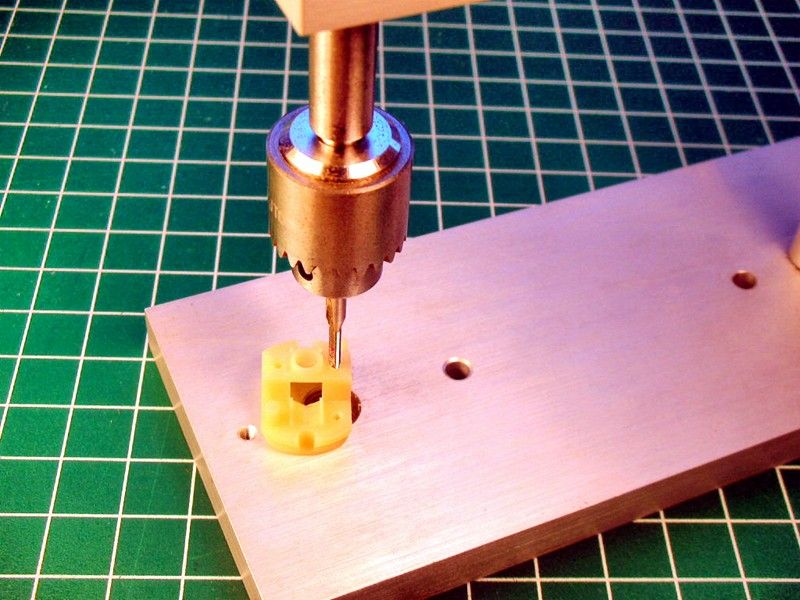

My "Toys" arrived and I'm finally back working on the motor I started almost a month ago. I have a new super small and light mini drill press and adjustable angle block to help with the motor building (any excuse for a new tool!)

Here's the link to the new tools post #176:

Toys For Retirement:

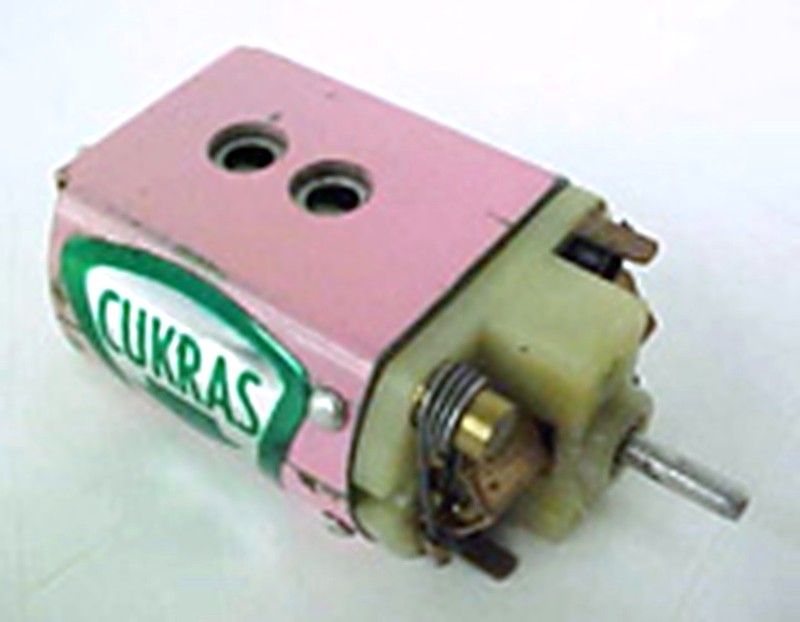

Below is where I left off with the motor:

Next up Paul, I'm going to try and make one of these up from parts. The photo is courtesy of PdL's excellent thread on the history of Mura motors here on Slotblog:

Here's an ad for the motor from Model Racing Journal November 15, 1968:

Mike Morrissey used one of these motors according to the above race report so I thought it would be fun to try to make one up and see how they run. Here's my pile of parts less the armature:

The Certus top and bottom magnet shims are something I'm going to add to my motor...I just can't help myself

The armature is next........

The heart of the motor is the armature. I don't know if what I'm using is exactly "korrect" for a Mura Cukras motor but it's as close as I can get with what I have. For reference I'm using this great story by PdL on the Electric Dreams web site. Here's the link:

MURA STORY

Here's a quote from the story:

"While John Thorp is generally credited to be the first to use electric tack welding of the wires to the commutator tabs, the "Series 2" Mura-Cukras armatures did get this improvement almost immediately. The armature wires were tied at the commutator with fiberglass thread and epoxy was much improved with a vacuum process. This made the motors much more reliable. Now painted in pink....."

The armature I'm using has the trademark Mura flat bottom balancing holes, is CCW timed, vacuum process epoxy coated, has thin lamination's and welded commutator wires tied with fiberglass thread. It's a double wind so I'm calling it a double 28 as that's what the Mura ad said was available for the Cukras motor.

Here it is in its original, sad, 45 year old condition:

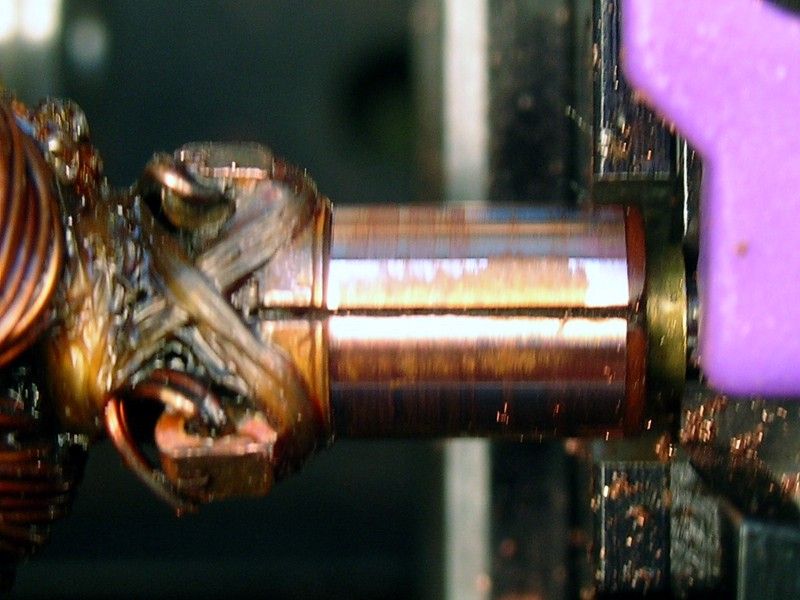

The commutator wasn't worn and showed no signs of the dreaded "Valley of the Comm"

Taking a super light cut in the comm lathe showed it was out of round. You can see the darker area that wasn't cut in the center of the shiny area that was cut:

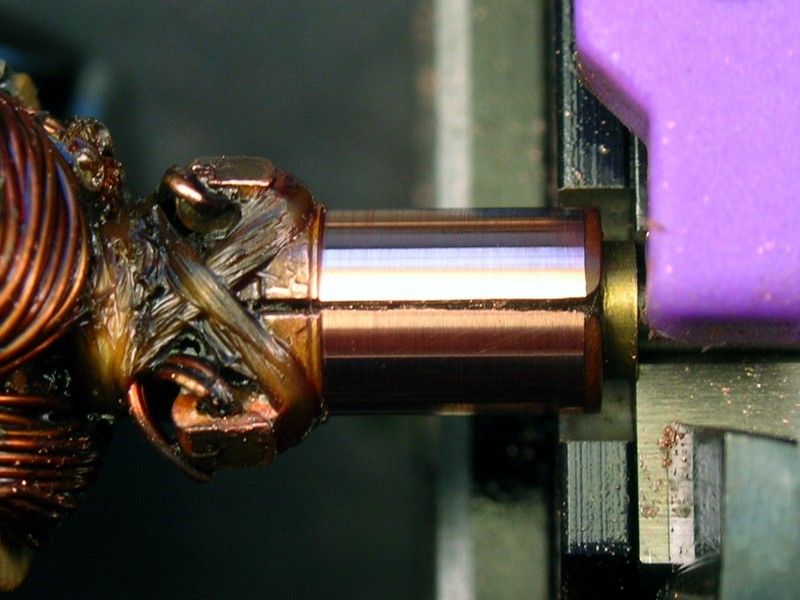

A few more cuts and she's a beauty now:

In fact, me thinks the entire arm is a beauty now that it's all cleaned and polished

End bell time..........

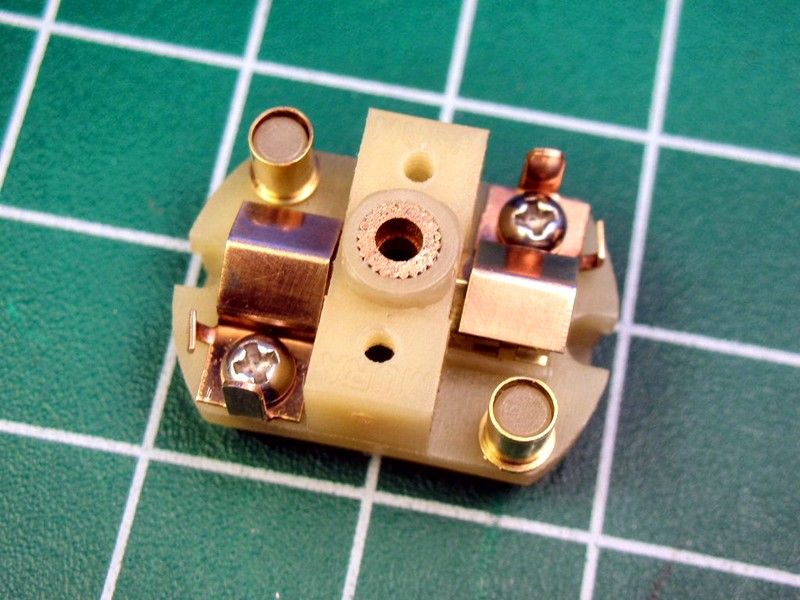

Endbell time. I'm what Lee Gilbert called an "end bell freak" in his famous Car Model Magazine Pro Car build series of articles. ![]()

So I started out with a brand spank'n new old stock Mura "white unmeltable endbell". I find these to be quite hard to find but I think my Cukras pink motor recreation deserves the best I have:

Endbell freaks need to use stainless steel machine screws instead of self tapping screws that are like driving a wedge into the old plastic and causes splits.

The Micro Mark tapping fixture tapped all the holes 2-56 nice and square to the endbell:

Then this dingy 45 year old hardware.....

.....gets the "buff" put to it:

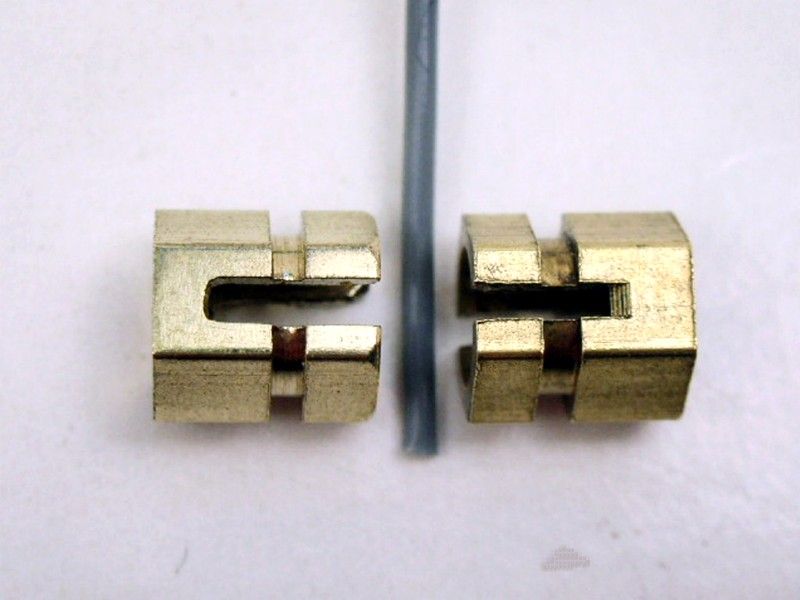

I did end up using a brand spanking new pair of brush hoods that aren't in this picture. But first the hex brush holders had their slots opened up to fit the brush spring insulation.

A screw slot file works great for this. The file's sides are "safe" and only the edges cut:

The stock brush holder is on the right, insulation is in the middle and the modified brush holder is on the left:

Next I wanted to align the brush holders and solder them to the brush hoods...without melting the endbell. ![]()

Here's the junk I use for that. Slick 7 High Temperature silver solder, Stay Clean acid flux and a jar of water to toss the endbell into as soon as I get a hood soldered:

The Gust Easy Duster blows off the water before soldering the next hood. The acid flux will screw up the plastic in a heart beat, so I taped it up to protect it.

Maybe paste flux would work? But with the acid flux I can touch a drop of solder on the front of the brush holder and it flows all the way to the back in an instant.

Besides, masking off the endbell is very time consuming and I'm retired...what else have I got to do? ![]()

Here's the finished product:

Time to get her mounted....I mean to her can........I mean......oh well.

Onward........

- slotbaker and Peter Horvath like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#125

Posted 18 July 2013 - 05:48 PM

![]()

![]()

Paul Wolcott