Bet its fun finding motors /magnets /lams like that from other sources

Arm winding #2

#226

Posted 02 March 2014 - 12:27 PM

Bet its fun finding motors /magnets /lams like that from other sources

#227

Posted 03 March 2014 - 01:43 PM

Thanks for looking guys ![]() Yep, this little motor is turning out really nicely!

Yep, this little motor is turning out really nicely!

Sounds like you got lucky with those FK motors you found John

will look forward to seeing what you do with them down the line

Bet its fun finding motors /magnets /lams like that from other sources

Well, you can get a good idea from the Mabuchi motor designations what exactly you mkight be getting before you buy them Paul:

#228

Posted 16 March 2014 - 09:35 AM

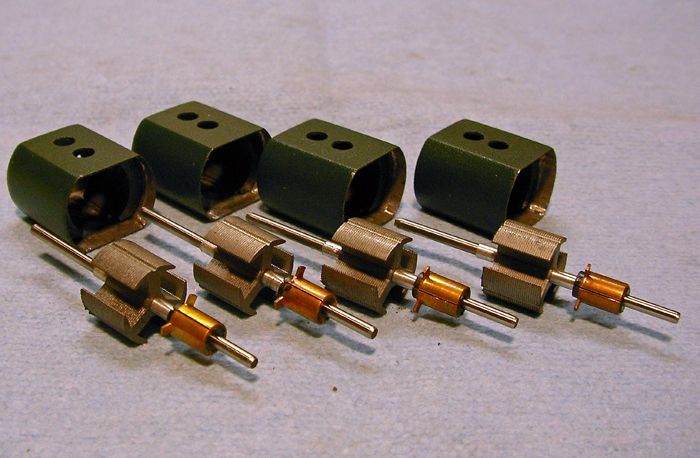

I was out working in the orchard this morning, and this crop of "Walnuts" is looking particularly healthy ![]() I'm doing a group of FK180SH-based Walnuts, figuring I can work more efficiently by doing a group instead of putting all that effort into one motor. With the basic motor only costing less than $2, most of what goes into these little guys is effort and some parts (new arms, shafts, coms and a Hawk end bell). I got all the cans cut, flattened, sanded, and did the "body & fender work" on the magnet-stop "dimples"...solder and then epoxy sanded smooth, as well as drilling and then reaming the can holes. Before painting them ("textured black"), they were all deburred and checked for square with a machinist square on my glass work surface. The magnets were all cut down and still measure about 1000 on my meter (surprisingly no real change), very healthy ceramics for the size and (low) weight indeed. The stacks have all been built and need to get powder coated...but things are coming along nicely. I'm guessing that I saved some time by doing them as a group, but it still turns into a bunch of work no matter how you slice it. Instead of doing them all with a #28 wind, I may do half #28 and half #27. I don't want to push the envelope too much, but a #28 on this .400" long stack seems like there still is some room to warm things up even further.

I'm doing a group of FK180SH-based Walnuts, figuring I can work more efficiently by doing a group instead of putting all that effort into one motor. With the basic motor only costing less than $2, most of what goes into these little guys is effort and some parts (new arms, shafts, coms and a Hawk end bell). I got all the cans cut, flattened, sanded, and did the "body & fender work" on the magnet-stop "dimples"...solder and then epoxy sanded smooth, as well as drilling and then reaming the can holes. Before painting them ("textured black"), they were all deburred and checked for square with a machinist square on my glass work surface. The magnets were all cut down and still measure about 1000 on my meter (surprisingly no real change), very healthy ceramics for the size and (low) weight indeed. The stacks have all been built and need to get powder coated...but things are coming along nicely. I'm guessing that I saved some time by doing them as a group, but it still turns into a bunch of work no matter how you slice it. Instead of doing them all with a #28 wind, I may do half #28 and half #27. I don't want to push the envelope too much, but a #28 on this .400" long stack seems like there still is some room to warm things up even further.

-john

#229

Posted 16 March 2014 - 10:11 AM

Those blank arms look really sweet

The cans really look like you've got a group of Mura's waiting for a hot wind !

#230

Posted 16 March 2014 - 10:52 AM

Thanks Paul. One...maybe two of them are supposedly spoken for, so i figured I'd try and stay ahead of the curve here.

The cans really look like you've got a group of Mura's waiting for a hot wind !

Yep, I'm definitely paying tribute to one of my all-time favorite motors, the Mura "Green Can" C-motor. Although it's way above my pay-grade, I figure the two-hole design must work well, so why not! ![]()

-john

#231

Posted 20 March 2014 - 04:09 PM

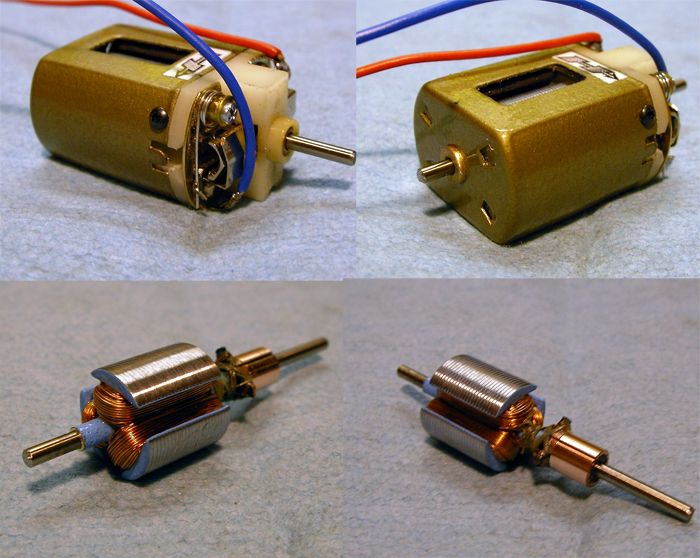

Another surplus motor find. I got a few of these motors for $1.75 each figuring "what the heck". Upon arrival, I take one apart and to my (pleasant) surprise, there's a perfectly good .590" armature in there (it has nylon end insulators that could easily be used, but I tossed them) and a set of very stout ceramic magnets that are almost the same size as Arcos...except a bit longer, but still short enough to fit with no trimming. Here's the kicker, these magnets measure 1148 (exactly the same for both) on my meter, and Arcos measure less than 1000. ![]() Installing them in a 26D can with the Arco can shim results in a .605" hole...a little on the tight side, but that can be managed.

Installing them in a 26D can with the Arco can shim results in a .605" hole...a little on the tight side, but that can be managed.

Anyway, these are some Made in China motors (no other markings), but for $1.75 you get a nice arm blank (BTW, the shaft is straight!) and a set of magnets that are a lot stronger than Arcos. I call that a pretty darned good deal! The picture shows the arm shortened by 4 laminations to get it down near 26D size.

-john

- Geary Carrier likes this

#232

Posted 20 March 2014 - 06:27 PM

Even sweeter hearing about the magnet strength & that rather nice looking arm blank you're left with

Will have to keep my eye open for motors like that to play around with. Look like another variation on those fk180 walnut donors.

Nice B can in the background too

#233

Posted 20 March 2014 - 06:33 PM

Yep Paul, you can find some really sweet deals on surplus motors, and a lot of the parts are interchangeable since many of the old motor sizes still apply...pretty much.

Nice B can in the background too

Yep, I got that from my buddy Brian McPherson a year or two ago and haven't had a chance to do it up. I got a Mura .007 blank and com and did a "PdL wind" for it (22T/#25) that comes in at .104 ohms. It should be a missile! I'm just missing some of the end bell hardware and will have to dig through my "pile-o-stuff" to see if I can come up with the correct pieces. Then it will be "all Mura and all correct"!

-john

#234

Posted 06 April 2014 - 03:42 PM

...one for my Buddy Ernie Layacan. Ernie asked me some questions about the direct drive stuff I screwed-around with. I told him I was going to do one in a C-can, as there's more room in there. After talking with him about the problems (for one, the com, for two, the stack, for three reaming out the bushings for the slightly-larger-than-36D-sized shaft...etc etc etc)...I figured I may as well do one for Ernie! Of course, it would be far easier to just sleeve the shaft ends to 3/32...or reduce the wheel ID to 2mm, I went ahead and did it the hard way ![]() Anyway, I took an old C can setup, reamed out the bushings, reamed out a Mabuchi 16D stack for a 3/32 DB axle, and slightly reamed out a Tradeship FT36D com to come up with this thing. Right now, it draws an amp or so at 6VDC/no load, but has beaucoup torque and brakes. I'd like to see the current draw come down, and am waiting to see what break-in does, but so far so good. Top end is nothing to write home about, but this is for direct drive, so I'm pretty sure it will be plenty fast. Pictured here with a set of .760 tires, there's still plenty of clearance...too much probably, but that's a good thing because the tire diameter is really the only "gearing" adjustment and the smaller the better. Minimum track width comes in just at or maybe even slightly under 3", so it should all fit under a body with no problem. Still going to try some more break-in and maybe spring and brush options.

Anyway, I took an old C can setup, reamed out the bushings, reamed out a Mabuchi 16D stack for a 3/32 DB axle, and slightly reamed out a Tradeship FT36D com to come up with this thing. Right now, it draws an amp or so at 6VDC/no load, but has beaucoup torque and brakes. I'd like to see the current draw come down, and am waiting to see what break-in does, but so far so good. Top end is nothing to write home about, but this is for direct drive, so I'm pretty sure it will be plenty fast. Pictured here with a set of .760 tires, there's still plenty of clearance...too much probably, but that's a good thing because the tire diameter is really the only "gearing" adjustment and the smaller the better. Minimum track width comes in just at or maybe even slightly under 3", so it should all fit under a body with no problem. Still going to try some more break-in and maybe spring and brush options.

When taking the picture, a screw got snatched up by the magnets ![]() no worries!

no worries!

-john

#235

Posted 06 April 2014 - 04:03 PM

Wondered when you'd have another go at the direct drive !! ! ![]() Should prove interesting to see how it goes

Should prove interesting to see how it goes ![]()

#236

Posted 06 April 2014 - 05:17 PM

Honestly Paul, I've been kinda busy with more "normal" motor stuff and had forgotten about this until Ernie reminded me. On this motor I had the sort of fudge my way up to 3/32 when reaming the bushings because my reams stop just short...so I had to make do with a drill bit for the last step. I have to order a couple more sizes of chucking reamers so I can do all of this on the two bushings while in the setup so they stay as "true" as possible. Still, the motor runs well and I *think* will work fine in a car. A bit more screwing-around with it and then it's off to Ernie's place ![]()

-john

#237

Posted 07 April 2014 - 07:25 AM

This probably comes as no surprise to the motor builders out there, but I changed the brushes and things are much better with the motor. This is definitely something to check with all motors. Sometimes even brushes of the same manufacturer are good and sometimes not so good.

-john

#238

Posted 07 April 2014 - 11:33 AM

Wow! That's perfect John; with those big tires it reminds me of the rear end view of a Funny Car/Rail Dragster, huge tires and all. Awesome!

Thank you John.

Ernie

#239

Posted 07 April 2014 - 11:38 AM

Hi Ernie,

Of course, the tire thing will have to be worked out so you don't have too much bite, but I figure you can always work down in tire compound and width from here. Height-wise (which is where the effective "gearing" changes can be made), you can always work up from these. It shouldn't be too hard to come up with a chassis that will work OK, but with all the weight so far back, I'm guessing that some added heft over the guide will be a good way to go. I think Mike Swiss has probably messed-around with d-drive cars as much as anyone and he may have some tips.

-john

#240

Posted 07 April 2014 - 11:44 AM

#241

Posted 07 April 2014 - 11:52 AM

![]() I love John, We love John ..... he is the 'Mad-Scientist' of slot car motors.

I love John, We love John ..... he is the 'Mad-Scientist' of slot car motors. ![]()

![]()

![]()

And ... ![]() for sharing.

for sharing.

- SlotStox#53 likes this

Bob Israelite

#242

Posted 07 April 2014 - 10:14 PM

Of course, it would be far easier to just sleeve the shaft ends to 3/32...or reduce the wheel ID to 2mm, I went ahead and did it the hard way

John is always making his own path, blazing a new trail, setting a higher standard! How awesome is that!

Thank you John for your efforts!

Ernie

#243

Posted 08 April 2014 - 07:19 AM

You're most welcome Ernie...and thank YOU. I "figger" this way may be more work up front, but then all you have to do is use standard wheels/tires for 3/32" axles. I'll stick a set of wheels in there with the motor so it's even a little more "plug and play" ![]()

-john

#244

Posted 08 April 2014 - 07:47 AM

John,

I believe they use 2mm axles on Eurosport cars. Ask Bill.

Nice new batch of motors. They're moving well I see.

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#245

Posted 08 April 2014 - 08:31 AM

Hi Sam,

Yes, that's true, but my aim with all of these things is to do them in a way that hopefully makes things "easy" for people. This way, you just source regular 3/32" wheels and tires...build (or even maybe adapt) some sort of chassis attached to the motor and let 'er rip. The eurosports and open guys run cars that are missiles built without much regard for cost and even durability to a point. They also turn-down 2mm motor shafts! Even a 2mm drill blank with the leverage of a tire on each end can be fragile when they "fly" ![]() On the other end, even a "soft" Mabuchi "36D" shaft is pretty strong.

On the other end, even a "soft" Mabuchi "36D" shaft is pretty strong.

-john

#246

Posted 08 April 2014 - 12:17 PM

John's arduous and ingenious motorwork always makes things easier - at least for me, AND is ALWAYS APPRECIATED!

Thank you very much John.

Ernie

#247

Posted 08 April 2014 - 06:28 PM

aw pshaw Ernie ![]()

Those little motors you sent me are astonishing. I mean, of course things like battery powered toothbrushes have teensy motors in them, but to screw around with some really is pretty crazy. I (of course) opened one up after trying them on the power supply and being surprised at how fast and powerful they are. They have super thin magnets that look to be ceramics and the wand of my gaussmeter just barely fits in the can. Those little guys measure a stout 700, and that may be a conservative measurement because the tip of the wand is the size of the magnet. The armature is made up of maybe six laminations, but the wire is surprisingly heavy for such a tiny motor...maybe around #34 wire. While it ain't rocket science, it really is a wonder that such miniaturization is so commonplace. Of course, we also have functioning motors on the "nano" scale now, but I'm still impressed!

-john

#248

Posted 08 April 2014 - 08:21 PM

Wow - those tiny motors pack that type of punch huh! Well, the specs state they're capable of 40,000 rpm at 6 volts. I don't have an HO motor but how much smaller are they compared to the HO motor John please?

Imagine trying to put a 3/32" shaft on one those micro motors?! LOL!

By the way, have you tried hooking one up to power to see how it spins? I bet it might sound similar to a dentists drill.

Ernie

#249

Posted 09 April 2014 - 09:53 AM

Hi Ernie,

Yes, I hooked all of them up to 6V and two were noticeably faster than the other two, but all of them packed a pretty good wallop into such a teensy package. With such a small shaft (1mm) it was hard putting my finger on it to get an idea of what kind of torque they have, but it seemed really good. Actually, it was kind of difficult just holding on to the motor and the alligator clips on my PS had a hard time holding on to the power leads of the motors. ![]()

-john

#250

Posted 10 April 2014 - 10:50 AM

I get a kick (still) out of these old motors. The venerable Russkit "23" all done up for racing, for a private customer, not for eBay:

-55T / #29awg

-Drill blank shaft

-Bugenis com

-Original Mabuchi lams (fiber end caps discarded, stack powder coated)

-Blind can bushing removed and replaced with a 2mm x 5mm through-bushing

-Can stripped and painted (2 coats) "Hammered Gold", drilled for end bell retaining screws

-End bell modified for bullet-proofing plates, post covers (screwed #0 x 1/4" tapping screws & washers), brush tubes soldered to plates

-36D hoods and heat sinks (tubes)

-15 gauge stainless steel springs, 3 coil

-"Yellow/Red Dot" magnets with can shim

-New lead wires

-john