One. And he does NOT race HO ![]()

Arm winding #2

#176

Posted 29 November 2013 - 03:39 PM

Paul Wolcott

#177

Posted 01 December 2013 - 11:33 AM

A 26/26 hemi wind, built to fit a C can. Measures .131 ohms. It ain't about whether you can wind a nice arm so much as...can you do it consistently. I still work on that, but things have gotten better and better over the years. Wax on/wax off.

-john

- Dave Reed likes this

#178

Posted 03 December 2013 - 06:38 PM

...and also built for a C Can, a #25 "regular" wind. This one comes in at just over a tenth of an ohm (.103)

-john

#179

Posted 03 December 2013 - 08:25 PM

Seriously love those 2 C can arms John ! Really done a great job on them , can see why you like that blue coating ![]() Contrasts so well against the wire color... .

Contrasts so well against the wire color... .![]()

What lams/blanks did you use for them John?

#180

Posted 04 December 2013 - 07:45 AM

Hi Paul and thanks,

What lams/blanks did you use for them John?

I assembled the stack from a medium crown .518 lam with what I would describe as a medium winding leg. In short it's a fairly average modern type lam, that seems to work well across many applications.

On the arms themselves, I'm getting to the point where most winds on most blanks are no problem and consistency is good. The eurosports arms, being such short blanks (some are .250 tall) can still be difficult, so I have to pay more attention to those. "Regular" (say .440) stacks in pretty much any wind almost always go well with no drama. Even when I do smaller less-critical arms for say the Hawk (if I build the stack for those, I usually go with a .350" height) are fairly easy. There's always the option of winding without the com installed to keep it "out of the way", but I've never had to do that even on the smallest arms.

Things that can add to the difficulty are the old Kirkwood coms with their gigantic fish hook tabs. Those tabs can get in the way on some arms, but I routinely bend the tabs to stay closer to the com itself before winding. Also, double winds make it tougher to keep things really neat, but not many people ask for them. Also, on the rare occasion that I use the old Mura .007" lams, certain winds can be a little more difficult because both the crown and the winding leg are thick on those, so there's not much room to get the wire on them.

-john

#181

Posted 13 December 2013 - 03:32 PM

So a Blogger got a hold of some of these later (Hong Kong version) FT16D motors for a very nice price. Many will have seen these before, but for those who haven't, they look like this:

As you can see, the motor is pretty much a dead ringer for the earlier Japanese versions except for the can holes and the center strap of the end bell, which has been widened/beefed up. Parts are interchangeable and the end bell is a perfect fit for the Japanese cans, which is a handy thing, because these end bells are cast out of a much better material than the "candle wax" Japanese versions, and they will also accept a regular sized bushing or even bearing with no mods (looks to be a 6mm job).

Opening up the can reveals a pretty modern looking arm/com. Arm has a fairly heavy powder coating instead of the fiber end caps and the com has been resistance welded to secure the VERY thin magnet wire...at least #35, maybe smaller (sorry about the fuzzy picture):

The can closely resembles the Japanese versions (again...except for the can holes), but seems to be made out of a heavier steel because bending the end bell retaining tabs takes some effort. Magnets look about the same, but they measure around 800 on my meter. That doesn't put them in "Arco" territory, but they're a very significant/solid step up (score one for the home team!). Bushings on both the can and the end bell seem to be of the more recent sintered magnetic (steel/iron compound?) type from their color. Note that the can bushing is fixed, instead of "caged" and movable like the Japanese versions':

In stock form, the motor seems more anemic than whatever is in your toothbrush. I don't know what these were used for (slot cars???), but whatever it was must not have needed much power (unless it ran on 110V ![]() )

)

So...the most economical way to have at these things was to see about reusing the com, shaft and stack. To make chassis mounting easier, I was asked to change the motor to end bell drive. So I stripped the angel hair...er...magnet wire ![]() , removed the com and tail spacer and pushed the shaft to the other side as far as I could go and still have it fully riding on the can bushing with the arm centered in the field. A little push...a little more...still a little more until bingo!. Afterwards, it all went pretty routinely. I added com and tail spacers, cranked in a bit of CCW timing advance (maybe 15 or so degrees), did up a #28 wind, silver-soldered the com tabs, tied/epoxied/static-balanced, cut the com...for a .305 ohm rewind:

, removed the com and tail spacer and pushed the shaft to the other side as far as I could go and still have it fully riding on the can bushing with the arm centered in the field. A little push...a little more...still a little more until bingo!. Afterwards, it all went pretty routinely. I added com and tail spacers, cranked in a bit of CCW timing advance (maybe 15 or so degrees), did up a #28 wind, silver-soldered the com tabs, tied/epoxied/static-balanced, cut the com...for a .305 ohm rewind:

The reworked motor is on the left and the original on the right. Redone, the motor draws a bit over an amp at 6VDC, runs fairly cool and spins up VERY nicely. There's still way more to be had from these setups...better magnets/shims, springs, better com, better stack, ball bearings on both ends...but you're talking about significant work and cost. Just like this, you have a really nice motor that would be right at home in a vintage type race series...giving strong vintage type performance. Just the endbell alone would be a large upgrade for a Japanese FT16D because of the better material AND the ability to change out the bushing for an easily-sourced bearing, or even just a better bushing.

Redone motor on the left, original on the right:

-john

- MarcusPHagen, slotbaker and Samiam like this

#182

Posted 13 December 2013 - 08:45 PM

Saw a whole box of these very motors on the "Bay" and didn't grab em... Comm looks to be of good quality as does the arm.. even better with fairly stout magnets ,very nice little starting platform.

The endbell being of same technology with the brush hoods & heatsinks would be a substitute for an original mabuchi for '66 Rod & Custom motors

Will have to keep my eyes out for anymore ,you have most definitely shown the way!!

#183

Posted 13 December 2013 - 08:46 PM

Sweet ! ![]()

Paul Wolcott

#184

Posted 13 December 2013 - 09:37 PM

Saw a whole box of these very motors on the "Bay" and didn't grab em...

yeah...there was another group up for sale, but the guy wanted way too much for them. These motors have to go to someone willing to put some effort into rehabilitating them...or more correctly..."repurposeing" them. They obviously aren't vintage FT16D motors, so you can't just resell them, unless you're vague, post fuzzy pictures and misrepresent what they are. Also, they're so weak in their stock form, they run like a bad 13UO. So they really either MUST be rewound (at least), or have the stock arm replaced. At a price of at least $10 or more plus labor, that right there starts to take the appeal out of the equation. Still, with a little elbow grease, you got a nifty "vintage flavored" motor that's very close to the old FT16D with some significant upgrades where they really needed it.

Sweet !

Thanks Pablo. I have a second one (the first is going back to the owner for evaluation) that I'm going to go the "whole enchilada" on...give it the full race deal (not sure if I have a pair of bearings floating around here). That one will get a #27 wind...maybe even a #26, with a new arm and com, magnets either shimmed or replaced, hoods soldered and brushes shunted...probably 36D brushes.

-john

#185

Posted 13 December 2013 - 10:41 PM

Always a motor worth waiting for !! A Havlicek "whole enchilada" motor ...... ![]()

![]()

![]()

![]()

#186

Posted 14 December 2013 - 02:03 PM

I got a good jump on this thing

1)Arm is built, but not wound

2)End bell bearing installed. Turns out the bushing pocket is larger than 6mm and the bearing had to sleeved much the same way I've had to do them for the Champion end bell

3)Can bearing is installed soldered in with acid and then all thoroughly washed out with baking soda...reamed out the bushing carrier and had to grind off the flange on a 6mm bearing to get it in there, so there's another minor difference from the one on the Mabuchi.

4)Can was stripped (carefully...the plating looks like it might just be cadmium), I opened up and squared off the can holes so they look a little more like the earlier FT16D holes (not a perfect job...but I went far enough so they don't look too hacked) and painted white.

All in all, it looks a lot more like it "should" ![]()

-john

- Samiam likes this

#187

Posted 15 December 2013 - 12:20 PM

So, moving on with this little motor job (making a Hong Kong Mabuchi look and work nicer), I started with this:

took it all apart and did this to the end bell:

...did this to the can:

(EPX magnets epoxied-in, bearing, strip and repaint can, square off the can holes)

...made and wound a #27 single that comes in at .205 ohms, and most of the big stuff is done:

Now it's a "tribute motor" recalling the French rewinds I lusted after as a kid, but this will go a lot faster than any of those did ![]()

-john

#188

Posted 15 December 2013 - 12:57 PM

Very nice Sir ![]() There's just something about a crisp & freshly painted white motor can

There's just something about a crisp & freshly painted white motor can ![]() See why you lusted after the French rewinds back in the day... Love the squared off can holes

See why you lusted after the French rewinds back in the day... Love the squared off can holes ![]()

WIth those EPX magnets John, would you say they are about the best modern magnet to match up with vintage style winds?

#189

Posted 15 December 2013 - 02:37 PM

Hi Paul

WIth those EPX magnets John, would you say they are about the best modern magnet to match up with vintage style winds?

Well, they're cheap as chips and VERY strong Paul...but you really need to use a large diameter arm with them...or you're going to have to do a heck of a lot of shimming. In this can, the Parma magnets produce a hole around .595". The Parmas also have finely tapered tips, reaching way around the radius of the arm. For a (nominal) .510" diameter arm, the Mura magnets made for their "can-in-a-can" shim are among the best I know of. Sometimes you have the opposite thing to deal with using the Muras, as they can make for a small hole...BUT...you can use them without the shim and shim them in a little if you need to, and use a pair of spring clips to hold them.

-john

#190

Posted 15 December 2013 - 02:53 PM

Thanks for the info about the large size hole using the EPX mags, should be perfect for the 16D arm blanks I got from Bill ![]()

Have one of the can in can shims & magnets aswell ,certainly are a powerful set & was wondering if you could use them without the shim. TIme for experimenting!

#191

Posted 15 December 2013 - 03:12 PM

I don't remember for sure, but I think the Muras are actually a C (maybe B?) size magnet in their shim Paul. I've used can material in the past as a shim for the D motor, as a C can will almost fit inside a D. Using C magnets in a D motor is possible by shimming the tops and bottoms to center them and/or just using thick enough spring clips and some epoxy. They come in different thicknesses, so you can play around in all kinds of ways to get a result you're looking for with a .510" diameter arm, which was what the original FT16D arms actually were. These big diameter arms are a new thing. To make things even more "interesting", these arms can even work (again with some magnet shimming) in an FT26D, as they're a little smaller than those arms.

-john

#192

Posted 15 December 2013 - 03:57 PM

John,

Super nice job. Love the way the can came out.

Arm is sweet too .. Stack looks short.. .350?

Bob Israelite

#193

Posted 15 December 2013 - 05:32 PM

Hi Bob,

Super nice job. Love the way the can came out.

Arm is sweet too .. Stack looks short.. .350?

Thanks. The arm is a "regular" .440" length. The width and sort of narrow crown of these lams makes the stack look shorter than it really is. Also, the arm was built and spaced for this setup, which may be a little different from a normal D motor because of the bearings on both ends. On the can end, it will need significantly more spacers because of how the bearing got recessed into the bushing pocket.

I really like the way a white can looks (again, that may be because of how much I loved the French motors as a kid)...but have had an awful time with white paint in the past. Two main problems were that the paint never seemed to get hard enough and didn't seem to bond well. This one (Rustoleum Appliance Epoxy) definitely gets hard enough...hopefully it stays on the can. The plating on these cans (if it's what I think it is) can cause fits if it's not completely removed...so I gave it the old college try and was careful to avoid contamination from finger oil, washing it all down with acetone before spraying...we'll see!

-john

- Gator Bob likes this

#194

Posted 16 December 2013 - 08:23 AM

This all reminded me to get some more Mura magnets and can shims, and Roger at Mid America still has 'em in stock. Great source!

-john

#195

Posted 16 December 2013 - 11:14 AM

Yeah have seen them in his store ![]() Also John if you need any period Hemi cans & magnets Roger has 'em aswell

Also John if you need any period Hemi cans & magnets Roger has 'em aswell ![]()

On a side note John, what sort of wind/s would be a good match to those can in can shim magnets? Would say a mild x number of turns of #29 be meaty enough to turn with those mags?

Just re read Bobs "built motor" thread and he slipped a lovely looking Mura 55 #30 arm in using the very same can in can shim & mags.

#196

Posted 16 December 2013 - 12:14 PM

John,

You mentioned you thought the plating on the can might be cadmium. I know what cadmium plating looks like and I thought so too, at first.

However, cadmium is not only expensive, but also environmentally toxic and it's use nowadays is confined primarily to aerospace and miliary applications. Most likely the finish on that can is electroplated (as opposed to hot-dipped) zinc, coated with either something called "Hexavalent Yellow Chromate" or "Trivalent Yellow Passivate".

Hexavalent yellow chromate (over electroplated zinc) provides a nice irridescent finish, like this:

Looks a lot like Cadmium plating, but it isn't.

Unfortunately, hexavalent yellow chromate is also pretty nasty stuff, being recongnised by some (not all) government agencies as carcinogenic. Because of this, most OEMs have simply discontinued using it.

That leaves trivalent yellow passivate as the most likely candidate... BUT...

If that is a "vintage" motor, and particularly because it was "Made in China", there's no guarantee the manuafacturer was, at the time, not using hexavalent yellow chromate; so you might want to exercise a little bit of common-sense caution when doing things like sanding or soldering the can.

Bottom line, I seriously doubt the can is Cadmium plated.

Steve Okeefe

I build what I likes, and I likes what I build

#197

Posted 16 December 2013 - 04:19 PM

Hi Steve,

Since the motors are "fairly old" (who knows how old???), and made in Hong Kong, I figure it's a possibility...after all, the Chinese have been sending us toys and whatnot with lead on them ![]() Cadmium-plated pieces have a distinct slippery feel to them, which is one of the reasons it still hasn't been entirely phased out to this day, and these motors have that sort of feel for sure. Then again, the "yellow zinc" plating that I'm familiar with (commonly referred to as "zince chromate") plating used on some hardware and fasteners to make them look like bright brass has a similar feel. I'm "pretty" sure this isn't that, but it could be. Either way, I wasn't taking any chances!

Cadmium-plated pieces have a distinct slippery feel to them, which is one of the reasons it still hasn't been entirely phased out to this day, and these motors have that sort of feel for sure. Then again, the "yellow zinc" plating that I'm familiar with (commonly referred to as "zince chromate") plating used on some hardware and fasteners to make them look like bright brass has a similar feel. I'm "pretty" sure this isn't that, but it could be. Either way, I wasn't taking any chances! ![]()

-john

#198

Posted 16 December 2013 - 04:26 PM

Yeah have seen them in his store

Also John if you need any period Hemi cans & magnets Roger has 'em aswell

On a side note John, what sort of wind/s would be a good match to those can in can shim magnets? Would say a mild x number of turns of #29 be meaty enough to turn with those mags?

Just re read Bobs "built motor" thread and he slipped a lovely looking Mura 55 #30 arm in using the very same can in can shim & mags.

I would feel fine putting anything from a #30 all the way to a big wire arm with those magnets...but the limiting factor is not going to be the magnets...it would be the FT16D motor itself. I know guys have put #25 singles in Mabuchis with good magnets, but a motor like that most likely isn't going to last very long, even if the setup is aces. Without doing something like fitting an end bell made of modern heat-resistant material (and then you'd have to ask yourself...what's the point?), I don't think it makes a lot of sense to go any hotter than a #27 wind in a Mabuchi FT16D. Besides, a #27 with good magnets is going to be a rocket anyway!

-john

#199

Posted 16 December 2013 - 11:10 PM

Hi Bob,

Thanks. The arm is a "regular" .440" length. The width and sort of narrow crown of these lams makes the stack look shorter than it really is. Also, the arm was built and spaced for this setup, which may be a little different from a normal D motor because of the bearings on both ends. On the can end, it will need significantly more spacers because of how the bearing got recessed into the bushing pocket.

I really like the way a white can looks (again, that may be because of how much I loved the French motors as a kid)...but have had an awful time with white paint in the past. Two main problems were that the paint never seemed to get hard enough and didn't seem to bond well. This one (Rustoleum Appliance Epoxy) definitely gets hard enough...hopefully it stays on the can. The plating on these cans (if it's what I think it is) can cause fits if it's not completely removed...so I gave it the old college try and was careful to avoid contamination from finger oil, washing it all down with acetone before spraying...we'll see!

-john

Champion had the little plastic 'cages' that could retain a can BB or bushing when rplacing the floating gimble bushing.

I have some of these made in Japan by Mabuchi. Basicly the same exept for a black endbell and the cheap 'no inner race' BBs.

Yeah have seen them in his store

Also John if you need any period Hemi cans & magnets Roger has 'em aswell

On a side note John, what sort of wind/s would be a good match to those can in can shim magnets? Would say a mild x number of turns of #29 be meaty enough to turn with those mags?

Just re read Bobs "built motor" thread and he slipped a lovely looking Mura 55 #30 arm in using the very same can in can shim & mags.

Yup... BTW the Mura magnets in the built Russkit 22 are the same mags that would have been used in production of the Challanger II 55t/30w x .440 'C' can.

The package header card calls it a "Replacement Arm - 16D Motor" part # R12A

But it is the arm the was in the Challenger II that is a Mura "C" can. ![]()

It works ![]()

Hi Steve,

Since the motors are "fairly old" (who knows how old???), and made in Hong Kong, I figure it's a possibility...after all, the Chinese have been sending us toys and whatnot with lead on them

Cadmium-plated pieces have a distinct slippery feel to them, which is one of the reasons it still hasn't been entirely phased out to this day, and these motors have that sort of feel for sure. Then again, the "yellow zinc" plating that I'm familiar with (commonly referred to as "zince chromate") plating used on some hardware and fasteners to make them look like bright brass has a similar feel. I'm "pretty" sure this isn't that, but it could be. Either way, I wasn't taking any chances!

-john

Those same motors were used in RTR 1/32 cars. One of the locals (Lee Fish) brought a car with that Hong Kong white end bell motor. He said he bought it new ... I took some pictures of it to show you guys .. but ... that computer " **** the bed". ![]() BTW: it had 'ear' type heatsinks AND a cheap comm. cooler.

BTW: it had 'ear' type heatsinks AND a cheap comm. cooler.

IIRC it was mid to late 70s Riggen's version of the Womp.

Were my parts originally cad or zinc plated?

Without a special laboratory analysis it can be very difficult to nearly impossible to tell the difference between the two. Cadmium use on fasteners began to rapidly dwindle in the early 70s, so fasteners made after that time would likely have been zinc plated.

http://yellowzincpla...gallery_14.html

NJ based mail order plating service if anyone gets sick of chrome or painted cans. The shims would look great zinc plated a slipped into a chrome can ![]()

![]()

- havlicek likes this

Bob Israelite

#200

Posted 24 December 2013 - 09:53 AM

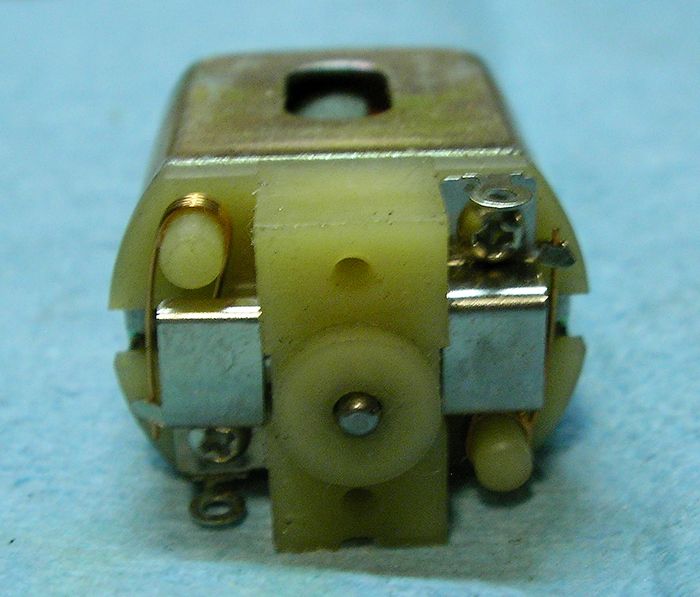

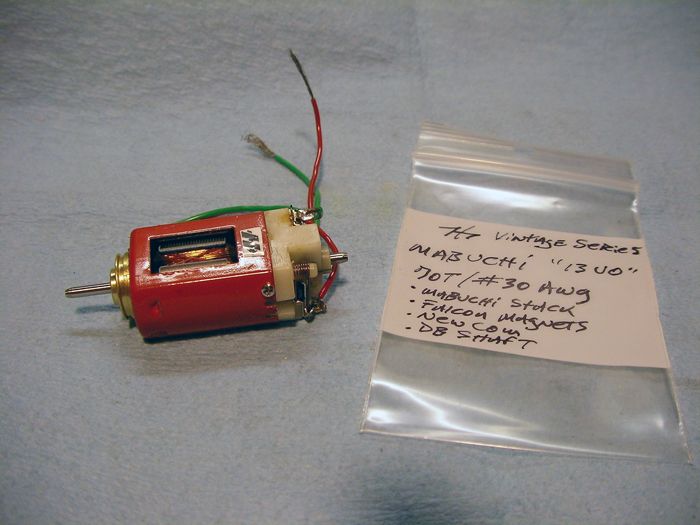

For the vintage crowd, a sweet (if I do say so m'self) Mabuchi 13UO. For a while, me and my buddies did a bunch of these as a kid (with...er...varying degrees of "success"). They were the "poor cousin" and so sometimes people just gave them to us, but the "13" made a dandy F1 motor for obvious reasons, and they'd fit in just about anything.

On this one, I reused the Mabuchi stack, tossed the fiber insulators in favor of powder coating, pressed in a new shaft and installed a new(ish) com with a bit of timing advance (I think around 15 degrees or something like that). I did make one other concession by epoxying in a set of the poly-neo magnets from a Falcon after a bit of trimming to get them to fit properly, because the stock magnets are just so poor on these things. Wind is 70/30 and I tied the stack as well as the com for a bit more of the "old school" flavor. On this one, even the stock leads were in good shape, so I cut them and stripped off a bit more insulation...resoldering them on (no...it wasn't me who scorched the end bell!). Result is a dandy powerplant that will run circles (and then some) around the stock version (duh!), but won't melt the end bell...drawing only a bit more than 1/2 amp at 6V no load. The glamor shot:

-john

- MarcusPHagen likes this