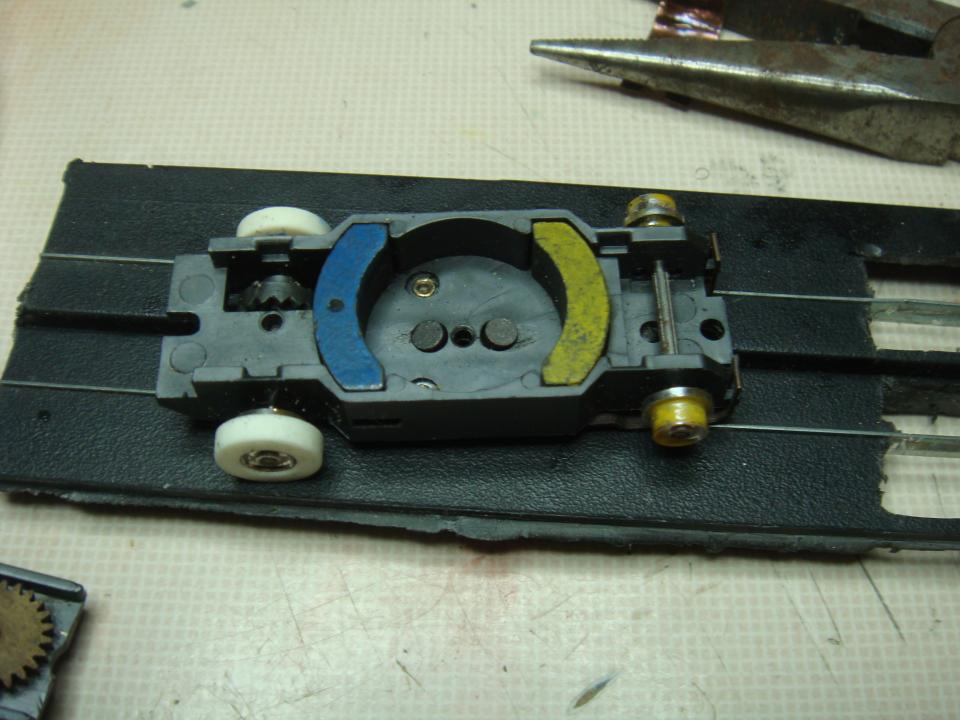

I Figure it must be time again for a "step-by-step" rewind, hopefully a help for someone out there

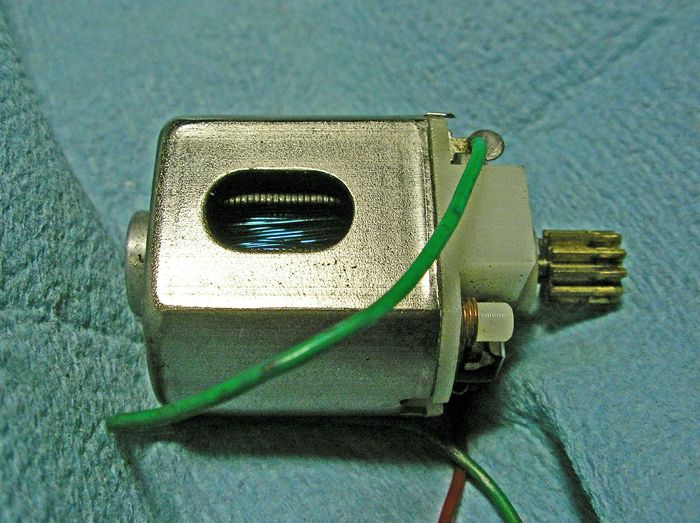

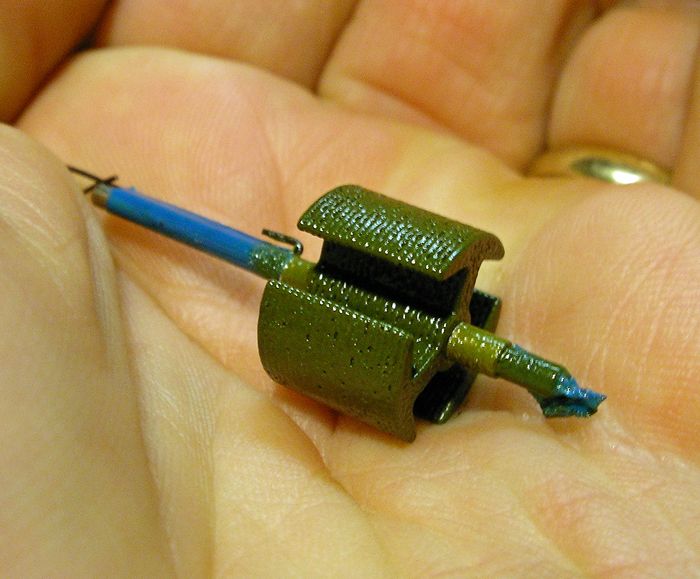

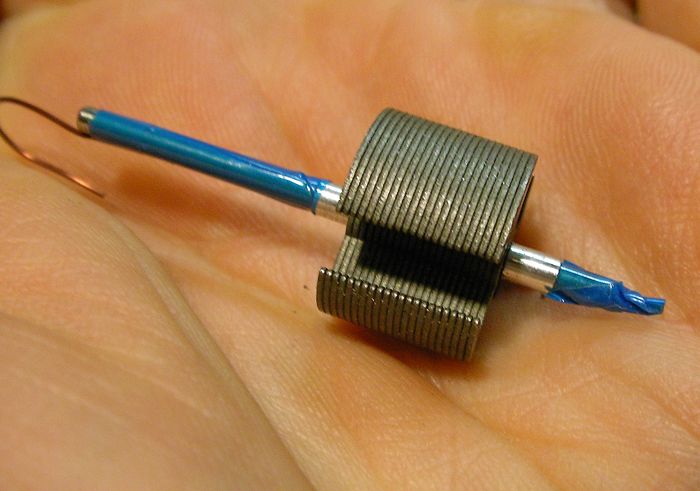

I give you the ubiquitous "blue wire" Mabuchi 26D (the "poor man's race motor"):

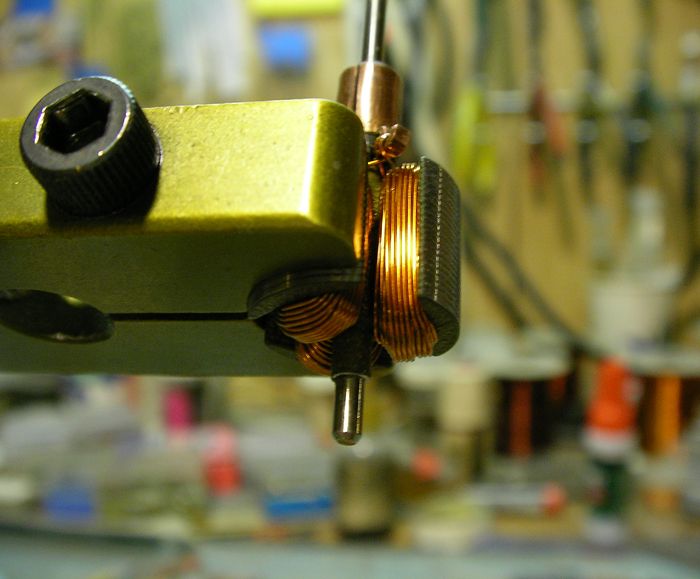

Prying the tabs open to satisfy my voyeuristic tendencies, I find 75 turns of what seems like #30 wire and the not-very-stout Mabuchi com:

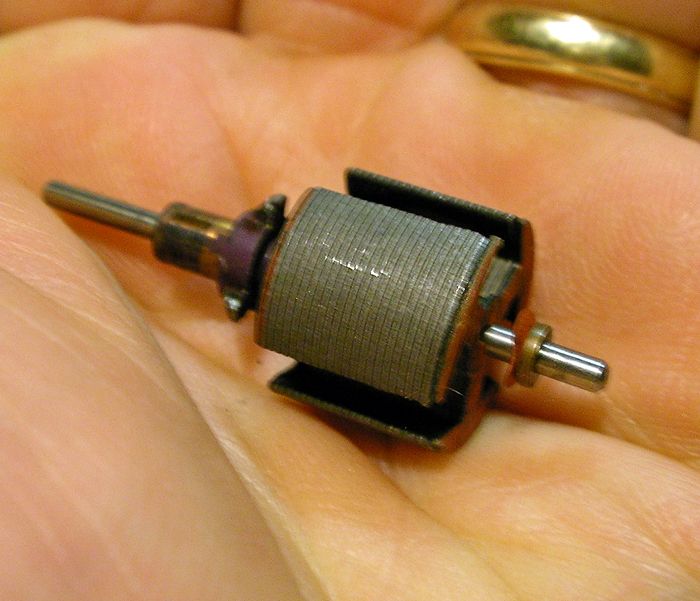

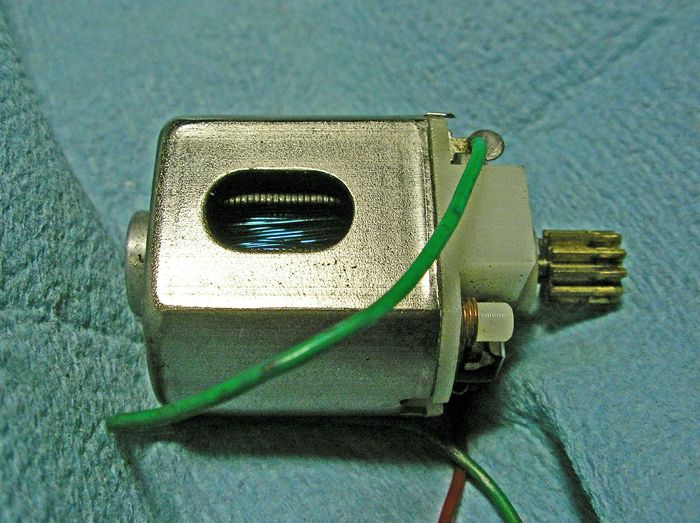

We can DEFINITELY do better than that mess, and after stripping...the thing looks better already!

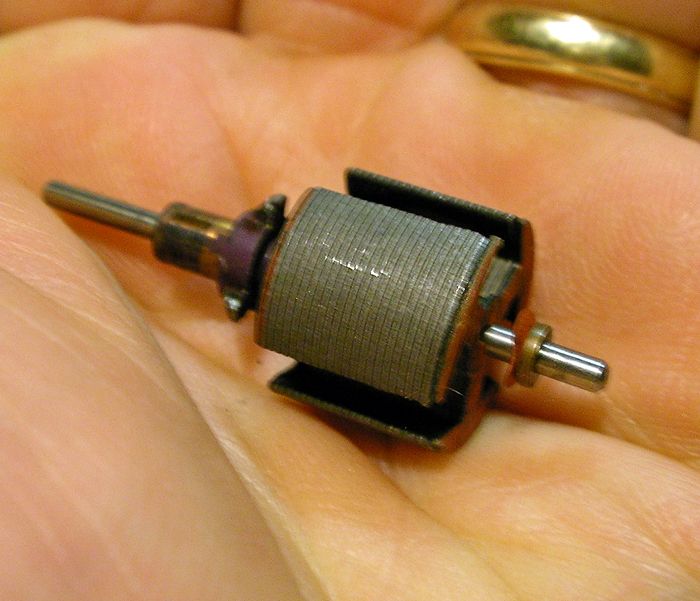

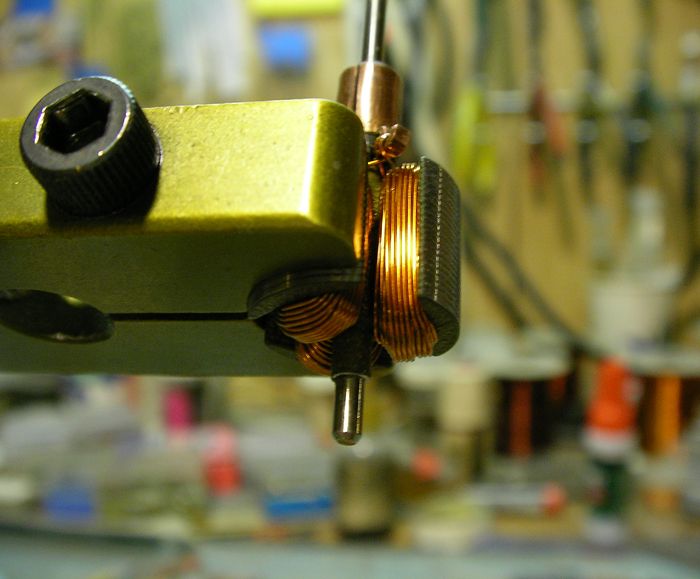

First things first. Toss that com (and those fiber stack insulators in this case...although they can work OK with a little tweaking) and substitute a NOS Kirkwood, carefully bending the tabs so they don't stick out that far. Afterwards, cut new tail and com spacers, temporarily assemble the arm to be sure it can be centered in the field later on. When it's all good, the spacers get tacked in place with a teensy drop of CA glue. BTW, it can be a help with many wind patterns to use the same diameter spacer material at both the com and the arm tail:

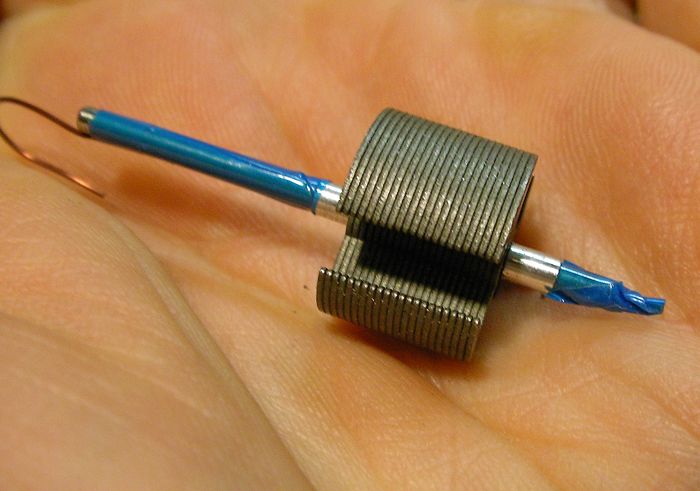

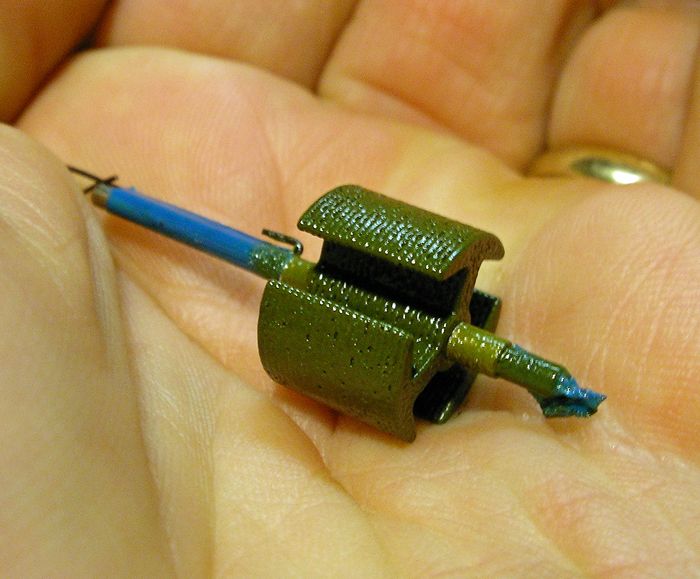

Now, remove the com and mask off the shaft so no powder coat will get on it...because the stuff is impossible to get off:

A little preheating, a dip in the fluid bed, a little post-cure afterwards and you get a super hard, durable and very heat-resistant insulating coating that almost seems like a ceramic:

Then it's down to permanently setting the com (and dialing in any advance), although you can set the com after winding...and it's off to LaGanke Land:

After all this, the com tabs get soldered or in this case they got welded. Of course, before epoxying, you also want to meter the arm to see that all is good (and it is!) Next time, finishing the arm and then onto building the motor!

-john