OK John. I got the first one done. 200 turns of #35 reads around .2 ohm...hard to get an exact reading as my meter is hooked up to a jig that fits "normal sized" arms. Does that sound in the ballpark?

-john

Posted 14 October 2013 - 07:13 PM

OK John. I got the first one done. 200 turns of #35 reads around .2 ohm...hard to get an exact reading as my meter is hooked up to a jig that fits "normal sized" arms. Does that sound in the ballpark?

-john

Posted 15 October 2013 - 07:10 AM

BTW...THANKS Tom!

-john

Posted 15 October 2013 - 11:50 AM

OK John. I got the first one done. 200 turns of #35 reads around .2 ohm...hard to get an exact reading as my meter is hooked up to a jig that fits "normal sized" arms. Does that sound in the ballpark?

-john

John,

Stock Tjet arms are about 16. ohms some hot drag arms 2.2. Super II quadurlams were 4.0 per pole. But i am not a pro someone can chime in.

SJJ

Posted 16 October 2013 - 11:13 AM

John,

What if you check some of the extras i sent, see if its the tester? But at same time not sure if they were any good.

SJJ

Posted 16 October 2013 - 03:22 PM

Hi John,

I did a better job of testing the arm today. Two poles read 2.59-2.60 ohms and one pole reads 2.60-2.61 ohms. I'm actually kind of surprised the poles are that consistent, because 200T of such thin wire is a fairly messy job. Anyway, my tester is definitely good, and I tested a couple of the other arms you sent...one read between 6.90 and 7.35 ohms (depending on the pole) and the other varied a bit more, reading between 7.80 and 8.43 ohms.

The recipe from that old article sure makes for a spicy meatball (!?). I hope you have some good magnets!

-john

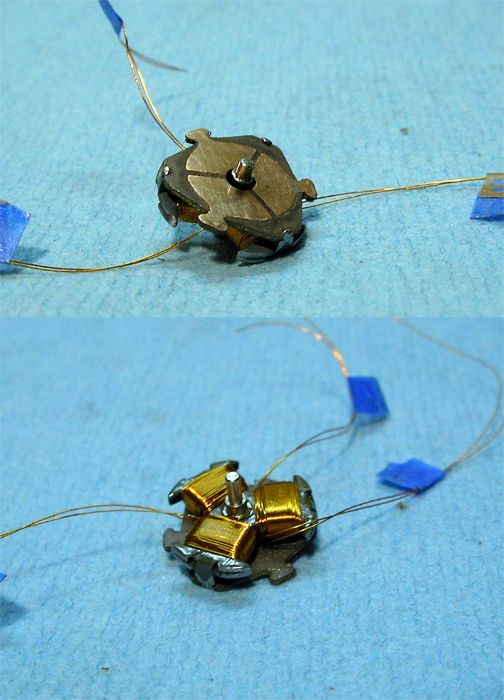

PS...I had the range setting off for the first test. Upon redoing it, I noticed I was getting negative numbers ![]() , so I increased the range 10X. I also cleaned the com off with Scotchbrite this time before testing. Still seems like a relatively hot arm for these things compared to the stock examples I have here. Here's a shot of the thing...like I said, it's pretty danged messy but seems to meter OK:

, so I increased the range 10X. I also cleaned the com off with Scotchbrite this time before testing. Still seems like a relatively hot arm for these things compared to the stock examples I have here. Here's a shot of the thing...like I said, it's pretty danged messy but seems to meter OK:

Posted 16 October 2013 - 06:15 PM

Posted 16 October 2013 - 06:31 PM

Posted 16 October 2013 - 07:04 PM

Hi John,

The arm blank was coated and the coils were epoxied. The wire ends have been soldered with 5% silver solder...and I have no idea if the thing will work ![]() The rest is up to you, but I have a question. The article says he did a second arm with only around 125 Turns of the same wire as a drag arm and you asked for that one too...that sounds like it's going to be PDH (pretty danged hot)...you still want that?

The rest is up to you, but I have a question. The article says he did a second arm with only around 125 Turns of the same wire as a drag arm and you asked for that one too...that sounds like it's going to be PDH (pretty danged hot)...you still want that?

-john

PS...I have no way of balancing this thing, even static balancing. Maybe you have a source for that?

PPS...I just saw your message and will do you up the 125 as well.

Posted 16 October 2013 - 07:50 PM

Hats off to you John ! ![]() That is just beauty in miniature !

That is just beauty in miniature ! ![]() great job.

great job.

Posted 19 October 2013 - 03:16 PM

Another one for John. This time I used the stock arm, meaning I took it apart and put it back together again. Like #1, I also powder coated the existing stack after cleaning it all up and did another 200T of #35 wire. I did my best to keep things neat, but that much super skinny wire (I think it's 8 layers per pole or something) makes it all-but-impossible. The stock arm has a much wider winding leg, but is only two lams thick instead of three, so I don't think there's an overall weight difference that matters. Even with the wider legs, this arm came in at a little under the first one, at 3.39 ohms per pole, so it's a bit warmer than the first one. Of course, it's also powder coated and epoxied...but who knows whether it will "turn or burn"?

-john

Posted 19 October 2013 - 06:48 PM

Thanks John...yep, that's a normal-type static balancing setup. Not knowing how straight these shafts are, I'm almost afraid to even mess around making one. There isn't a whole lot of material to remove on these things, and if the shaft is out even a little, it can take removing more material than is there in the first place.

-john

Posted 19 October 2013 - 07:32 PM

John,

I am amazed, a couple days ago, we thought we would not see you till 2014.What kind numbers are you getting before you remove wire from the stock arms?

SJJ

Posted 20 October 2013 - 07:27 AM

Hi John,

I've toyed with the idea of doing HO for a while, but without a suitable clamp for the tiny things, it's a no-go. These pancake arms, being about the same diameter as FT36D lams, are doable because I can clamp those. I guess you could say I've gotten "involved" now, so I'm motivated to make progress. I saw some improvement on the second arm, so that makes me want to do some more as well. These things are so small and fidgety that the amount of work that goes into them is pretty stupid, so these can only ever be a "fun" thing and I'll not be doing a bunch of them for people...that's for sure!

What kind numbers are you getting before you remove wire from the stock arms?

If you mean resistance numbers, I've been getting "around" 8 ohms. I haven't measured the wire length, and don't know what gauge is on there...but it's REALLY thin...like #38??? I doubt I'd be able to remove the wire by simply unwinding it without it breaking, and honestly it wouldn't be worth the effort to me.

-john

Posted 22 October 2013 - 07:22 PM

Posted 24 October 2013 - 07:24 AM

John sent me a bare chassis to be able to test one of these things. So I hooked it up and the arm (200/35) spun up nice................................................................................................................for about two seconds, then it stopped and smoked. Opening it up for the post-mortem, one of the brushes had apparently welded itself to the com. Not the desired outcome for sure, but certainly entertaining! Pretty hard to tell what went wrong, even after the autopsy.

-john

Posted 25 October 2013 - 05:28 AM

Posted 25 October 2013 - 06:30 AM

Hi Mark,

I'm pretty sure the problem has nothing to do with the wind spec. The way these things go, you just epoxy the commutator on top of the stack. Problem is, the three poles would have to be the exact same height to wind up with the com spinning true. With the com moving up and down really fast as it spins, there's no way to get it to stay in contact with the brushes. The only answer is to rig a com-spacer for it to rest on, and the hole in the com is larger than the shaft anyway.

-john

Posted 26 October 2013 - 07:25 AM

More info. John installed one of the arms and says it spun up real strong, so the 200T/#35 wind spec seems to be a good one for these. I'm more and more convinced that finding a way to set the com "true" is where the problem lies.

-john

Posted 27 October 2013 - 06:36 AM

The tjets have taps under chassis to ajust brush tension againest com, later AFX had springs . John do you think problem worse then that? See the shaft in post 111 longer Then shaft in 105. This part of shaft needs to go though top plate & hold drive gear.Is it short because of three lams?

Realy spins strong , Don`t know what the 125 wind would do.

Thanks again SJJ

Posted 27 October 2013 - 12:30 PM

Hi John,

Got another one done and the epoxy is curing. Using the stock stack, I took it "down" to 190 turns, and it's a lot flatter and neater, so I think it will be a better fit in the chassis/motor thing...not much taller than stock.

-john

Posted 02 November 2013 - 08:42 AM

Two more "pancakes" for John Falzarano and I'm making some progress. They're still not where I'd like them to be as far as neatness goes, but they meter nicely. The left one uses the stock armature blank and has been powder coated, the right one is the stock arm blank with the stock coating (seems like some sort of lacquer or other paint). The stock arm blank produces flatter coils than using the 36D lams, so I prefer it from a winding standpoint. When you're doing around 200 turns of very thin wire, it's hard enough to tension the wire and keep things fairly neat without worrying about the shape of the coils. I "think" that adding a third lam to the bottom of the stack might work, but these two-lam arms are nice to work on. I think these will run very nicely!

...I have another one clamped-up and ready to roll, now that I'm fairly set on patterning.

-john

Posted 02 November 2013 - 12:30 PM

Wow the powder coat one looks great. What parts you need for testing? What did they OHM at?

LUCKY ME Thanks John F

Posted 02 November 2013 - 01:30 PM

Hi John,

I actually like using the stock coating best. I tried both the different powders I have and both produced a too-heavy coating for some reason. Anyway, they both meter at a little over 3 ohms, with the non-powder coated one being almost dead-nuts-perfect from pole-to-pole, and a little more variation on the powder coated one. I doubt these arms need to powder anyway, and neater is better most often with these things. The last one I have chucked up right now will be "special". ![]()

-john

Posted 03 November 2013 - 10:23 AM

Before I go out to tackle the leaves...again, I did up the third in this group of pancake arms. This one should be more of a drag-type wind. Things are still improving here as I figure out how to approach these tiny-and-bizarre stacks. Anywho, this shouldn't quite "dim the lights in Fresno", but it should be pretty exciting!

-john