Super sweeeet ! If it didn't have the "H" emblem, they would never know what hit 'em ![]()

![]()

Good to know I'm not the only addict working on hobbies this Christmas Eve ![]()

Posted 24 December 2013 - 10:43 AM

Super sweeeet ! If it didn't have the "H" emblem, they would never know what hit 'em ![]()

![]()

Good to know I'm not the only addict working on hobbies this Christmas Eve ![]()

Paul Wolcott

Posted 24 December 2013 - 10:54 AM

Posted 24 December 2013 - 11:01 AM

Thanks Pablo. I figure that people who run vintage 1/32 F1's (or 1/24 for that matter) need motors too!

Good to know I'm not the only addict working on hobbies this Christmas Eve

Well, technically, the motor was done this past Sunday and I just didn't get around to posting pictures ![]() OTOH...I AM working on another motor anyway

OTOH...I AM working on another motor anyway ![]()

-john

Posted 24 December 2013 - 01:03 PM

Posted 24 December 2013 - 02:48 PM

Those motors seem to be a good deal for doing things with Paul. I don't think you can go wrong with them, as they're close enough to the older FT16D motors to be useful, and have some good upgrades.

Another motor John? Sweeeeet

just one sweet mill after anothe

I'm thinking about testing the eBay waters with this one and the white FT16D "tribute motor" when the arm comes back from grinding/balancing Paul. I've never put anything up on there and have no idea what that would be like...maybe???

-john

Posted 24 December 2013 - 11:17 PM

Posted 25 December 2013 - 10:07 AM

John...I know I would definitely be watching and bidding on anything you did on ebay...as far as Mura, Champion, and Mabuchi wise that is...(depending on the amount of "expendable income" available at that time, of course ![]() )

)

Tom Hemmes

Insert witty phrase here...

Posted 26 December 2013 - 12:35 AM

Nice 'lil red' John... ![]()

(no...it wasn't me who scorched the end bell!)

I am of the belief that ... that is not a scorch ... IMO, when the leads were put on at the factory the rosin flux was not cleaned off and 'attacks' the 'plastic' over time.

Mr. H - What springs are you using?

Posted 26 December 2013 - 08:34 AM

Mr. H - What springs are you using?

On the motors I try and keep as "vintage" as possible, I use the stock springs with the standard extra bends that we did back then Bob. For me, that meant bending the short leg so it sat parallel to the end of the brush (perpendicular to the brush body), and an extra bend to the long leg for more tension. On the "13" in particular, I don't like to go with heavy(er) springs because the brushes on that model seemed particularly soft. Heavier springs eat up those brushes fast.

The other thing about the "13" in particular is that the brush spring retainer tabs are on the top of the brush hoods...so they use an odd tall coil (like 5 coils maybe?) so that the long leg winds up on top. The "13" got actual metal brush hoods that are functionally the equivalent of the arrangement that is still in use today, a pretty neat thing if you think about it. Too bad Mabuchi didn't realize what they had there ![]()

-john

Posted 15 January 2014 - 09:07 AM

...my fingers hurt.

-john

Posted 16 January 2014 - 02:22 PM

It's been a while (quite a while!) since I've done one of the old Champion .005" lam arms and just got one in for winding the other day. For a lam with a fairly thick "winding leg", these are awfully nice to wind. Unlike the old Mura .007" lam that has a bunch of wasted space nearest the shaft AND a thick "crown" making winding difficult, these are MUCH more winder-friendly. It sure would be nice to have a couple of rods of these babies, although assembling the stacks is probably pretty fiddly. ![]()

-john

Posted 22 February 2014 - 02:03 PM

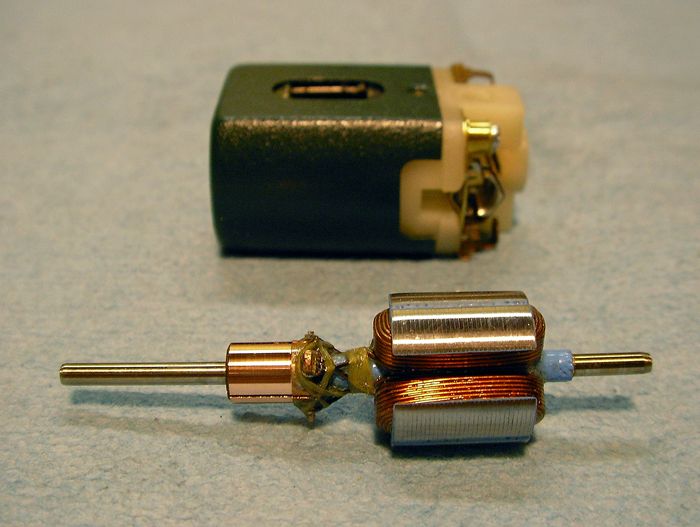

I figured I'd post this up here because this is a special build. I wanted to go all out on an FT16D...or at least the Champion version. So, after a whole bunch of work I got this:

For the arm, I did a #27 (again because that's as hot as I want to go with these), and at .184 ohms (exactly per all three poles) the arm will be a real monster. Of course, it got a Bugenis com and as neat and a consistent a wind as I can manage:

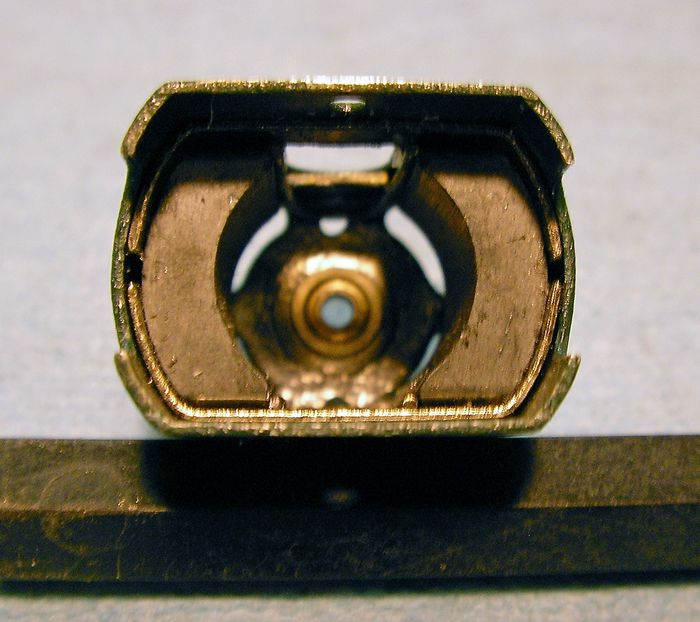

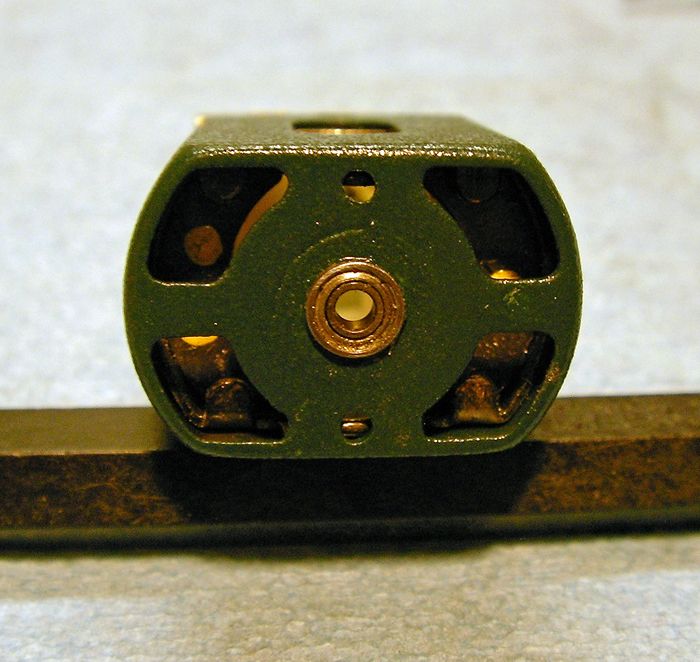

The can was one of the one-hole Champion black jobs with the ginormous bushing. I ground the bushing almost flush with the outside of the can, trimmed it down some on the inside and soldered it into place. After that, I reamed it out for a 2mm x 5mm quality bearing and soldered that into it's new home, neutralizing the acid afterwards with a good baking soda wash down. Last before paint, I flattened-down the top and bottom of the can with a piece of sandpaper stuck onto my glass table top. The Champion cans (as nice as they are) aren't quite as nicely formed as the Mabuchis. It then got a nice heavy coat of "Textured Black" paint after masking the bearing. To finish the can up, I installed a pair of the Champion "semi-can" or "split-can" shims. These are a very good way to install c-can-sized magnets into a D motor. There are other ways, but if you can find these...they make life a whole lot easier! To complete the can, I installed a fresh (NOS) pair of "Yellow Dot" magnets. After installation, these magnets measure a very healthy 1200 on my meter...this is gonna be good!

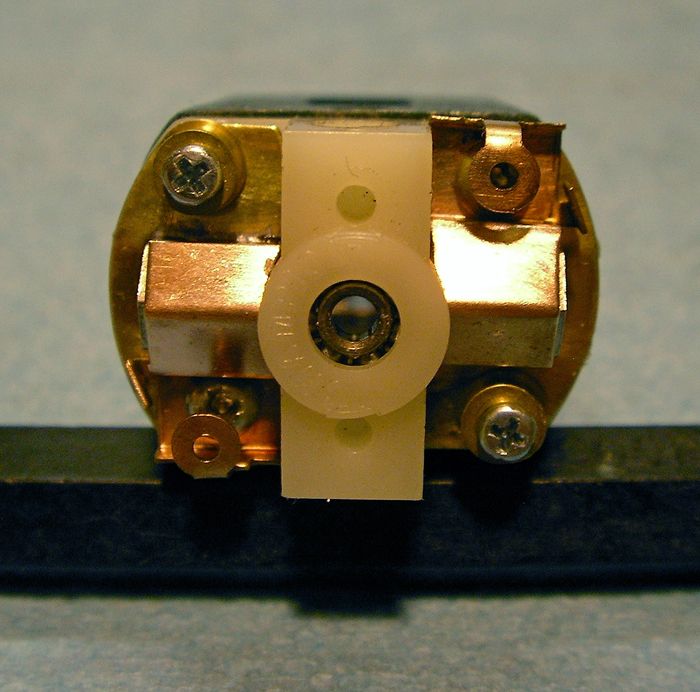

Of course, this left me with a whole bunch of work to do on the end bell, which is typically the weakest link in the chain. I started off with a Champion end bell, having better ventilation and clearances, as well as being molded from a somewhat better material than the Mabuchi. The Champion also allows for the (somewhat tedious) installation of a good quality modern bearing, with it's bigger/beefier bushing pocket. I sleeved a 2mm x 6mm bearing with brass tubing, then took that down (the bearing's flange as well as the tubing's O.D.) until it was a "snap-fit" into the Champion's bushing pocket and cut off the extra brass flush to the interior of the bearing's outer race. Having done this many times before, it hasn't gotten much easier, but at least I have "a plan" that works consistently for what is a pretty fiddly procedure.

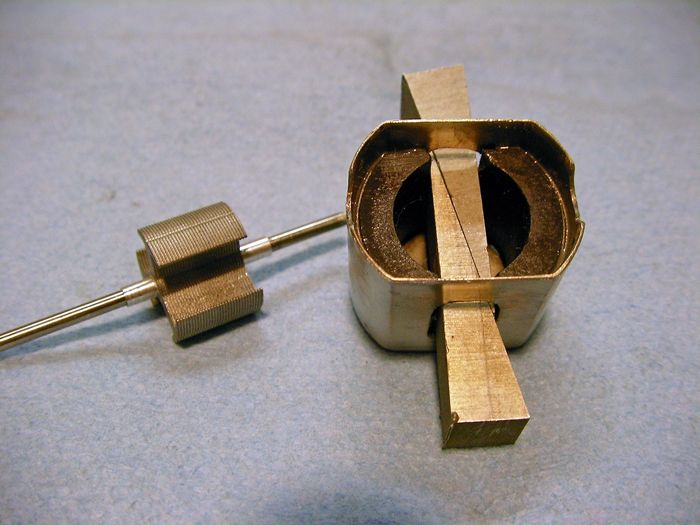

On the outside of the end bell, I soldered a pair of FT36D brush tubes ("heat sinks") to a pair of modified (for spacing) "bulletproofing" plates. This seems much better than soldering them to the hoods to me, and the entire assembly would have to reach the melting point of solder before things started getting ugly ![]() To make sure these are secure, I cut down the molded spring posts somewhat and capped them with a pair of inverted Mura spring cups...drilling through the molded spring posts and securing it all with a pair of #0 tapping screws and an armature washer. At the other end of both sides of the end bell, I installed a pair of FT36D hoods, trimmed slightly to fit. Their larger surface area should help dissipate any heat a little better than the smaller FT16D-sized hoods (although either can be made to fit the larger brush tubes). Screwing the hoods down also screws down the other side of the bulletproofing plates, so both the top and bottom of the hardware is secured to the end bell. This all represents a bunch of eye-squinting and fiddling, plus a bit of finger-burning, but I think it's worth it for a unique and very functional end bell that (except for the Mura cups) is all-vintage:

To make sure these are secure, I cut down the molded spring posts somewhat and capped them with a pair of inverted Mura spring cups...drilling through the molded spring posts and securing it all with a pair of #0 tapping screws and an armature washer. At the other end of both sides of the end bell, I installed a pair of FT36D hoods, trimmed slightly to fit. Their larger surface area should help dissipate any heat a little better than the smaller FT16D-sized hoods (although either can be made to fit the larger brush tubes). Screwing the hoods down also screws down the other side of the bulletproofing plates, so both the top and bottom of the hardware is secured to the end bell. This all represents a bunch of eye-squinting and fiddling, plus a bit of finger-burning, but I think it's worth it for a unique and very functional end bell that (except for the Mura cups) is all-vintage:

I really can't think of anything else to be done to the motor...at least nothing functional. It shouldn't really need shunts, but I have a pretty nifty way of installing those if I feel the urge that I've been meaning to try. The arm just needs a light grind and balance, it shows really good "natural balance" as is, so that shouldn't present any drama and like I said, it meters a perfect .184 ohms per pole. For me and what I can do...this is as good as it gets!

-john

Posted 22 February 2014 - 03:04 PM

![]()

![]() Some very kewl mods on that 16D John! Especially the sleeving job on the endbell bearing & the can end treatment...

Some very kewl mods on that 16D John! Especially the sleeving job on the endbell bearing & the can end treatment... ![]() That thing is gonna FLY

That thing is gonna FLY ![]()

Posted 22 February 2014 - 07:21 PM

Thanks Paul ![]() I have no doubt it will be a rocket for sure. I'd be embarrassed to say how many hours are in the motor, so I'll just say..."a LOT". I have a pretty cool FT26D coming down the pike with an interesting twist and I'll post that one up when it gets closer to being done

I have no doubt it will be a rocket for sure. I'd be embarrassed to say how many hours are in the motor, so I'll just say..."a LOT". I have a pretty cool FT26D coming down the pike with an interesting twist and I'll post that one up when it gets closer to being done ![]()

-john

Posted 22 February 2014 - 09:00 PM

Keep up the good work John!

Posted 22 February 2014 - 10:40 PM

Thanks Mike...I'm tryin' ![]()

-john

Posted 22 February 2014 - 10:48 PM

...and the beginning of a very cool 26D. "Something old, something new"

Posted 22 February 2014 - 10:57 PM

![]()

![]() Liking where you're going with this 26D already

Liking where you're going with this 26D already ![]() That stack looks good even at this early stage all naked

That stack looks good even at this early stage all naked ![]()

Posted 23 February 2014 - 08:27 AM

Thanks Paul. See...here's the thing, and some insight into my...er..."thought process". ![]()

- Modern D motor "big diameter" arms are something like .030" smaller than 26D arms (give or take...I don't have the numbers in front of me).

-The Champion 26D Arco shim is "OK" as is, but doesn't do a good job of exactly centering the magnets in the setup. I'll often cut the sides of the shim from the bottom part and install Arcos with two clips instead of the normal one.

-The Mabuchi 26D stack is good, but is relatively thick and heavy, at least compared to more modern designs.

-Using two of the Arco shims (cut apart)...or two per side gets you down to an ID that's appropriate for ...TA DA!...a big diameter modern D motor arm. Of course, the stubby dimensions of the 26D means that you can't just drop a D motor arm into a 26D setup.

-Opening up the top and bottom holes of a 26D can a bit allows the use of "magnet wedges" (really just a small set of "tapers" or "parrallels") to install the Arco magnets. This method is a great way of installing magnets (with epoxy), as it pretty much forces the magnets into the best possible contact with the can and centers them very well.

So, I now have a 26D can with Arcos that will be a perfect fit for a D motor big diameter arm. This is one of those jobs that, when done won't look like I did much (except for the modified can openings for the eagle-eyed), but it's a fair amount of work that I think will be well worth the effort! The newer lams make for a much lighter stack that should spin up and down faster.

-john

Posted 01 March 2014 - 10:34 PM

I like it ,a 26d restomod .

Posted 02 March 2014 - 08:21 AM

Thanks Mark. I don't know what a restomod is, but it sounds cool! ![]()

-john

Posted 02 March 2014 - 08:25 AM

I took a chance on some Mabuchi "FK" sized commercial motors (5) because I got them from a surplus electronics place for like a buck a throw. Inside was an interesting long stack armature (nominal .510" OD on a 2mm shaft) and a set of thin ceramics very much like the Hawks that measure about 1000 on my gaussmeter. I figured at that price, I wouldn't mind tossing them if they were useless. These on the other hand will go into my "interesting parts" bin to show up sometime in future builds. I like when that happens. ![]()

-john

Posted 02 March 2014 - 09:28 AM

Thanks Mark. I don't know what a restomod is, but it sounds cool!

-john

Restomod means you have restored something old, but made it better than the original specs.

Posted 02 March 2014 - 12:16 PM

AH...thanks Jeff! Then again, since the dawn of slot cars (or at least the golden age of slotcars), builders have been doing those restomod things. Good enough has NEVER been good enough! ![]()

-john

Posted 02 March 2014 - 12:25 PM

This is going to be a good flick. ![]()