Guys, here's what she going to be rolling on. Up front, Revell skinny wheels and Goodyear front tires. I at first used some McMaster Carr big o-rings (same as used by Riggen) but I wanted the sidewall detail of the skinny Revell Goodyears:

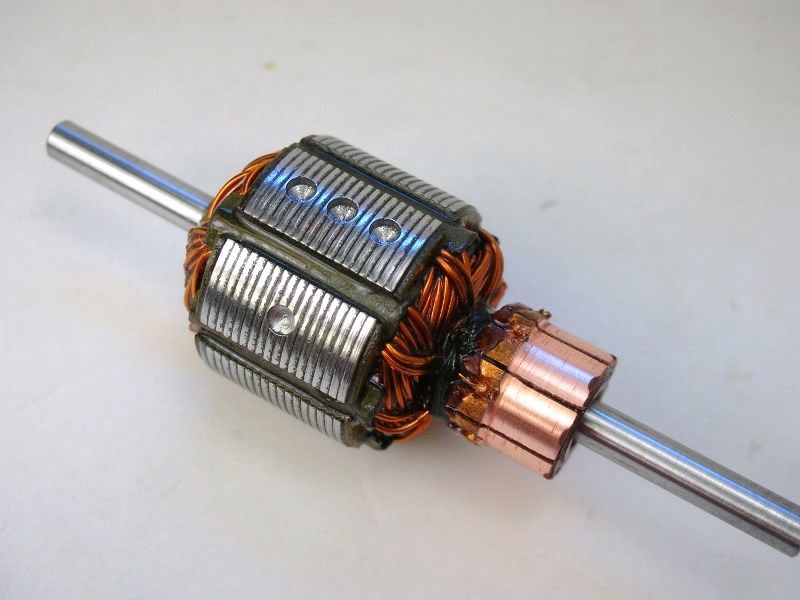

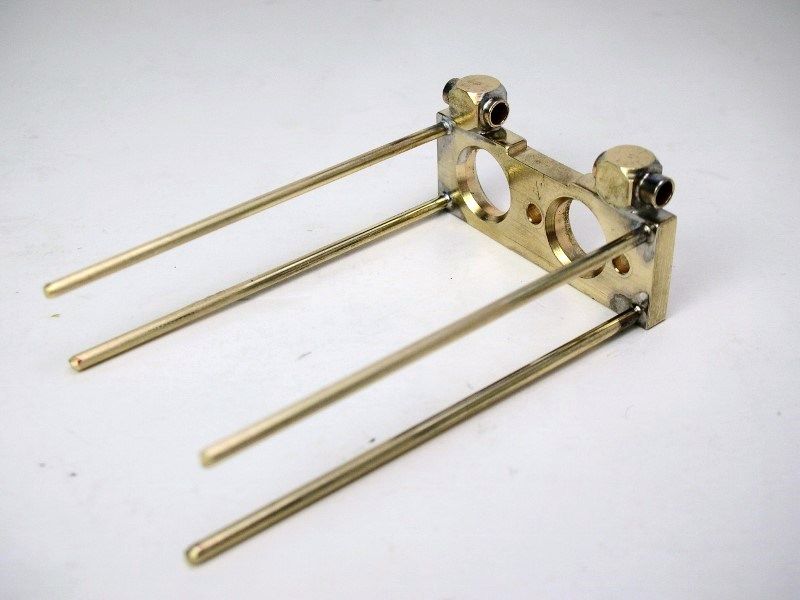

For the rear, I'm using Russkit Dragster set screw wheels and some beautiful MDC silicone drag slicks. The front axle is an unknown (to me) independent rotating job. Unlike the Ulrich version that has the axles staked in place by a few punch marks, this baby has a nice roll crimp all the way around the axle. It doesn't bind when you put a side load on it like an Ulrich:

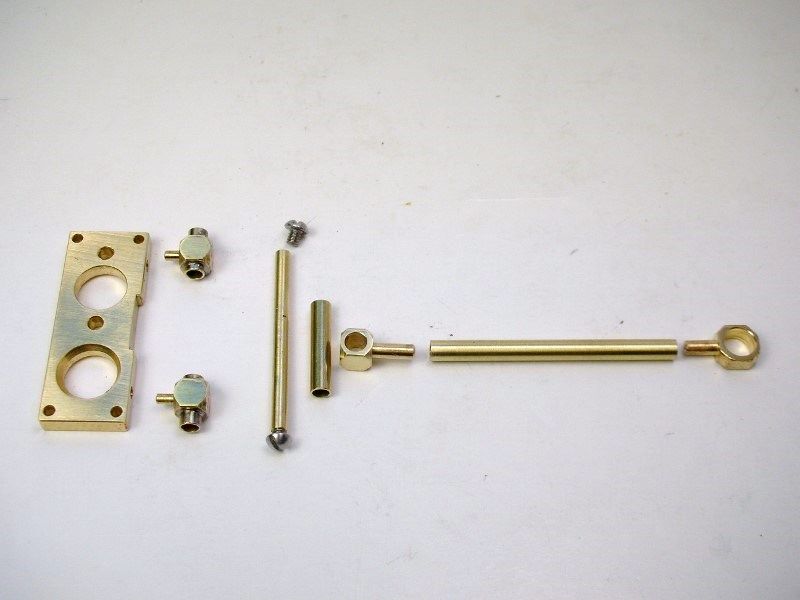

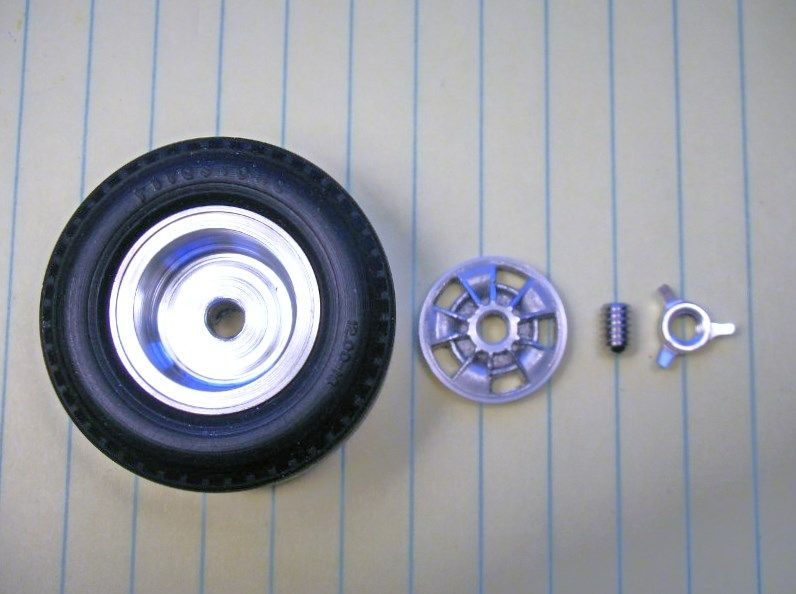

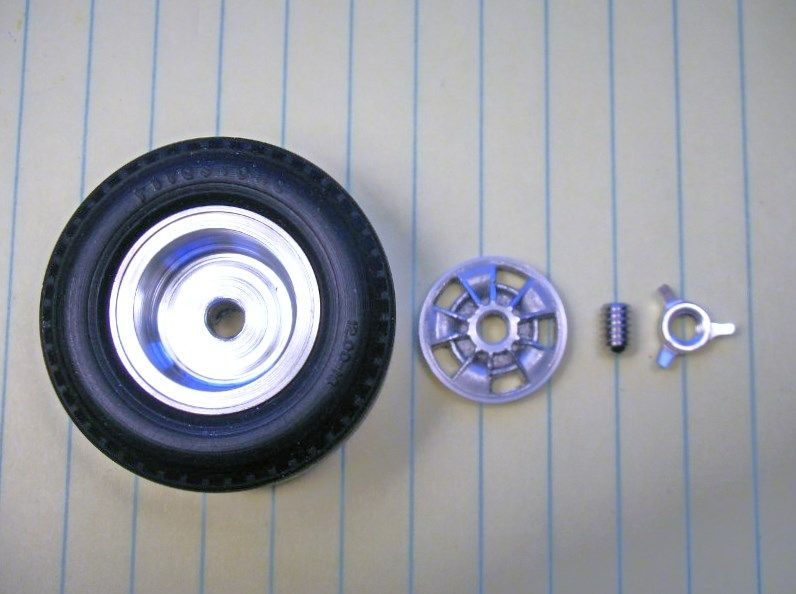

Also using Cox precision flanged axle nuts and 3-prong knockoffs:

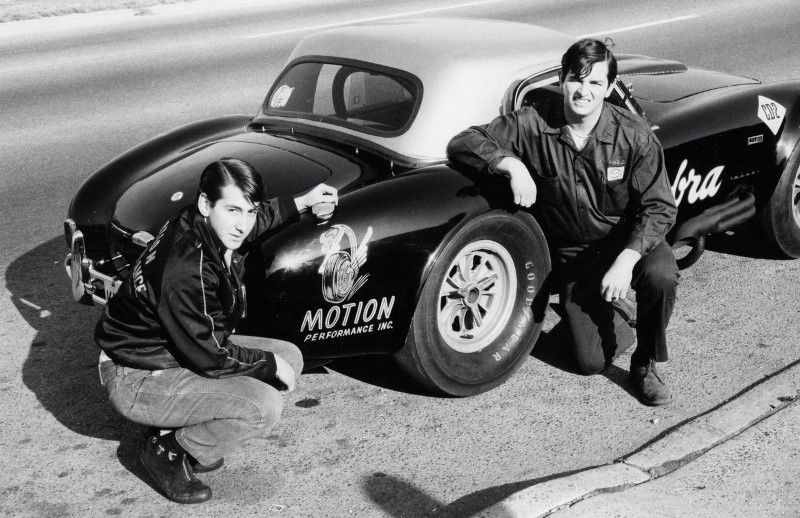

Finally, I wanted to make the wheels look something like these:

The method I use seems to be controversial so others might not like my approach. "Your results may vary"

Personally, I'm really unimpressed with threaded wheels and axles especially when used on the driven axle. I'll go through over a dozen NOS axles before I find one that is only a bit "off". I check them by clamping the axle in a collet in my lathe and spinning it slowly.

Then there are the wheels themselves. I went through 10 pair of NOS skinny Revell front wheels to find 2 that only wobbled a little. The wheels are machined nicely but they dropped the ball when they threaded them. Also if you have to remove a threaded wheel it will never go back on the axle exactly the same.

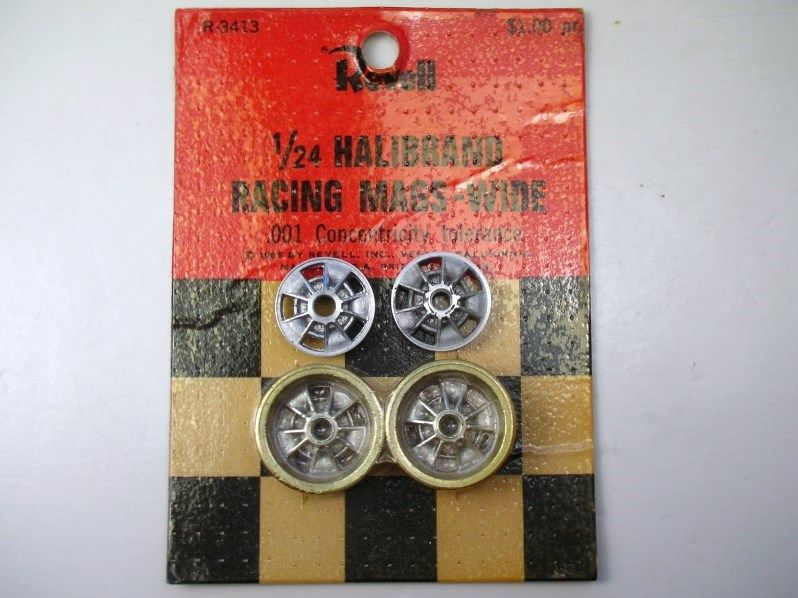

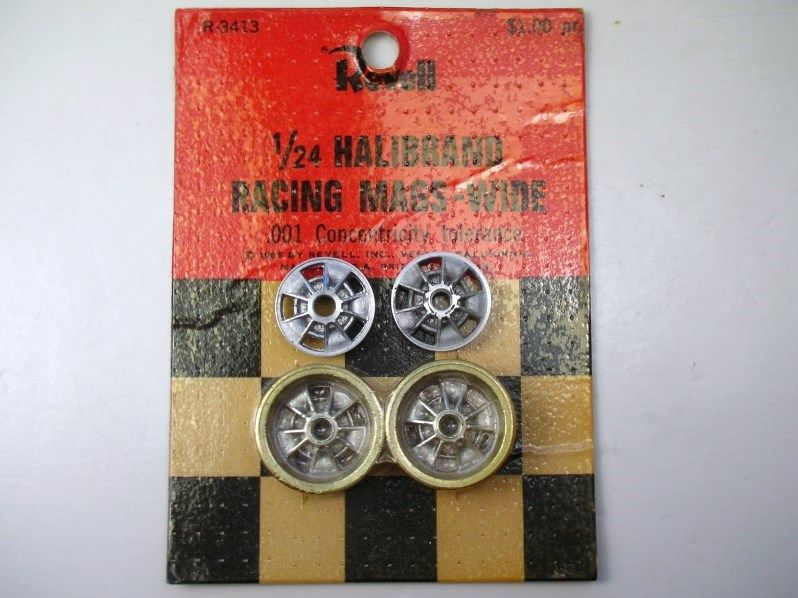

However, I think the die cast threaded "mag" wheels by Cox, Dynamic, Revell and especially Ulrich are truly beautiful to look at:

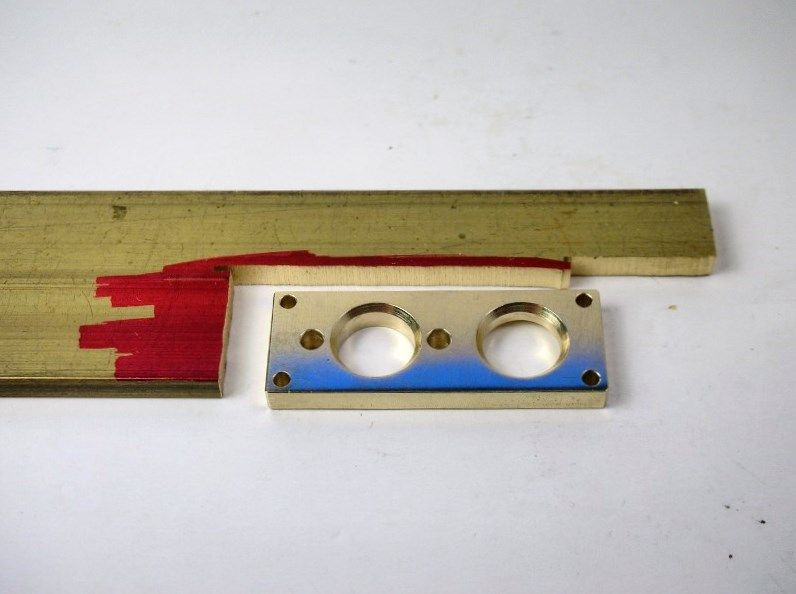

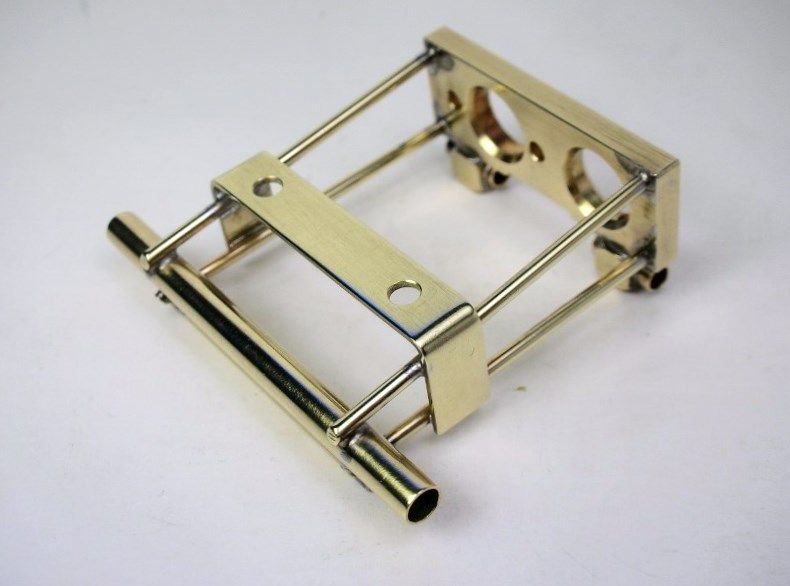

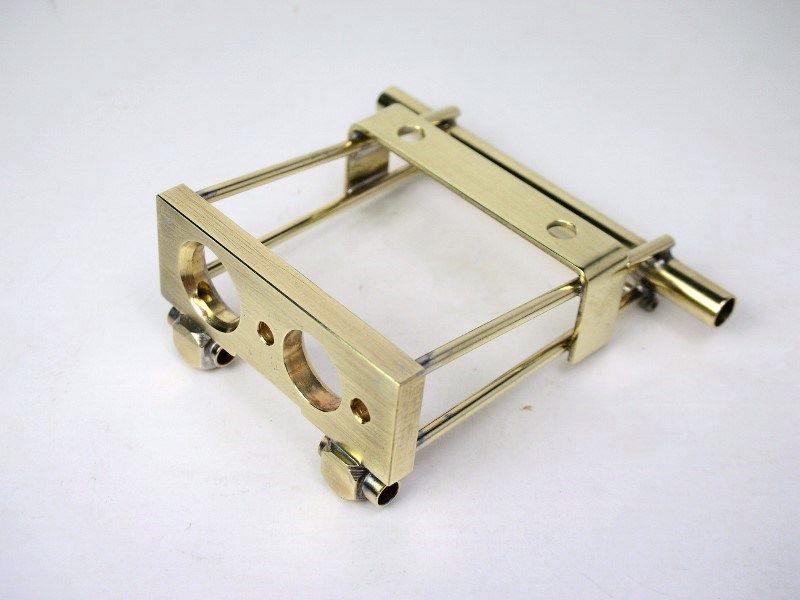

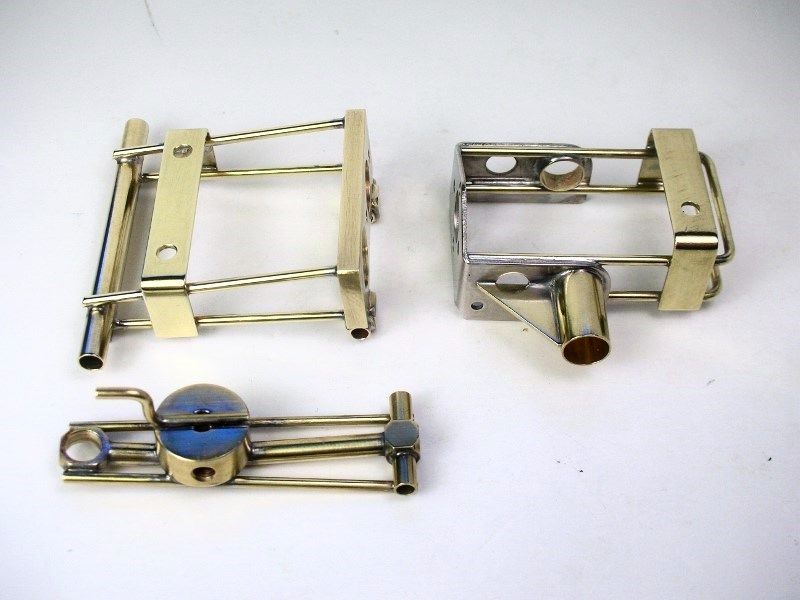

I choose to enhance these wheels by machining off the dreaded threaded mounting system and fitting them into set screw wheels. Now I have the performance of a set screw wheel with appearance of a threaded die cast wheel:

I did the same approach with the skinny Revell front wheels as the cast wheels were way to wide. Check out that MDC drag slick sidewall detail.....NICE!

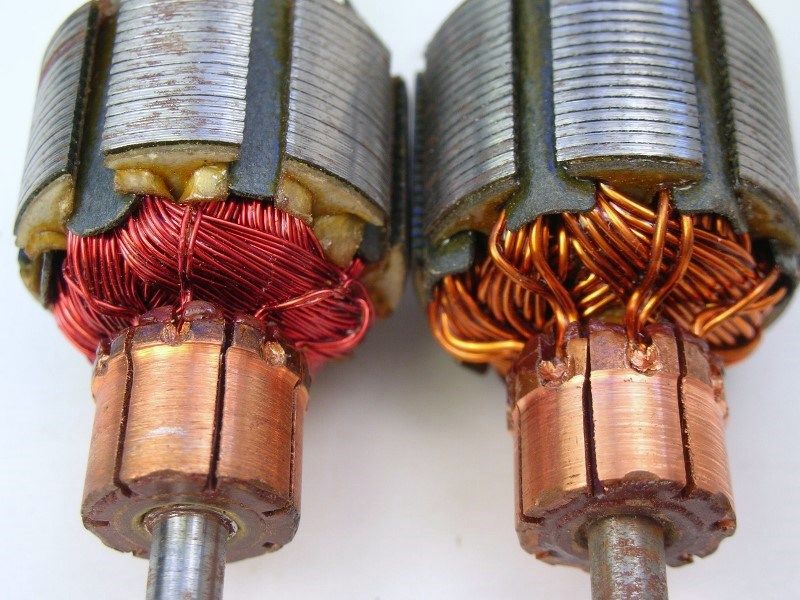

The Russkit drag wheel had to be turned down to a smaller diameter of a scale 15" wheel as shown on the left:

Anyhow, there they are. Everyone is free to do as they please. For me, I think they look really nice and I know they will perform well too.

On to the "anti-wheelie" weights..........

![]()