One Wed night at Modelville, I watched a group of friends casually bombing around the Modelville Fig 8 with a variety of cars, a couple with a pair of Can-Ams, a guy with a sprint car, and another couple with a pair of hardbodies (the woman was driving an AMT '57 BelAir kit), and I thought that might be fun for me and my girlfriend to do... she's a car girl.

I suggested the same, said I'd scratchbuild a car of her choice, and then we went through my boxes of static unfinished static models which - except for a trio of AMY/ERTL Dogde Vipers I bought in the mid-'90s - have follwed me around since the late '70s or so.

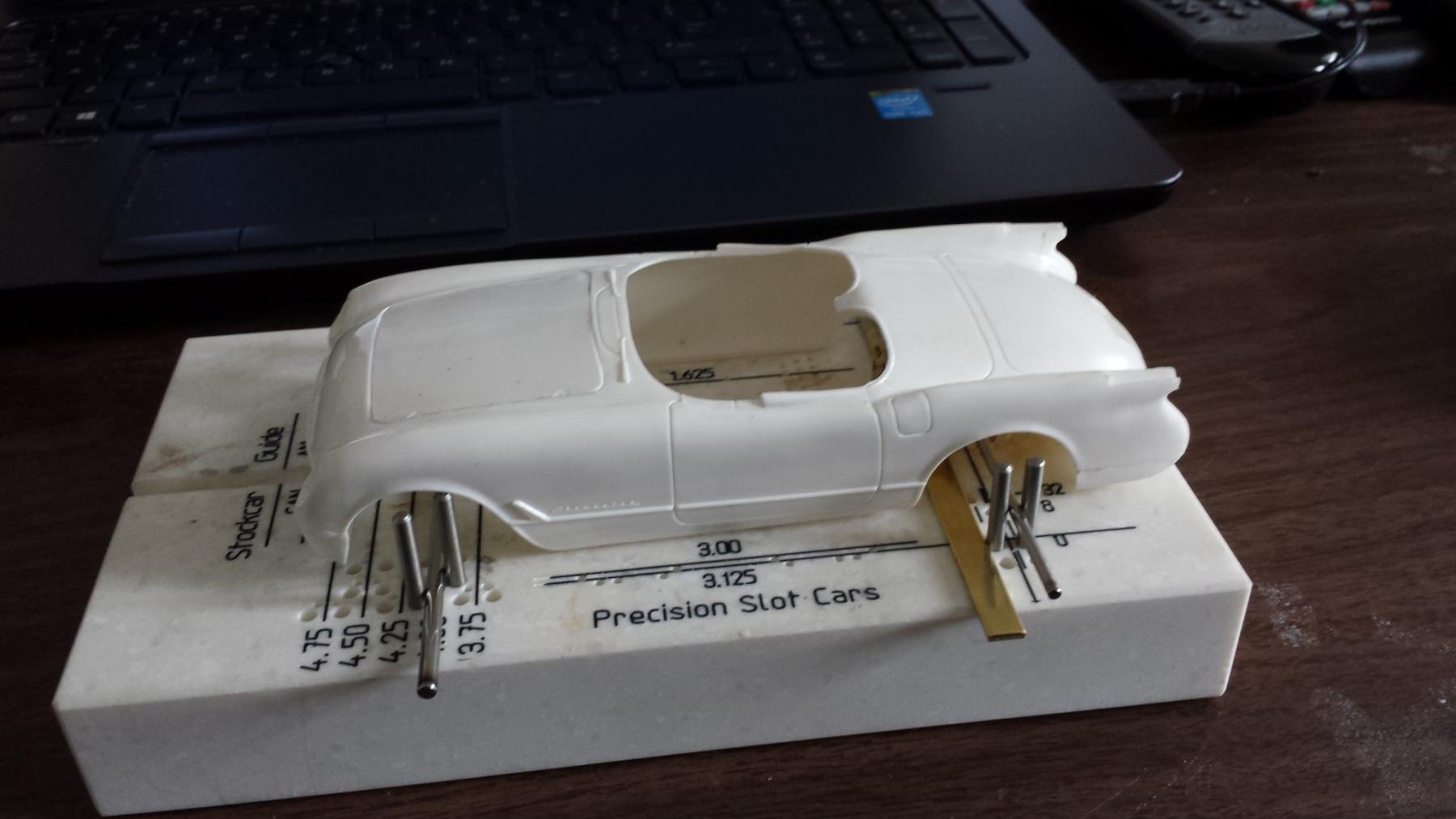

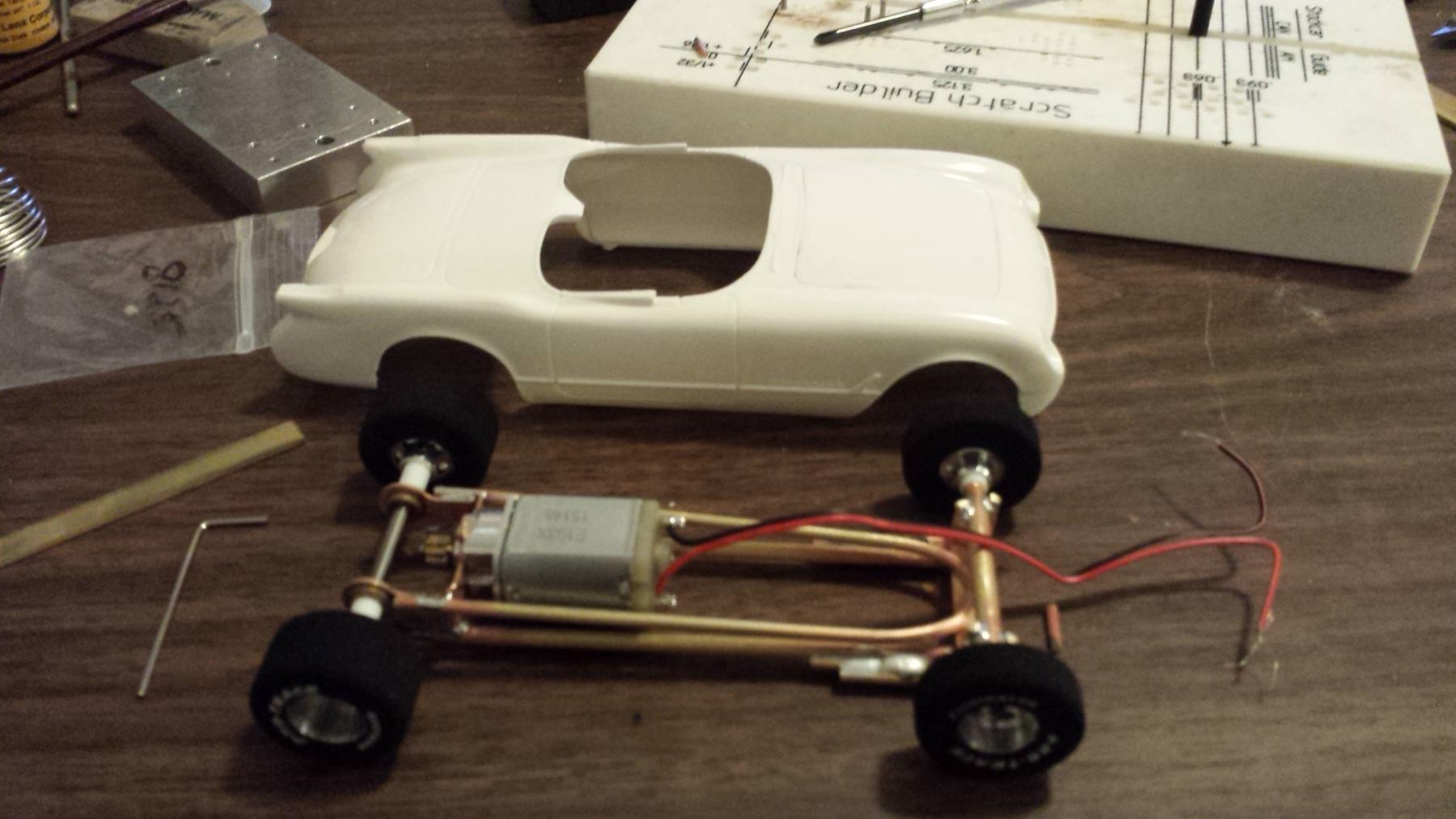

For her car, Pam picked out an AMT 1953 Corvette, which she deemed shall be pink, with a white convertible top.

So, over the course of this past weekend (including Friday off) I had some fun fabricating my very first scratchbuilt 1/24 chassis.

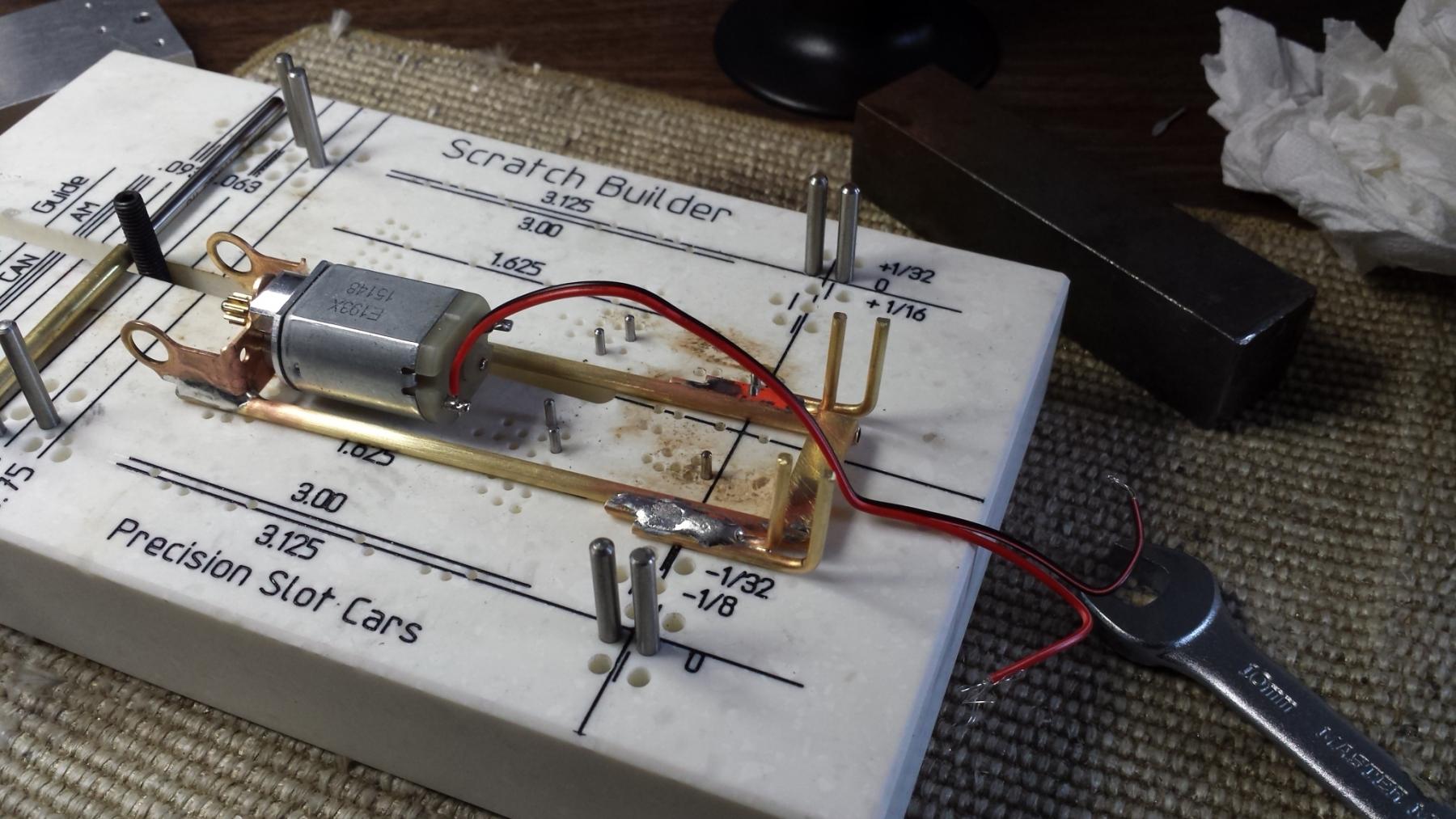

Initially on the jig, setting wheelbase.

Once upon a time, I thought I'd go utterly hardcore and fabricate my own motor brackets, but then I realized that was a stupid idea... for now.

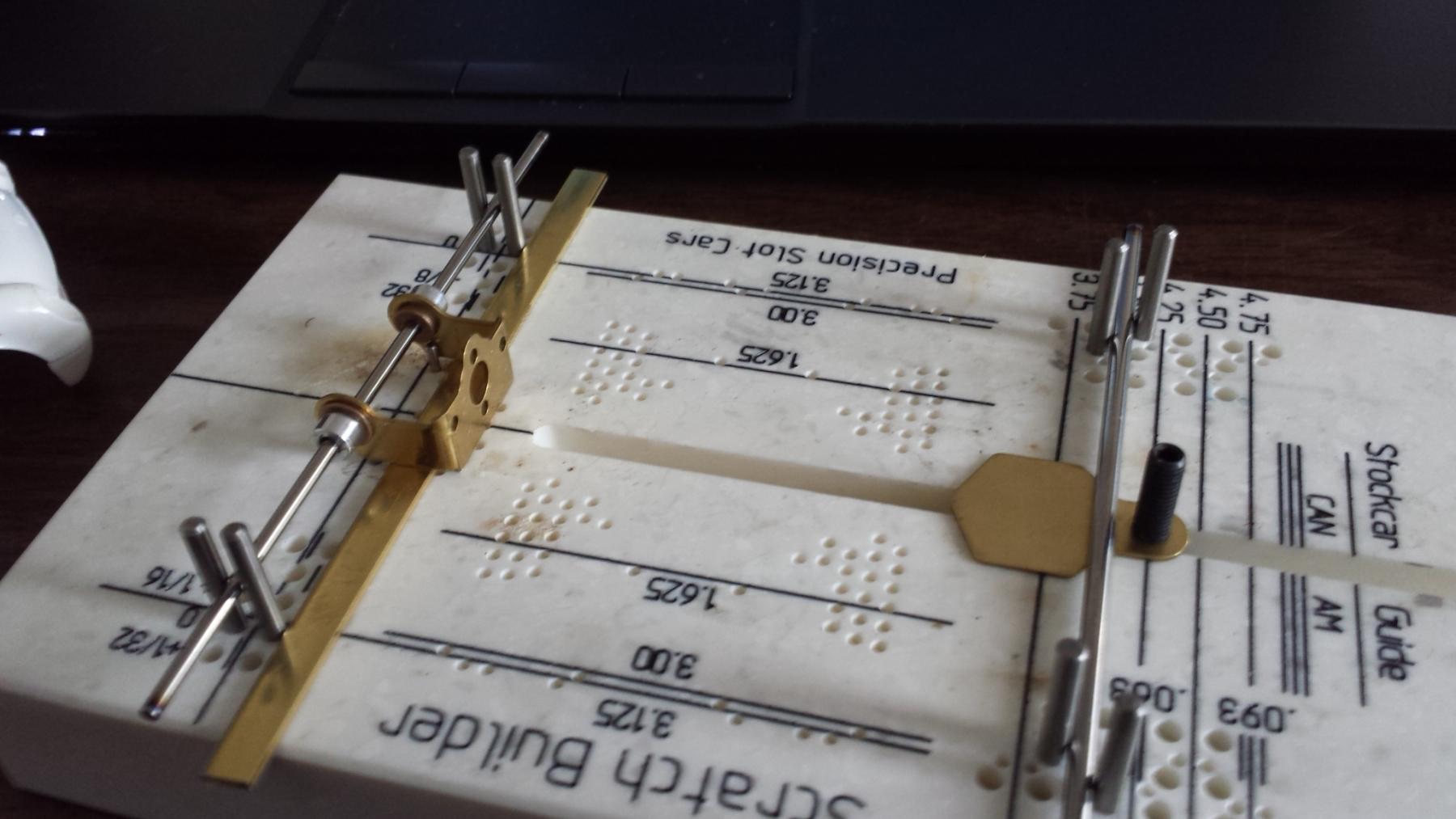

Thus I bought several, with holes for the usual 1/8" x .25" oilite. Because my jig came with pin spacing for 3/32" axles, I bought some 3/32" x .25" oilites to set rear axle position. Fortunately, I was able to find a pin spacing that accomodated a 1/8" jig axle at the front.

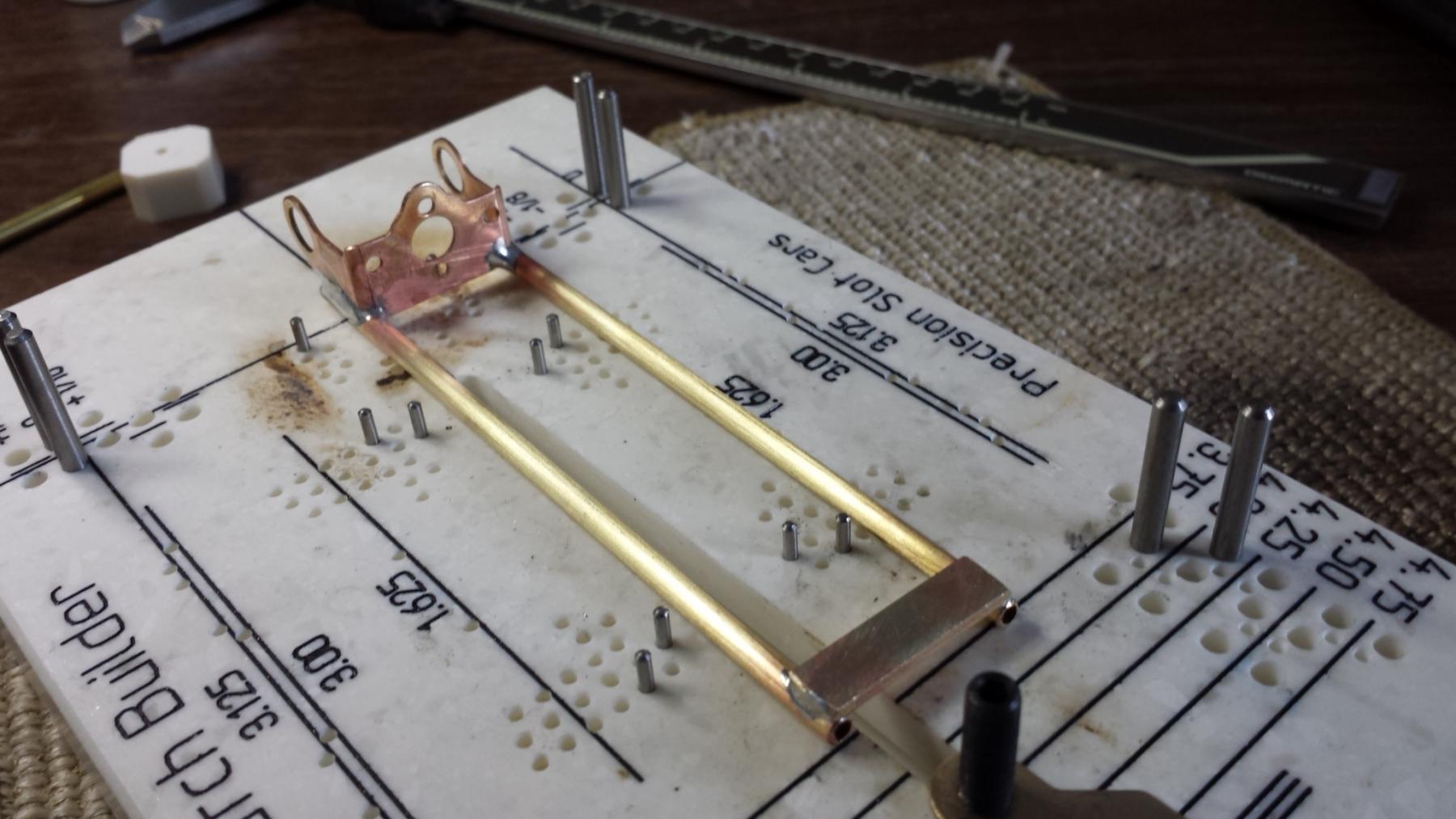

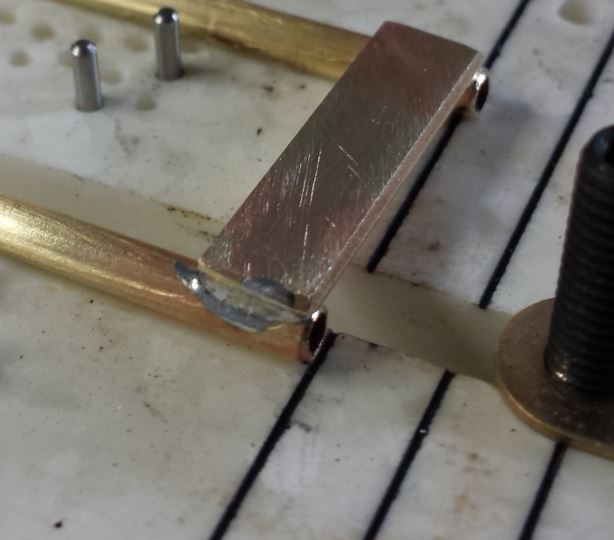

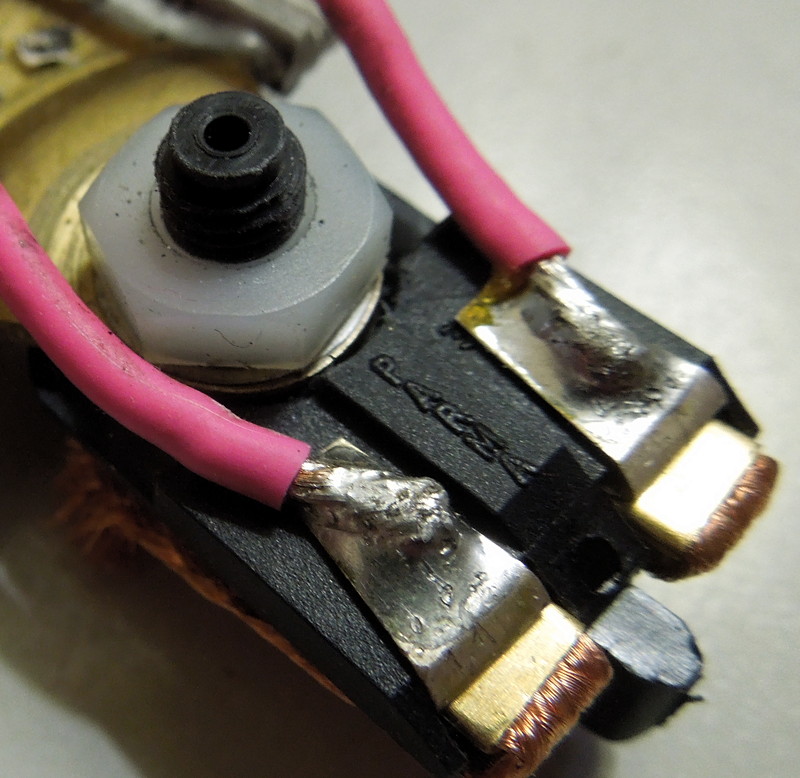

I cut some main rails of .125" brass tube, massaged the bracket corners to fit, set up the pins on the jig to hold the tube in place, did my base metal prep, fired up the microtorch, and was not displeased with the results. A short bar of .25" x .065" was added at the front to close the rectangle.

On this build, I tossed the Lenk 50/50 solder in favor of the Stay Brite silver solder, and I find I like it. I still apply too much in places but I'm getting better at that... I think.

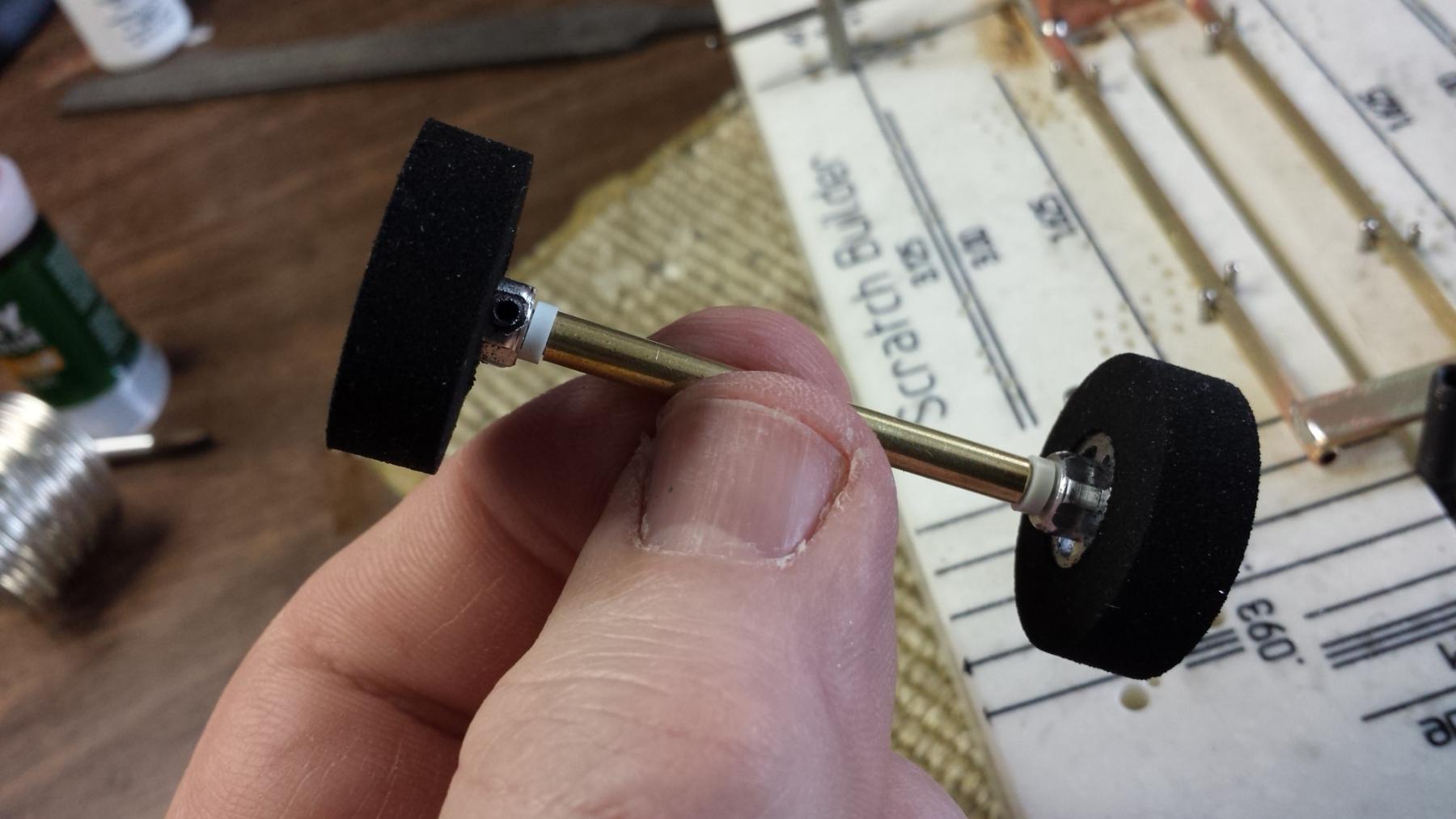

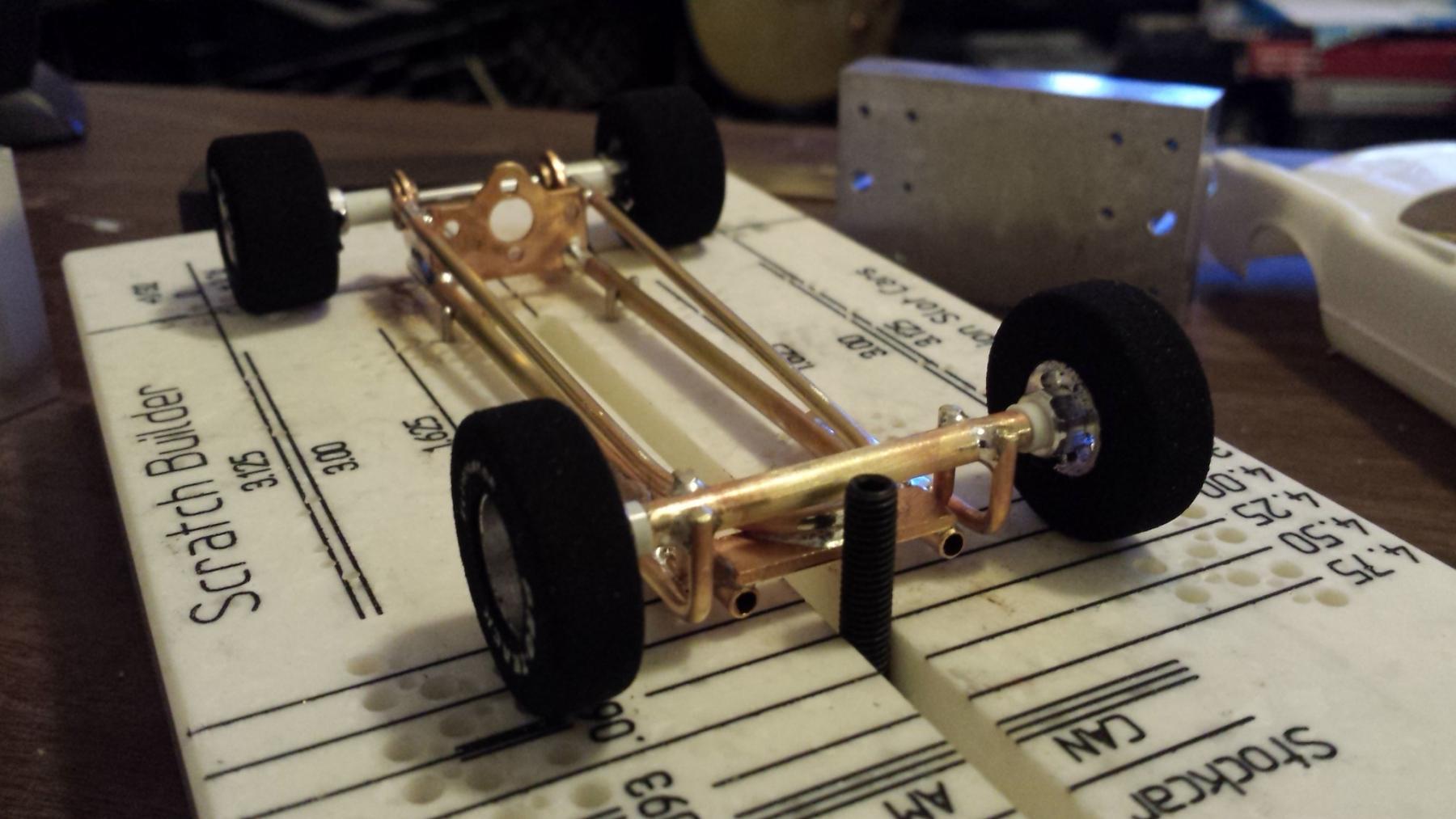

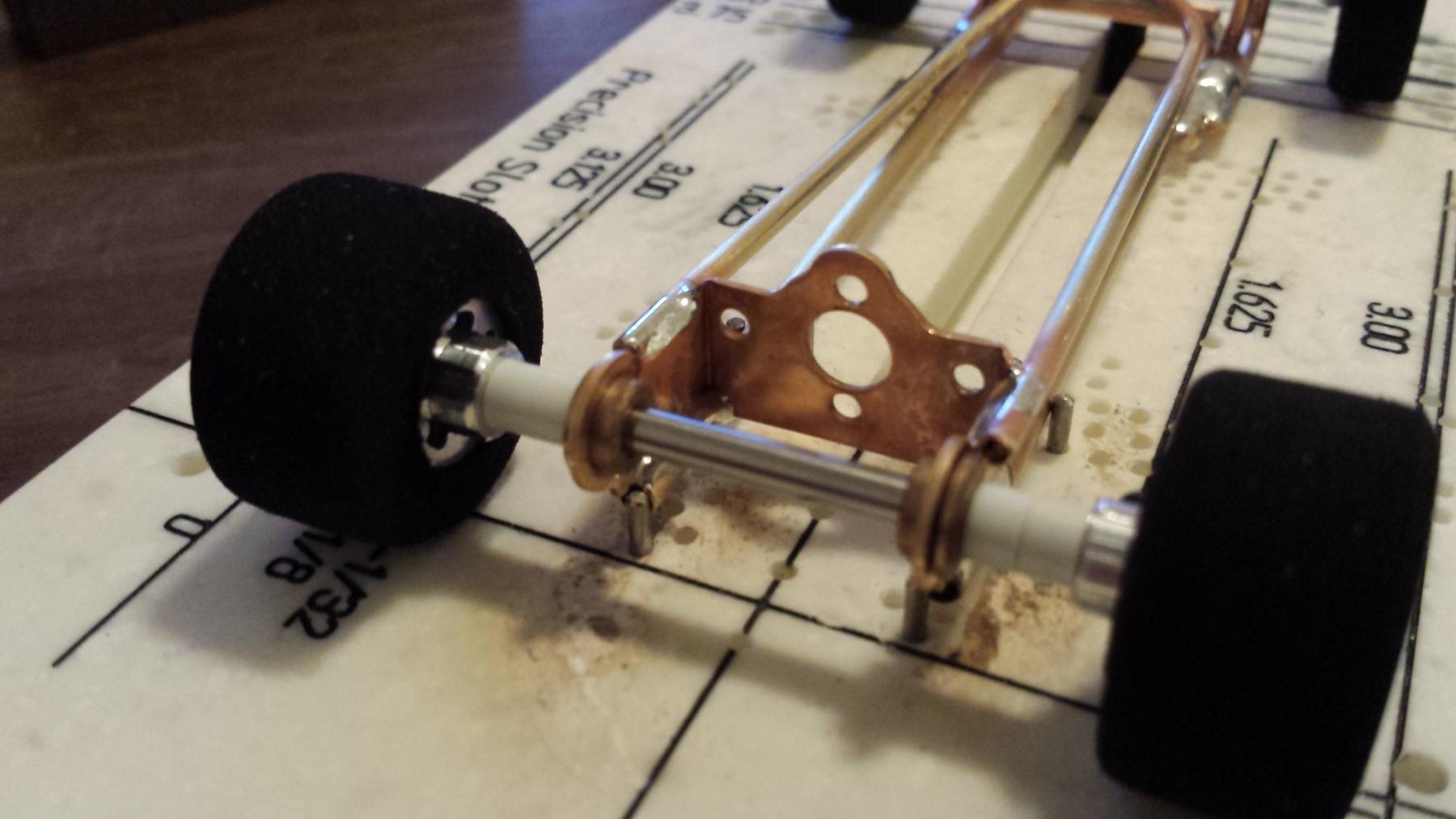

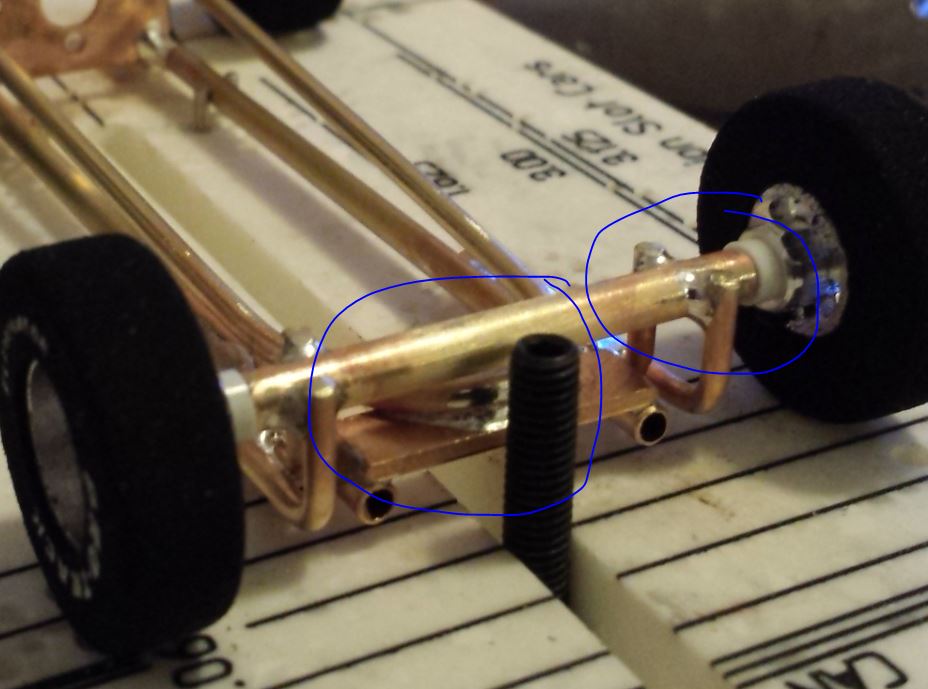

Next I fabricated the front axle tube of 5/32", to accept an 1/8" axle. Front tires are Pro-Track .980" x .300" wide drag rears, with the edges rounded.

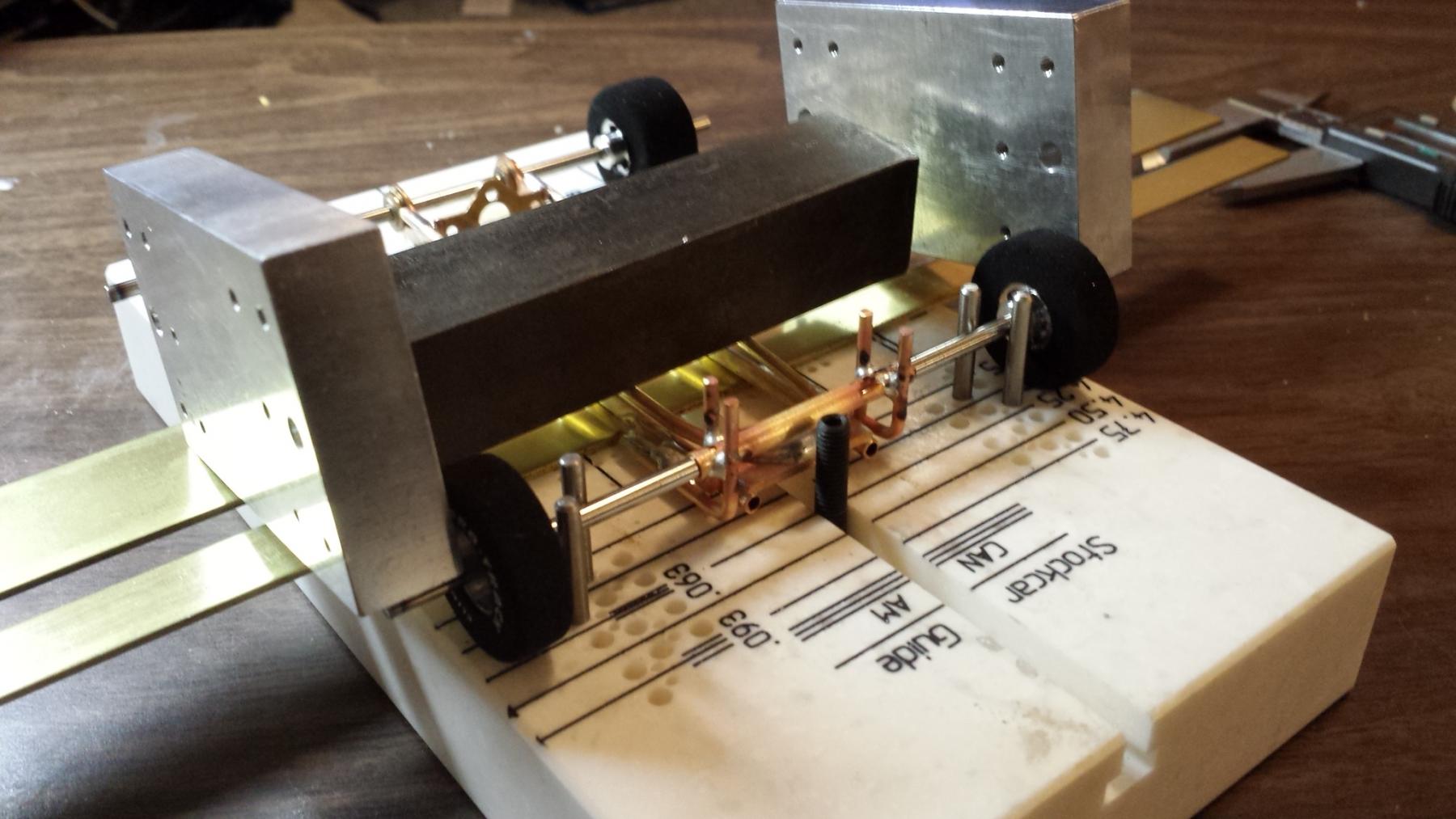

With the rear tires on (Pro-Track .950"x .800" wide) the chassis sits at a just-right .063" off of the track surface.

Front axle mount - bent-up .063" brass rod - soldering setup, "drivers" side...

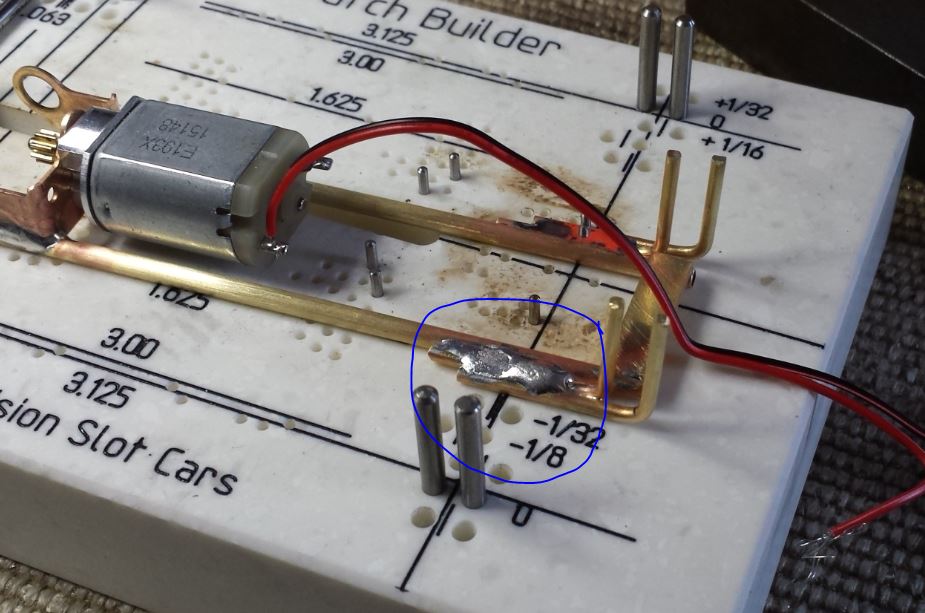

And the result, after minor tweaking of vertical element straightness, including first check fit of the motor, which in this case is the original AMT motor/endbell set up from the Catalina.

Lastly, I added the frame bracing, with a piece of finger-bent 3/32" tube...

... And that, it seemed, was good enough for Friday.