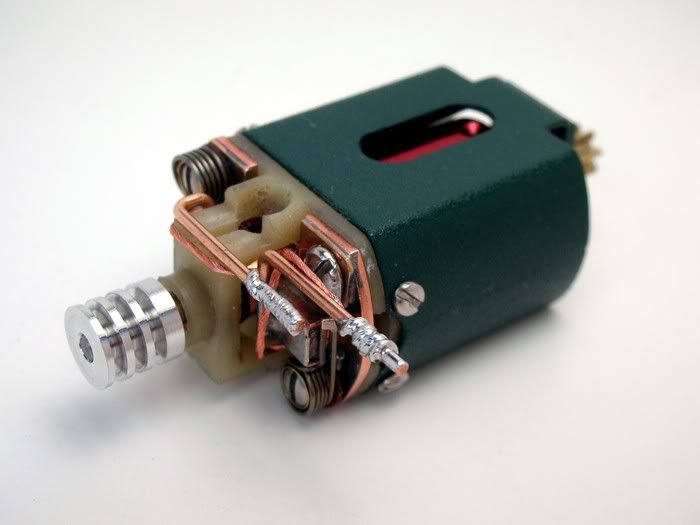

I've been drilling the end bell mounting holes in motors like the Associated C-can below with a hand drill and "eye balling" the angle for years:

Most of the time it turns out OK but sometimes I'll goof and the angle is wrong. Then the screw head doesn't sit flat against the can....AND I HATE THAT!

What to do..........A NEW TOY FOR RETIREMENT!

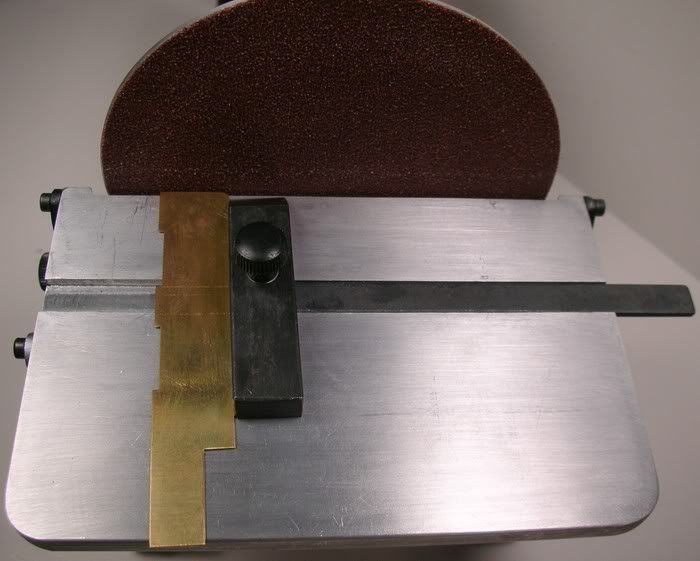

I found an adjustable angle block goodie on eBay. There are many sellers and the prices and shipping cost vary widely. Here's the picture from one seller's auction:

Here's my gizmo in the flesh:

OK, so now I can hold the can and end bell at the Korrect angle but I'll need to go out into the garage and use my milling machine to drill the holes..........

But I don't want to go out there. It's too hot, it's too cold, I don't want to put on shoes..........wha wha wha. What to do? A NEW TOY FOR RETIREMENT!

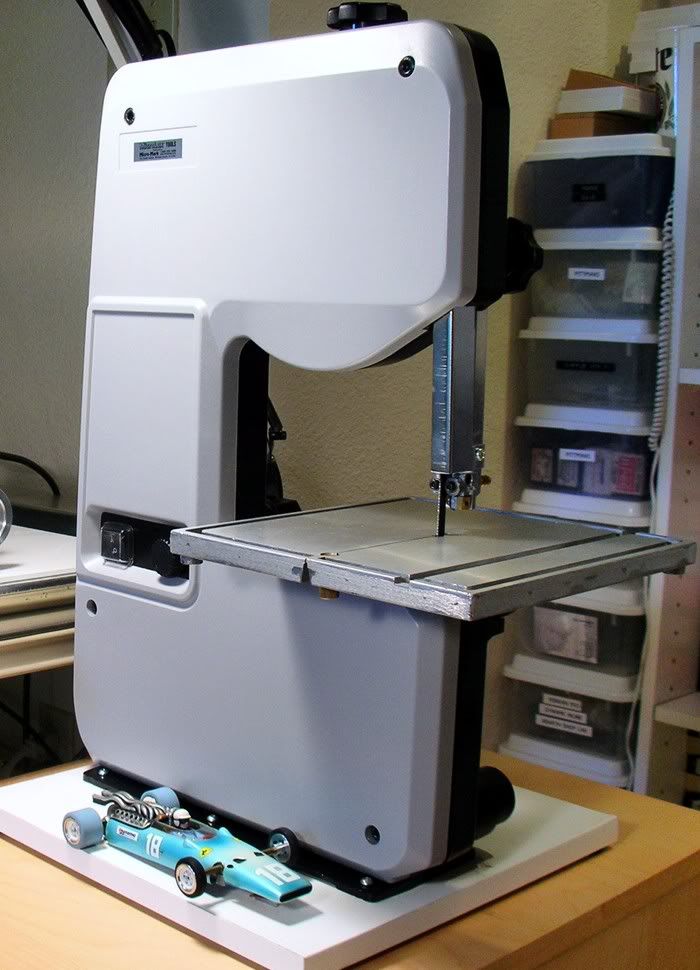

How about a super small and light drill press for about $80 with turn of a knob variable speed? Ebay to the rescue. Here's the sellers picture from his auction:

There must be a dozen different sellers selling this "mini drill press". Prices are all over the map but I like this green one so I paid to much for it ![]()

![]()

Here's my baby with a brewski next to it for scale:

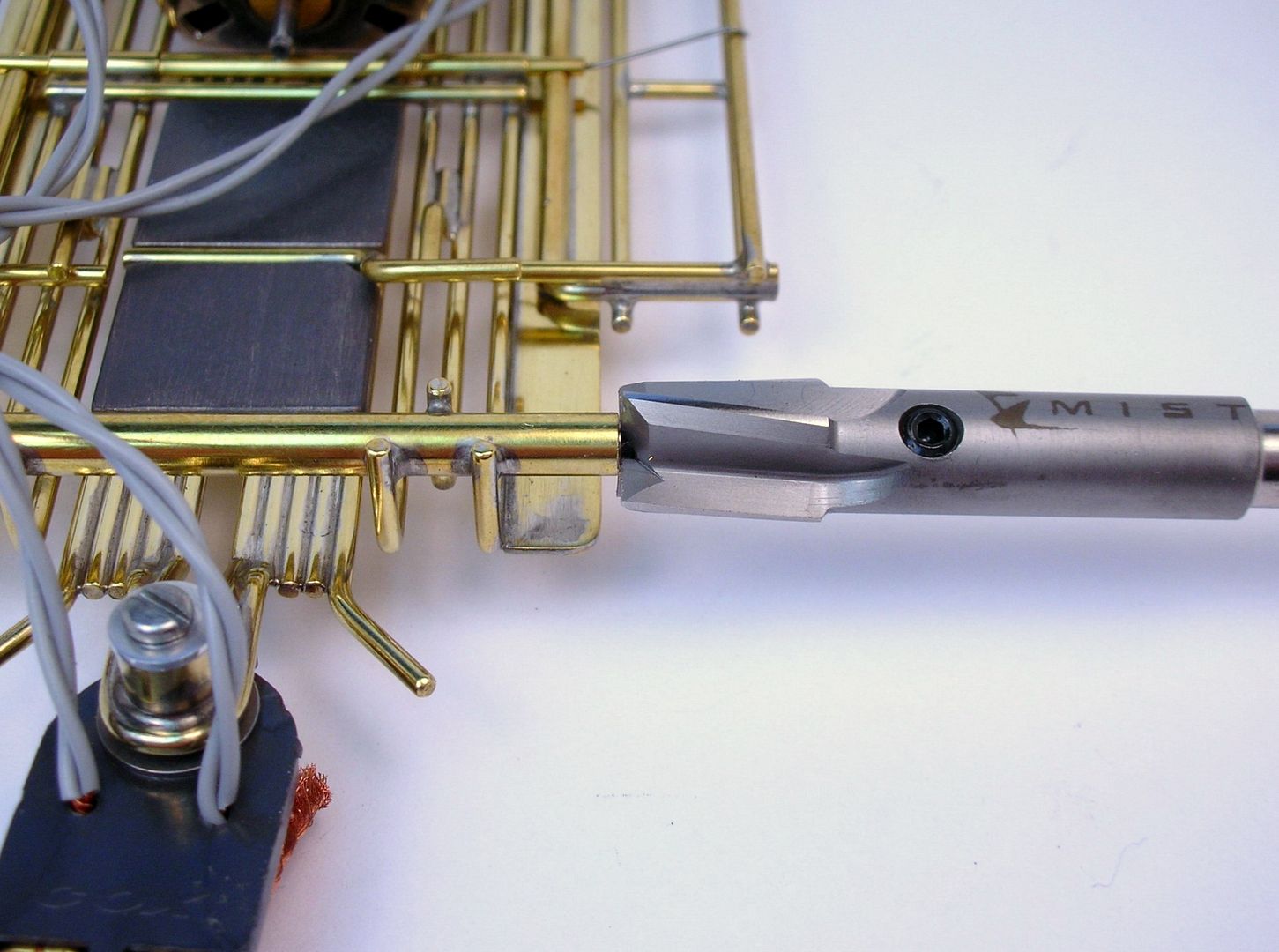

And finally, my new friend "Little Dillo" the beverage entry tool that made this all possible:

I'll see if all this works out according to plan in the 6-wheel racer thread.

Onward