1241.2-Cd3 (1241-Cd3 revision)

Back To Basics, Season Finale…

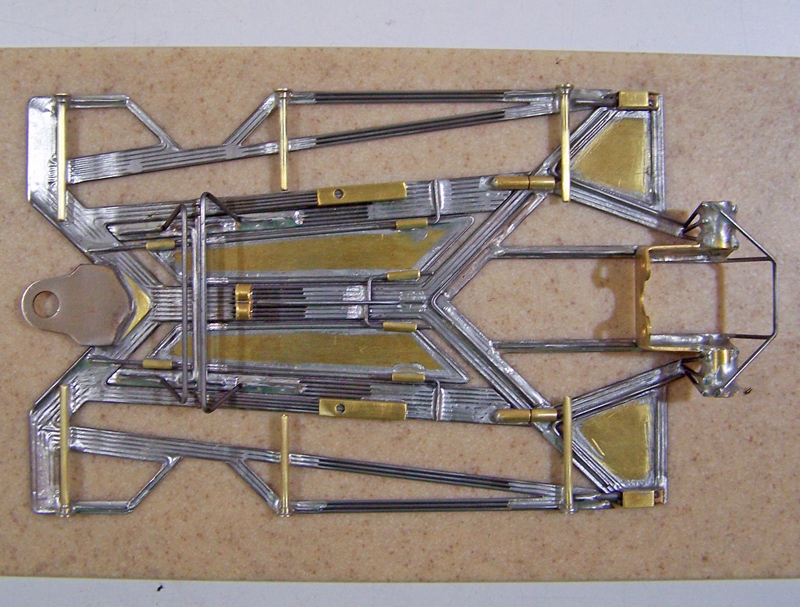

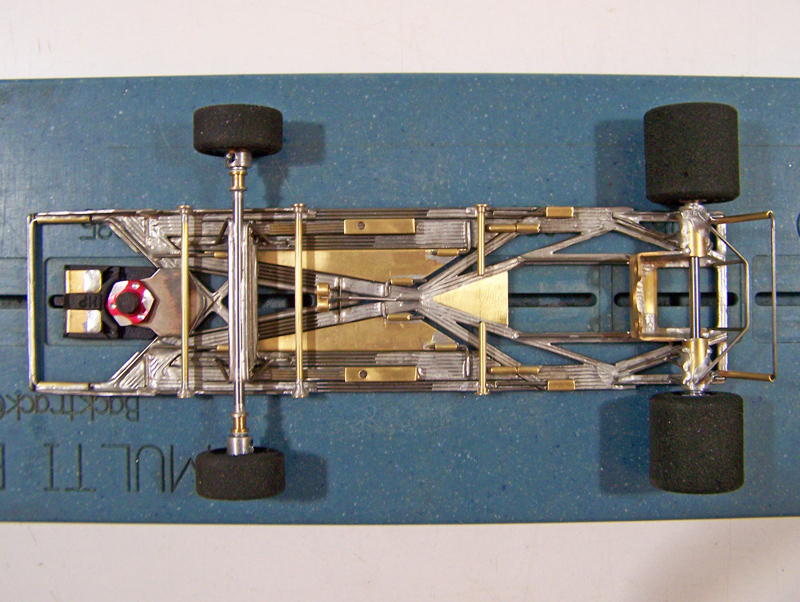

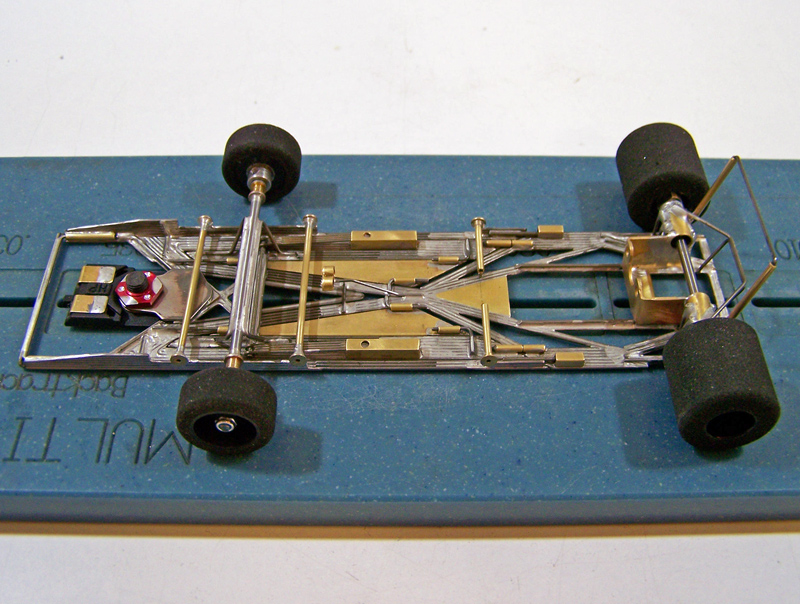

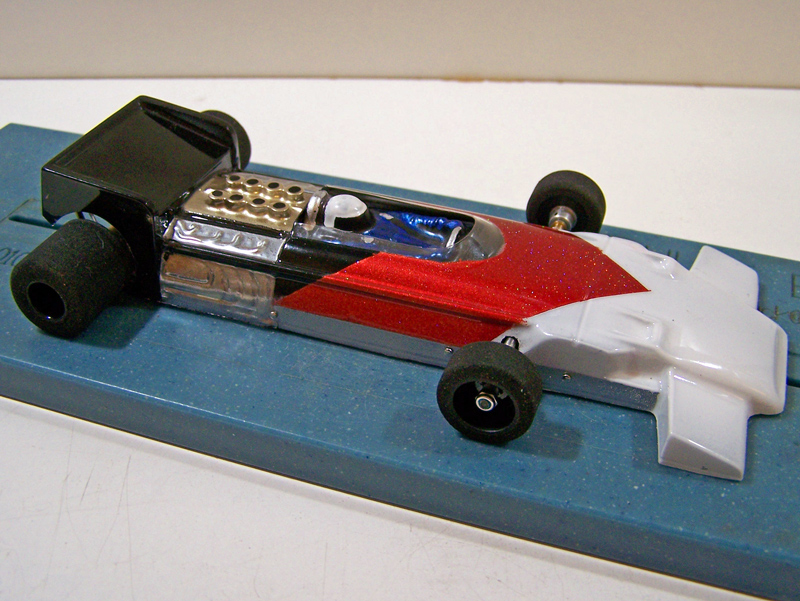

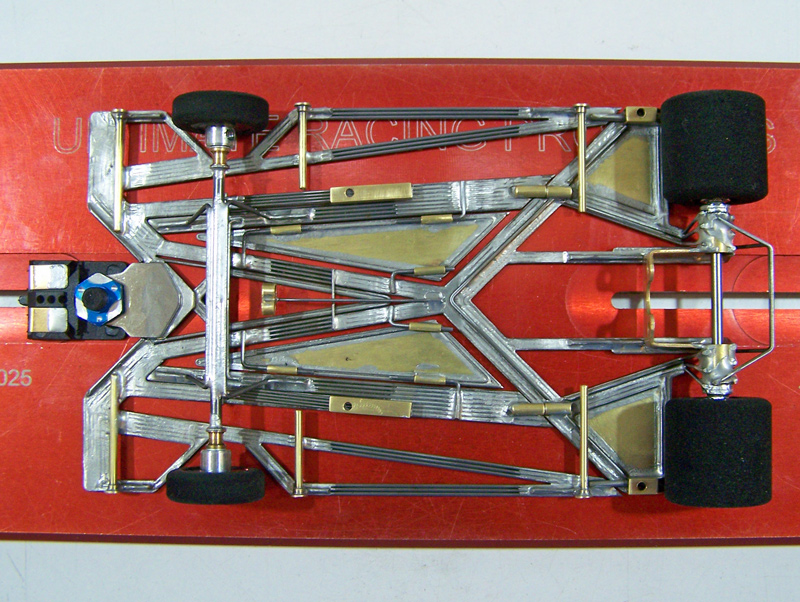

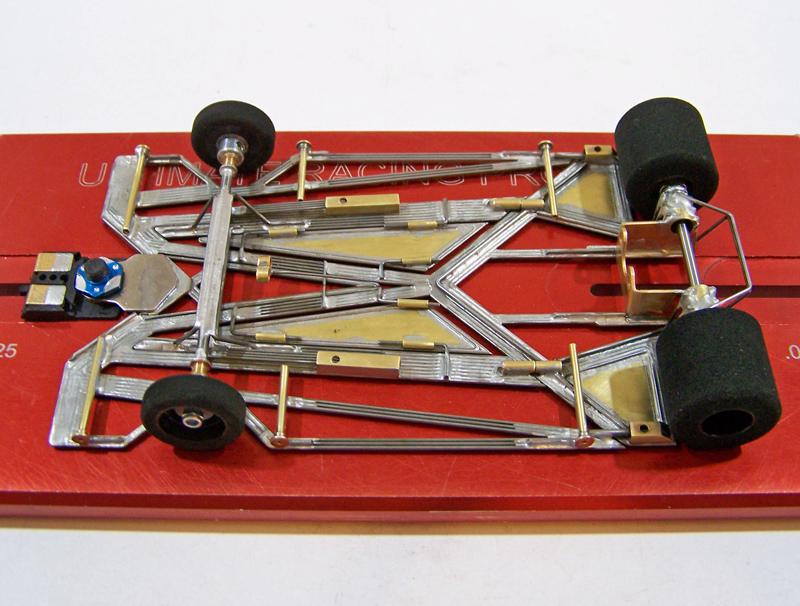

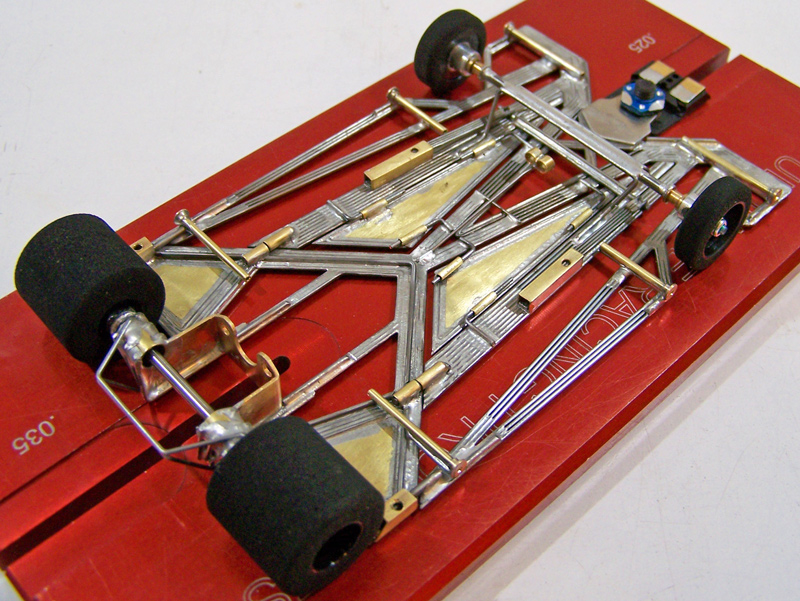

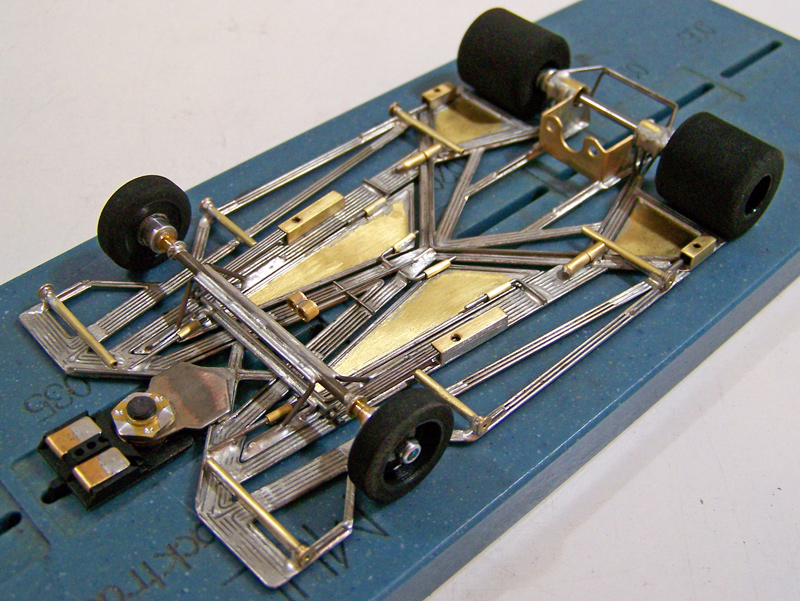

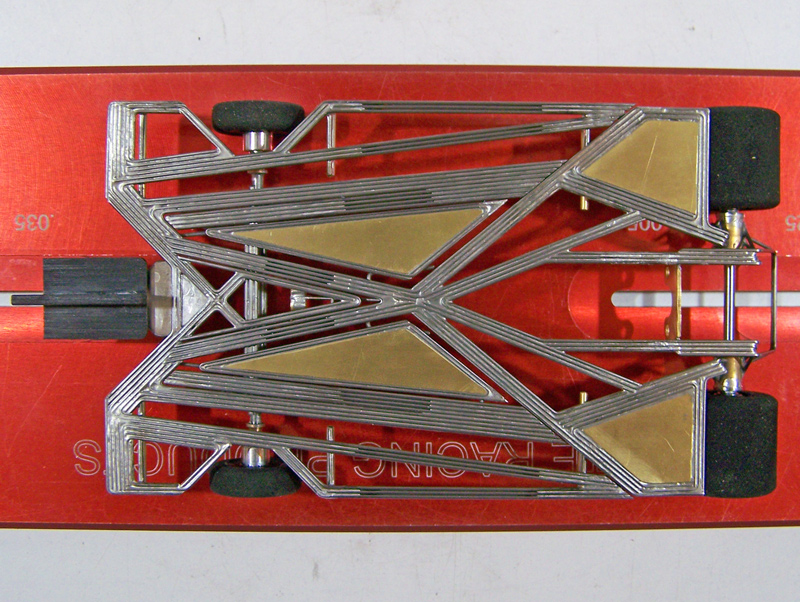

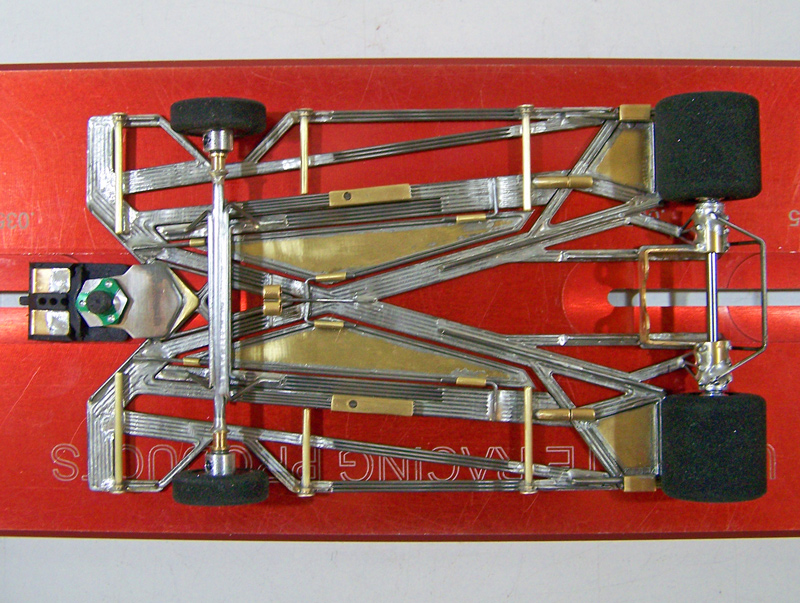

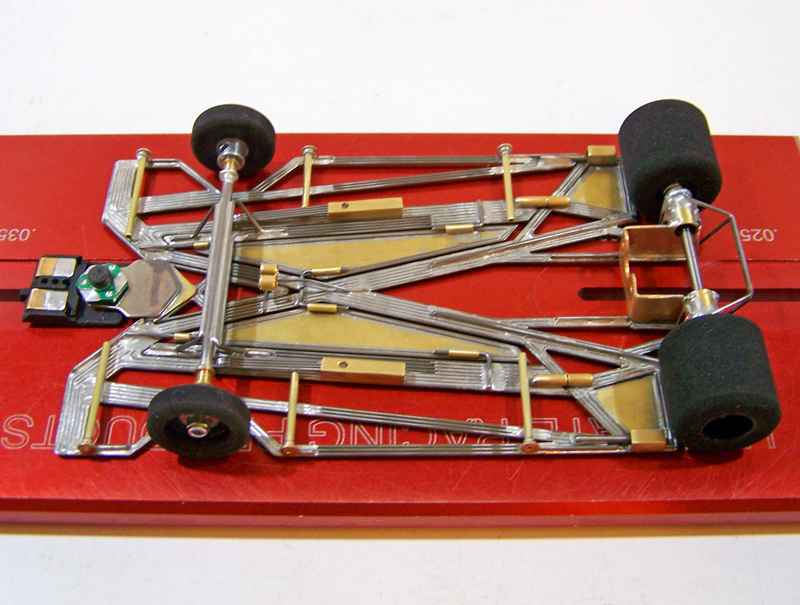

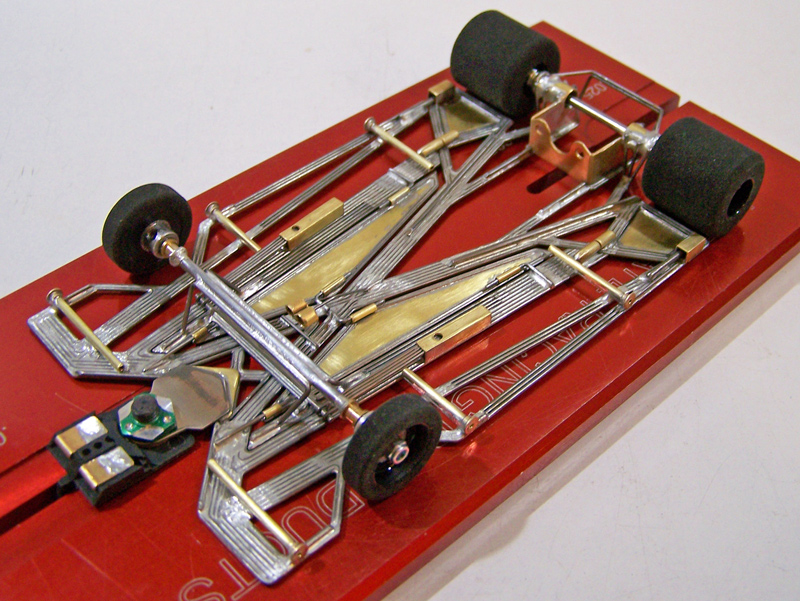

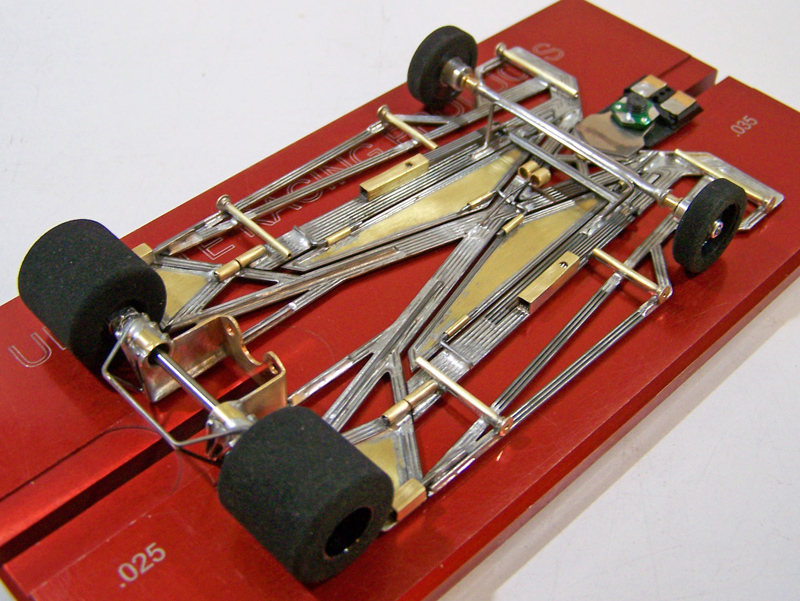

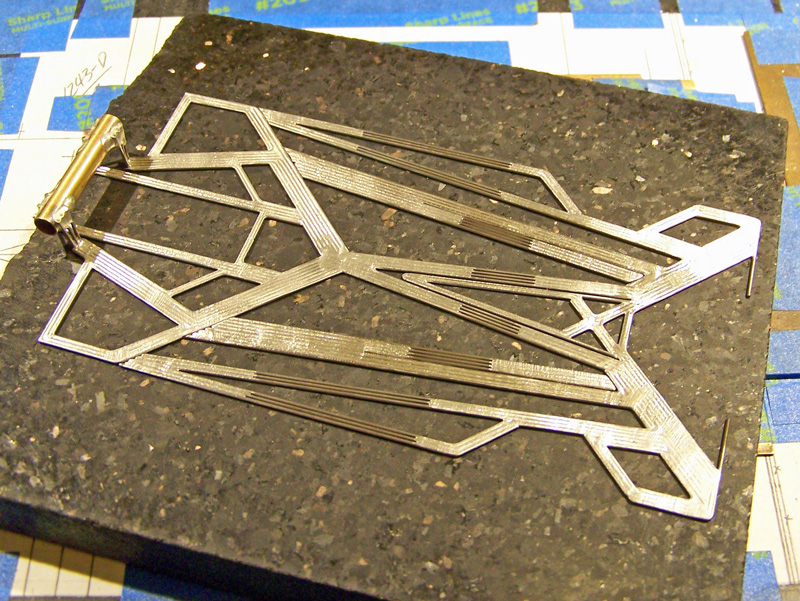

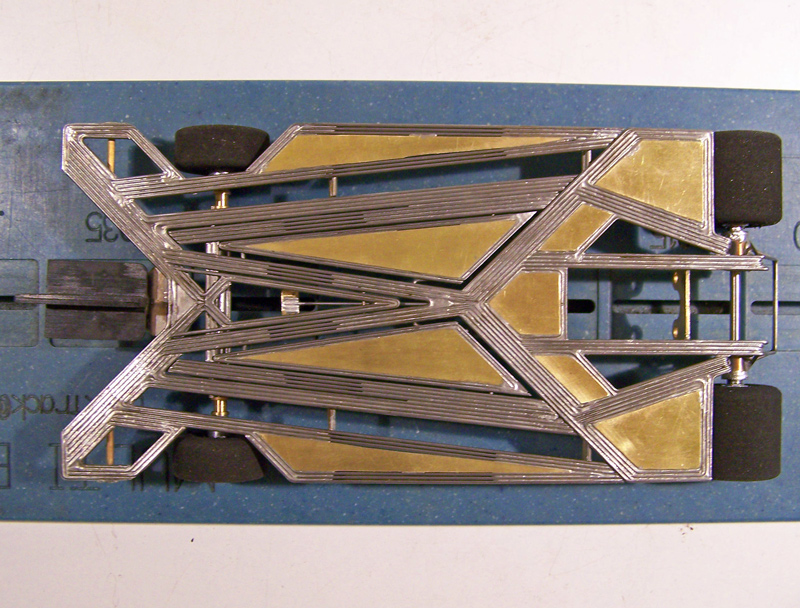

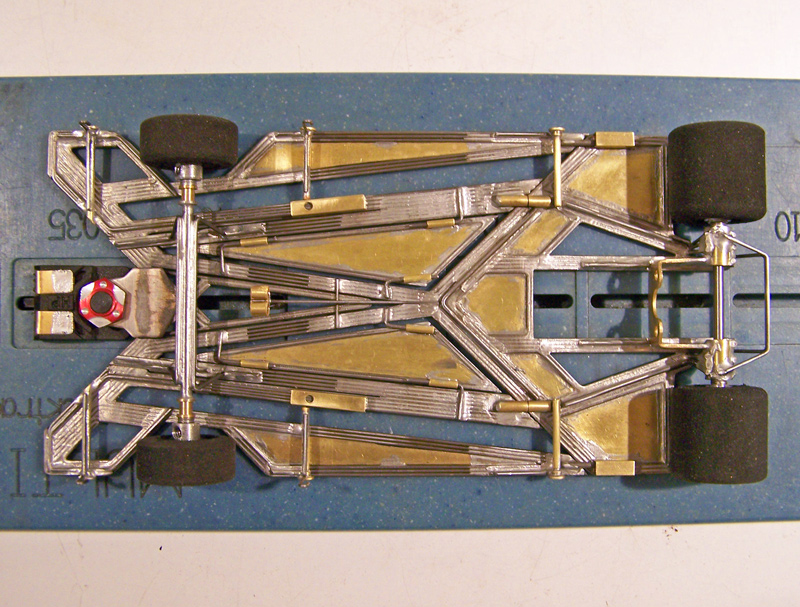

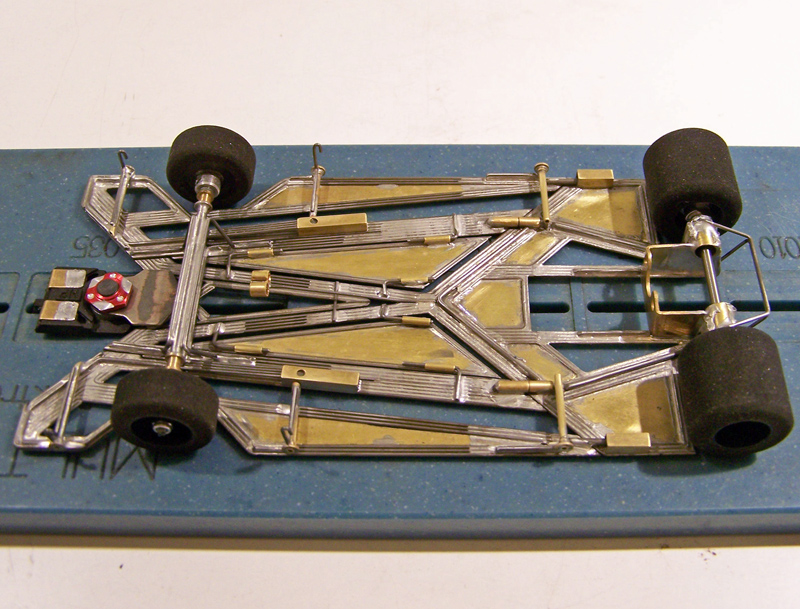

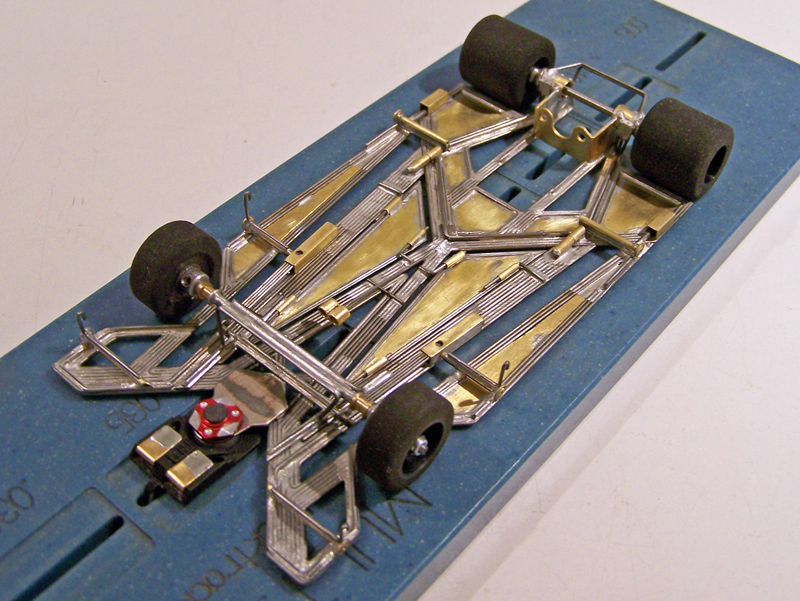

The last of the revised 1241 builds, the “d” dimensioned (3.750” WB, 4.875” RAx-GPC, 1.125” GL) 1241.2-Cd3. Finally. This gets the 1241’s up-to-date with the 1254’s, 1256’s, 1259’s, and 1258’s, and keeps “c”, “d”, and “b” dimensioned versions of all five designs… Sheesh.

This 1241.2-Cd3 actually replaces three previous 1241-Cd3 chassis/cars in the active CMF3 CanAm slot car stable. After I built/tested the original 1241-Cd3 I decided to build two more 1241-Cd3’s to have three of the same chassis to try set-up variations (for those who get a “buzz” from the lack of blood going to their brain trying to figure out the CMF3 chassis ID’s, the two copies were the 1241-Cd3/2 and 1241-Cd3/3). They’ve served their purpose, and all three 1241-Cd3 chassis join the 1241-Cc3 and 1241-Cb3 originals in retirement from the active CMF3 slot car stable...

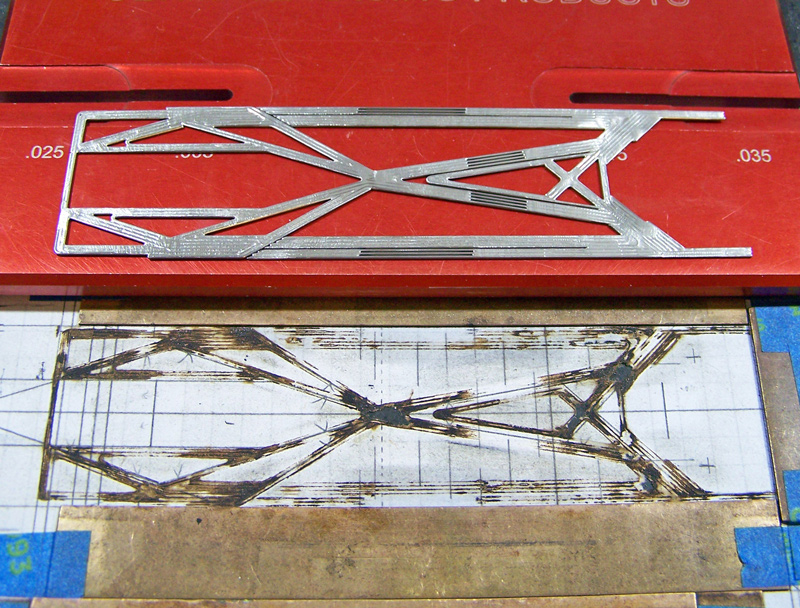

The “d” dimensioned chassis are by conventional-wisdom scratchbuild slot car freaks when looking solely at the unusually long GL (1.125”) with the atypical shorter WB (3.750”). However, ignoring those numbers leaves the more important RAx-GPC of 4.875”, which is fairly common, albeit in this case with the front axle/wheels a bit further behind than would be typical for that value. Is this a “better” dimensional lay-out for these cars? Don’t know. Probably subject to debate. What I do know is I’ve built a bunch of “d” chassis in the 1219-Series and 1237-Series, that I like them, and have yet to find a reason not to build them. Your results may vary…

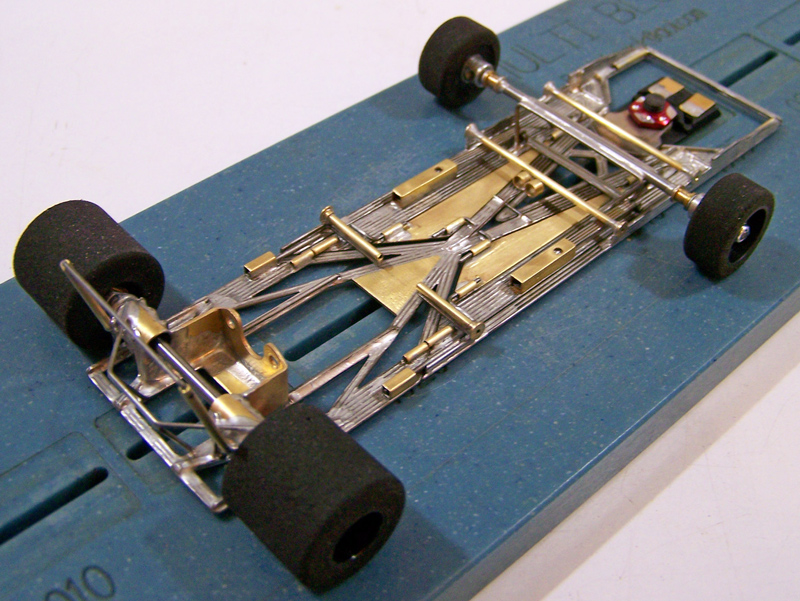

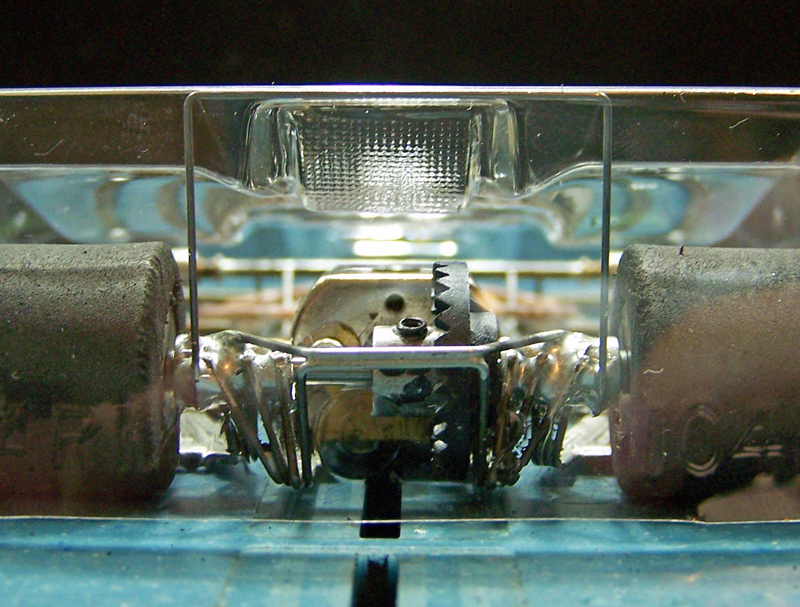

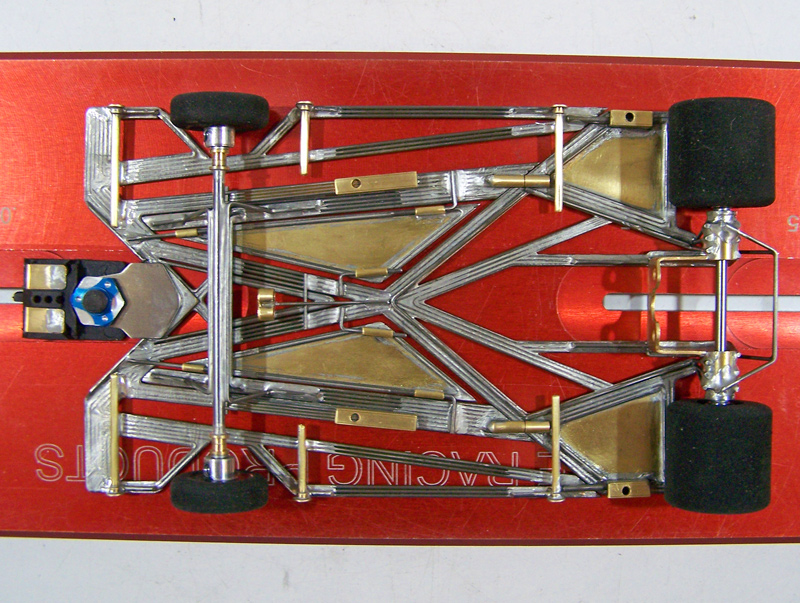

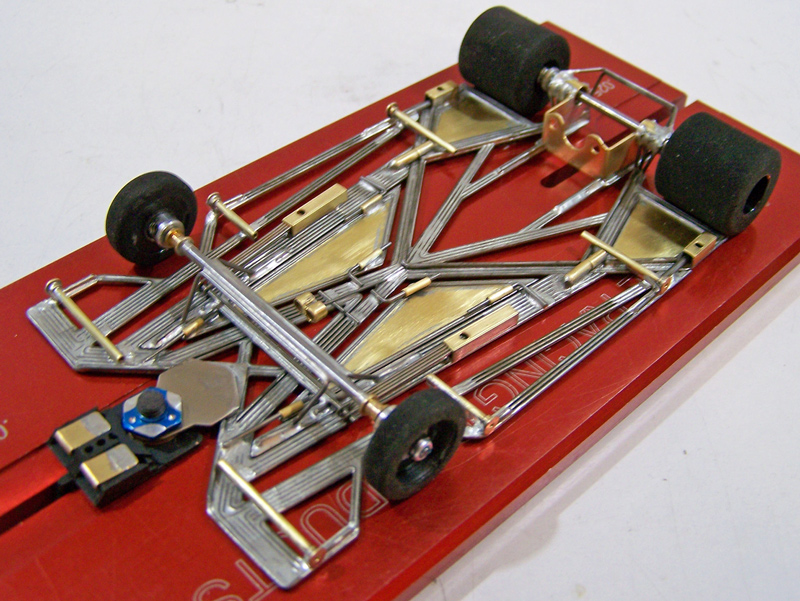

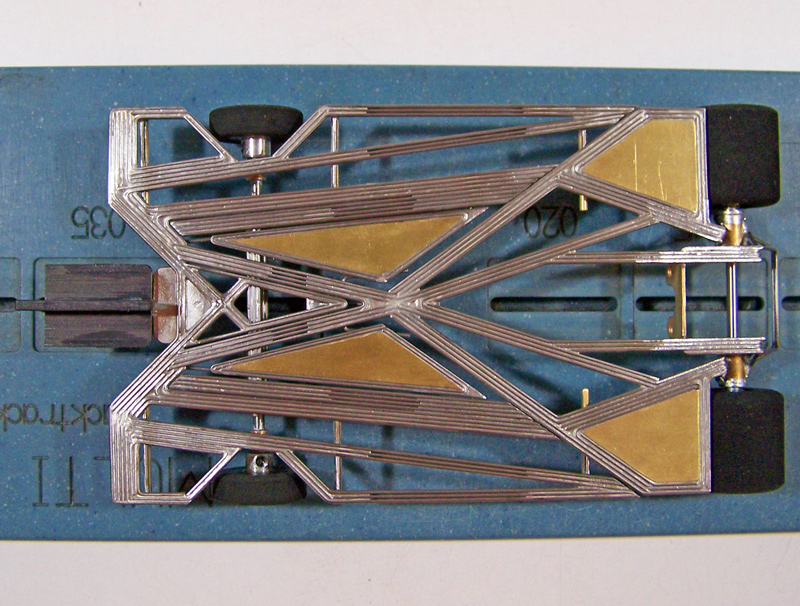

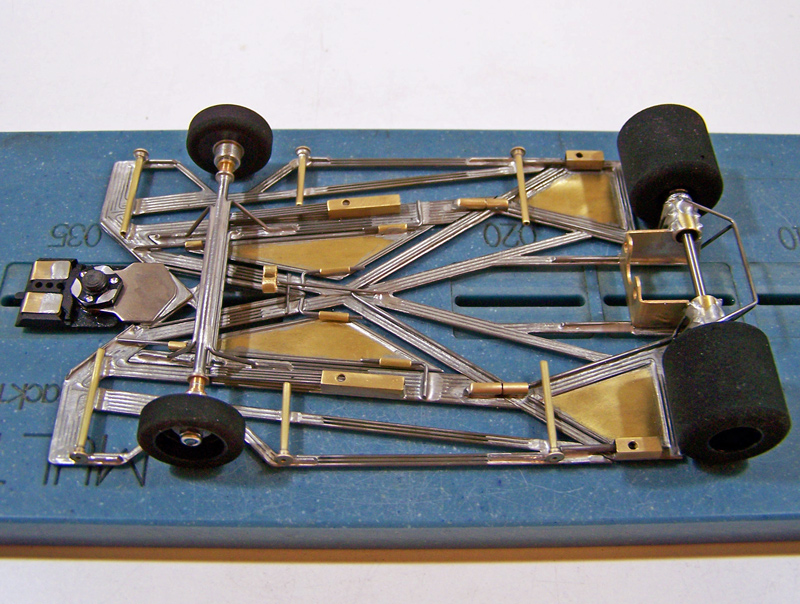

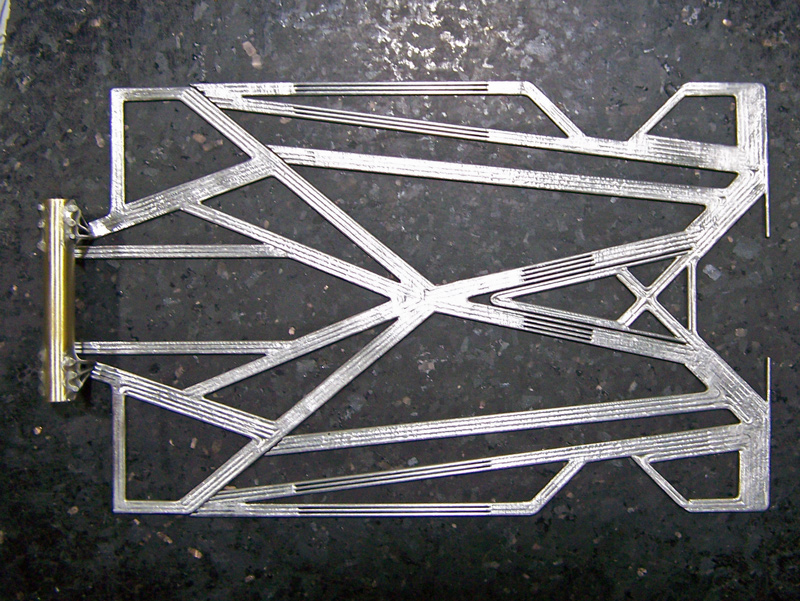

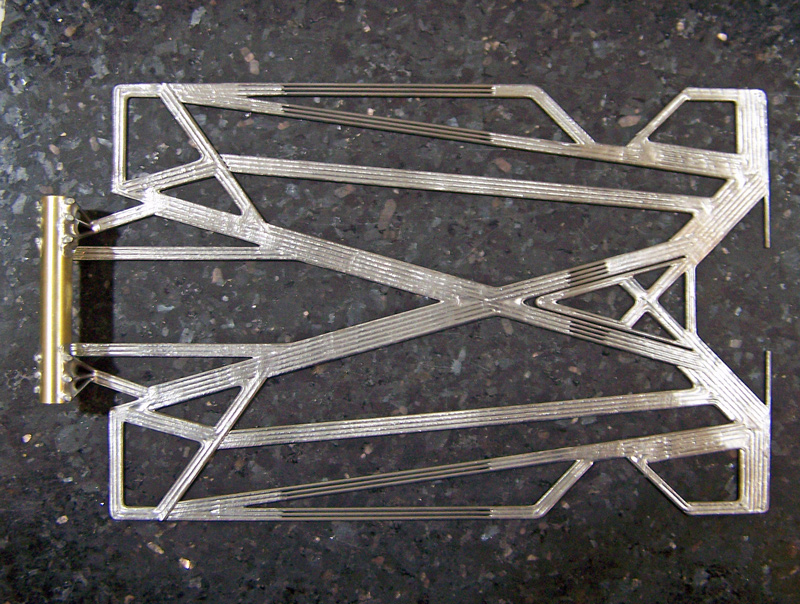

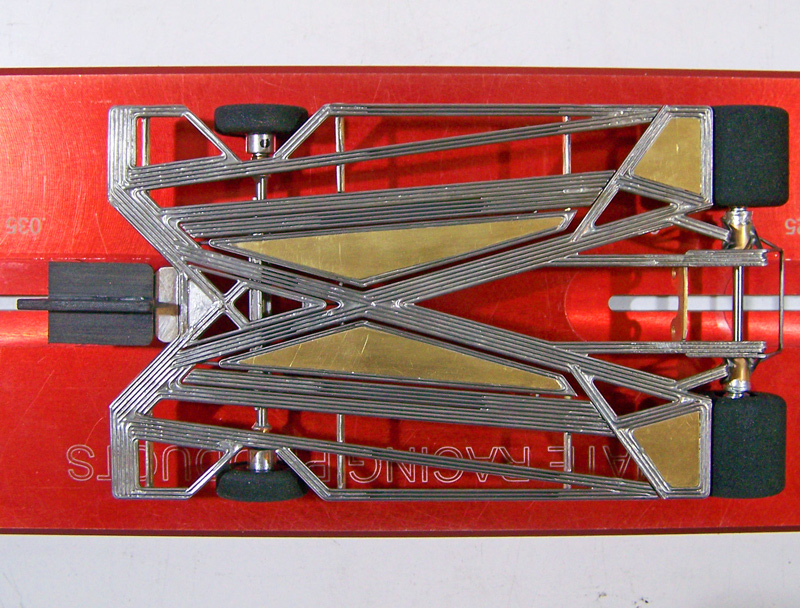

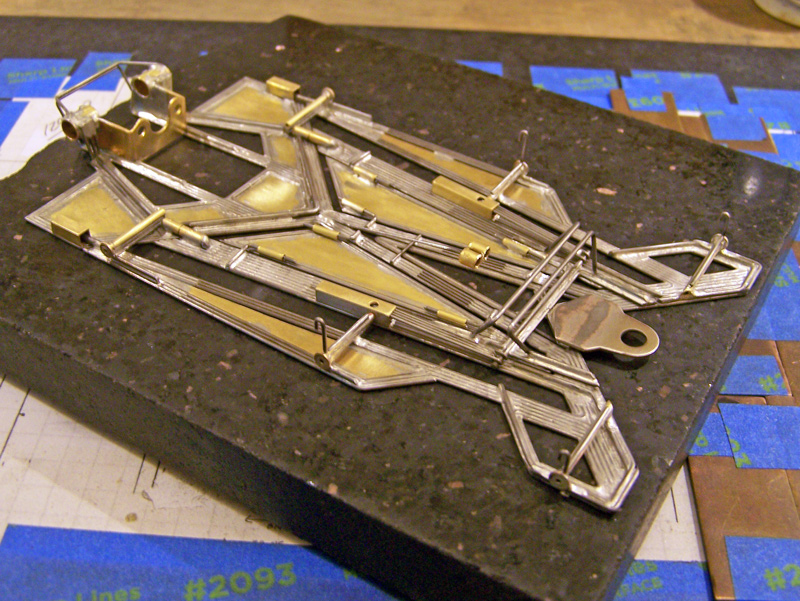

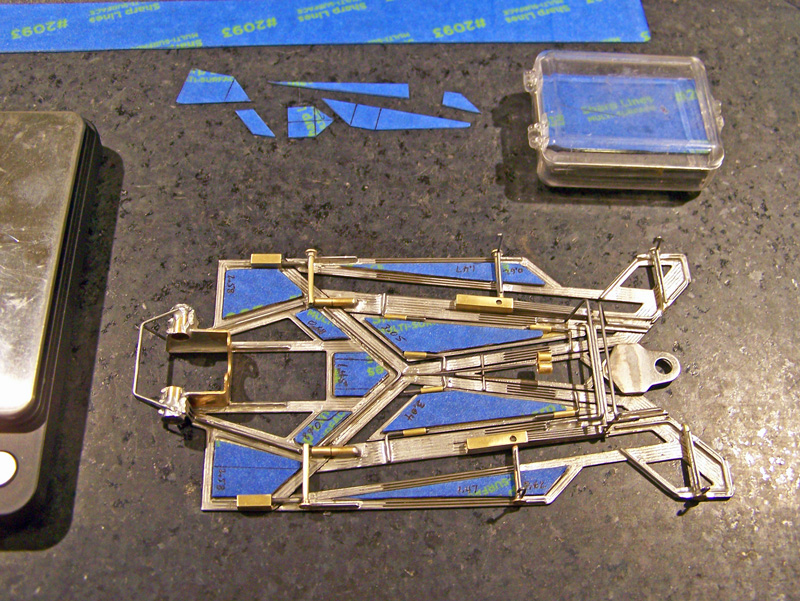

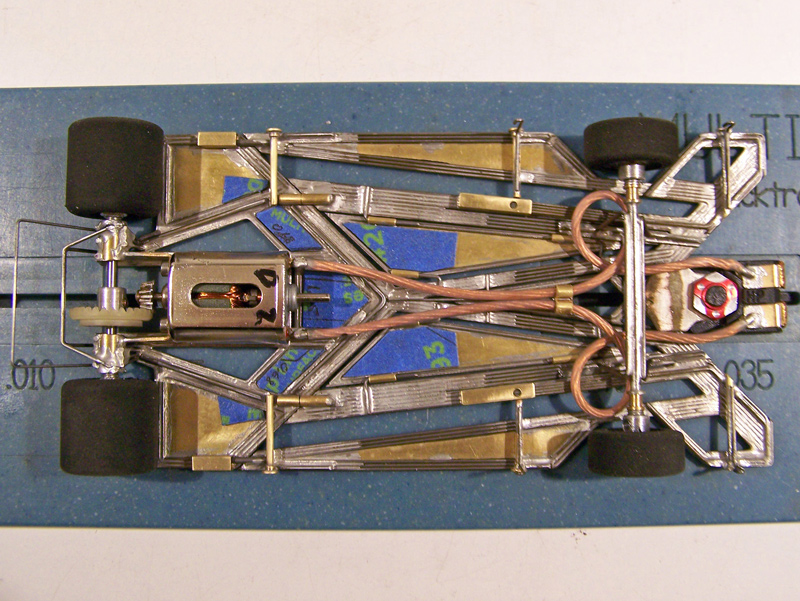

Anyway, with an adieu to this phase of back-tracking in the 1237-Series, and without further ado, the 1241.2-Cd3:

More groans. And more of the same, with more of the not the same... In another vain attempt to mollify the repetitive boredom I posted up pre-roller pics this time. Please try to contain your excitement.

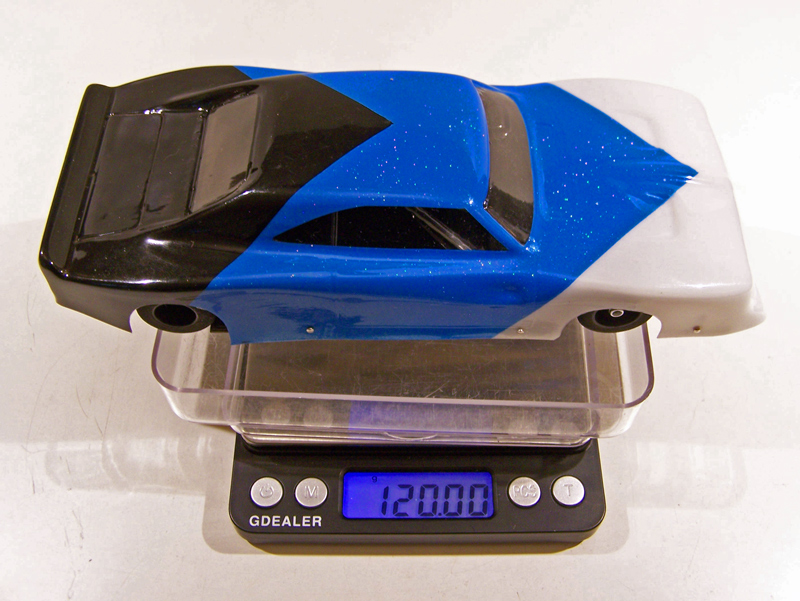

Pre-Pb off-the-build RTR mass for the 1241.2-Cd3 came out to 99.6 grams (with CR-102; versus original 1241-Cd3 with lighter JK-HR at 101.1 grams), post-Pb at 100.4 grams. Not sure why the 1241.2-Cd3 came out about 1.7 grams lighter than the 1241.2-Cc3; hopefully it’s not because I forgot to solder a lot of it together…

No Test Yet:

Planned to go to Fast Eddie’s today for some general testing and get the 1241.2-Cd3 on the track, but I weenied out. Two factors contributed to this: One, it’s been raining cats-and-dogs in Tampatown, and anyone familiar with the relationship between geography, meteorology, and demography of South Tampa where I live will understand most of the streets are flooding with every possible moron driving like they deserve that description. And, two, work at the hospital has been brutal of late and I’m pretty much exhausted, too many traumas while yet again the hospital fills with another wave of COVID patients. I’ll minimize any further statements regarding the latter part of reason two, sufficing it to say most healthcare workers are over all the continuing verbal support from a general populace that appears to have completely lost their marbles.

Besides, considering how the 1241.2-Cb3 and 1241.2-Cc3 fell right into place with testing it is a pretty safe assumption the 1241.2-Cd3 will also fall in line accordingly. Maybe confirm it next week; see how I feel then. If the 1241.2-Cd3 does not run as expected, I’ll make reference later, otherwise y’all can assume (we all know what that stands for…) along with me…

Hey, it’s not like it’s the first time a season finale was a dud.

Think I’ll get back on the drafting board and finish up the final draft for that next chassis, maybe even get the finger-burning phase started tonight…

Keep your boots on, it’s getting deep…

Rick / CMF3