Timkens are more a side load bearing. Check out Torrington.

Gangster Caddy 4.5"

#51

Posted 12 January 2017 - 07:05 PM

Timkens are more a side load bearing. Check out Torrington.

9/18/51-8/30/24

Requiescat in Pace

#52

Posted 17 January 2017 - 07:49 PM

Red, did you really think I wouldn't know an idler would change direction of rotation ?

Do I have "newbie" pasted on my forehead ? Maybe I do..... ![]()

I could have weenied out and made it an anglewinder. Probably would be done by now. But I like this type of challenge.

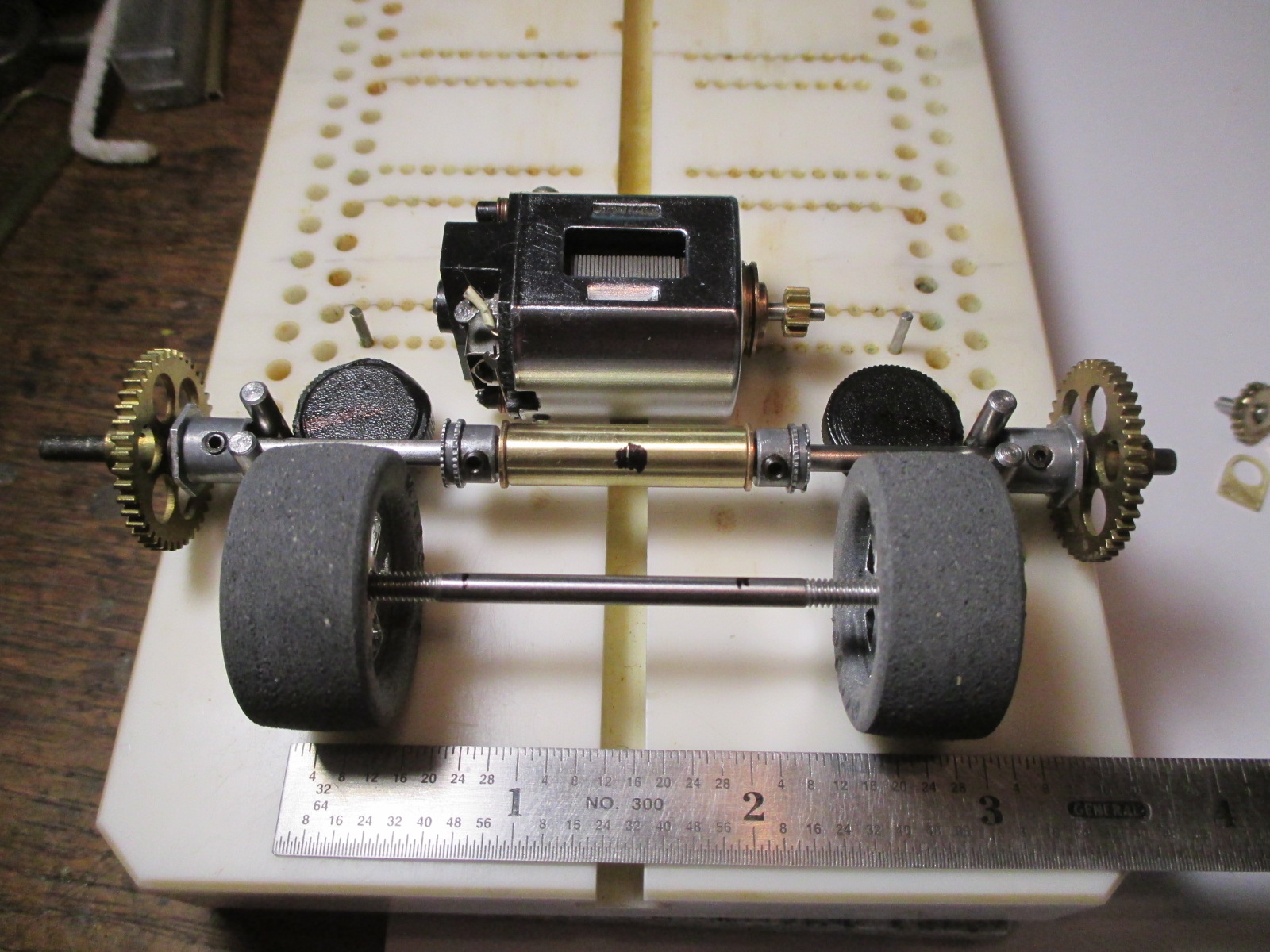

After lots of thinking and mock ups on the Rick's Jig, I like the Magoo slicks on the threaded rims with the set screw 42 T 48P brass spur.

At this point, the new improved idler gizmo is only half way constructed and awaits some other things to "fall into place" before being finalized

Mid point on the can notches is the left/right balance point on both the real and jig motors. I didn't plan that; just got lucky.

Axle tubing is sized and centered in the jig. I got lucky and had two 42 T spurs, .917" OD, so I put one on each end to adjust the axle height screws

Now I have a pretty good idea on how and where the main rails/motor box/idler gear gizmo/spur/wheels/etc. etc. will sit ![]()

- Jencar17 likes this

Paul Wolcott

#53

Posted 18 January 2017 - 07:22 AM

That's why I said I was sure you already knew it. Only one more thing to say. I think your going to find out that with that hot motor and all the traction, your going to want a larger idler. But I'm sure you have it all under control. Good luck. ![]()

9/18/51-8/30/24

Requiescat in Pace

#54

Posted 18 January 2017 - 10:44 AM

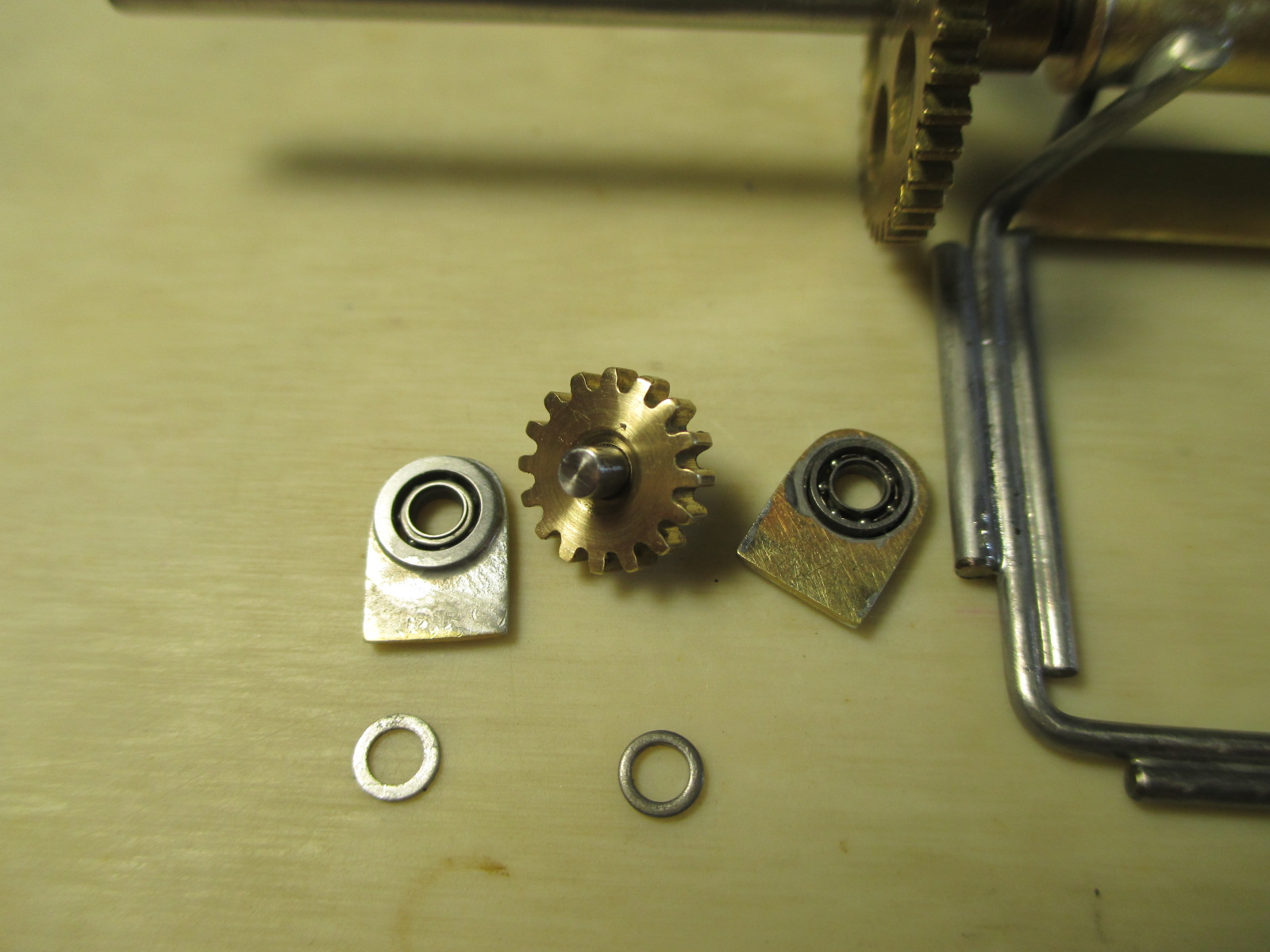

I actually have increased the idler size, from .250" OD to .375", but I did it to enable moving it down lower and to clear the gimbal better.

Any larger than that and it would start creating more space problems than I already have.

Paul Wolcott

#55

Posted 18 January 2017 - 02:40 PM

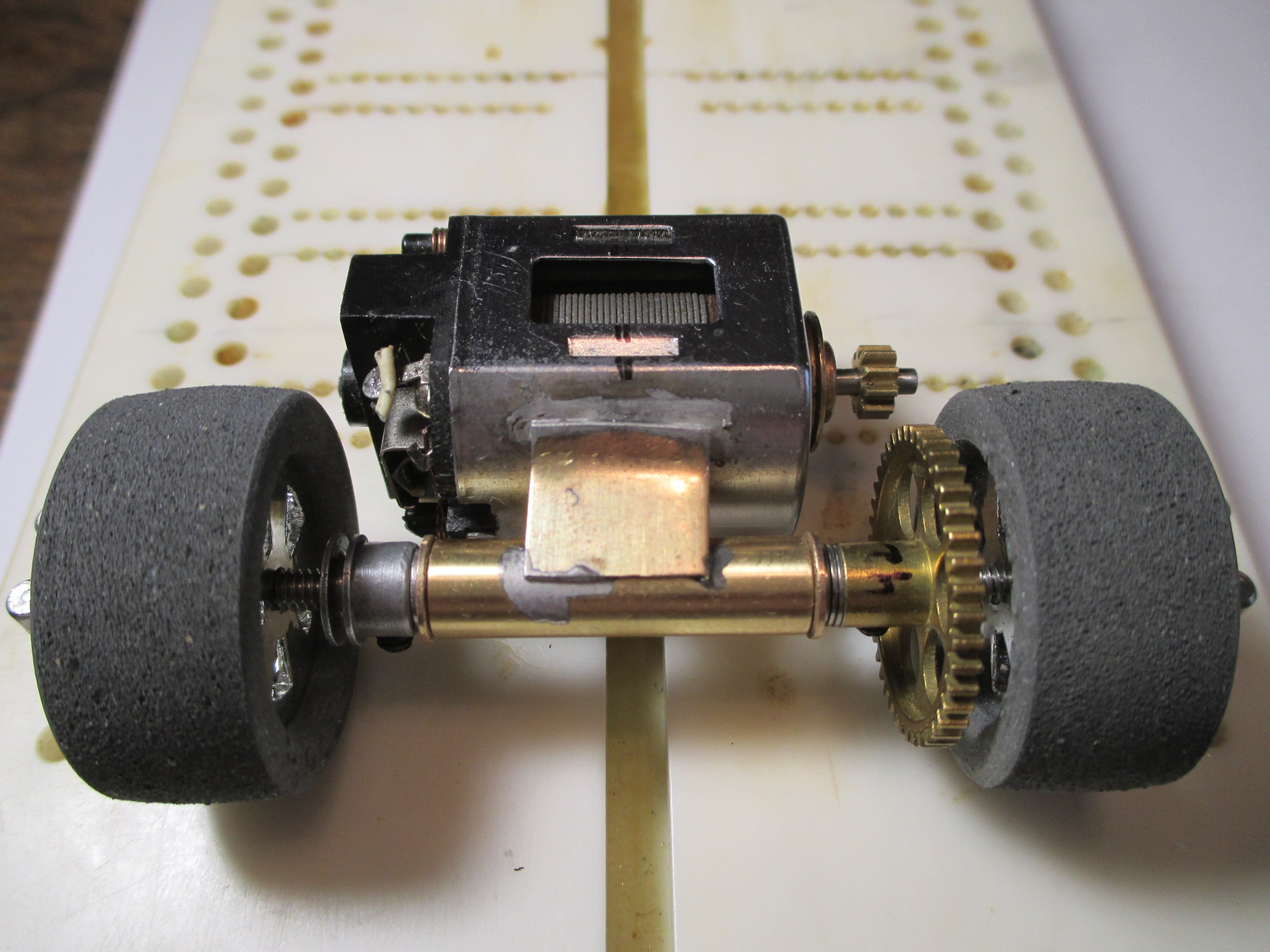

With everything laying flat, I secured motor to axle tube temporarily with a bent piece of scrap brass.

Just so stuff won't flop around while I thrash a motor box together ![]()

Now I can get the axle height adjusters out of the way and mock up the threaded axle, wheels, and spur gear.

With a piece of .063" under the jig motor, now I have a real time view of exactly what is going to fit where

- Jencar17 likes this

Paul Wolcott

#56

Posted 20 January 2017 - 05:20 PM

The motor box may be overbuilt, but my theories are:

-big heavy powerful vintage motor needs a strong box

-a little more weight (even some up high) to make it happen is acceptable

-it's a Cadillac ![]()

The motor fits like a glove, and will be screwed in left side with a brass 2-56 screw (lower only) and soldered in on right side.

Perfectly weight centered left/right

- Jencar17 likes this

Paul Wolcott

#57

Posted 21 January 2017 - 06:56 PM

Idler gear box, take 2. This time I took a smart pill and used two old tricks for delicate maneuvers like this:

-used my 25W N454 Hakko, a small iron for delicate work, in addition to the Ungar

-silver solder in some places and 60/40 in others to avoid melting joints when I didn't want them to ![]()

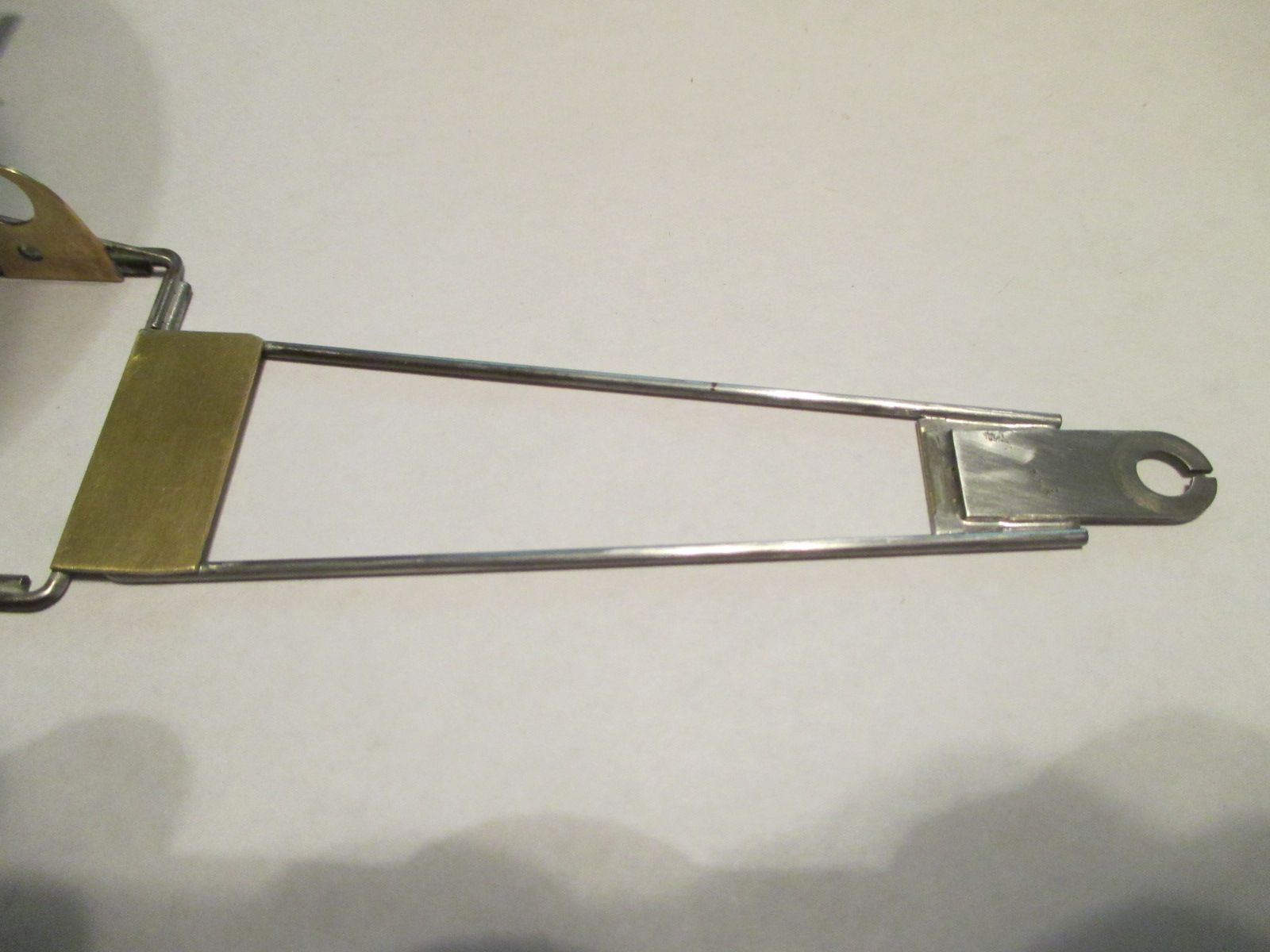

VXB BB's silver soldered to the tabs, 16T gear and 3/32" shaft polished. A piece of .078" wire added to the motor box rails is the starting point

.039" wire wraparound braces connect to and secure the outboard tab. Right rear wheel barely clears the gizmo, just like I thought it would

Magoo tires trimmed and trued to 1.044" OD and .485" width

- Jencar17 likes this

Paul Wolcott

#59

Posted 23 January 2017 - 04:34 PM

Are you putting the 36D behind the rear axle to build a wheelstander?

I intend to live forever! So far, so good.

#60

Posted 23 January 2017 - 05:23 PM

I guess you aren't following this build much to think the motor is behind the axle.

But what would you say if I told you I can put all the horsepower into forward motion yet still have the car pop a wheelie?

I can't guarantee it, but I'm working in that direction...

Paul Wolcott

#61

Posted 23 January 2017 - 06:08 PM

#62

Posted 23 January 2017 - 06:40 PM

Charlie McCullough

Charlie's Speed Shop

Kelly Racing Wanna Be

#63

Posted 23 January 2017 - 07:28 PM

I guess you aren't following this build much to think the motor is behind the axle

So far I've only seen the motorbox, with no main rails laid out. What I've seen could be placed anywhere in a chassis, even front wheel drive.

Not to bore you, but a few years ago, a slot drag racer from CA or HI built all of his vehicles to be front wheel drive. They all had big slicks on the front axle. None of those cars would do a wheelstand.

I intend to live forever! So far, so good.

#64

Posted 23 January 2017 - 08:19 PM

Paul Wolcott

#65

Posted 23 January 2017 - 10:29 PM

Steve Okeefe might be the exception.

I intend to live forever! So far, so good.

#66

Posted 24 January 2017 - 11:52 AM

I will certainly test rotating flag vs locked. If it does work better locked, at least I know it will be flat and true, not skewed. ![]()

Bill, I'm surprised you haven't read my mind yet about making the energy push the flag down the strip yet have the car wheelie. ![]()

It may work, or it may be another classic Pablo failed experiment. ![]() I ain't skeered...

I ain't skeered... ![]()

- Bud Greene likes this

Paul Wolcott

#67

Posted 24 January 2017 - 12:16 PM

My buddy Pablo ain't skeered of nothing except Cracker Barrel being closed after a race. LOL!!! ![]()

- Cheater and Samiam like this

9/18/51-8/30/24

Requiescat in Pace

#68

Posted 24 January 2017 - 01:16 PM

I'm seeing a motor/drivetrain and guide tongue assembly staying down with the body/front wheels raising up in a beautiful wheelie.

- Pablo likes this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#69

Posted 24 January 2017 - 01:29 PM

I will certainly test rotating flag vs. locked. It it does work better locked at least I know it will be flat and true, not skewed

Bill, I'm surprised you haven't read my mind yet about making the energy push the flag down the strip yet have the car wheelie

It may work, or it may be another classic Pablo failed experimentI ain't skeered

Lookin' forward to seeing that one.

- Pablo likes this

#73

Posted 29 January 2017 - 06:32 PM

Drag racing rules don't seem to be real picky, as far as I can tell.

Matter of fact, the only rules I've been able to find are SDRA.

Regarding wheelie bars and wheels, the only restriction is less than 5" from center of rear axle to center of wheelie bar axle.

Why can't I snap O-rings onto 3/32" ball bearings and use a brass tube axle with retainers ?

At this point I need to paint the body before proceeding. Yes, I know it sounds weird. ![]()

I scrubbed the partially finished chassis and now turn my attention to the airbrush... ![]()

- Jencar17 and Eddie Fleming like this

Paul Wolcott

#74

Posted 29 January 2017 - 06:44 PM

Clever idea for the wheelies!

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#75

Posted 29 January 2017 - 08:42 PM

You're going to need a lot of weight on the tongue section I think.

9/18/51-8/30/24

Requiescat in Pace