Preston, your work is just getting better and better. Awesome builds my friend.

Scratchbuilt chassis gallery

#1376

Posted 25 March 2013 - 10:42 PM

- ejgehrken likes this

#1377

Posted 25 March 2013 - 11:00 PM

Great build Preston!

Gehrken Retro Chassis

2015-16 Retro East Overall Champion

2015-16 Retro East Constructor's Champion

2013-14 New England Retro Racing Overall Champion

#1379

Posted 28 March 2013 - 08:25 PM

Joe "Jobiwan" McIntosh

Team RTR

#1380

Posted 28 March 2013 - 08:32 PM

Thanks James, but, how do you get "Joe McIntosh" from "JVRP" or JVRD" ?

Just askin' ![]()

Paul Wolcott

#1381

Posted 28 March 2013 - 09:48 PM

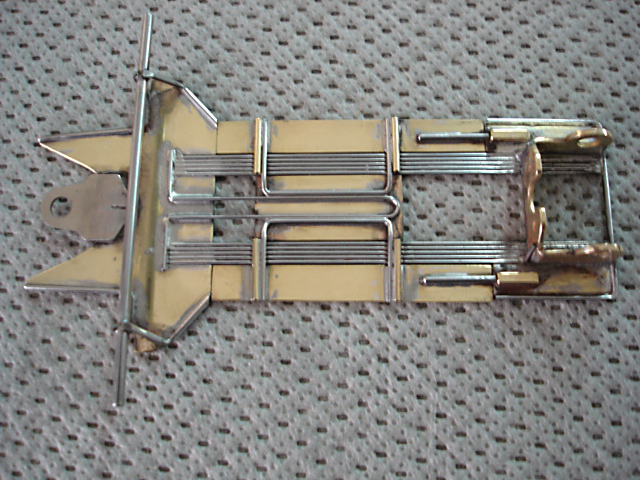

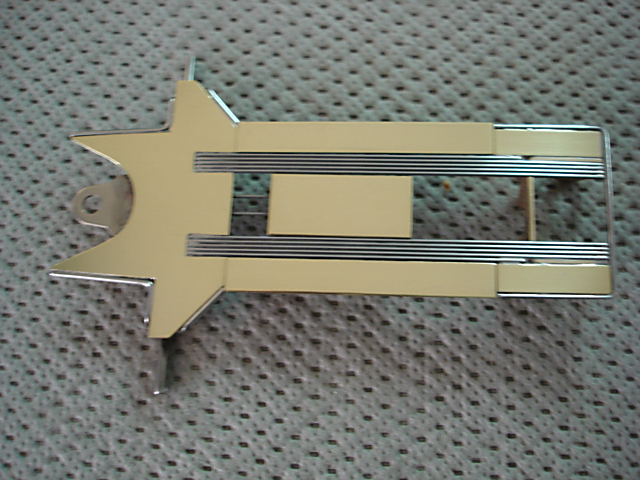

Here's an f1 I just finished. I started with an FSF kit with 1" motor bracket. The idea was multiple small rails (037) with a tuning fork of 047, to try and have it twisting around the center wishbone. I intended to use 4 037 rails on each side and narrow the stock pans a little, but ended up adding 2 rails per side, so I had to go with a single 063 wire for each "pan", with a set-up similar to Tony P's "Wallenda" design. The biggest PIA was the center rattle-pan set up with the 3 pieces. It will get tested at the next Retro East race on April 6th...I just hope it was worth all the trouble LOL

#1382

Posted 28 March 2013 - 09:49 PM

deleted duplicate post

#1383

Posted 28 March 2013 - 09:55 PM

It's actually "TVRP", something Joe has used since I've known him.

The real reason I know this chassis is becasue I've been beat by it more times than I'd like to admit. Joe builds some of the best cars around, and I wished he would race more than he does.

Team RTR

#1384

Posted 28 March 2013 - 10:06 PM

Thanks James ! ![]()

I'm tumbling it, and installing BB fronts. The new owner is John Clow. It is a sweet chassis !

Paul Wolcott

#1386

Posted 29 March 2013 - 11:36 PM

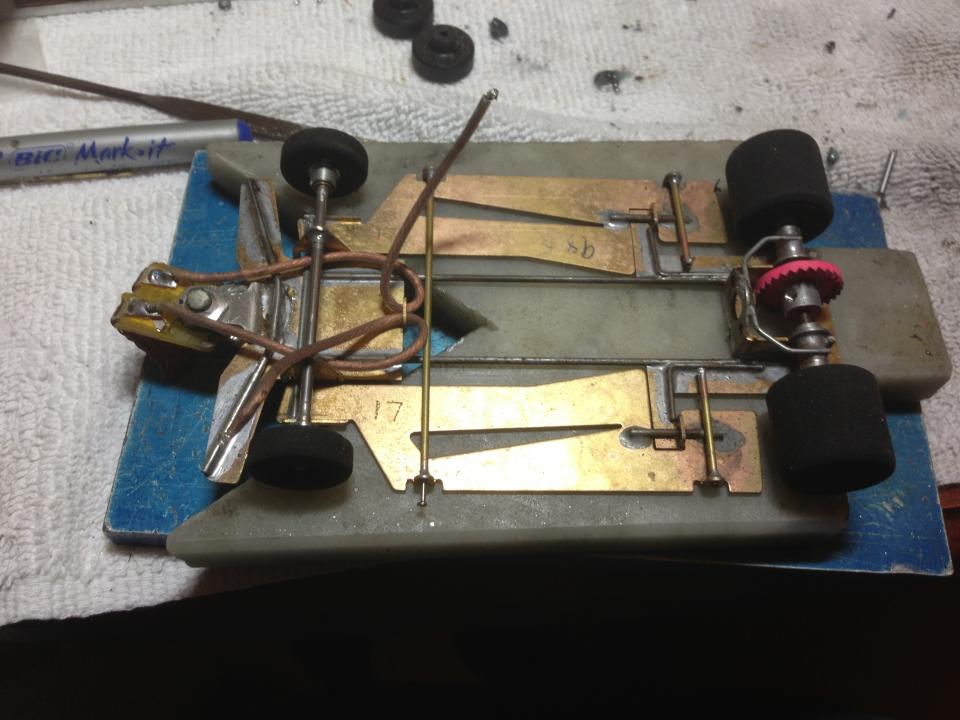

Just finished my first F1. 10 rails of .039, torsion pans. I dig the flex this thing has. Kinda like a eurosport. Can't wait to try it at the Zimmerman. I piled all the components on the scale an it looks like it will weigh about 92g.

- DCR, Tim Wilkins and SlotStox#53 like this

#1387

Posted 29 March 2013 - 11:55 PM

"DCR Slot Cars" on FaceBook

#1390

Posted 30 March 2013 - 12:44 AM

Brian Ambrose

#1391

Posted 30 March 2013 - 02:09 AM

Terminal Velocity Racing Products

It's actually "TVRP", something Joe has used since I've known him.

The real reason I know this chassis is becasue I've been beat by it more times than I'd like to admit. Joe builds some of the best cars around, and I wished he would race more than he does.

June 8, 1955-March 20, 2021

Requiescat in Pace

#1392

Posted 30 March 2013 - 08:13 AM

Thanks, Tommy, I will relay that info to the new owner....

Paul Wolcott

#1393

Posted 30 March 2013 - 10:48 AM

You did Agreat at the R4......

11/4/49-1/23/15

Requiescat in Pace

#1394

Posted 30 March 2013 - 02:22 PM

Love the look of the F-1 Jim

A motor is only as fast as the chassis it's in.

Dominic Luongo

Like Dominator Custom Chassis on Facebook

NERR photos from 2012-April 2016

NERR photos from 2016 to now

#1395

Posted 30 March 2013 - 03:09 PM

How do I solder on my jig and not make it look like crap on the bottom of what I'm soldering? ( rails ) it always looks like ruff sand paper when I turn it over.

One more question... What can I use to clean up the chassis after I'm done soldering. I don't have a tumbler yet. I always use motor cleaner & lighter fluid durning and after building. But hours after the chassis look horrible.

Brian Ambrose

#1396

Posted 30 March 2013 - 04:32 PM

A toothbrush, a small hand brush, liquid soap, water, and Comet or Ajax. Works almost as good as a tumbler.

Then rinse well, dry completely, and soak in WD-40.

2,000 grit wet and dry sandpaper from the automotive section of Wal Mart shines brass sheet real well.

Paul Wolcott

#1397

Posted 30 March 2013 - 04:36 PM

A few suggestions. First make sure all of the parts you are soldering are cleaned and polished before you start building. Secong I suggest putting the solder on the tip of the iron and then on to the part you are soldering. This way you can control the amount of solder you put on and start with a small amount and after it flows evenly you can add a small amount more if necessary until the joint looks correct. Third I recommend bringing your work to the sink and using SOS pads during and after the build. This works great for removing the acid and shines the parts. Hope this helps.

Mike Katz

Scratchbuilts forever!!

#1398

Posted 30 March 2013 - 05:29 PM

Brian Ambrose

#1399

Posted 30 March 2013 - 06:27 PM

Sounds to me like you have too much solder on there. Use very little and if the bottom doesn't look right put some acid on the bottom and put it back on the jig and reheat the joint. Can you post a picture of what you are talking about?

Mike Katz

Scratchbuilts forever!!

#1400

Posted 31 March 2013 - 02:10 AM

I quit using cleansers with bleach. I find it tarnishes the solder and the piano wire. I use toothpaste. Crest seems to work the best with a stiff tooth brush. This gets the acid off. Then I use an SOS or Brillo pad to get that brass nice and shiny. My wife made the mistake of leaving a naptha soap bar on the wash sink and now I use that for a final wash. Rinse everything with as hot of water as you can get and then immediately towel and blow dry. Oil anything that moves with Tri Flow. My frames look nice and shiny now if I could only get them to handle better.

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven