Scratchbuilt chassis gallery

#1926

Posted 01 November 2013 - 11:17 PM

Brian Ambrose

#1927

Posted 01 November 2013 - 11:45 PM

Jim Fowler did a build like that. Great thread with very detailed step by step.

Sorry, don't know how to do a link. ![]()

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#1928

Posted 01 November 2013 - 11:52 PM

Brian Ambrose

#1929

Posted 01 November 2013 - 11:56 PM

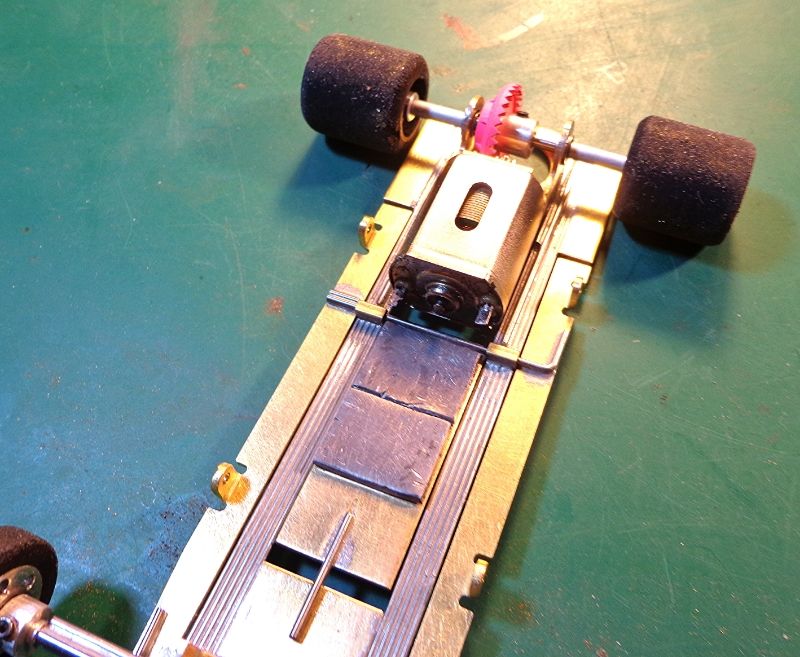

Here's my latest F1 tuning fork design:

Instead of pivoting in the middle, it pivots on the outside edge. The only part that moves is the rear end; the front end, side & center pans stay stationary.

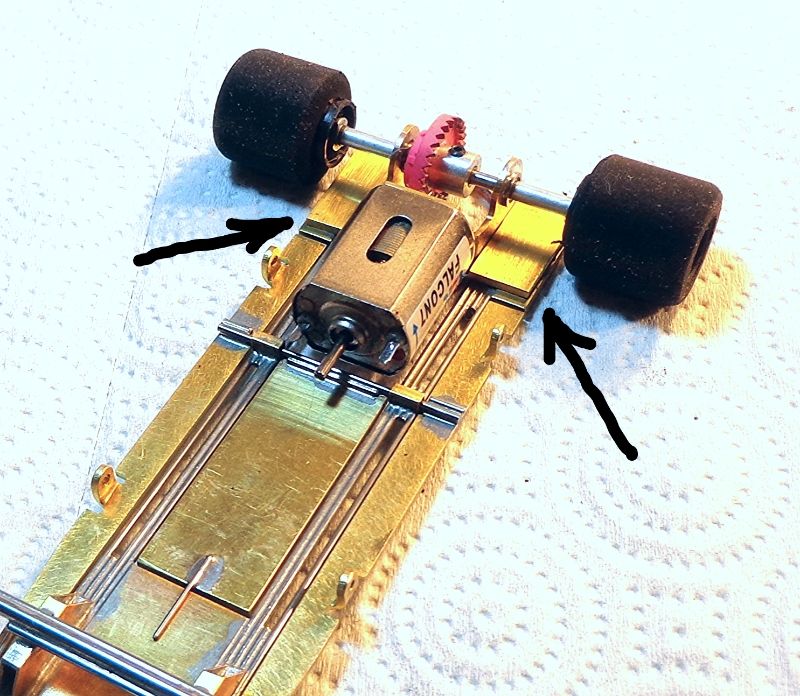

And here's a close-up the reinforced rear end; I used the same design on my previous chassis I raced two weeks ago. That race, I broke off the front end & blew out both rear bearings (I even lost a shield). One side of the motor bracket was slightly bent, that was it.

I made the rear upright brackets from .015" brass; this straighten the rear end better than anything I've tried before.

- brnursebmt, George Kimber and DCR like this

First Place Loser in the JK Products

International D3 Builders Competition

#1930

Posted 02 November 2013 - 01:17 AM

Here's my latest F1 tuning fork design:

Instead of pivoting in the middle, it pivots on the outside edge. The only part that moves is the rear end; the front end, side & center pans stay stationary.

And here's a close-up the reinforced rear end; I used the same design on my previous chassis I raced two weeks ago. That race, I broke off the front end & blew out both rear bearings (I even lost a shield). One side of the motor bracket was slightly bent, that was it.

I made the rear upright brackets from .015" brass; this straighten the rear end better than anything I've tried before.

Nice design and beautiful work,,,,,Please let us know how it runs………….Thanks DC

- Tim Neja likes this

"DCR Slot Cars" on FaceBook

#1931

Posted 02 November 2013 - 01:17 AM

Brian,

It's in Scratchbuilding. Building the R-Geo GVP Chassis.

Russ,

That is a bullet proof rear end for sure. Nice job.

- team burrito likes this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#1932

Posted 02 November 2013 - 03:35 AM

I'm working on another new rgeo/GVP chassis. As I sit here and look at different ideas on how to build her. I wonder if it would be better to install the pans backwards from what's the norm on all the others? I got to thinking as I used to race real cars and front to rear ratio is pretty important in a chassis setup. So has anyone ever done this? If so how did it work compared to the other?

In case you're having trouble locating the thread...........http://slotblog.net/...eo-gvp-chassis/

- fohoover likes this

#1933

Posted 03 November 2013 - 10:48 PM

for stemmy

for stemmy

- Tim Neja and Danny Zona like this

Team R-Geo

#1935

Posted 07 November 2013 - 07:52 AM

Yet another GVP clone, this time for me! If it's better than my Kamo car this is what I will be running at the Checkpoint Cup.

Please let us know how it works with the light pans. I had to add a bit of rear weight to mine.

Raisin

Proud to drive an American car, from an American manufacturer, assembled by American workers.

I own a car from each of the big three: I have a Ford, a Mercury, and a Lincoln.

#1936

Posted 07 November 2013 - 08:02 AM

Here's my latest F1 tuning fork design:

Instead of pivoting in the middle, it pivots on the outside edge. The only part that moves is the rear end; the front end, side & center pans stay stationary.

And here's a close-up the reinforced rear end; I used the same design on my previous chassis I raced two weeks ago. That race, I broke off the front end & blew out both rear bearings (I even lost a shield). One side of the motor bracket was slightly bent, that was it.

I made the rear upright brackets from .015" brass; this straighten the rear end better than anything I've tried before.

Beautiful work, Russ.

- team burrito and Tim Neja like this

Bobby Robinson RN, BMTCN

"Nobody rides for free." - Jackson Browne, 1980

"Positivity and optimism can overcome a lot of things." - Tom Brady, 2019

"Trying is the first step towards failure." - Homer Simpson

#1937

Posted 07 November 2013 - 11:32 AM

Please let us know how it works with the light pans. I had to add a bit of rear weight to mine.

Raisin

Raisin, this is the third installment of this style chassis I have built. The first had additional .0625" brass slabs just in front of the rear tires and out of the box, no tuning, it was a 4.4/4.5 car.

The down side, it weighed 99 grams. This new car is going to come in right around 90 and the flex feels much better than version 1.

So I'm hoping with the lighter (this new car) and the improved flex it's going to get me in the 4.3 or even 4.2 range. I would love to qualify into the A Main at the Checkpoint Cup!

I'll let you all know how it does when I test it.

11/27/57-8/12/22

Requiescat in Pace

#1938

Posted 19 November 2013 - 09:27 PM

Well I took the plunge and gave a shot at my first solo retro build. Many thanks to Cap for answering my many texts asking stupid questions and finding entertainment as I described the smell of burning flesh to him as I tried to figure out how to hold the little parts in place while soldering. Also thanks to folks at JK for a kit that first timers can build!

- MSwiss likes this

Frankie

Professional Track Wall Tester.

Rob Voska's only friend.

#1939

Posted 19 November 2013 - 09:47 PM

Good job, Frankie! You've taken "the big step" in creating your very own chassis!

- MSwiss likes this

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#1940

Posted 19 November 2013 - 11:28 PM

Frankie did great! Didn't even grab the wrong end of the iron LOL

- MSwiss likes this

#1941

Posted 20 November 2013 - 03:30 PM

Making the trip to Washington, PA next weekend, need a stock car to try out.

JK X25R narrowed and lengthened

4.5" WB .75" GL

Plumber pans with the front axle on the Pans

2 rails .062 per side soldered solid

Added a half inch of .032 to the back of each pan

- One_Track_Mind, macman and Hack like this

#1942

Posted 03 December 2013 - 11:36 AM

Going spelunking....................

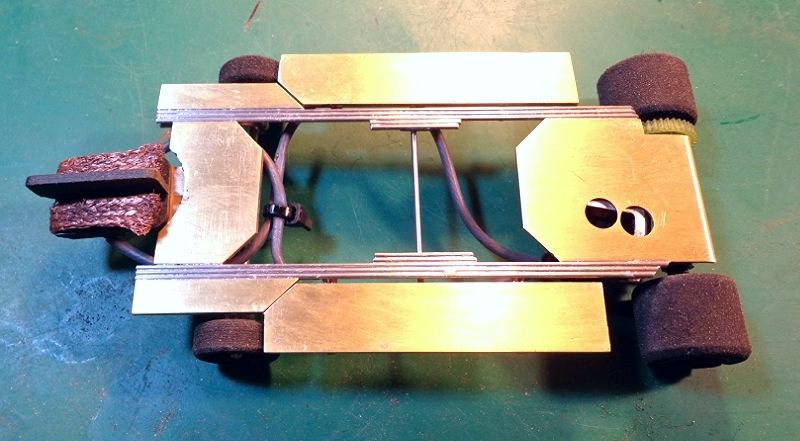

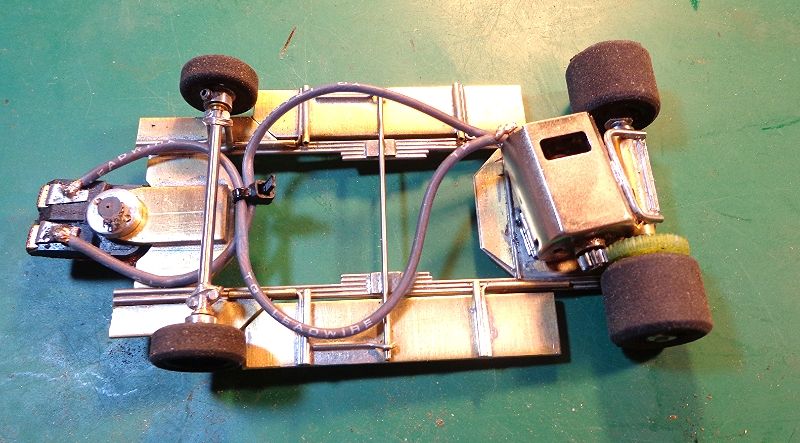

Here are some new frames I put together to take to SoCal for a "Caving" expedition. The two F-1s are made up with bracket, guide block and pans from R-Geo. These parts make the frames come together and fit the width regs very well. Testing notes scrawled on the frames are from Slot Car Raceway @ Rohnert Park Ca on their Testa Rossa flat track which is similar to the "Cave"

This one uses a 1" guide block that is notched out so that the frame rails mate w/the 3/4" bracket.

5 rails of .039 wire soldered. Samson BB fronts, brass tabs @ rear are 1/16", bracket plate is 3/32"

Added some lead on the top of the center plate to reach the 114 gr.

Falcon 7 geared 7-29 and will probably narrow the JK treated tires.

This one uses a 3/4" guide block and 3/4" bracket rear weight tabs are 1/16" brass bracket plate is 3/32" brass.

Frame rails are 3 X .047 with a space. Could have been 4 X .047 solid as well.

Two additional brass bits (arrows) on top of the rear rails add ~~ 2.0 gr/side directly under the rear axle. 110 gr.

F-7 motor, geared 7-27 with JK treated (narrowed) This car was a little light. Will add 5 gr on top of center plate.

This car feels the better of the two but that could be narrowed tires which I personally think are a big deal..

Last is a new 1/32 car. No testing yet as I just discovered that my standby 1/32 was pretty heavily damaged.

Rear motor tray is .032, rails are 3 X .039, all other brass bits are 1/16" weight 100 gr all up.

S-7 Mini Brute geared 11-40, rear tires are JK 8713 treated and narrowed from the outboard side to 1/2".

Gear side tire is reversed so that the gear hub tucks inside the wheel a bit.

Now......all I need is a headlamp....................

- DCR likes this

#1943

Posted 03 December 2013 - 01:18 PM

Very nice work.

12/4/49-4/17/24

Requiescat in Pace

#1944

Posted 03 December 2013 - 03:56 PM

Yes, to paraphrase his own words, he "builds quite well"

![]()

#1945

Posted 03 December 2013 - 04:15 PM

#1946

Posted 03 December 2013 - 04:19 PM

Very nice builds Jim, as always. Second to none!......

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#1947

Posted 03 December 2013 - 05:15 PM

What front tires are on the f1's?

They look just like the Samson Ball Bearing fronts that I have!

11/17/49-1/30/24

Requiescat in Pace

#1948

Posted 03 December 2013 - 05:15 PM

What front tires are on the f1's?

Blair, on the first F1 the front tires are Samson Classics. On the second, they appear to be something Jim may have cut down from a worn out set of rears.

11/27/57-8/12/22

Requiescat in Pace

#1949

Posted 04 December 2013 - 09:15 PM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#1950

Posted 04 December 2013 - 09:41 PM

Looks like team RGEO is gonna be hard to beat !

Proud to drive an American car, from an American manufacturer, assembled by American workers.

I own a car from each of the big three: I have a Ford, a Mercury, and a Lincoln.