Sam,

I posted recently that the 1" x .031 and 1/4" x .016 brass strips, .055 wire and pin tubing were my "F1 chassis kit".

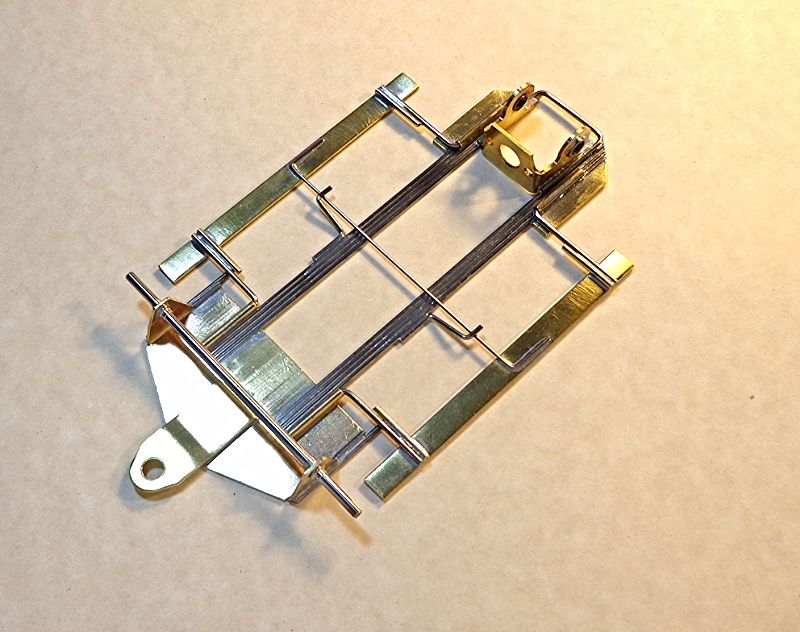

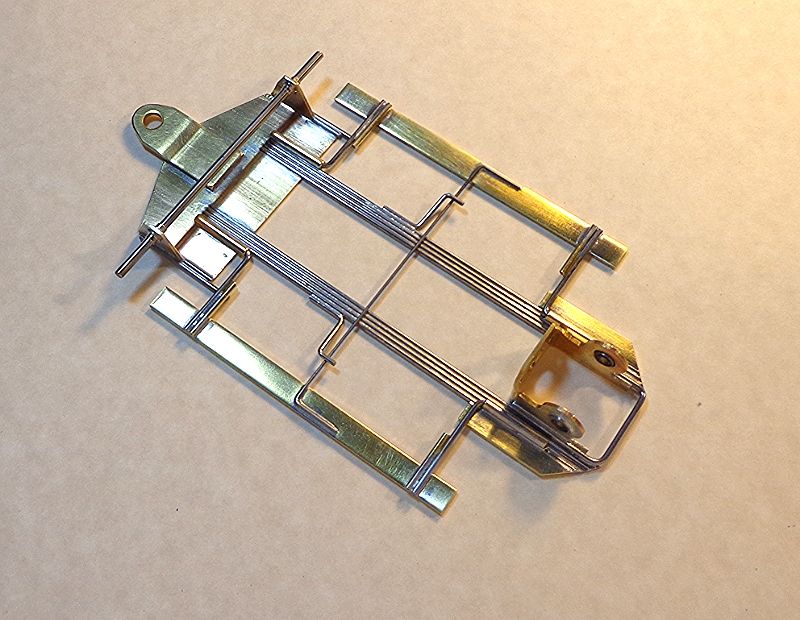

I intentionally did not talk about the motor bracket but, since inquiring minds want to know, I have always made my own brackets. My engineering sense tells me that it should have a shape that mimics the way we triangulate/brace them and that it would house the bearing/bushing without a high CG extra part like an axle tube or steel wire bracing. Therefore, they are very wide to support the bearing where the load is. However, this prevents me from using the collars that facilitates the very quick tires swaps necessary to get the last tenth or two out of tuning the chassis to the track on race day, so the tire swap is slower for me.

Also, I can make the bearing holes as tight as I want them. I don't solder the bearings in as I want them to be free to "re-align" a little bit if I take a side shot and it bends a mite. If the hole ever gets loose, I just stake it with a 4 fluted center drill tool to raise some material in the center so the ball bearings are a light press fit.

I like the bevel mesh and keeping the motor flange to axle distance constant. Once broken-in, I keep motors with their crown gears and I can move them from chassis to chassis with no additional break-in necessary.

The five-sided bracket just makes sense to me and it was an original thought but I have recently seen a couple of Crutchfield chassis made this way years ago so it is not new - credit where it is due - but, lest anyone comment, it IS legal ("...minimum 3 sided..."). My CAD and FEA simulation tells me that it is 40% stiffer (where it needs to be) and 30% lighter than an equivalent material 3 sided bracket (before adding the braces). I form them by hand with the brass clamped between two blocks of rectangular tool steel in a vise (old school, yo!). I can make these faster than the 3 sided brackets now - my last Retro Stock Car crash cemented the deal that I am not going back to 3-sided (unless the rules change).

Maybe some industrious Retro chassis parts supplier would create a 5-sided bracket - it would save me a bunch of time if I could buy them! Plus, they would be spot on accurate and square!

Keep it in the slot,

AJ

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"