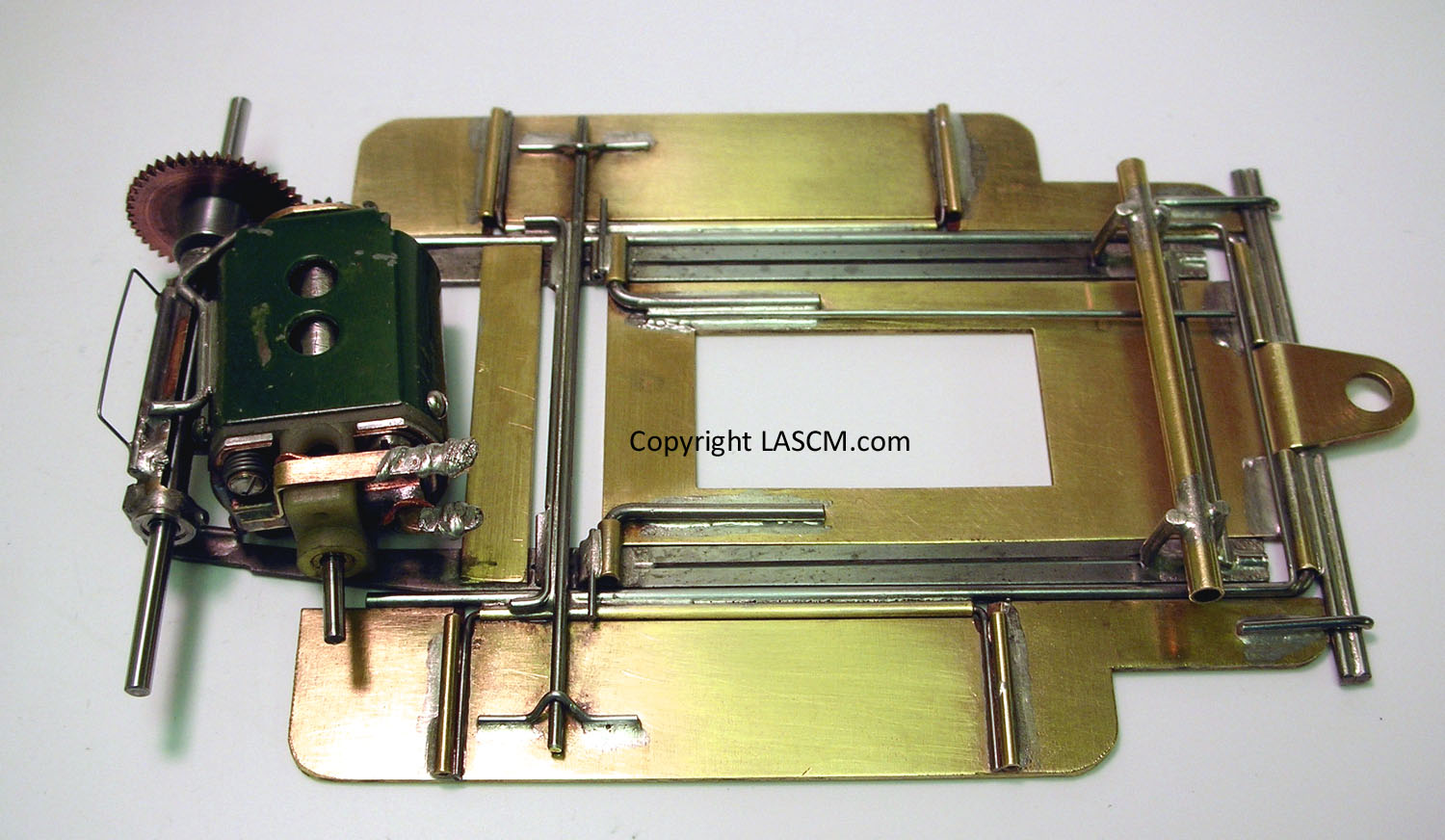

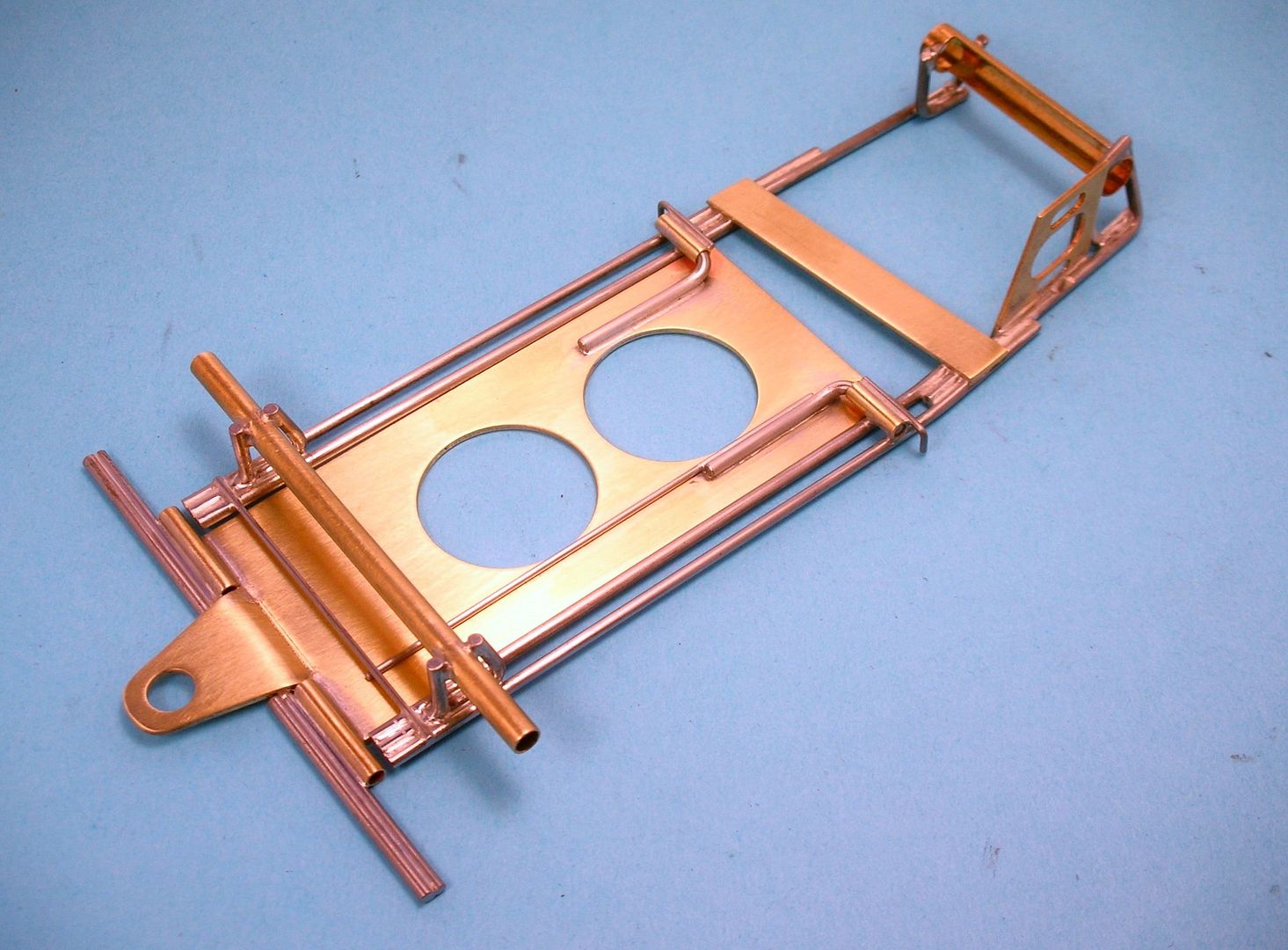

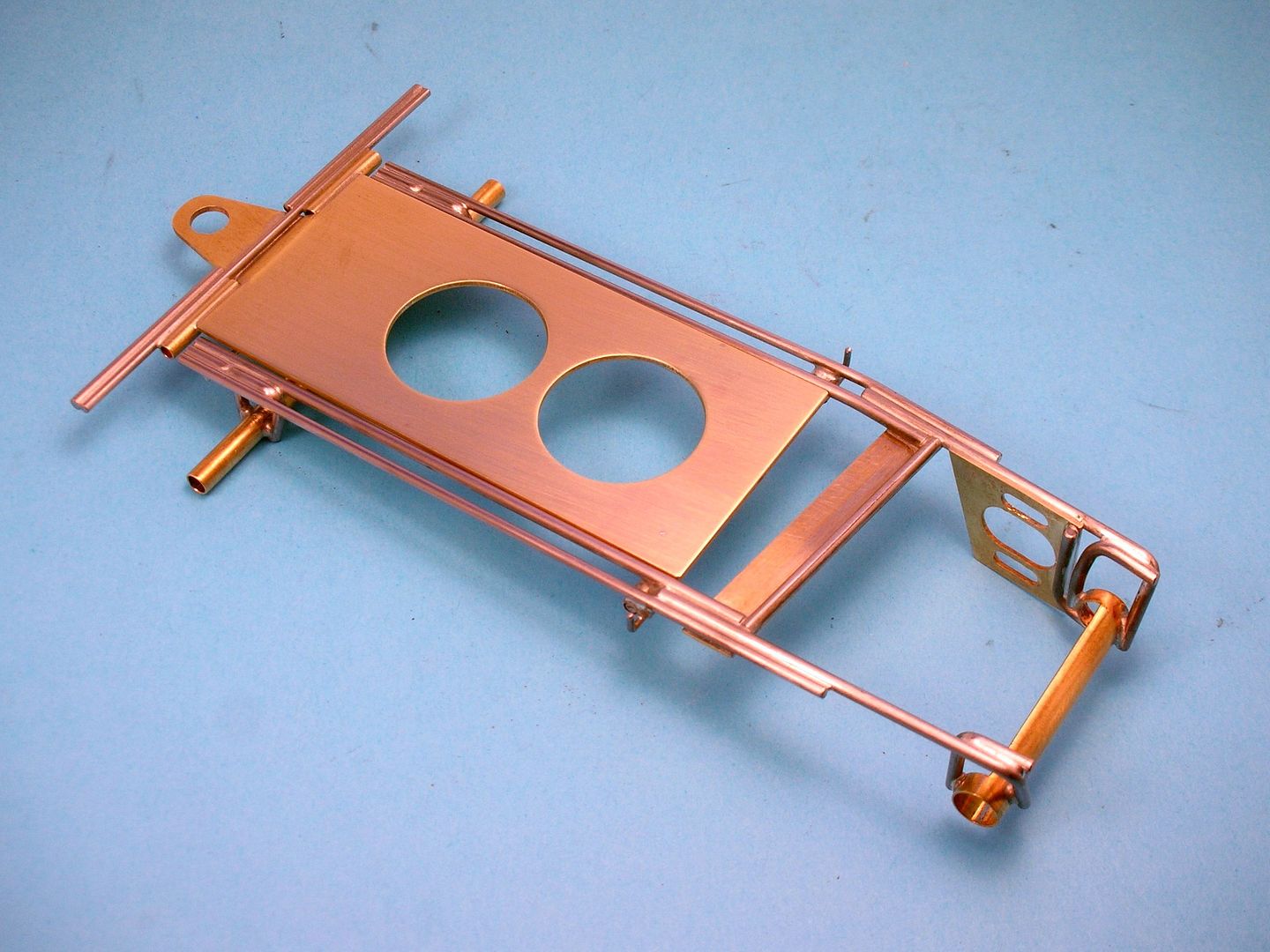

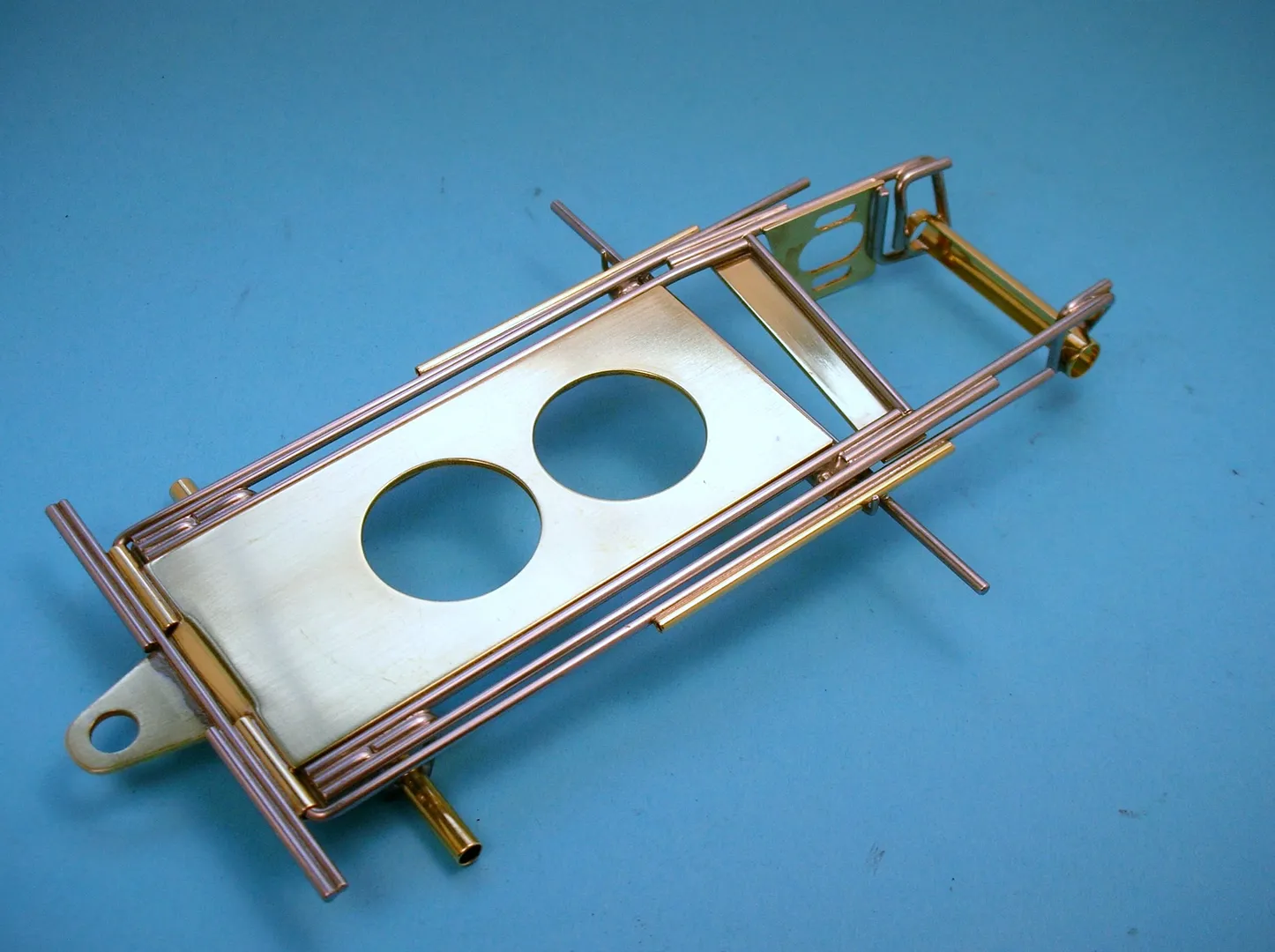

Here's one example of a steel center section that I've found available lately Mike:

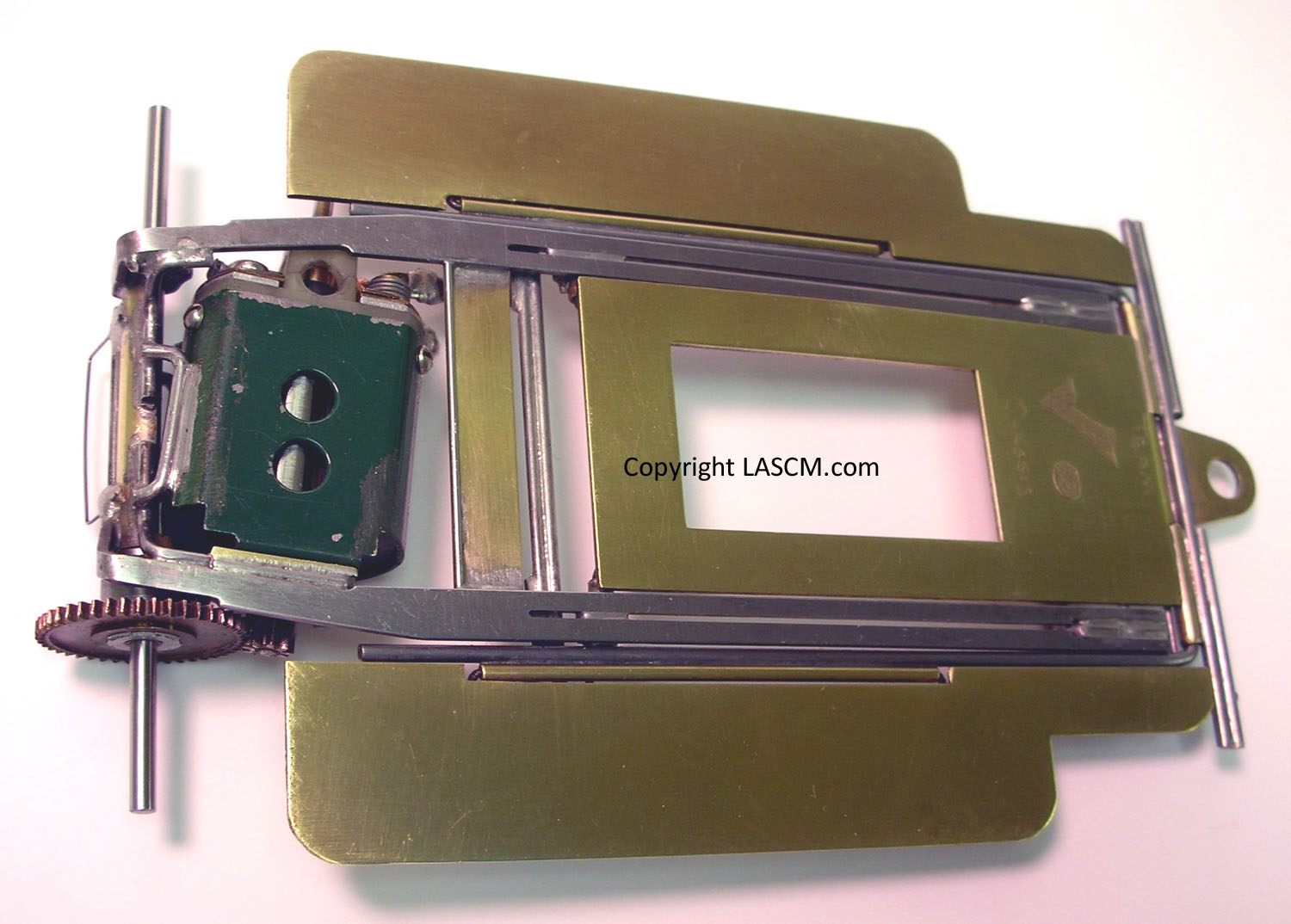

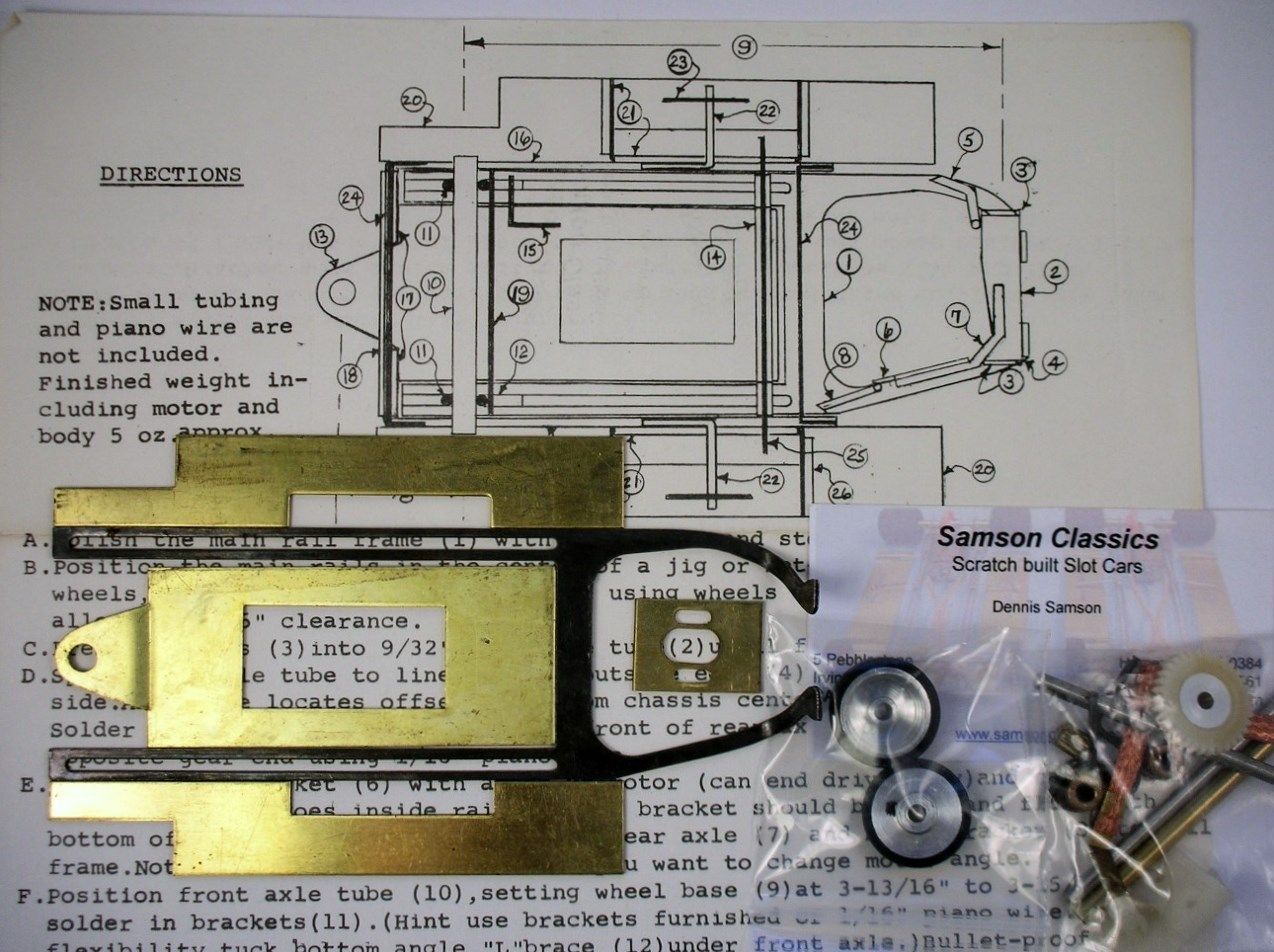

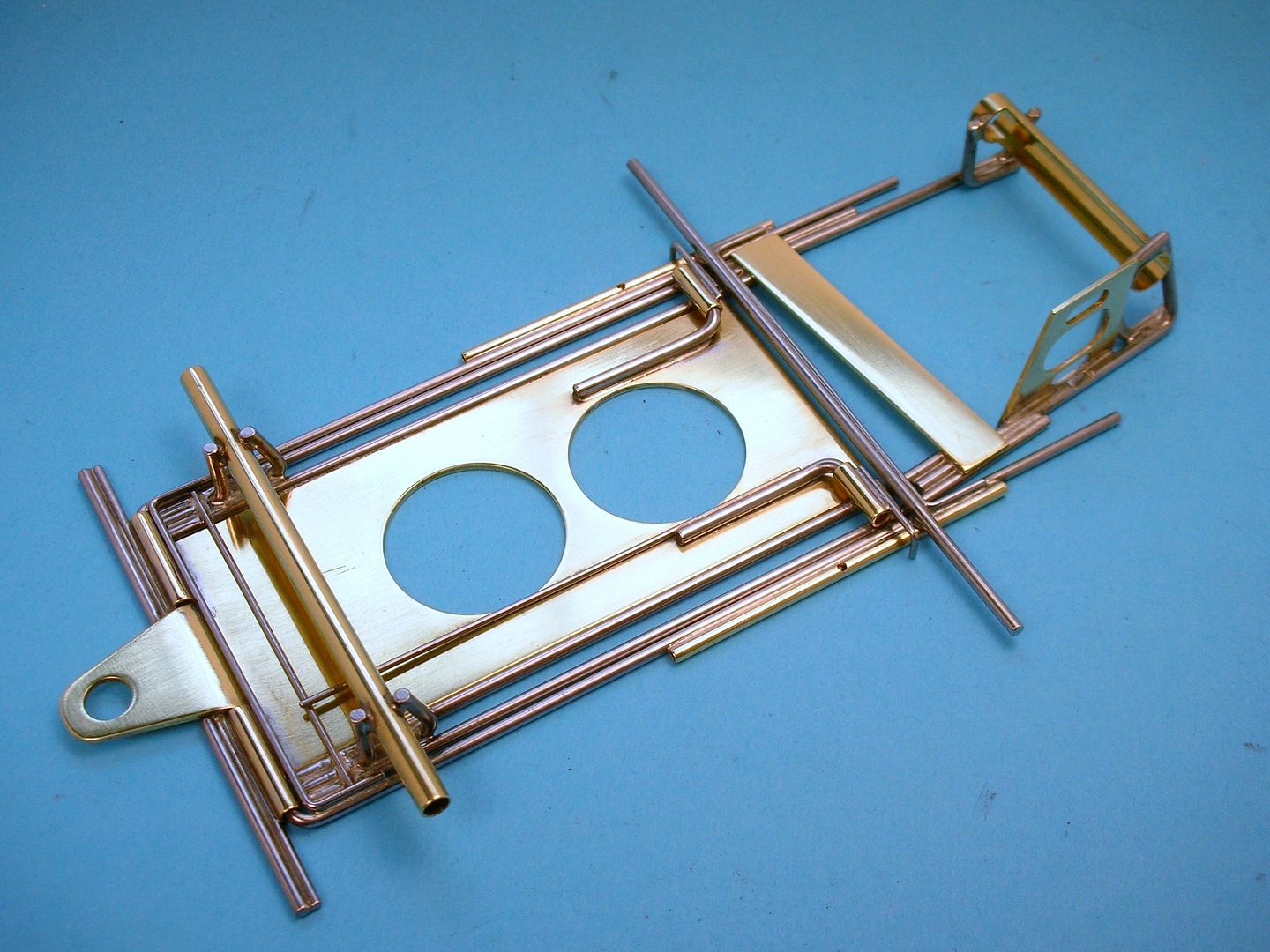

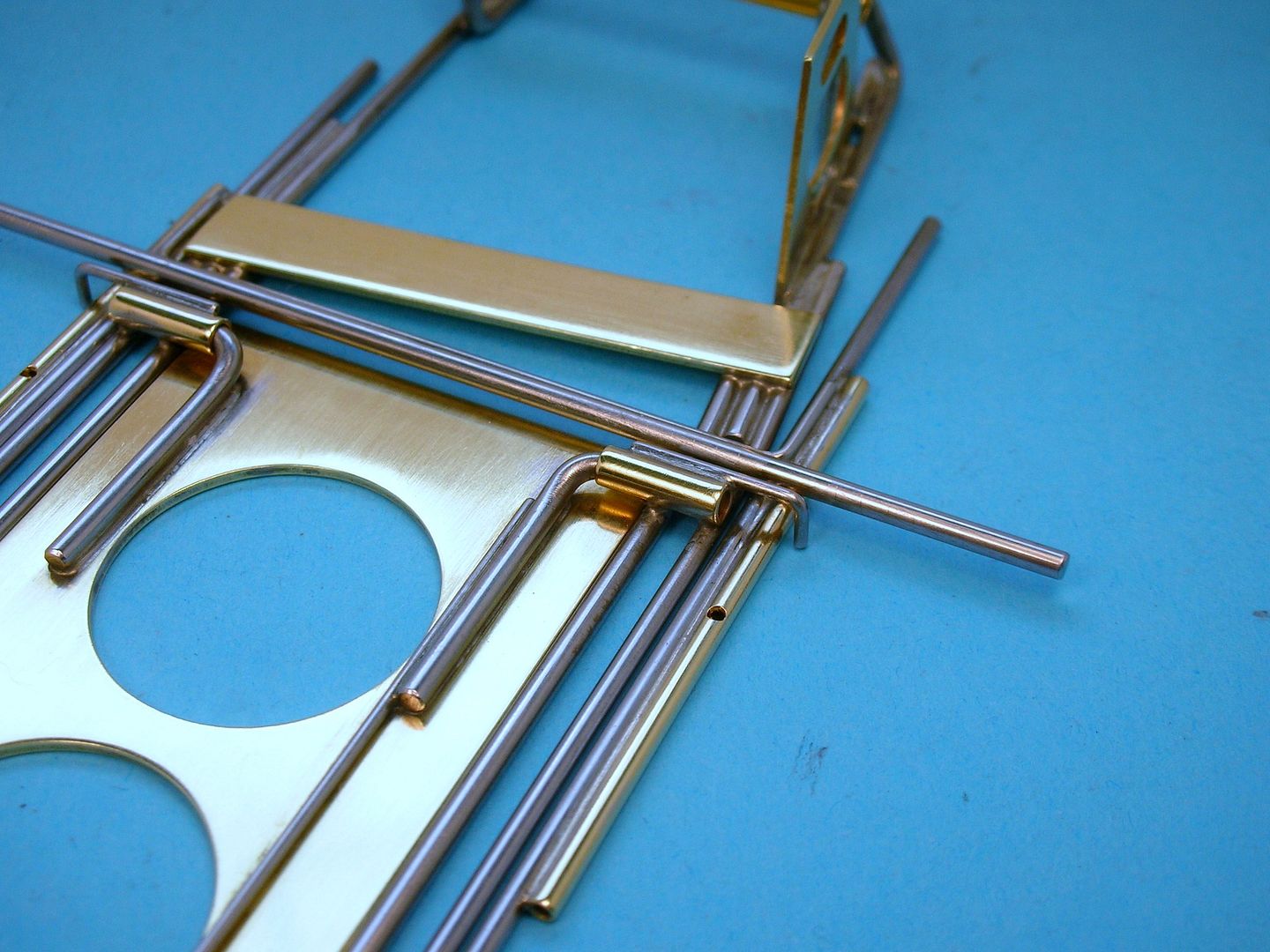

I don't think this style could have been used by cutting out the cross piece. Bill Jr.'s rails are straighter. I wish it would work with this style because I'd like to build a steel car like PdL's picture. It's very cool.

Jeff, I hope to send the finished car down to Rodney for a test on a full size track. The track is nicely kept up with a spray glue finish. I don't think there will be any additional glue used.

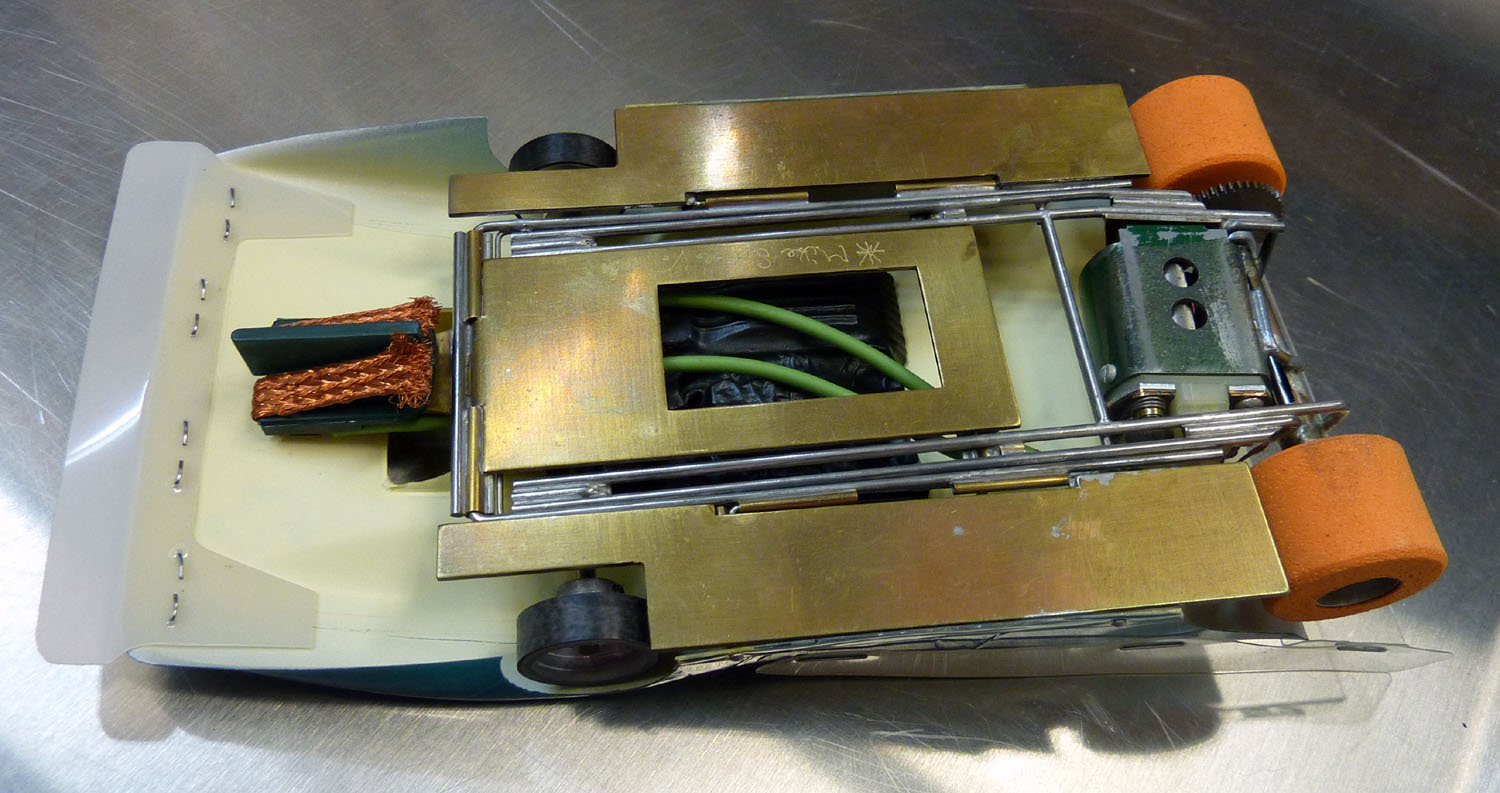

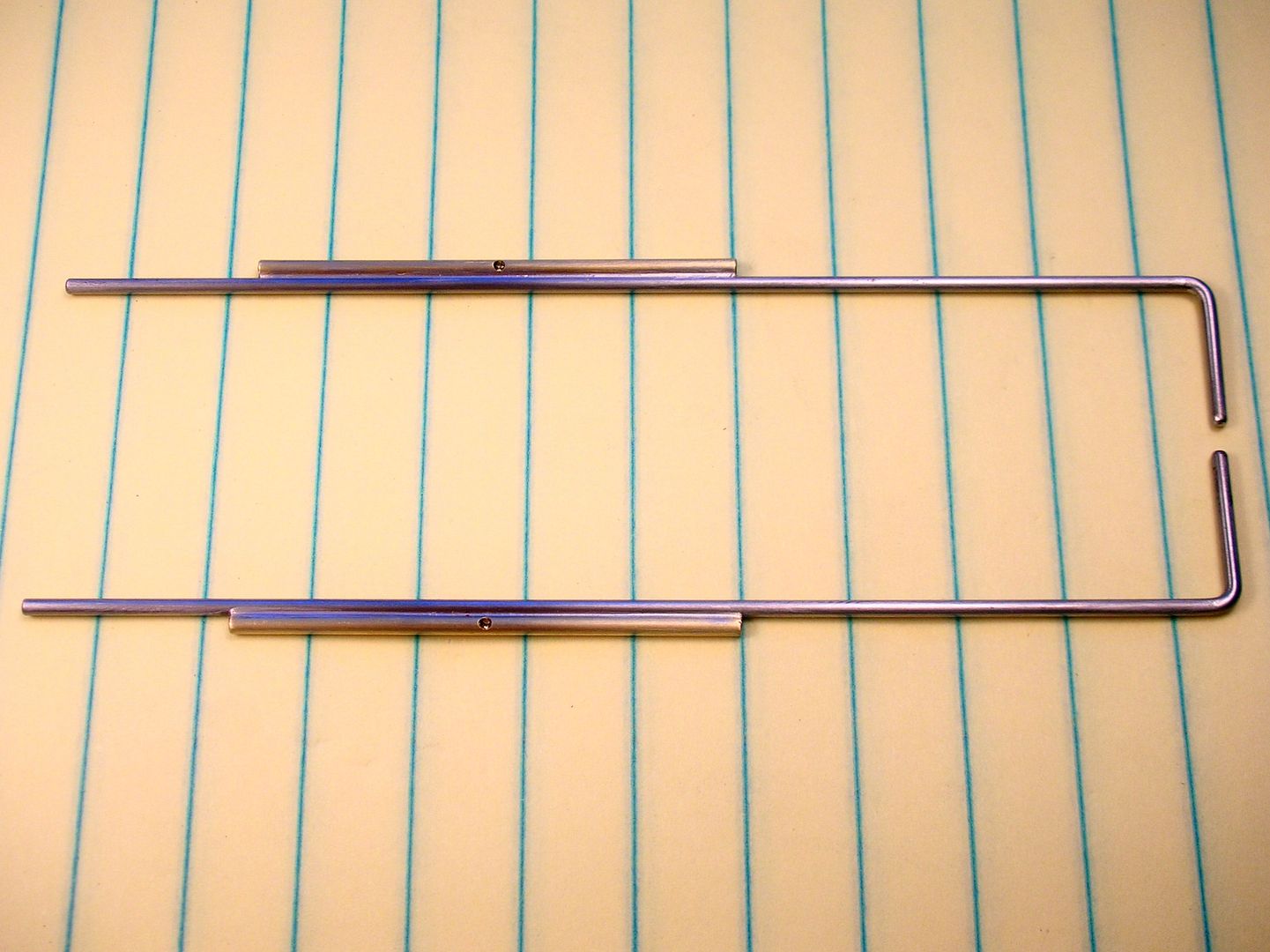

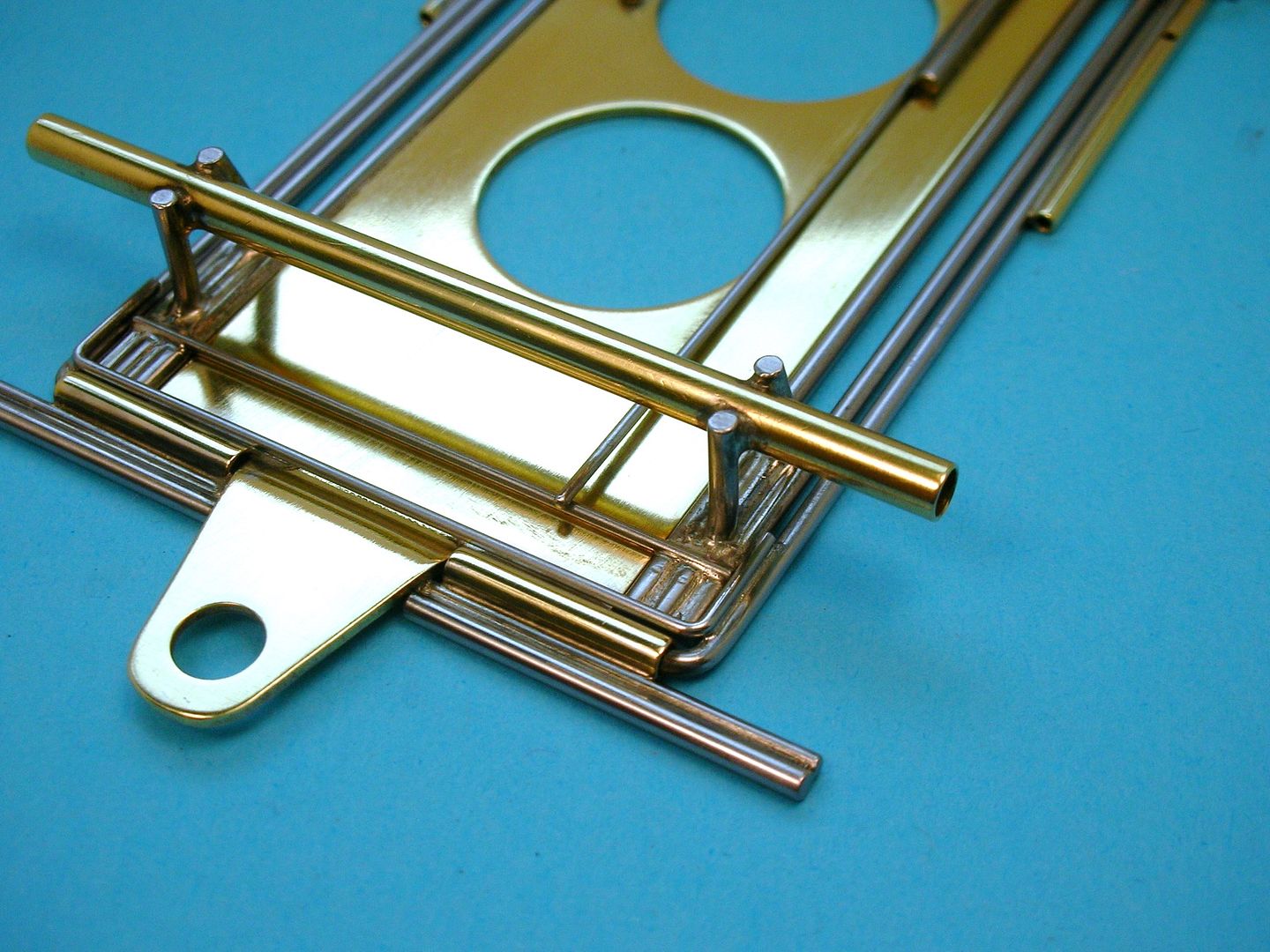

Here's the corrected boo boo zone Bill:

I've never made a plumber stop with a "hook" before, just a straight piece of wire. On my first attempt I only left room for the plumber and forgot about the pan hinge that the "hook" had to clear.

Now I can get back on track with the plumber install.....