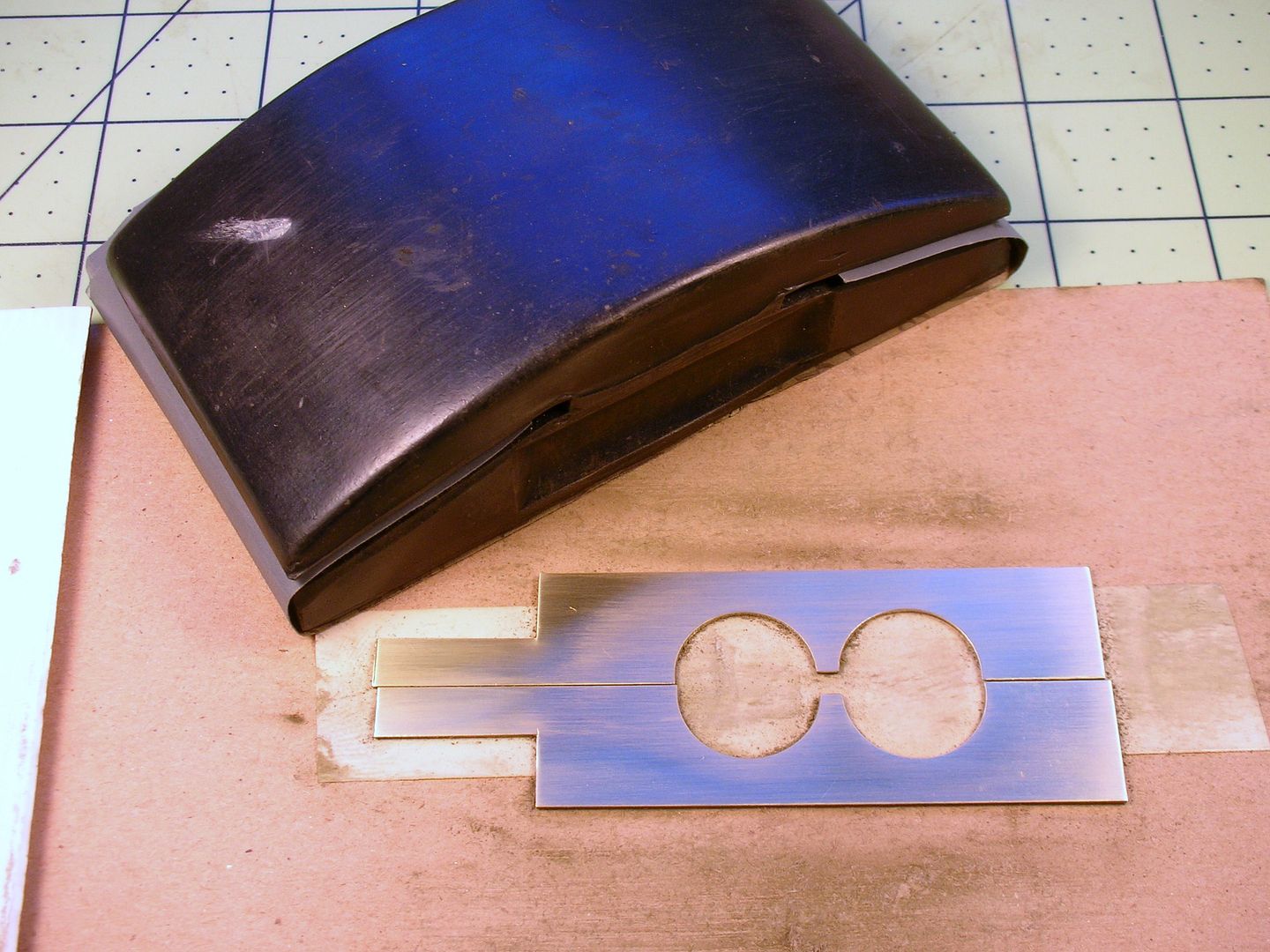

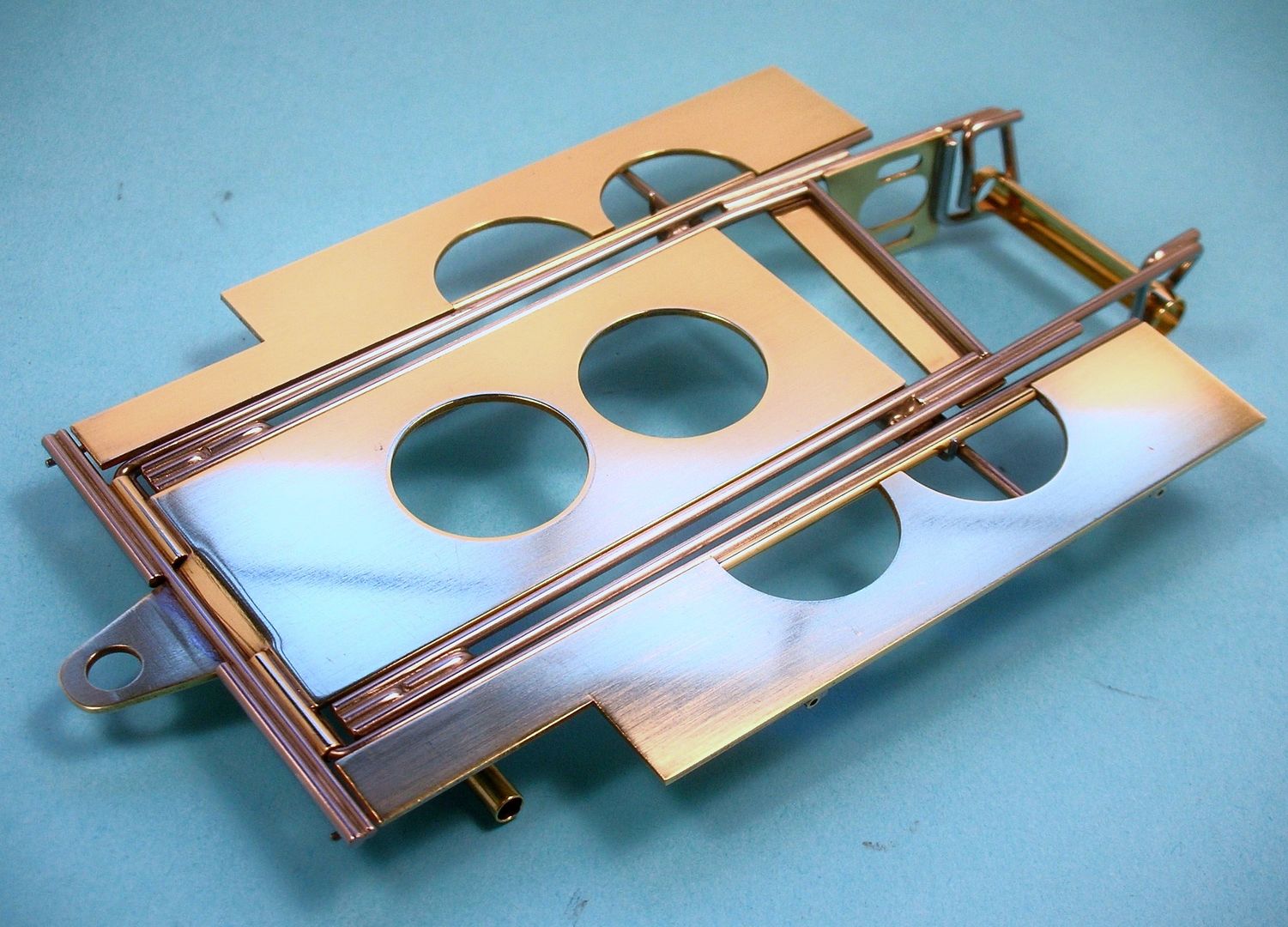

I had to flatten out the pans and put the buff to them:

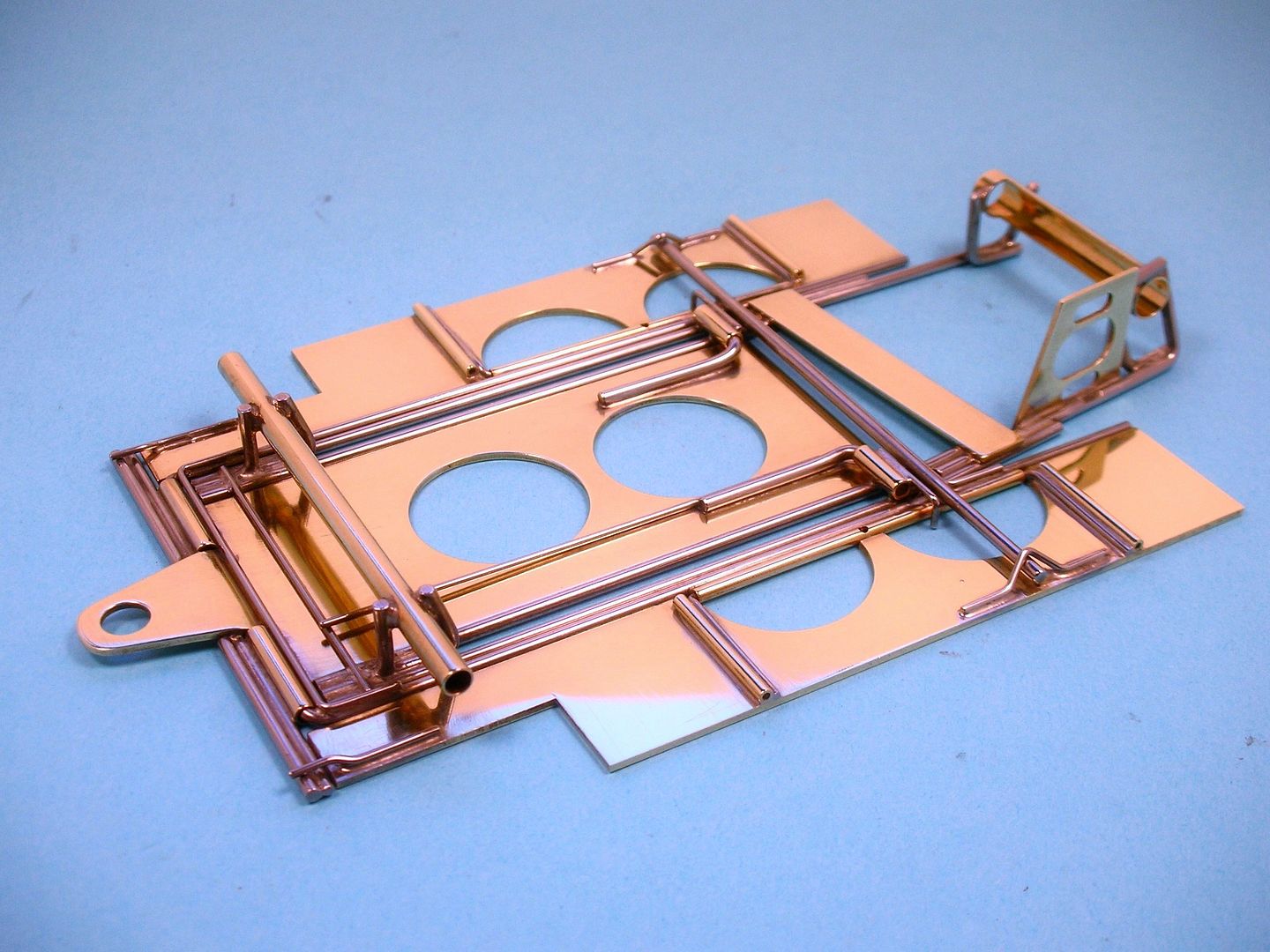

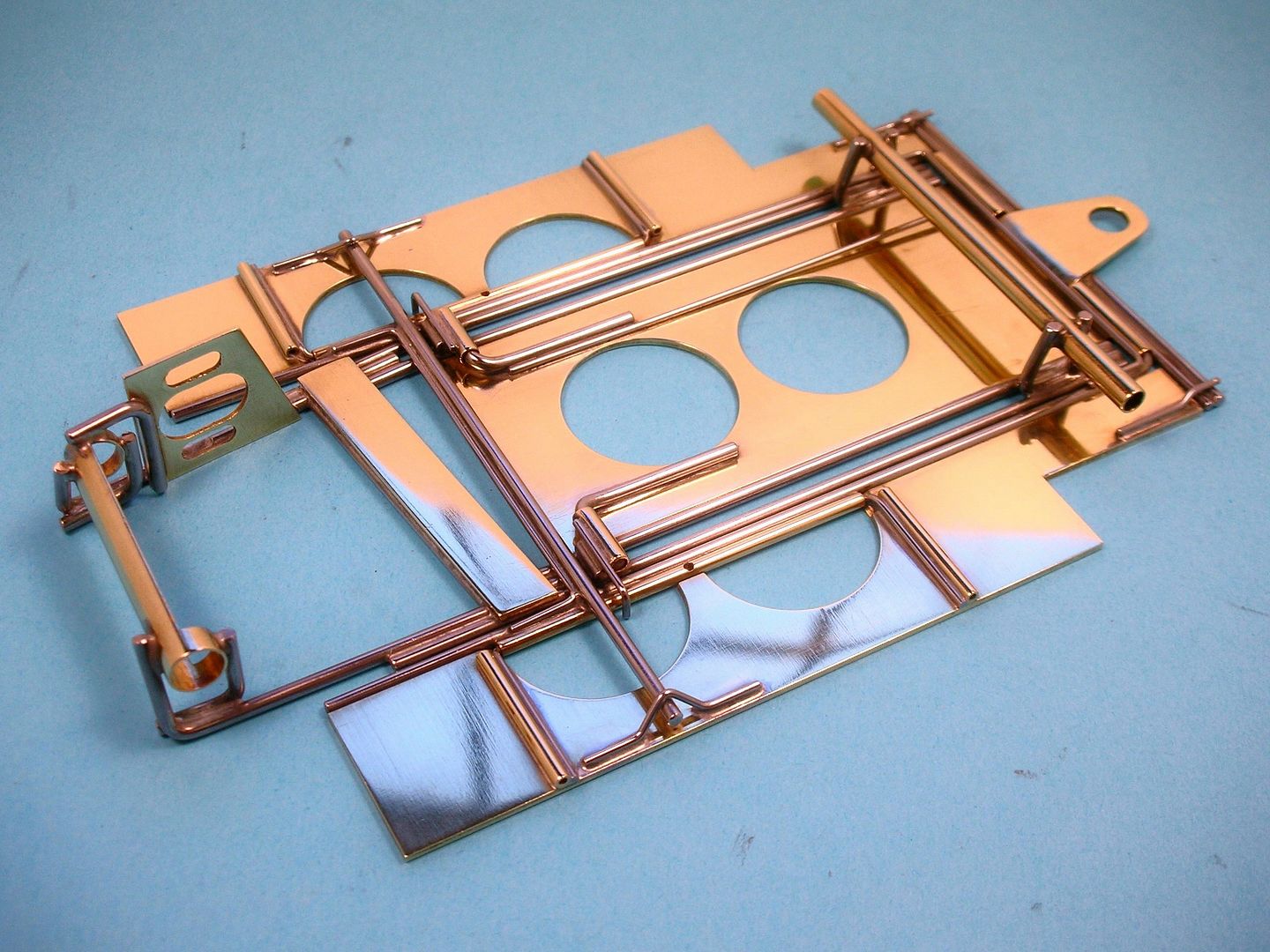

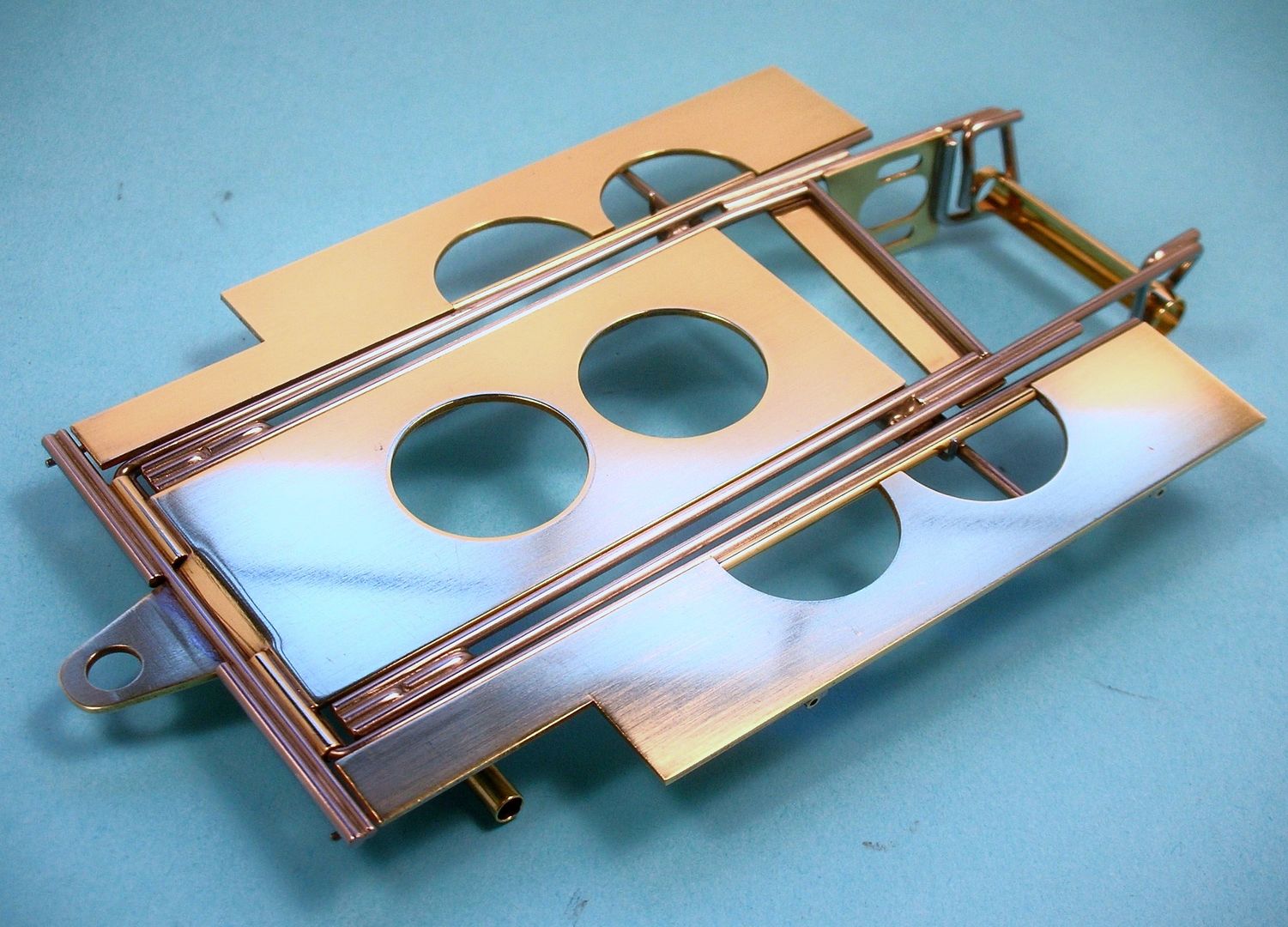

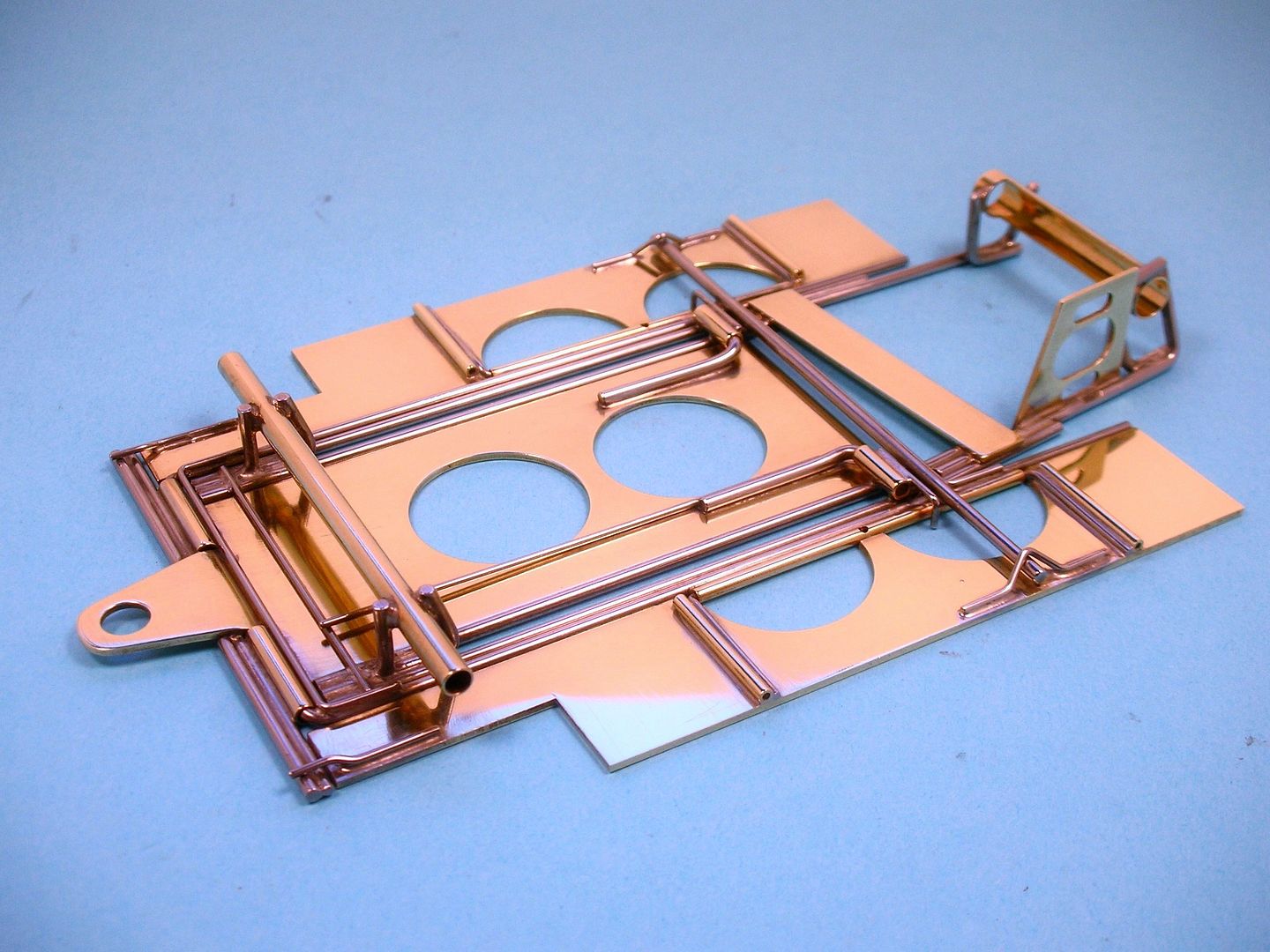

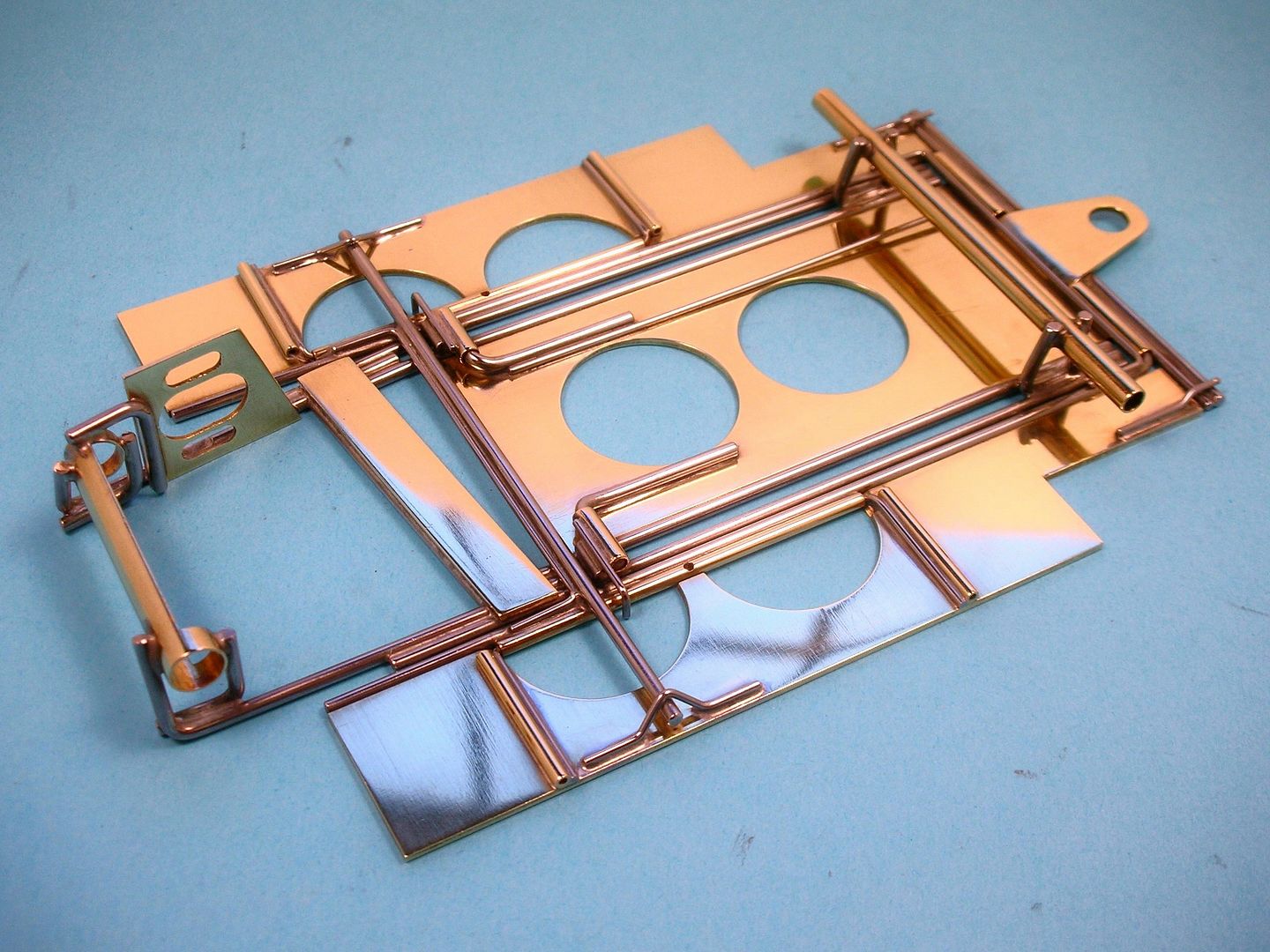

The chassis is finished: ![]()

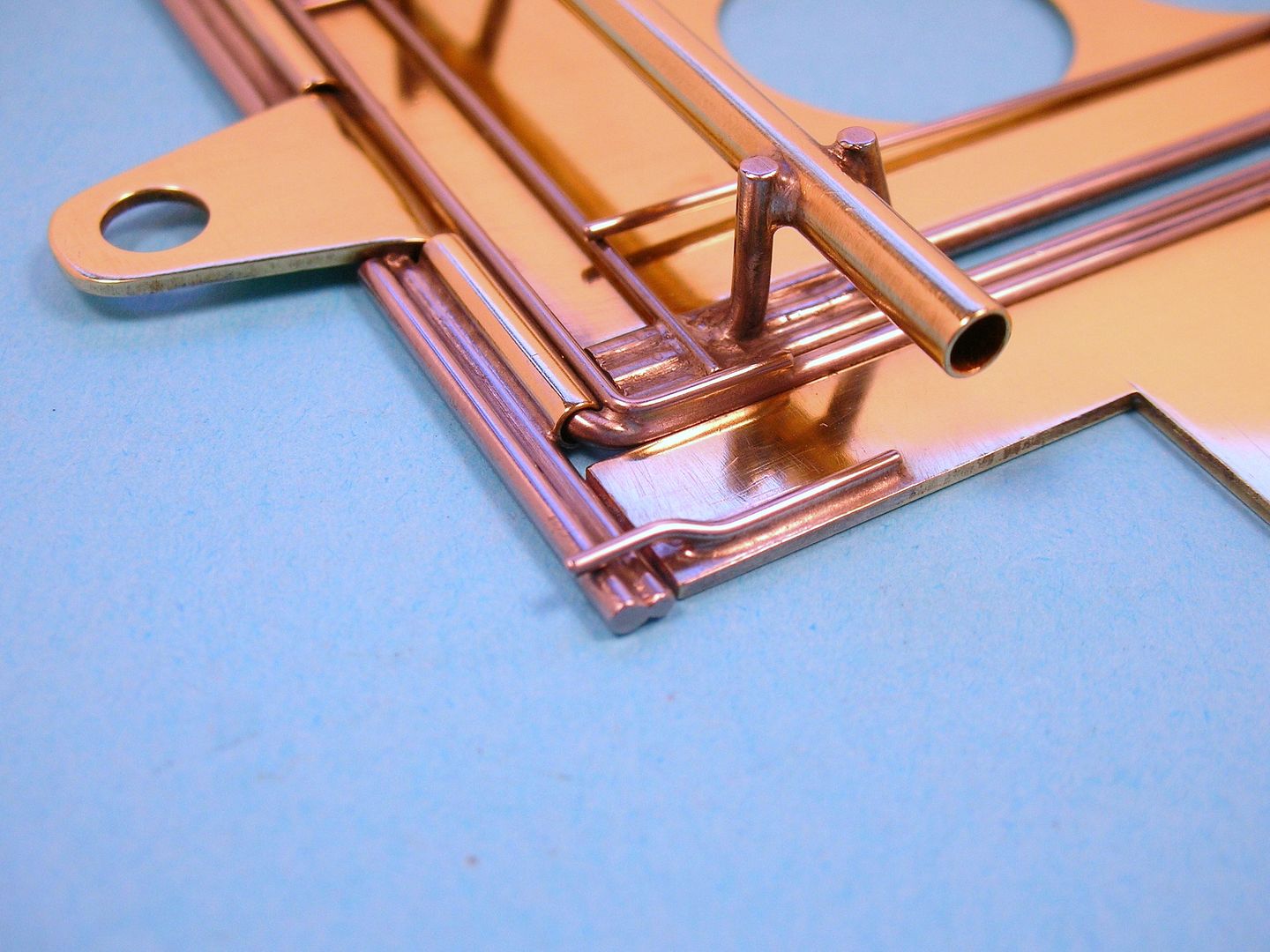

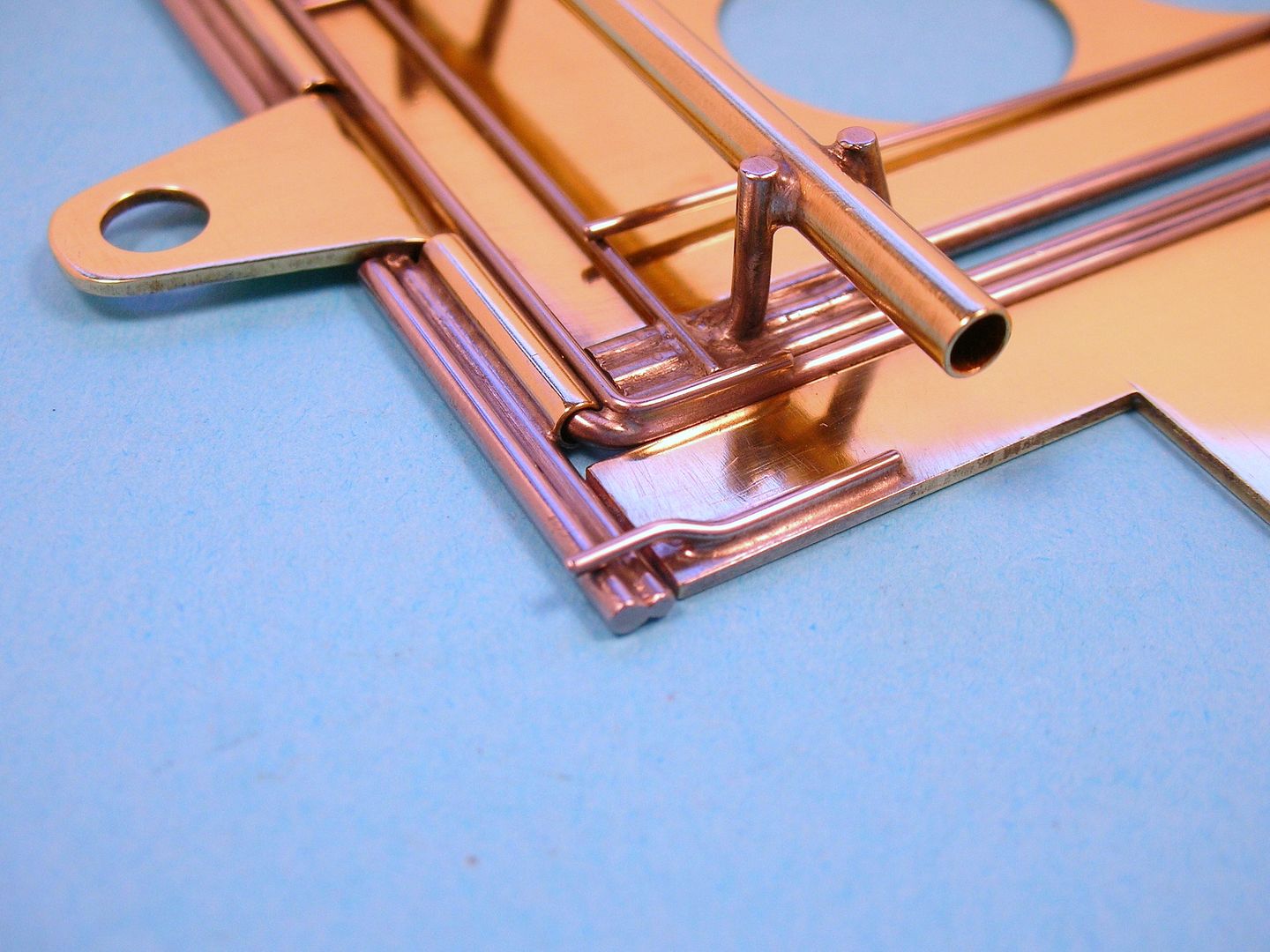

The front of the pans have a Steube style stop:

Time for a motor ![]()

Posted 04 August 2017 - 03:53 PM

I had to flatten out the pans and put the buff to them:

The chassis is finished: ![]()

The front of the pans have a Steube style stop:

Time for a motor ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 04 August 2017 - 03:58 PM

It looks great.

Posted 04 August 2017 - 04:02 PM

Another beauty Rick! Now we'll enjoy watching it become a complete slot car. ![]()

Posted 04 August 2017 - 04:14 PM

Really pretty Rick! Another beautiful job!

Don

Posted 04 August 2017 - 04:39 PM

That one had a S25 and a Faas 9/42 ratio for the Speed & Sport AMCRC "Blue King" track that was not in the best of condition at the time.

I seem to remember we ran S24's and 9/47 at Buzzy's and it worked at Nutley. Needed to pull thru all the glue.

Jeff Morris

"If you push something hard enough, it will fall over." Fud's 1st law of opposition

Posted 04 August 2017 - 05:11 PM

Man, if that doesn't draw Mike Steube out of his cave, nothing will ![]()

Shock and awe ![]()

![]()

![]()

![]()

Paul Wolcott

Posted 04 August 2017 - 06:20 PM

Thanks guys ![]()

Here's an interesting motor building article. It's from the Miniature Auto Racing Newsletter 1 month before their article on the Steube RTR: (CLICK ON IMAGE TO ENLARGE)

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 04 August 2017 - 07:21 PM

That's a good concise motor build article Rick. Ill have to compare it to that in the CM Gilbert chassis building series. I keep an old Ungar tip around to deal with oilites. I set them on the hot tip until they stop smoking. If for endbell use, I drop them in a bottle cap of clean oil. If for cans or axles, I let them cool before soldering them in dry. Once soldered, I apply clean oil.. I don't recall if I got my procedure from the article you just posted, or from John Ford, but thanks for posting it again.

Posted 05 August 2017 - 03:55 PM

What happened is that I was kind of in racing partnership with Lee Gilbert at the time, and when the story came out, Bill Steube was not too happy because there was a strong rivalry between the Steube gang and the Gilbert/Green gang. So I was asked to write a story on the Steube car, and this is why both were on the newspaper.

Philippe de Lespinay

Posted 05 August 2017 - 08:23 PM

I'm sure glad you did Philippe. ![]()

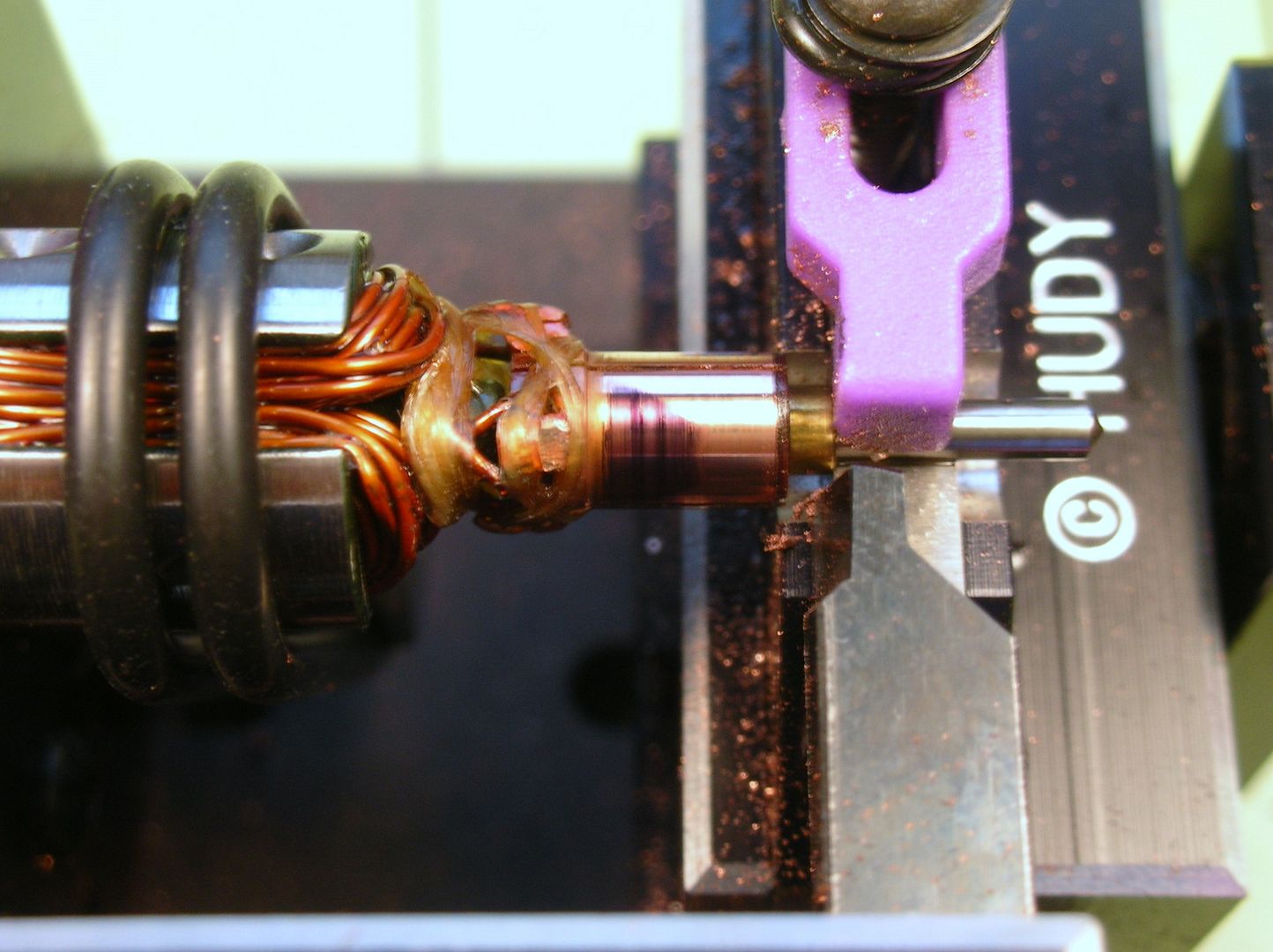

Here's the heart of my motor:

It's not a hand wound masterpiece but it is a new old stock single 24 arm by Certus:

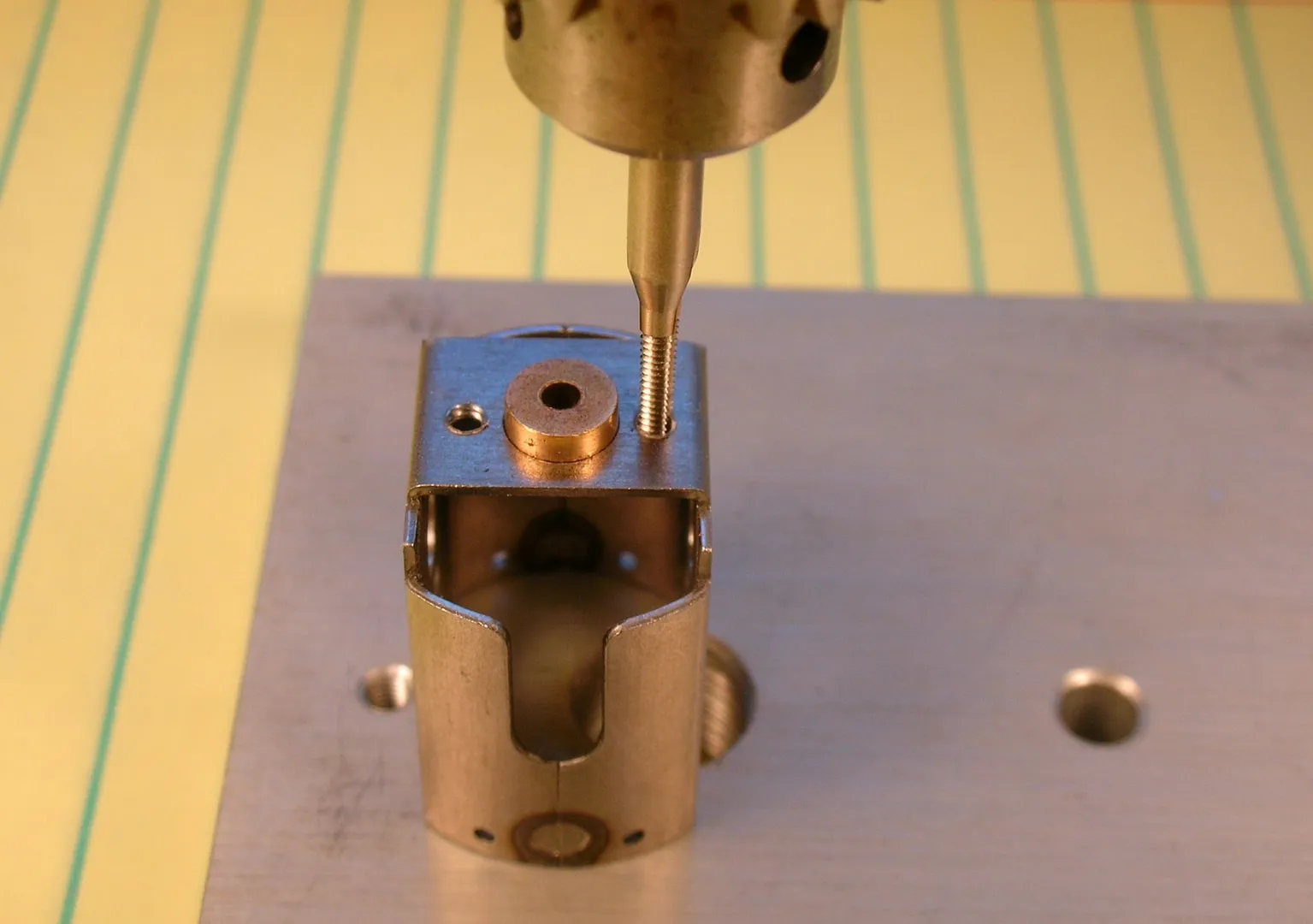

The comm needed some truing up:

She's ready to rock now ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 05 August 2017 - 08:58 PM

Posted 05 August 2017 - 11:45 PM

JEEZUS, that's an ugly wind.... we know why it was still NOS! LOL

Posted 06 August 2017 - 06:46 AM

Sometimes the ugliest looking arms are the fastest. ![]() I never owned Certus arms so this is my first up close look ar one. Certus sold some unique products in the day, they didn't just rebadge another manufacturer's items.

I never owned Certus arms so this is my first up close look ar one. Certus sold some unique products in the day, they didn't just rebadge another manufacturer's items.

Posted 06 August 2017 - 10:01 AM

I wondered if Certus was just a "re-packager" of things like, for example, REHco was Bill.

Yes Tex, it is ugly up close! ![]() But hopefully being new old stock and with no visible signs of corrosion damage, it will run for a bit before it blows up.

But hopefully being new old stock and with no visible signs of corrosion damage, it will run for a bit before it blows up. ![]()

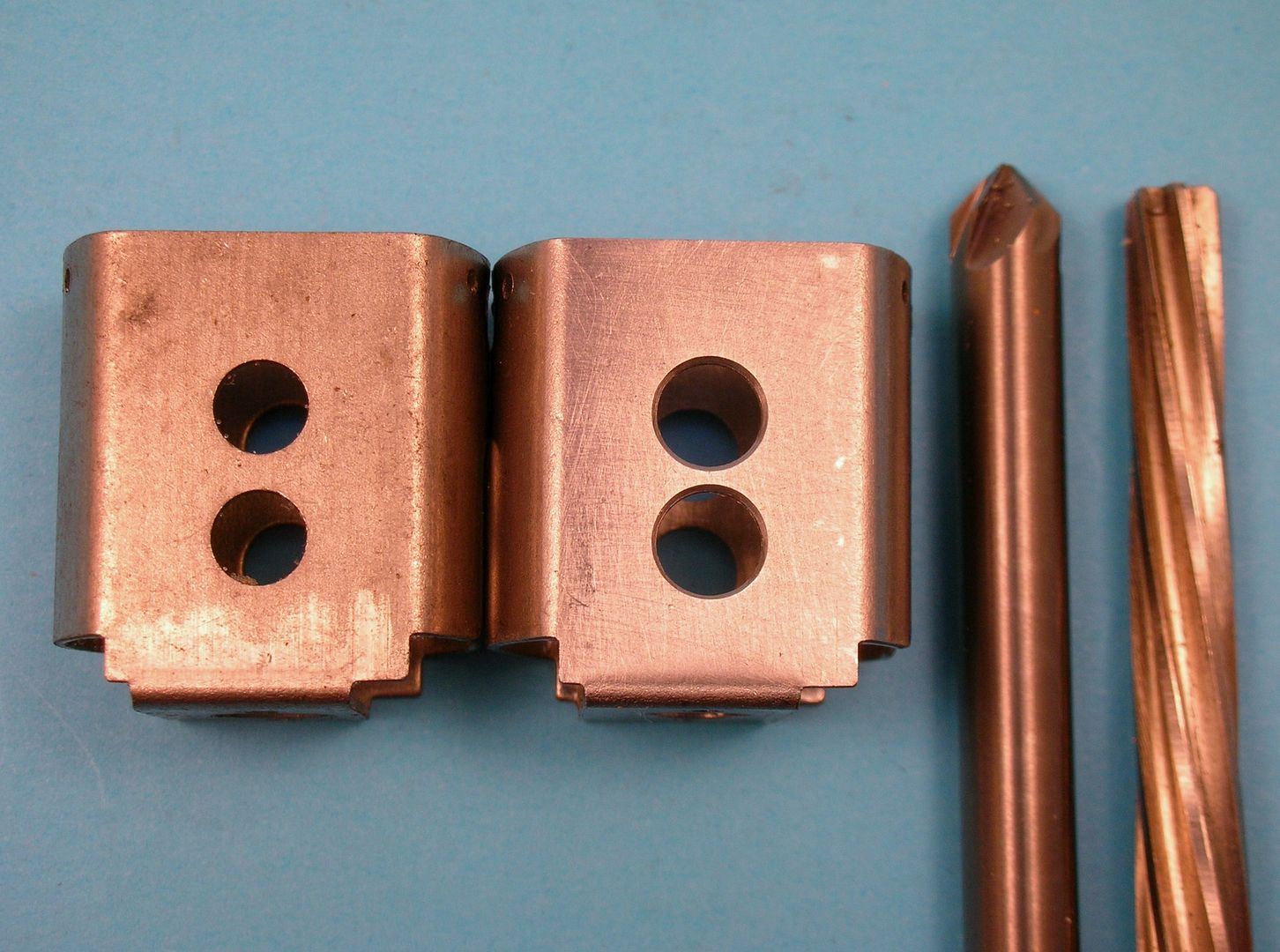

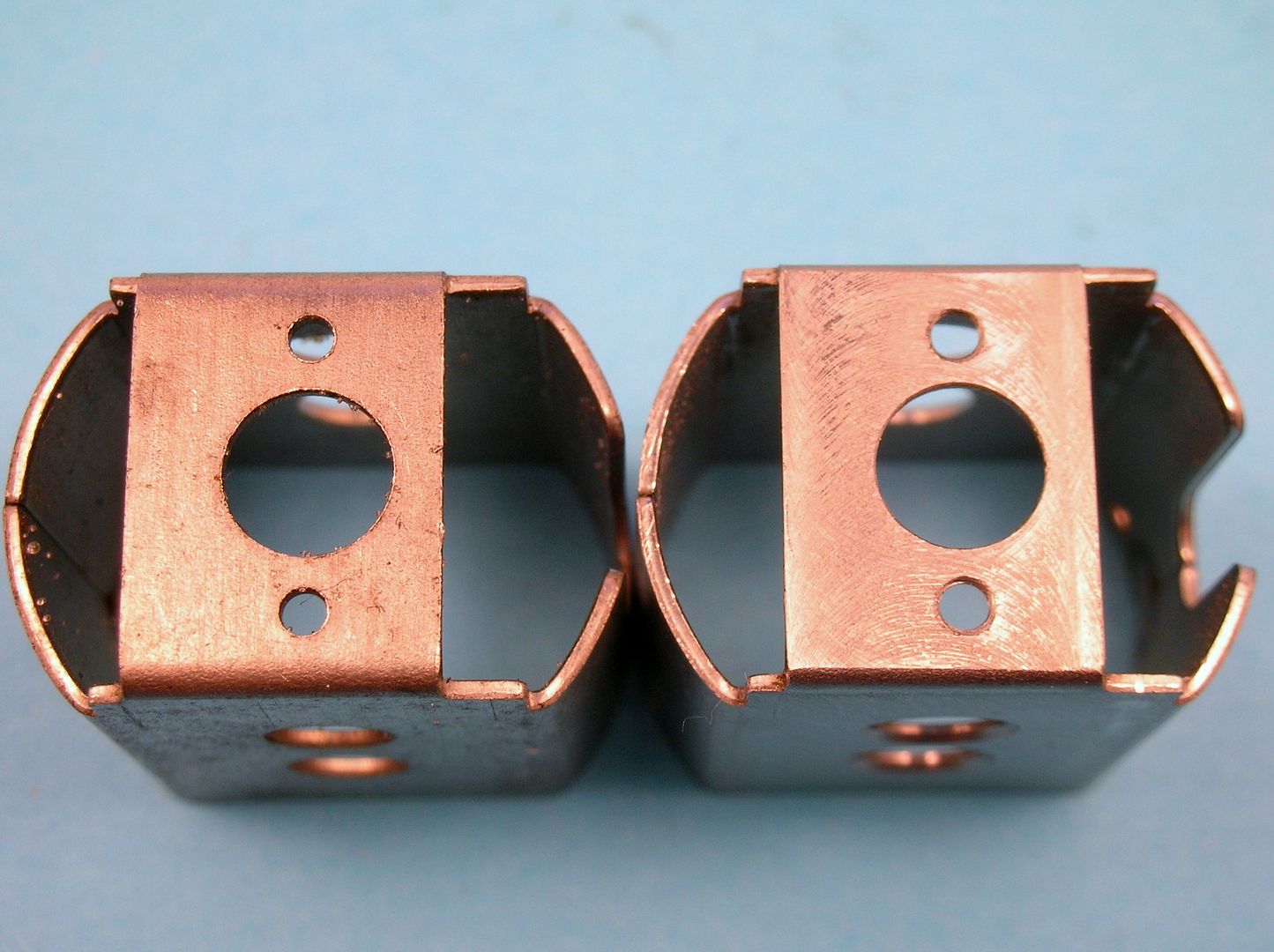

Perhaps, since the wind is UGLY, I shouldn't have opened up the can holes....but I think it's a cool touch:

I also tapped both can mounting holes for 2-56 machine screws...........

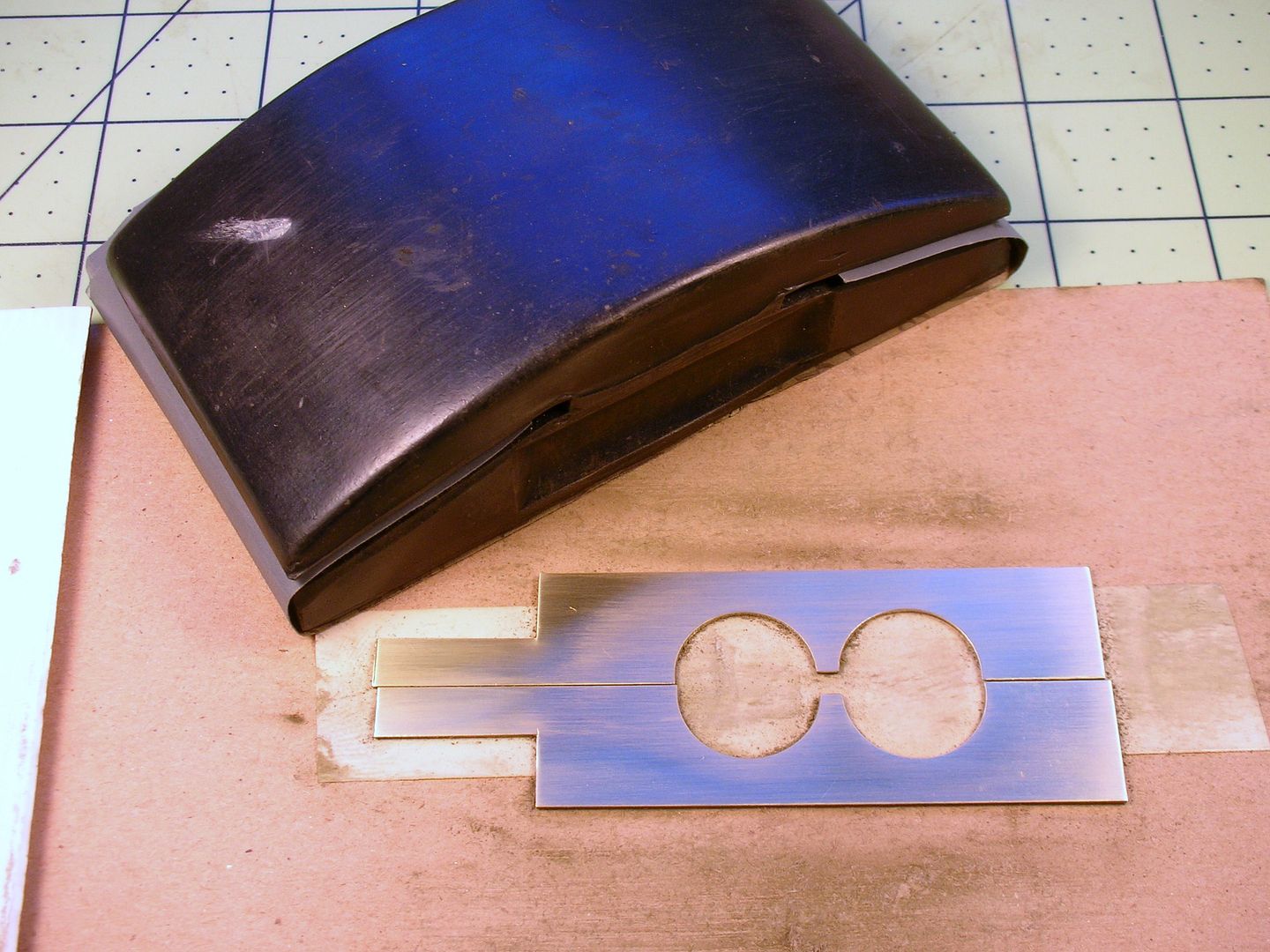

.............and to make the motor bracket fit nice and flat when screwed to the can (like the one on the left)..................

I used Mr. Milling Machine to flatten out the back of the can (shown on the right):

Magnets are next......

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 06 August 2017 - 12:28 PM

Nice!

Pretty sure that Certus was a small producer, like Dyna, but don't know if they had ties with any major manufacturers - don't think so, since they had a factory team (Mike Staskie in particular) that competed with the other guys. They were a well known name in Chicago, not sure about the coasts.

Don

Posted 06 August 2017 - 06:55 PM

I'm looking forward to seeing how the Certus arm runs Don.

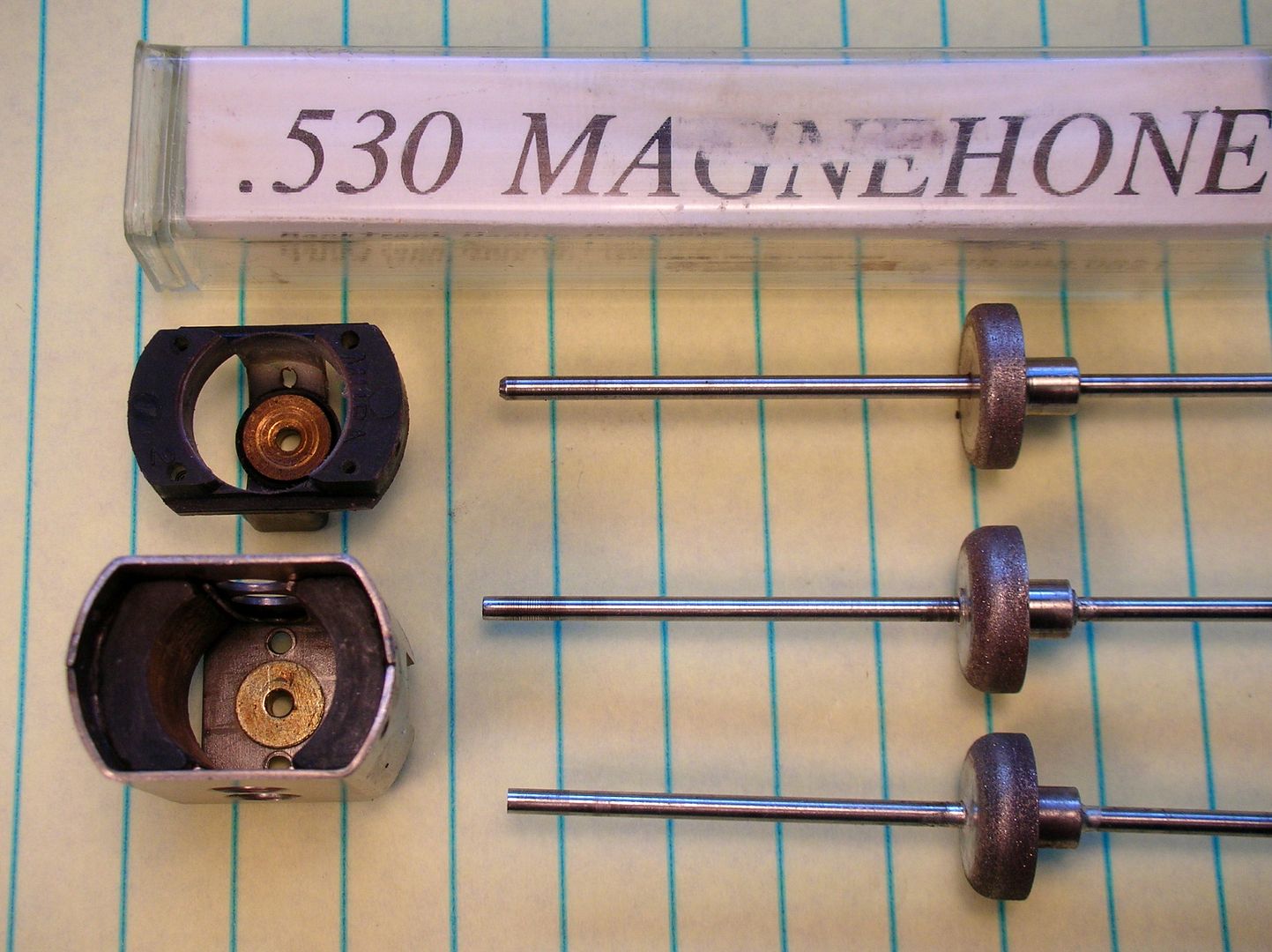

I forgot to show a picture of the parts I'm using in the can along with a vintage packaged piece:

I know the MAR articles talk about using ARCO and DZ magnets but I have more Blue Dots so that's what I'm going with.

I assemble the magnets in the can, positioned them so the arm floats, measured the offset distance and then bonded the magnets into the can at that offset distance:

I honed the air gap to .530" in 3 steps with an end bell opened up for the job. I used a ground down oilite bearing that's a slip fit into the can to save my ball bearing from getting filled with magnet dust..........

.............then a ZAP with the Big Dog...........

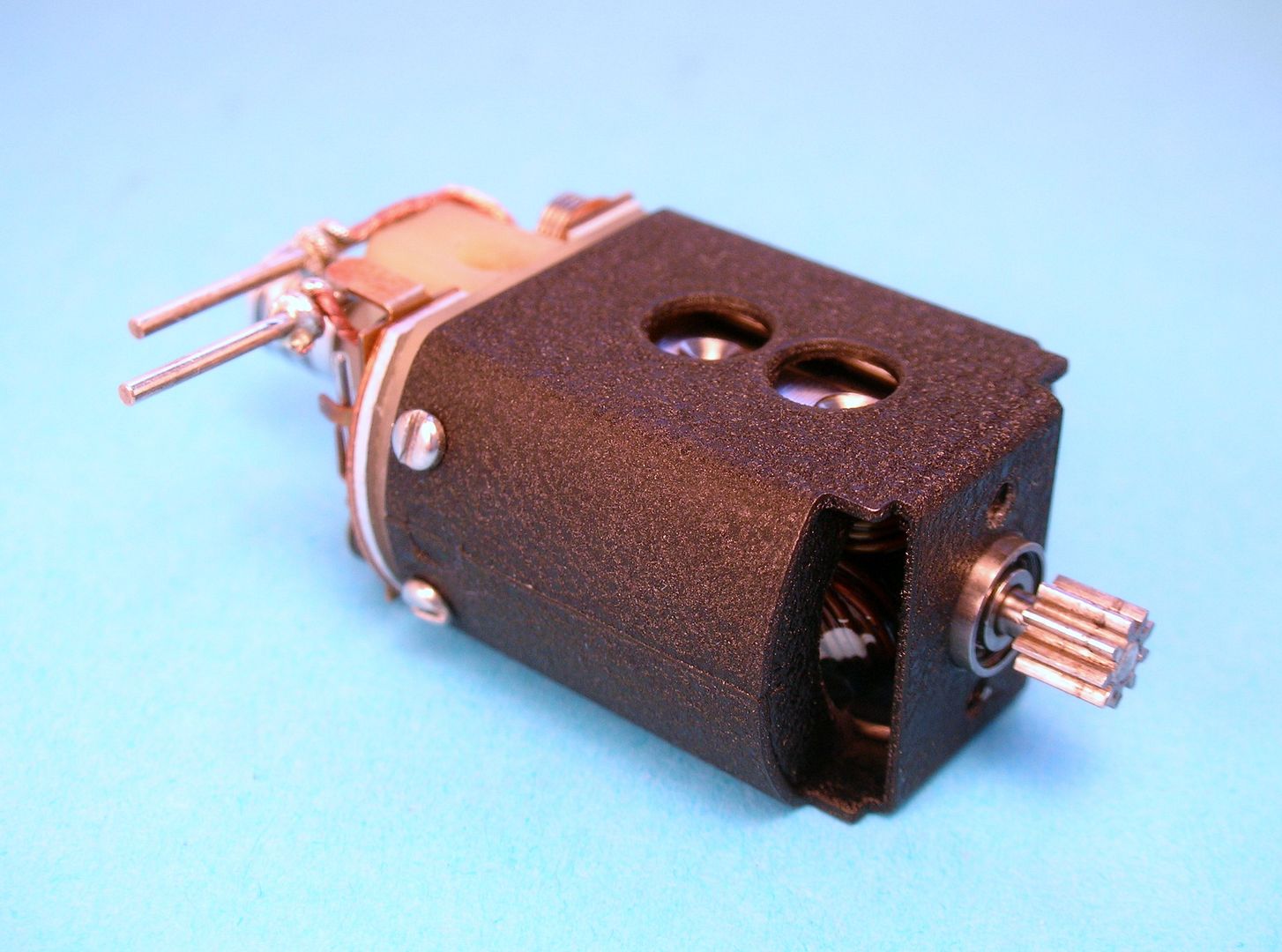

............and finished off the can with a tinned area to solder the motor in and a black wrinkle paint job:

End bell time ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 06 August 2017 - 07:25 PM

"Pretty sure that Certus was a small producer, like Dyna, but don't know if they had ties with any major manufacturers."

Don, Certus was in Muenster, IN. They were far smaller than Dyna-Rewind in sales volume. Like Dyna, they purchased their basic parts from other larger manufacturers. At first, they used like everyone, Mabuchi parts, removing arm wire from FT16 and FT26 motors, fitting Tradeship comms and winding them to their own spec.

They never used Champion parts, but when Mura issued their "D-size" motors in 1968, they purchased armature blanks and endbells from Mura, stuffing them in Tradeship cans. Later they also experimented with Associated "oval-hole" cans. When Mura got their dreadful "B" motor on the market, Certus marketed plenty of motors and parts using B parts, that eventually led to their demise. This is an excerpt of that book that refuses to be born:

"Certus was a small company based in Muenster, IN. In 1966, Marty Varney and Dave Cleary began rewinding motors for their own use at G&G Hobbies in Griffith. They also offered their rewinding services, advertising in period specialized newspapers. This grew into a small business. At first, Mabuchi FT16 motors were offered, the “610” and “612” using the standard FT16 can, while the “614” were rewound versions of the 1967 FT16DBB with the can-side ball bearing. When the new “medium” Mabuchi became available, Certus marketed an FT26 motor featuring an air cooled endbell (probably obtained from SimCo) called the “622”. As technology progressed, Certus purchased cans from Tradeship in which they placed their own magnets apparently obtained from a supplier in Japan, while endbells molded in a special blue color, armature blanks and inner magnet shims were obtained from Mura. When the Mura “B” can design became available, Certus again marketed “B” parts under the label “Baby X” and had their own rewound versions of the motors featuring purple endbells, but like most “B” based motors, they failed (see “Mura”) and it eventually signified the end of the company. They briefly had a “factory” team in 1969, with pro-racers Mike Staskie and Lee Gilbert being helped by the little company. In 1969, they introduced upgraded version of the Mura low-profile motor called “Super Bee”, but by that time, the Mura “B” was already a boat anchor to the serious racers."

Philippe de Lespinay

Posted 07 August 2017 - 06:15 PM

Great info and pictures Philippe, Thanks!

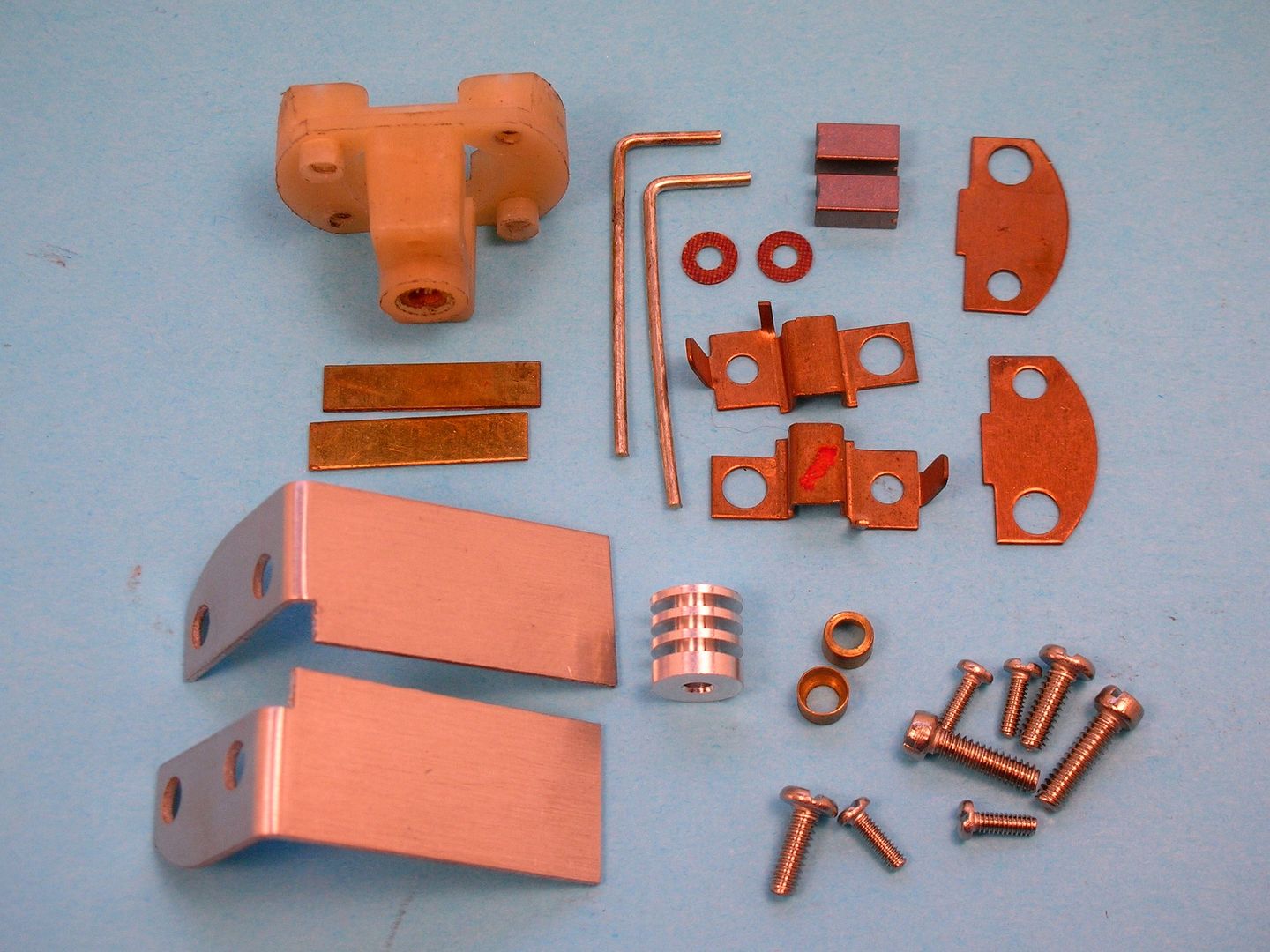

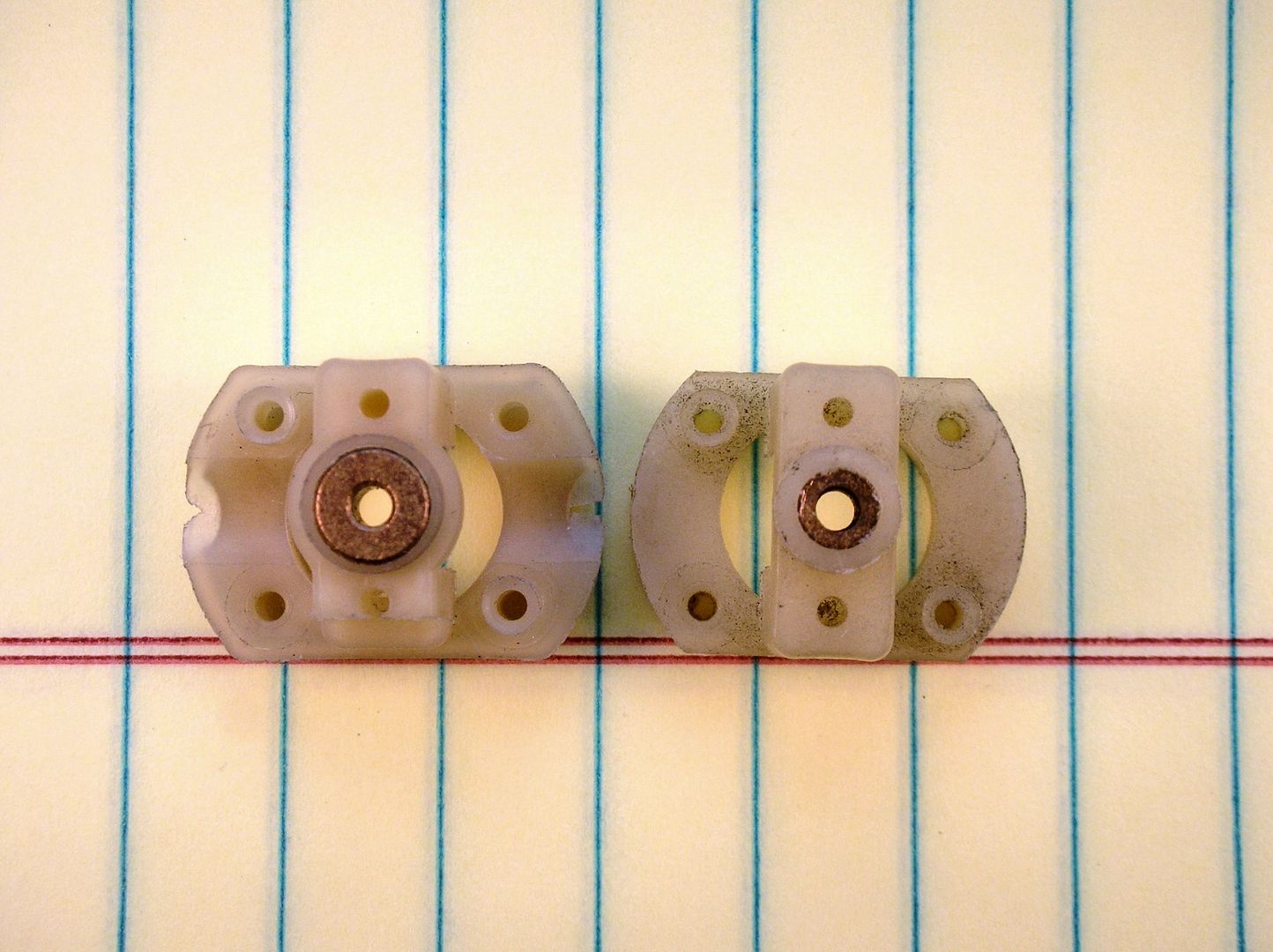

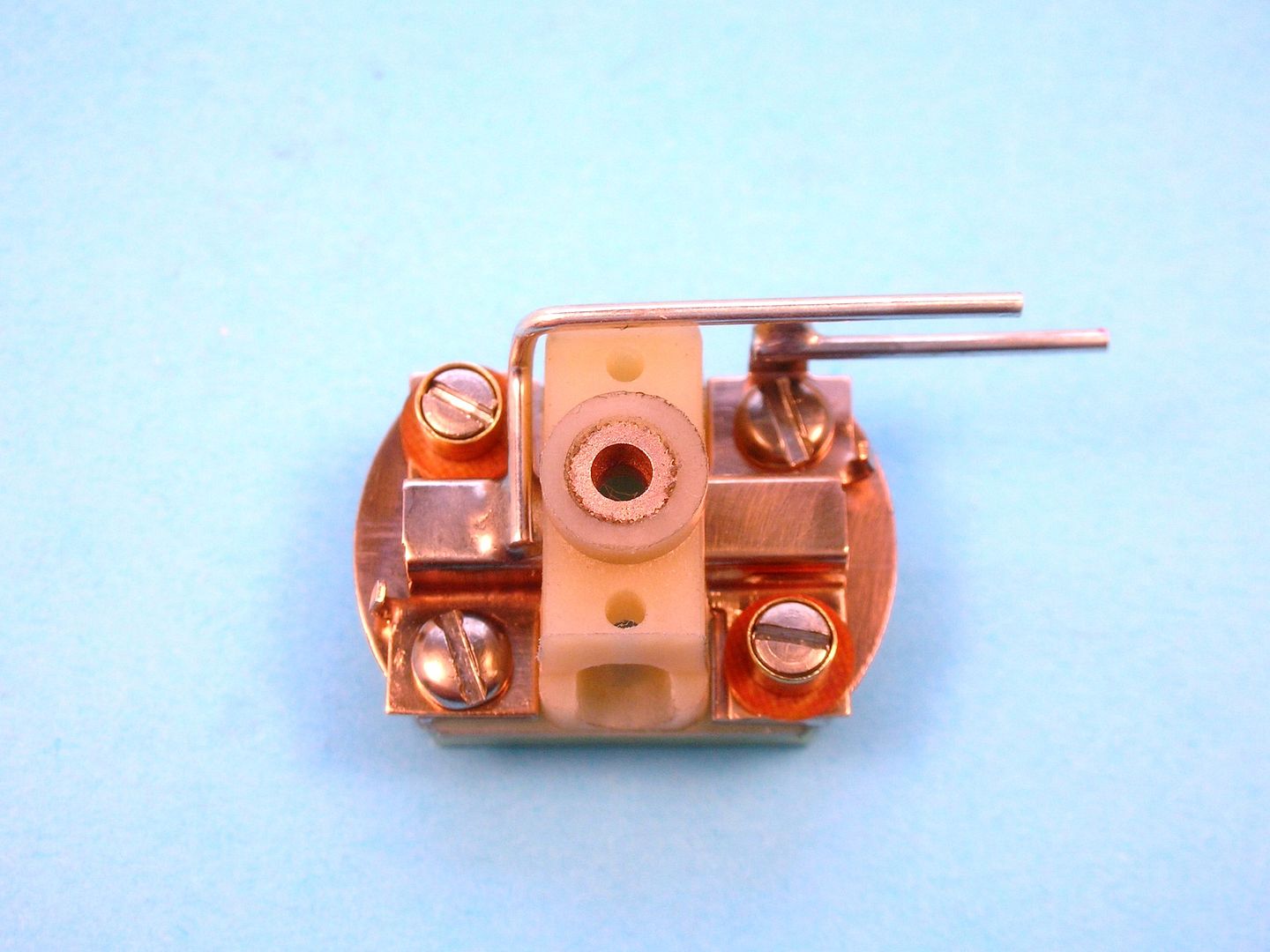

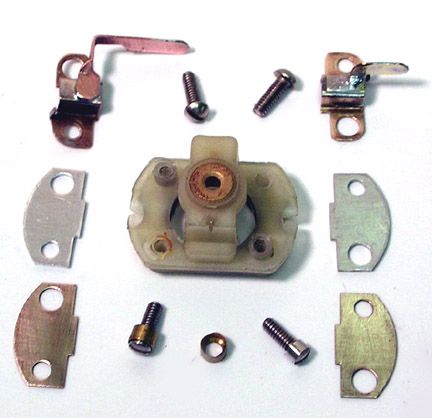

Here is the pile-O-parts for the endbell. The elephant ear heat sinks won't be used. They don't quite clear the body I'll be using. It's all Mura stuff except for the repop comm cooler and stainless steel machine screws (no self tapping stuff):

Here's a comparison between the early and late C-can end bells. The "small bearing" end bell on the right (which I'll be using on this '71 build) is really a modified B-can end bell modified by Mura to fit the narrower C-can. The Mura C-can specific and commonly encountered "big bearing" end bell is on the left:

The end bell needs some cutting up. It at least needs a frame clearance notch and I've also added comm inspection holes as shown on the end bell on the right:

The small bearing used is a carry over size going back to the B-motor and even the Mabuchi 16D. I polished its face which probably doesn't do anything but it was fun: ![]()

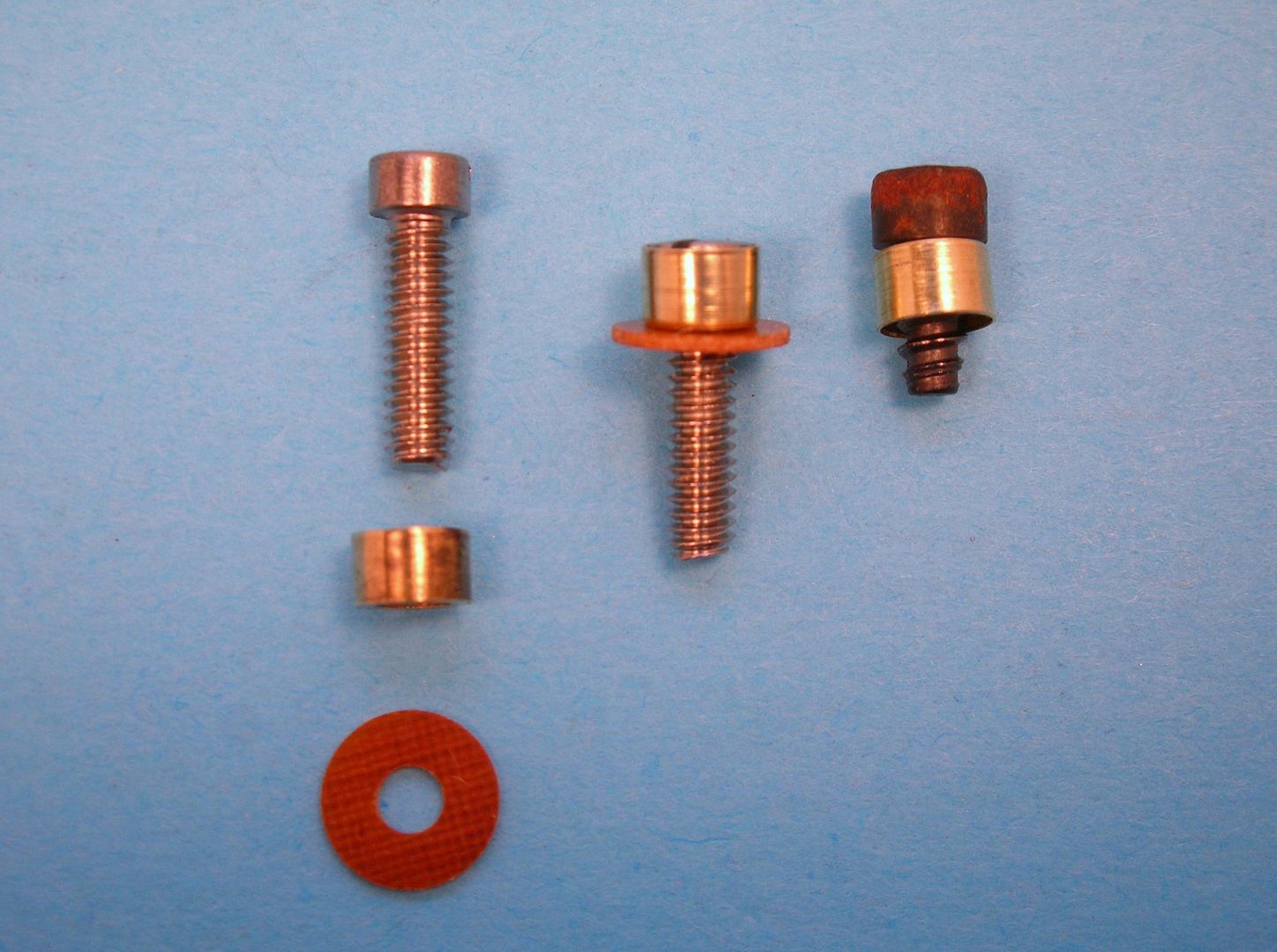

On the right below is the stock Mura brush post screw and bushing. On the left is a #2 machine screw, reversed bushing and fiber insulator. In the center is the assembled piece:

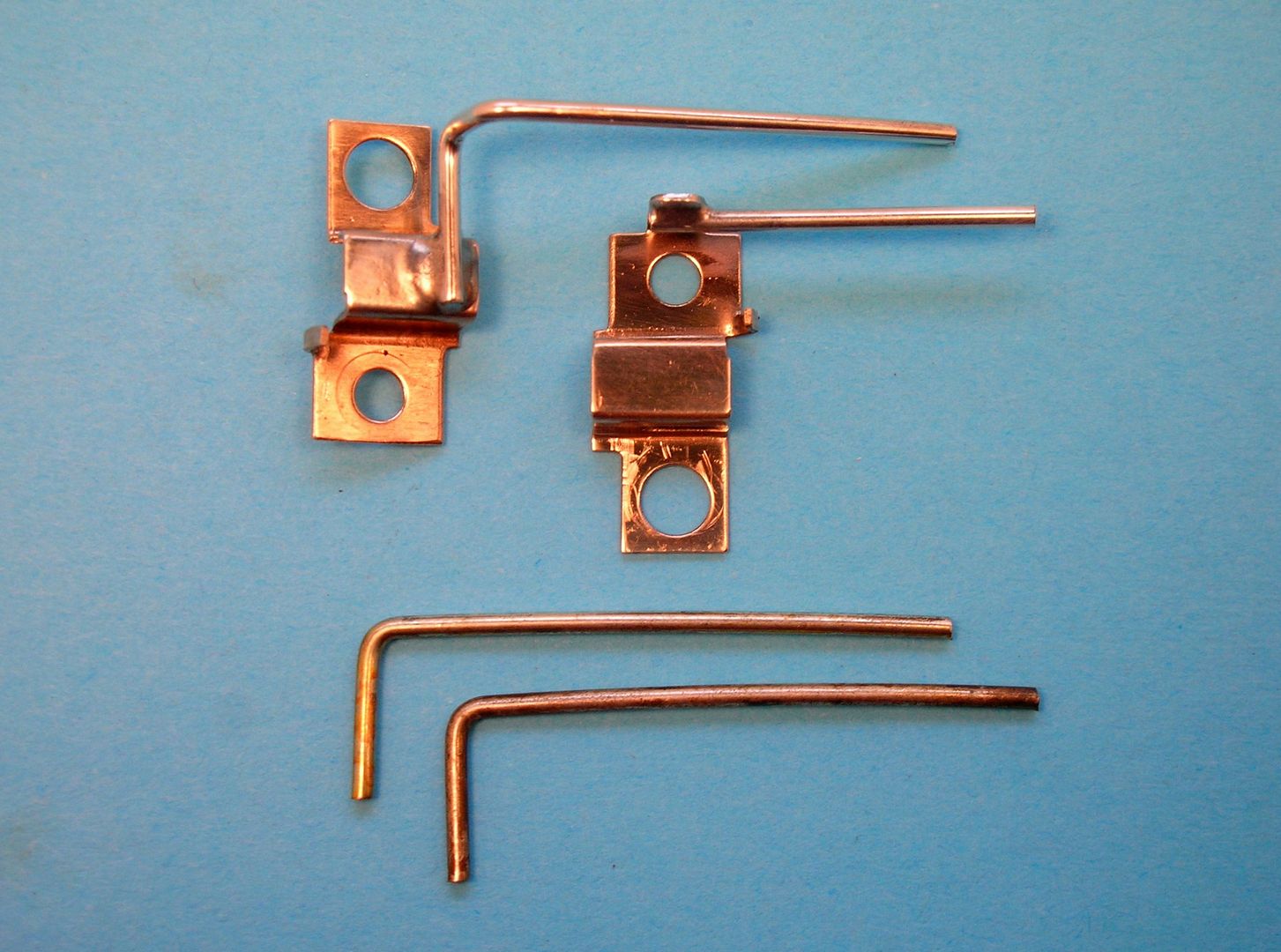

The brush hoods with the wire buss bars (shown on the bottom) installed:

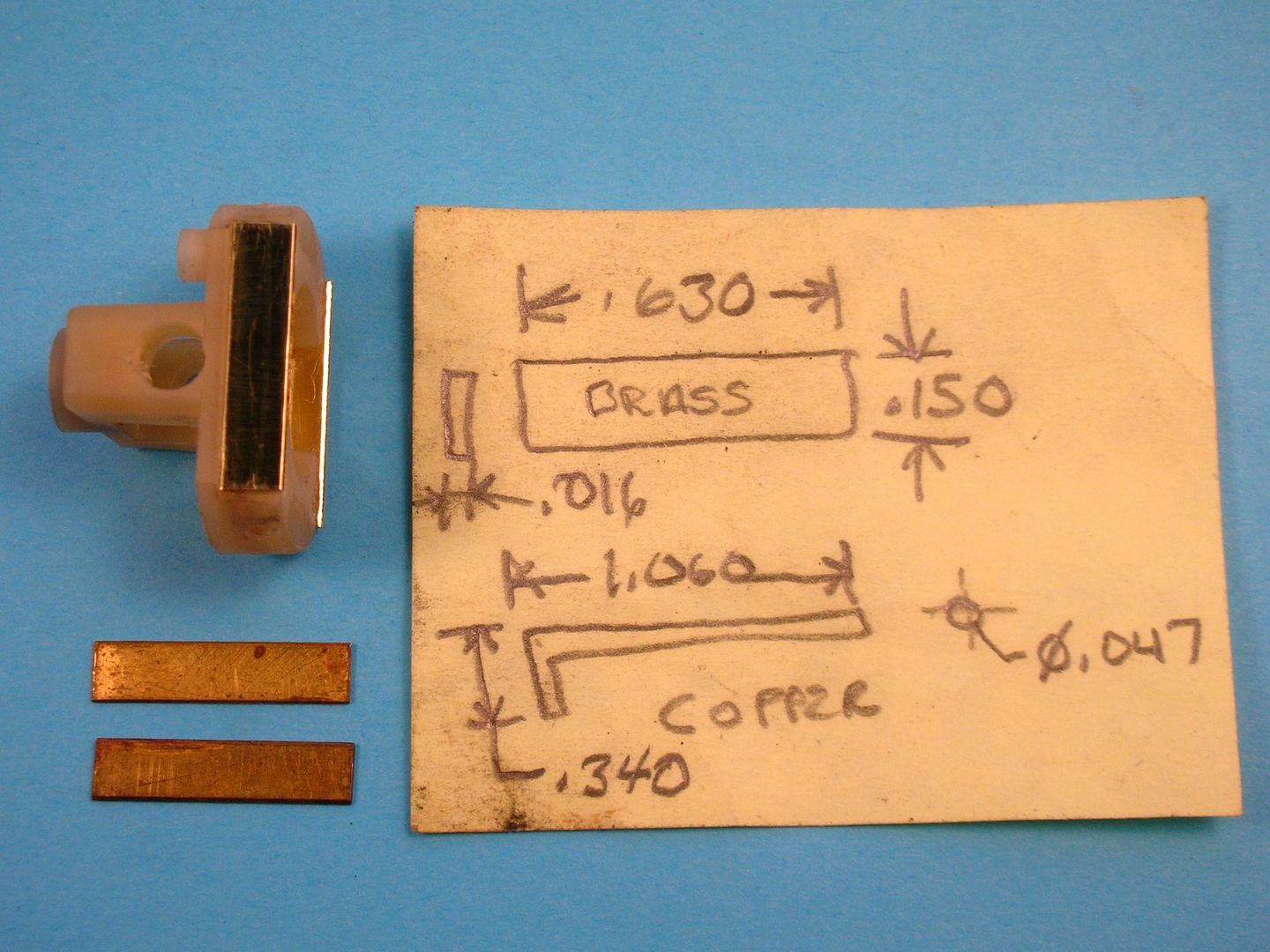

Since this is a low profile B-motor endbell, brass shims are needed to center it up in the taller C-can. The sketch on the Post-it note is something I made 20 years ago from the parts in a new in the package Mura-Green motor kit I bought from PdL.

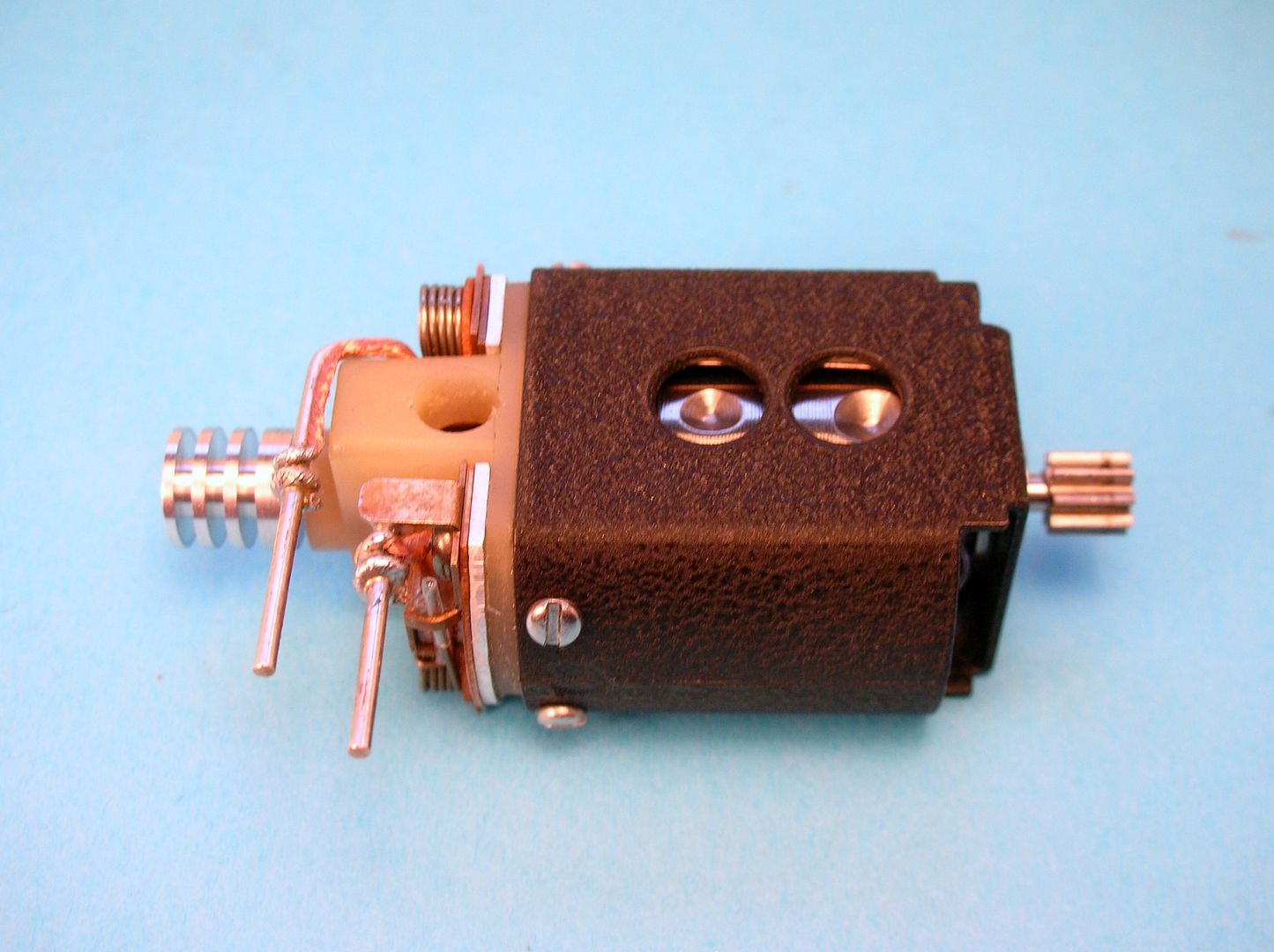

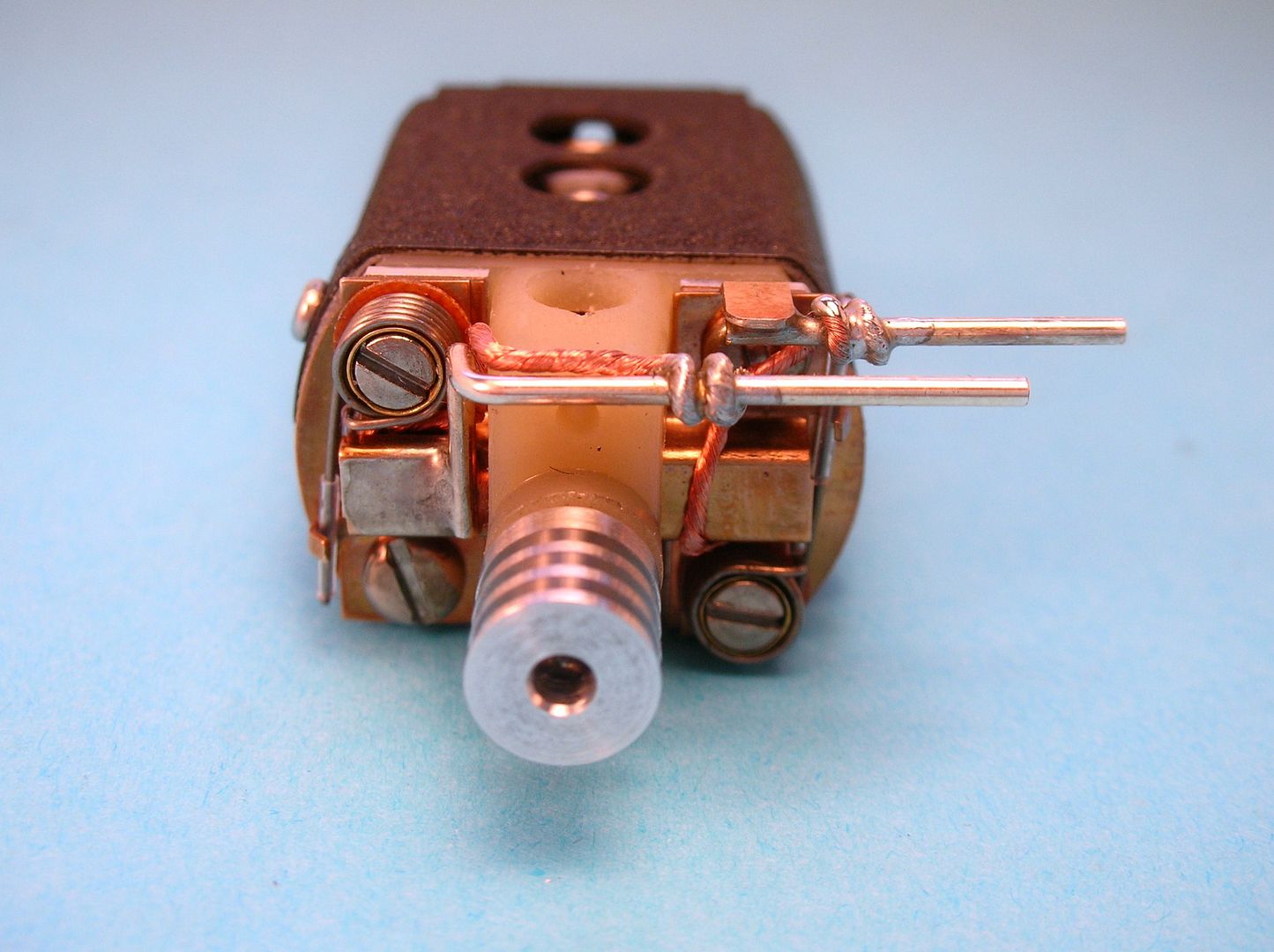

The finished end bell:

Motor assembly time ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 07 August 2017 - 06:44 PM

Engineering masterclass.

![]()

Steve King

Posted 07 August 2017 - 08:33 PM

Thanks Steve. ![]()

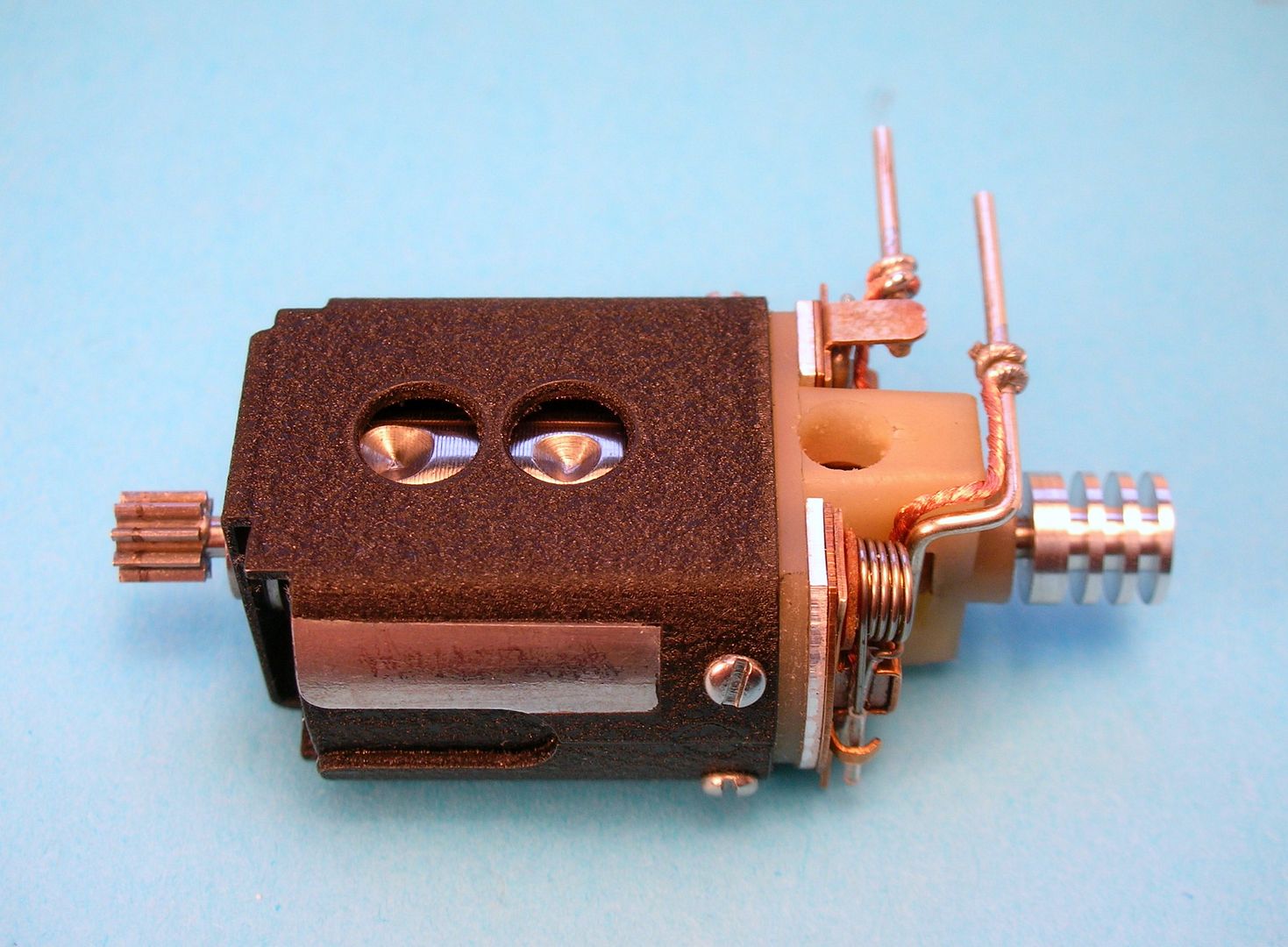

Check out the real deal Steube end bell PdL restored and photographed for us. It's a bit later "big bearing" than my early '71 "small bearing":

Very cool ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 08 August 2017 - 11:06 AM

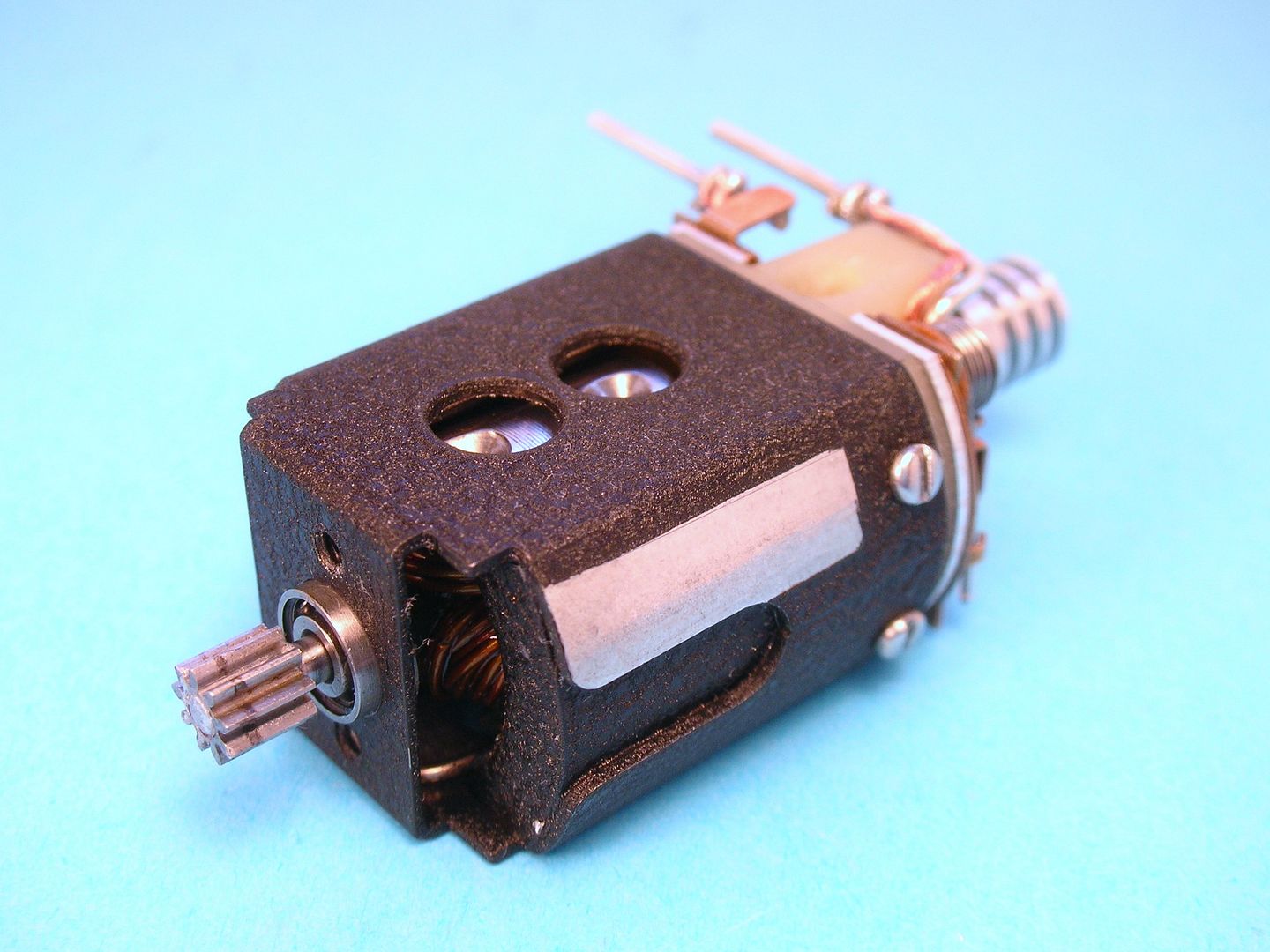

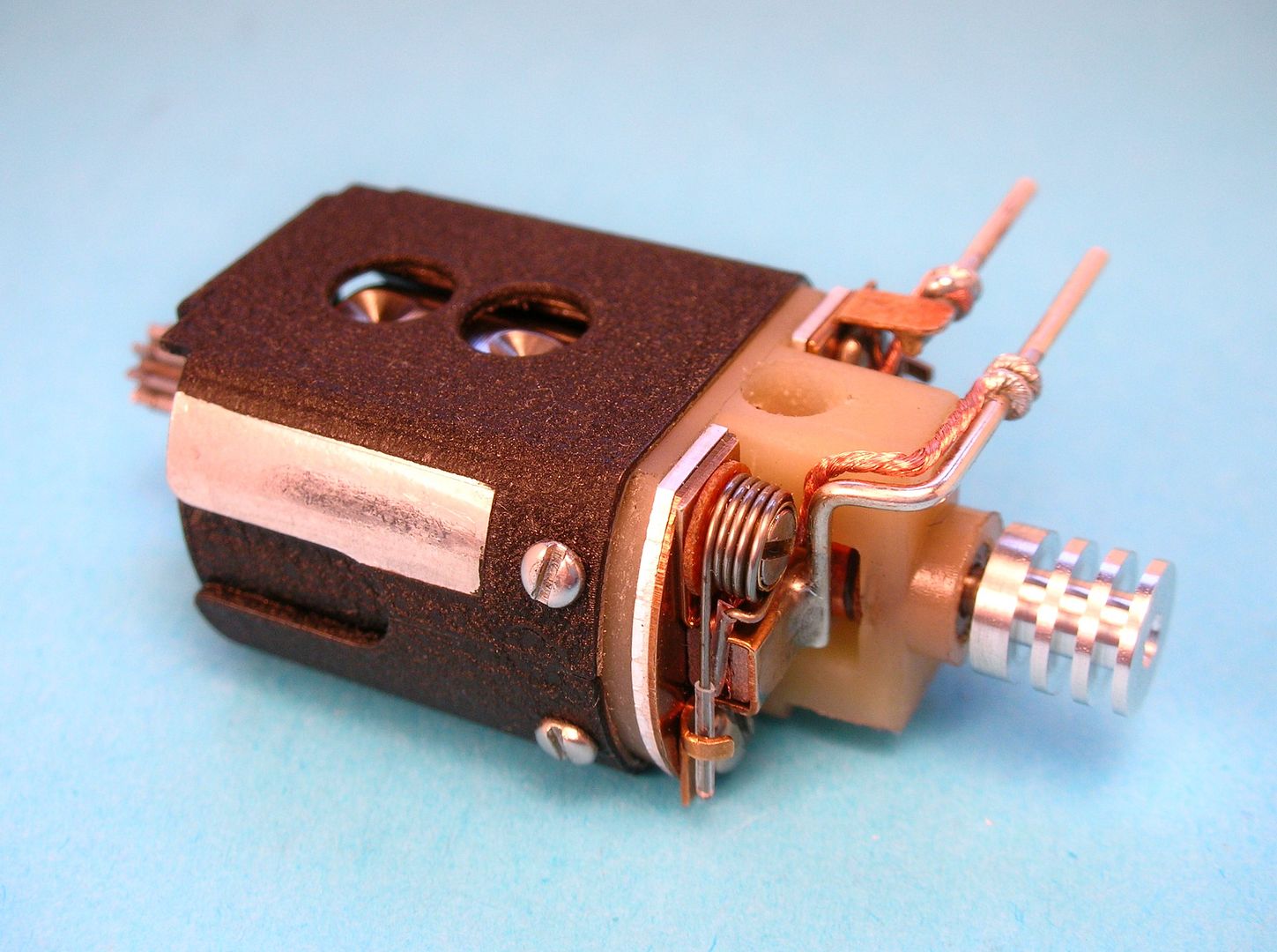

The motor is done and so far so good:

It draws 1.9 amps at 3 volts and doesn't get crazy hot:

The brush spring is completely insulated from electric current by that fiber washer and the clear Teflon tube spring insulation. The shunt wire doesn't contact the brush spring:

Time to get this motor installed in the chassis...........

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 08 August 2017 - 12:27 PM

Mechanical jewelry, ![]()

Posted 08 August 2017 - 02:44 PM

Was silver solder used to attach the buss bars to the endbell? Very nice work, glad to see the step-by-step pictorial.

Posted 08 August 2017 - 02:56 PM

Very sick ![]()

![]()

![]()

![]()

Paul Wolcott

Posted 08 August 2017 - 04:18 PM

Thanks guys. Yes John, I used Slick7 598 degree silver solder on the buss bars. I think Joel Montague's screw on method is more bullet proof but that's another story ![]() Below is a replica motor I made of one of Joel's beasts:

Below is a replica motor I made of one of Joel's beasts:

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...