On a different note you stated your arm meters .484 ohms

now with you saying that I think I'm using my arm meter wrong.

I'm using a Kapriwa the arms meter and I gently press on the arm when I use it with hardly any force because I dont want to dint the com.

So I think I'll just let the arms just sit there on there own from now on .

Yeah big difference between a real nice looking well wrapped arm metering 484ohms to mine with me pressing on it getting 015ohms

but theres two big differences as well to concider you got the smaller wire and I use the bigger wire so my thoughts are still all over the shop

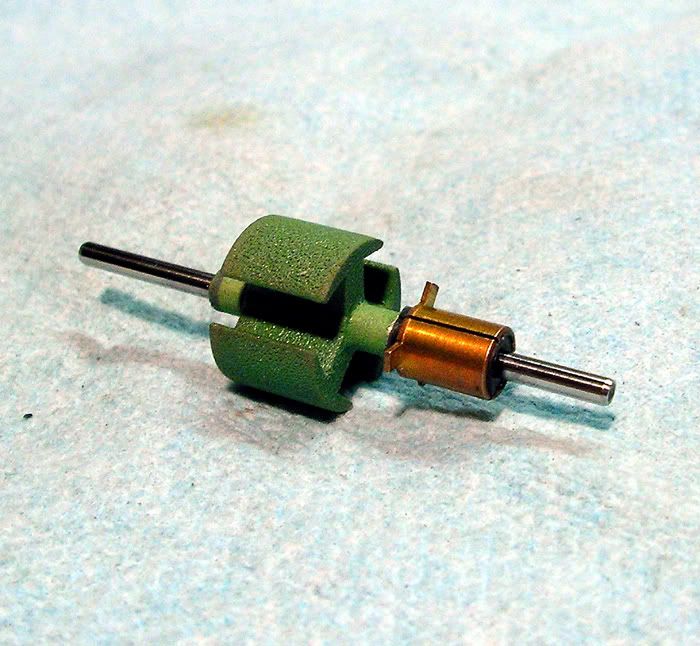

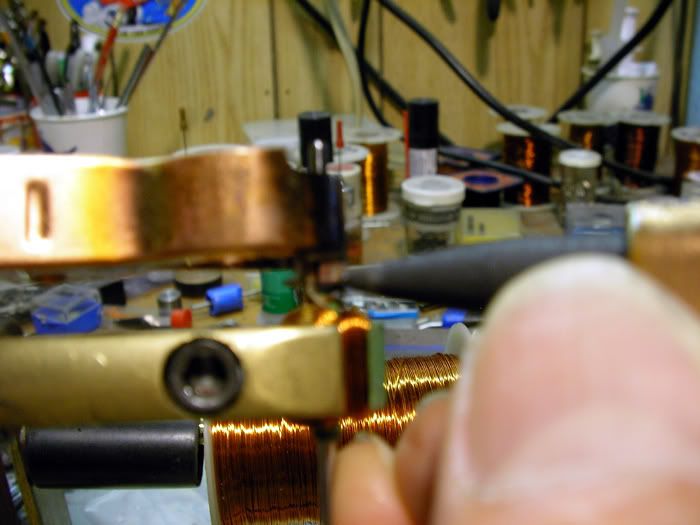

Well look at it this way Robert. A typical #25 wind on a long-ish stack (say for a Mura "Green" can setup) could probably meter anywhere from .15 to .2 of an ohm. This is a hot motor and probably "right there" compared to what the pros were running in those days. A eurosport #25 today on say a .300" stack might measure around .1 of an ohm ...I'm throwing out ballpark numbers off the top of my head here. .015 ohms is an order of magnitude less even than that, so I think there's something about the way you're contacting the com to get your readings. Also, and this is important with such low resistance values, it's best to carefully meter the arm after the com has been soldered (or welded) and cut. Just the oxidation of a clean but not freshly cut com can throw the readings off. So I test the arms as they're wound, just to see that there are no shorts and the resistance values are "in the ballpark" from pole to pole. Typically, the readings will get closer after welding and closer still after cutting the com. It's not uncommon to get identical readings down to the thousandth of an ohm on a finished arm if you're careful. The above #29 is within a thousandth on each pole, and that's good enough for sure. When you get an arm that meters that well and is close to "naturally balanced" (ie: almost balanced BEFORE balancing), it's most likely going to be a good one.

-john

This topic is locked

This topic is locked