-john

#726

Posted 27 October 2009 - 04:35 PM

-john

#727

Posted 27 October 2009 - 11:39 PM

"El Wappo"

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#728

Posted 28 October 2009 - 05:58 AM

-john

#729

Posted 28 October 2009 - 06:23 AM

I intend to live forever! So far, so good.

#730

Posted 28 October 2009 - 06:50 AM

...my fave! Oh wait...is is a slot car motor? Maybe a Cox?

...my fave! Oh wait...is is a slot car motor? Maybe a Cox? -john

#731

Posted 28 October 2009 - 08:51 AM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#732

Posted 28 October 2009 - 09:57 AM

-john

#733

Posted 04 November 2009 - 10:19 AM

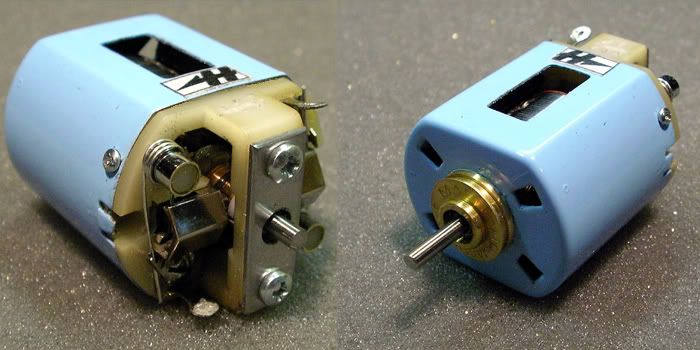

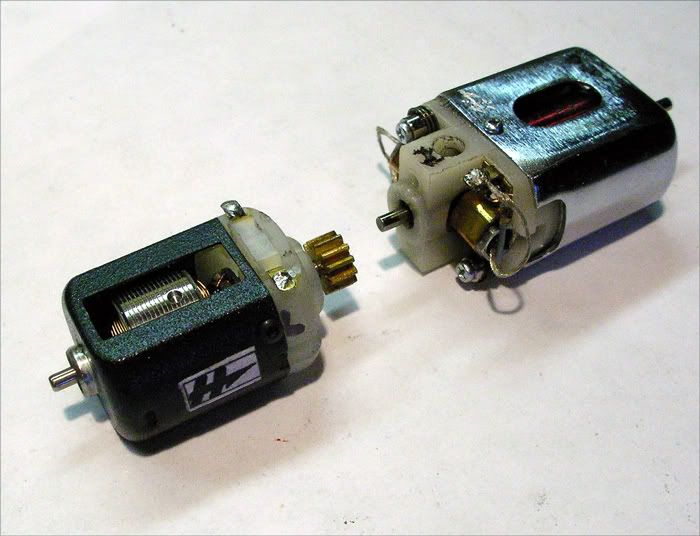

Anyway, it started out looking like this:

...and came out looking like this (shown next to a Champion 16D sized motor for scale):

-john

#734

Posted 04 November 2009 - 10:34 AM

What did you do with the brushes, if anything? And do these kinds of motors have real brushes, in fact? The cheapo motors I remember from my childhood just had brass rubbing on the commutator...

Don

#735

Posted 04 November 2009 - 01:05 PM

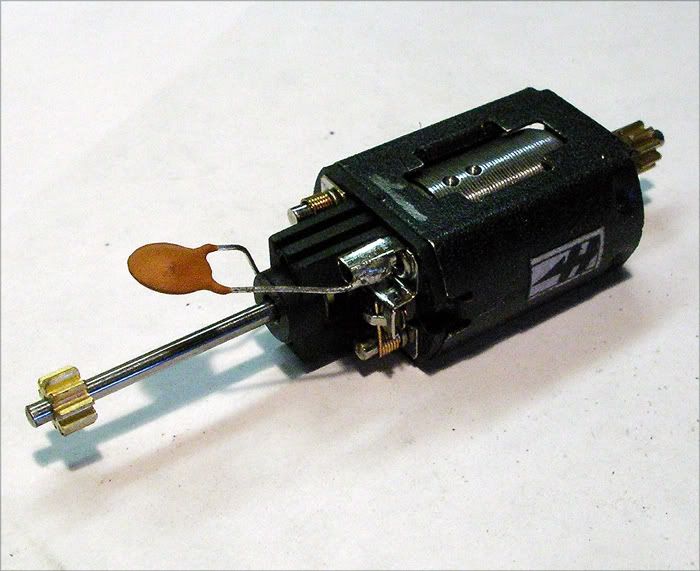

The brushes were left as is. They're like miniature versions of the Pittman brushes with regular carbon-type brush material at the end of brass arms. They're attached at a clip-on plastic retainer that snaps into the endbell proper and it's a pretty fiddly thing to get the whole thing assembled. It's even more fiddly because the shaft is so heavily splined that you can't get the endbell bushing off the shaft, so removing and replacing the arm means doing it all with the bushing in place. You have to spread the brushes just enough to slip the arm and bushing past them without damaging them and lessening the tension on the brush arms. A real PITA

-john

#736

Posted 04 November 2009 - 01:21 PM

-john

#737

Posted 04 November 2009 - 03:35 PM

The First motor is a mabuchi code "FC130" Usually listed with letters after the 130 to indicate the wind. The motor Don remembers without the little carbon numbs is coded "FA130". Both start with a wind of 300 turns of 36 wire and various applications get fewer turns. The stock Fly/Scalex etc motor for the 1/32 plastic cars is 160 turns of the same 36 wire!

The SCX motor is a direct decendent of our 60s FT13uo like the Monogram X88. Unlike that original, the endbell takes a lot more heat and is a valid candidate for building a "proper" motor with.

I love them. My usual "plan" is to talk clubs that require a spec motor like the NC1/8 or the FC130 to give/seel me the ir SCX motors. Most of my motor builds are for cars that will never be legal for anything except pick up races with my friends around here.

Fate

3/6/48-1/1/12

Requiescat in Pace

#738

Posted 04 November 2009 - 06:38 PM

-john

#739

Posted 04 November 2009 - 11:09 PM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#740

Posted 05 November 2009 - 05:19 AM

"TANSTAAFL" (There ain't no such thing as a free lunch.)

Robert Anson Heinlein

"Democracy and socialism have nothing in common but one word, equality. But notice the difference: while democracy seeks equality in liberty, socialism seeks equality in restraint and servitude."

Alexis de Tocqueville

"In practice, socialism didn't work. But socialism could never have worked because it is based on false premises about human psychology and society, and gross ignorance of human economy."

David Horowitz

Mike Brannian

#741

Posted 05 November 2009 - 06:44 AM

...thanks MikeVerrrrrrrrrrrry Coooooooooool

Thanks Barney. The mags are VERY thin...around .111", but surprisingly good and this is another area where these motors don't suffer the way the 13UO Mabuchis did. They also use a good sized motor brush and an enterprising hot-rodder could probably figure out a way to use stouter springs without too much difficulty. The real kick here is that modern C-can endbells can easily be modified to fit the can and that opens up all kinds of other possibilities for commutators, ball bearings etc. Trying a couple out, the ProSlot endbell seemed the best fit of the ones I had. I built one like that and it was a real hoot...Mike Brannian got that one.Cool little motor John! How thick are the mags?

Ed Miller is the guy here who first asked me to rewind one for him and I'd never seen one before that. I immediately saw the possibilities in this motor for all kinds of "extra-curricular fun" and did a little web browsing to find out what's what. It seems the first generation RX42 was ragged by a bunch of guys for it's anemic power output...hmmm...that right there was like an invitation to dig deeper. Tearing the motor apart, it's all pretty much familiar territory. .078" shaft, pretty ordinary arm that could have come out of any vintage or modern motor, an endbell that makes disassembly/reassembly a snap and can take some heat and the option to mount them either endbell or can drive with a hole pattern that's very close to FT16D specs to boot! Like I said above, at $8 or so...they'd be a cool motor to build a series around running either stock or open classes or both to keep the racer's costs down. Because of the size, they can easily go inline for those extra skinny bodies, or anglewinder in a nice light chassis.

-john

#742

Posted 05 November 2009 - 10:56 AM

Where are they 8 bucks each? The only ones I have seen are more than twice that. Sigh.

Anyway, the complaints about the RX42s in the early days were two fold. First the wind was very mild. 200t/36! Second, the com was this really awful press fit leaf commutator like on the FA motors that Don mentioned.

The magnets in the FKs and this FT 130 are a better upgrade for vintage 13uos than zapping them. On my meter, the originals never measured over 120 guass and would "zap" irregularly. The more modern ones read about 300 to 350(not counting the neos and cobalts).

Anyway, in the 70s the brits made modern endbells for these motors. Almost impossible to find, but worth looking for. What you want are "p can" endbells from Inphinity and 101. Thinking on it, i should probably look around myself, I have a period survivor with a melted purpole inP on it!

Fate

3/6/48-1/1/12

Requiescat in Pace

#743

Posted 05 November 2009 - 11:09 AM

Man, oh man, John!...Another SCX motor...

That SCX is certainly not my cup of tea, but what a beauty!

Actually, whichever motor you lay your golden hands on, magically becomes a beauty (yes, even those horrid little modern chinese motors

Ciao John!

E

#744

Posted 05 November 2009 - 11:35 AM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#745

Posted 05 November 2009 - 01:02 PM

Where are they 8 bucks each? The only ones I have seen are more than twice that. Sigh.

Pretty easy to get them for that price. Tower Hobbies (where I got them) has them for $8.49. Hobbylinc has them for $7.59. Horizon Hobby has them for $8.49. Of course, you can get them on E Bay and pay a lot more, but that's normal

Anyway, in the 70s the brits made modern endbells for these motors.

Completely unnecessary...as I mentioned above a regular old Pro Slot C can endbell can be fitted with just a touch of trimming (takes less than 5 minutes) and then you have a motor that you can take even further.

Man, oh man, John!

That SCX is certainly not my cup of tea, but what a beauty!

Hey thanks Edo. Tell you what though...a little tweaking and they can be made to look very "vintage". I certainly understand the appeal of the old motors (heck I love them too!), but these things are cheap, easily available and great fun to work on. You never know what projects using these SCX motors in a traditionally vintage application might surface. I think of them as a modern Russkit 23...except skinnier

Hey John I may have some of my old Front Line R&D mags that are about that thick or a little thicker if you want to hone them. Next care pak will send ya some.

Hi Barney. That would be cool! If they can fit (or be made to fit), that would be the next step up for hot-rodding these things. A set of those magnets, a C can endbell, ball bearings on both ends, shunts and a #27 single wind would be a pretty potent little sonofagun. I gotta see about that

Thanks for looking guys...

-john

#746

Posted 08 November 2009 - 05:48 PM

I'm waiting for a ProSlot endbell to get here so I can set the arm length and start winding...but I'll also be replacing the com on this one with either a Tradeship or a Mura. I'm leaning towards the Mura as it wil fit with just opening up the inside of the endbell around the brush holders a little bit AND should be bulletproof.

-john

#747

Posted 08 November 2009 - 10:03 PM

I know I need to insulate against shorting if the wire insulation is compromised, but since I'm going to coat the lams with epoxy before winding anyway, why bother?

Why would the upper and lower lams be more prone to shorting than the insides ?

Thanks !!

Paul Wolcott

#748

Posted 08 November 2009 - 10:38 PM

The place where the magnet wire is most likely to short against the stacks is at the sharp corners around the top and bottom of the stack...which is where the fiber insulators do a great job. On the sides of the stack, the wire isn't likely to short unless you really manhandle it. Having said that, you don't need the fiber insulators at all if you're careful and I use them only on the older motors because they look cool

I know I need to insulate against shorting if the wire insulation is compromised, but since I'm going to coat the lams with epoxy before winding anyway, why bother

Those laminations are obviously punched from steel sheet as you can see that one side is slightly sharper because of the way they're formed. That means one end of the stack is pretty sharp and often just coating the arm with epoxy doesn't work well enough unless you really butter it on there. Doing it heavily enough to really protect those sharp corners (where the epoxy doesn't easily build) can make it hard to do a neat job winding. Give it a try...you might get lucky!

-john

#749

Posted 09 November 2009 - 08:32 AM

I forgot to mention that the fiber stack insulators are also just wider than the actual stack profile. If you check them out...they sit just proud of the stack which keeps the magnet wire from even touching the metal...much less shorting out against it. However, that also makes winding neatly a little more difficult and also makes it more difficult to use as many turns as you might want on some winds. If I use the stack insulators, I epoxy them to the stack so that they stay centered and then trim them flush with the stack after curing so that they still protect those sharp edges...but don't take up any additional space when winding.

The other thing about these that may or may not be a negative (?) is that they are obviously not magnetic. As each pole of the arm is energized when spinning, it may or may not produce as tight a field with the coils separated from the stack ends by the thickness of the insulators...the physicists with a specialty in magnetic flux theorey can clear that up

-john

#750

Posted 09 November 2009 - 11:24 AM

It doesn't SEEM that way, but in fact, every time the stack is powered, the wire MOVES. Epoxied, it MOVES. This is why you refurbish serious motors by getting them rematerialized and this is what causes them to die eventually. Epoxy is actually less mallible than the copper wire and coating. And old arms get little micro fractures that cause a leak through the coils to the stack. This "leak" changes with heat as well as everthing else. Thus, a motor that gets slow when hot, but doesn't show a short to the stack is usually subject to this epoxy crack problem.

A long way of explaining WHY the fiber ends and their being slightly proud of the stack itself. Doubles or more the lifespan of a given wind and makes refurbishing work more often.

Your mileage may vary!

Fate

3/6/48-1/1/12

Requiescat in Pace

This topic is locked

This topic is locked