#1076

Posted 27 January 2010 - 01:10 PM

Thank you.

Ernie

#1077

Posted 27 January 2010 - 01:29 PM

I intend to live forever! So far, so good.

#1078

Posted 27 January 2010 - 02:01 PM

I don't know about now, I have not recently done an autopsy on one, but a few years ago, a Deathstar from parma might have anywhere from 69 to 73 turns per pole.

The balenced "super 16ds" had a similar problem.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1079

Posted 27 January 2010 - 03:46 PM

Yes look hear if you are tearing out gears as you have too much flex... it's not the power doing it.

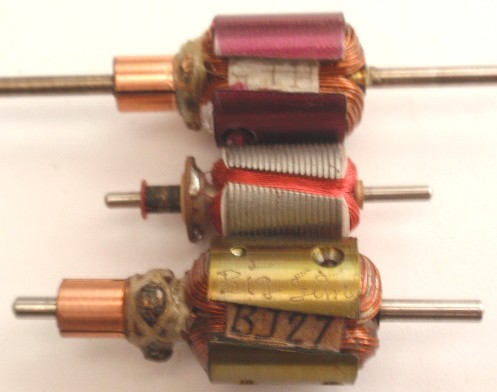

Anyhow, while looking for more "junk for John" care pak stuff (eh.. fine used vintage racing gear) I found some more interesting arms and stuff so ....

Here is another skewed stack arm John. The BJ-27 and a H-15 Camen I think??? never ran because they were not legal so just for fun along with a skewed stack HO size arm I always wanted to rewind but never did.

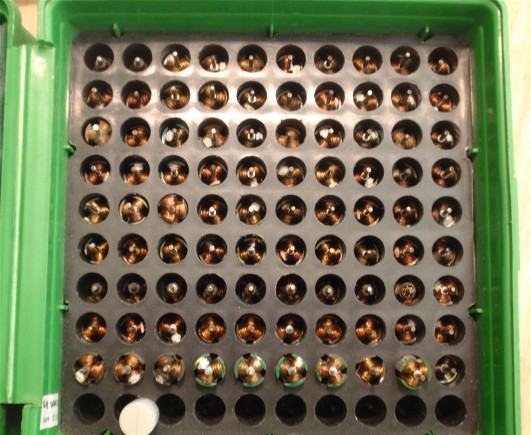

A BOX O ARMS! Here are a few (about 75) of my old I-15 arms with a few Box Stock 15 (Hey Craig your Western States BS arm could be in here?) and about a dozen GP-27 arms I still have.

My old GP-27 arm box till I stopped racing them after the 86' Nats ( 6th fastest in qualifying but did not make the move up into the main)

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#1080

Posted 27 January 2010 - 09:17 PM

I realized after seeing all the replies I had best check the flex in that wire chassis...it was moving, if I could have just stayed out of the throttle ...but ya just cant resist...John the thing is a beast...no one believed what I was telling them until I let them look at it...and yes I was using metal gears and the nylon, dont think it mattered..LOL ...seeya all in Thomasville, John ..wish you could be there, gonna be fun...Kim

#1081

Posted 27 January 2010 - 09:50 PM

but ya just cant resist

...Kim, sometimes a man's gotta do what a man's gotta do. I'm sure I would have been "stomping it" too had I been there

-john

#1082

Posted 27 January 2010 - 09:54 PM

Thank you.

Ernie

#1083

Posted 28 January 2010 - 03:50 PM

Here's where we started. The can has had some clearance cuttting done around the rear and had some rust/pitting, but the endbell was very clean. I only added Mura spring posts later on:

After some straightening-out of the clearance cuts and rust removal, ie: grinding. filing, sanding, Scotchbrite-ing, the can is ready for paint

Now with a fresh coat of gloss purple...all dressed up for the party. I had a set of B motor mags here that are strong as an ox and they feel like you could pull tree stumps with them. They're thick and long, and probably a little over-the-top for this arm, but they're the right mags for the motor. Besides, they saved me from having to reshape another set of magnets and dealing with that magnet dust

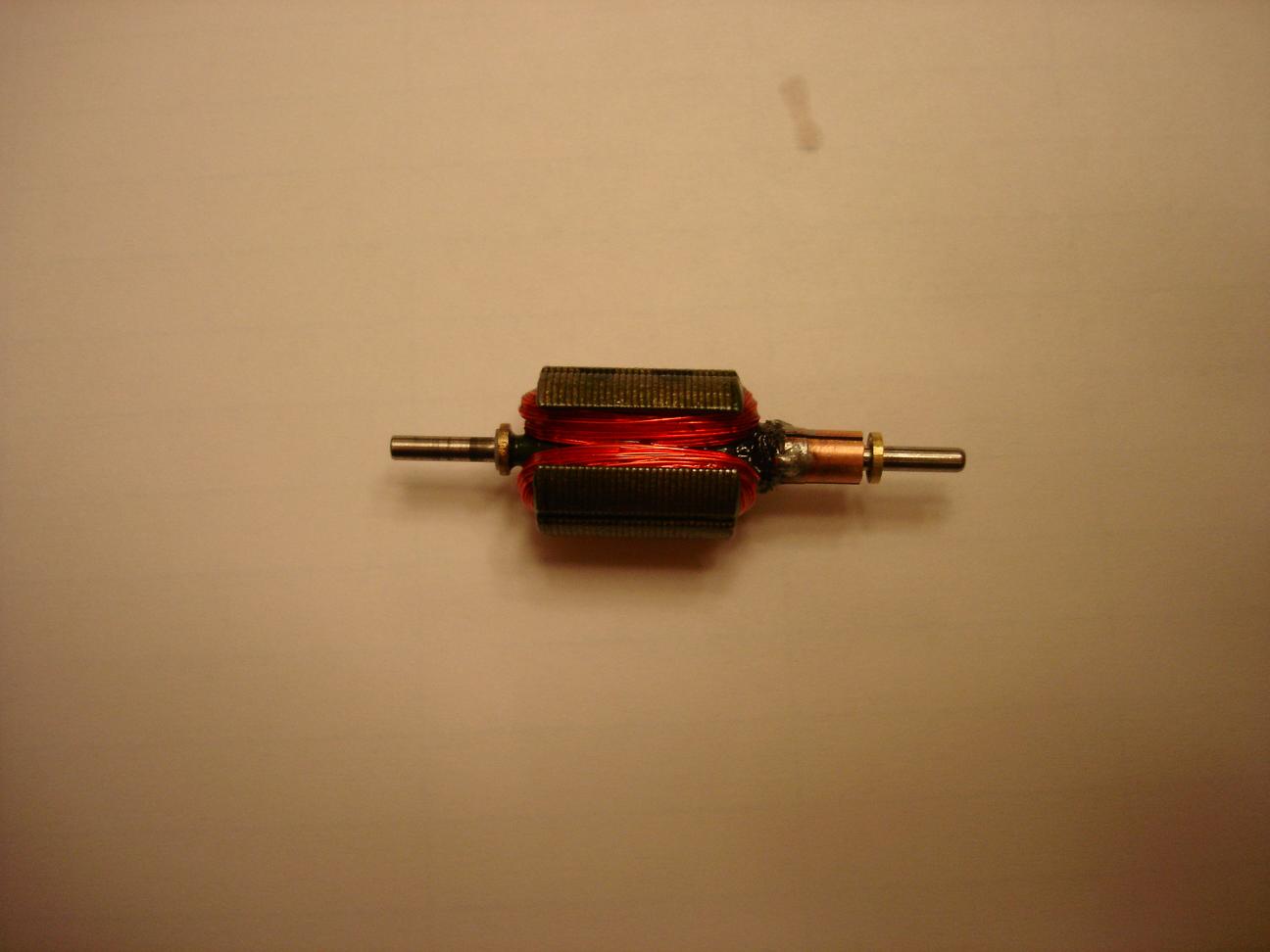

Time for the arm. I used one of my reclaimed vintage 007" Mura blanks here with a recycled Mura com. I replaced the shaft with a spiffy new drill blank and after winding I hard a very difficult time balancing it, as it seemed pretty much balanced. I think that's more because of the new drill blank shaft than anything. Wind is a #28 and I kept it on the conservative side. It meters around .3 ohm and draws about 1 3/4 amps no load on the PS, but will "bounce" past 2 amps when you goose it all the way.

All put back together, I think it's one clean "B". Personally, I have a new fondness for the B motor after seeing Rick T's build with one and getting to play with a few now. I understand they had a bit of a problematic reputation as regards getting hot, but it's a super solid motor that is after all...a Mura!

-john

#1084

Posted 28 January 2010 - 04:22 PM

I don't think you'd ever notice + or - one turn unless you burnt the arm & dewound it to count. One sure way to eliminate the possibility of extra or missing turns would be to wind each pole with a certain length of wire rather than by a number of turns. But I don't really think it's an issue.

After screwing up the 3rd time on one arm.

JOHN, WHEN YOU DO A JUMPER..DO YOU GO STRAIGHT UP OR FALL BACK WHEN SHOOTING???

OLPHRT

PHIL I.

#1085

Posted 28 January 2010 - 05:20 PM

When you receive a motor that has corrosion inside and outside of the can - do you address the rust inside the can as well? Or it isn't necessary? From what I can see, it looks like the inside is nicely prepped too!

Thank you.

Ernie

#1086

Posted 28 January 2010 - 05:51 PM

Thanks , but I would bet we're doing pretty much the same thing

Hi Ernie,

Yes. On this motor there was significant corrosion on the inside as well and I took care of that. I always worry that the corrosion was caused by acid flux at some point, so I want to get it out of there.

-john

#1087

Posted 28 January 2010 - 08:28 PM

I'm dumb-founded...

This is the motor I always wanted as a kid... I'd go to shops in the greater Los Angeles area, w/ my Dad, to deliver Grand Prix Racing Tires to the various venues, & if the track still had the American Raceway "power-packs", then I'd have to run my Classic FT16BB-powered F1 car, as my tilt-pan CanAm w/ the FT16BB can, Mura X88 mags & folded shim, Mura "no-melt" endbell, w/ Tradeship springs & Mabuchi brushes, & the double-29 Thorp hand grenade would crow-bar those power packs, in an instant!

Oh, yeah... The track owners LOVED me!

Now, I can build the car I wanted to, but couldn't afford to, because of John's talent & my ability to scrounge-up parts...

As always, the finished-product is light-years ahead in comparisson to what I had envisioned it becoming... Now, I'll build-up a no-motor box style chassis, like I'm running in RetroPro, but build it w/ a loooong drop arm, like we ran during that era...

Stunning, John.... Just stunning... Thank you so much... You brought tears to an old man's eyes, when he saw it for the 1st time!... WOW! ... A race-ready "B"-production Mura motor!... I can remember spending 4 or 5 hours, trying to cut, sand, file, & get a set-up ready, when these 1st appeared on the market here in L.A. ... Words alone won't convey my graditude, buddy... YOU DA MAN!!!!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1088

Posted 28 January 2010 - 09:01 PM

Couldn't pass that up Jeff...hehehe

OLPHRT

PHIL I.

#1089

Posted 28 January 2010 - 09:04 PM

I'm stoked you like the result. I gotta say that Mr. Kiyomura gave you some excellent parts (wish he was my friend too!). Everything was super straight and clean. The bushings in both the can and the endbell were so tight it was amazing. I could actually spin the arm in just the can/magnets with no endbell installed and with the very tight airgap these magnets produce...that's something I can't remember being able to do before! The vintage Mura .007" arms come in at almost a dead-on .510" even after reassembling the stacks and polishing them and the air gap is so tight, it wouldn't be a good thing to shim the magnets even if you could. Actually with this type arm and anything but hard racing, you don't need to do anything else to this motor, no shunts, elephant ears, no shims. It's by no means a "puppy dog" and still needs breaking-in, but you should be able to pretty much install it and have fun

-john

#1090

Posted 28 January 2010 - 09:32 PM

I will see if I can get a picture of the car top and bottom...I`ll have to send to John and get him to post on the blog...I`m not real computer savy, I do good to get on the blog, as we used to say in the old days..."Thumbs Down"................Kim

#1091

Posted 28 January 2010 - 09:47 PM

Jeff,

That's a great story about your motor and your youth. You've got some great memories - very nice of you to share! May we see some pix of the motor in the chassis and the body please - of course - when it's completed. Progress pix are great too (please Jeff?!))

Thanks John! Can't get enough of your "wind-ups/buildups" LOL!!

#1092

Posted 28 January 2010 - 10:28 PM

Hey Kim,

By all means, send the picture to me and I'd be happy to post it. I'm looking forward to seeing it all done up!

-john

#1093

Posted 29 January 2010 - 07:31 PM

Would you mind describing a double wind?

Do you use two separate pieces of wire and wind both of them at the same time?

Or do you use one piece of wire and go around the arm twice?

Thanks,

Kelly

#1094

Posted 29 January 2010 - 09:19 PM

I've done it both ways, both now...and back then. Mostly I use two pieces of wire winding a bunch of wire on an empty solder spool I keep for this. I haven't any scientific way to gauge if one is better than the other although my thought is that it's a wash. They both seem to work really well. If you're doing a mixed wind (like a 28/29 double), then it would make sense to use two spools and lay the wire side-by-side...I think

-john

#1096

Posted 31 January 2010 - 09:02 PM

#1097

Posted 31 January 2010 - 10:20 PM

I know this is Johns thread

Who sez Kelly? This is, as far as I'm concerned, a thread where people who are similarly disturbed as I am about rewinding and motor work can share projects and tips. I'm a member here just like you and only post by the good graces of the people who run and own the place. Speaking of which your winder is aces! Mine looked really nice at first, but now I've written all kinds of stuff about winds on both of them and they've gotten a certain "patina" (ie...ugliness).

-john

#1098

Posted 01 February 2010 - 02:31 AM

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#1099

Posted 01 February 2010 - 02:53 AM

Sano-looking winder, dude!... Very cool!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1100

Posted 01 February 2010 - 06:54 AM

1)The can

2)The magnets

3)The commutator

4)The arm stack

5)The endbell

etc. etc. In other words, it has been a LOT of work. So I get the arm all done and in the setup and start the motor up and notice sparking coming from one side of the endbell. The com was just hitting the brush hardware on that side and the arm (which was an awfully nice one too

.......................I'm a dummy

-john

This topic is locked

This topic is locked