#1326

Posted 07 March 2010 - 02:34 PM

#1327

Posted 07 March 2010 - 02:42 PM

And interesting info about the flue cement.

John, have you ever thought of wrapping the stack with Kapton Tape instead of painting it with some insulating compound? The tape will handle 750 degrees F and it has a silicon-based adhesive.

#1328

Posted 07 March 2010 - 03:57 PM

Very nice work on both of them John, you said you brazed the wire on the tabs how can you braze something that small i use to see my farther braze stuff when i was a kid he used some kind of torch i think ? oh yes i like the paint work also.

Hi Robert and thanks. On the brazing, to my way of thinking...welding is fusing two metals together by heat, brazing is fusing two metals together with a third intermediary metal at high heat (as opposed to soldering which is "low heat"). I use jeweler's silver and a 55 amp car starter to fuse the magnet wire to the com tabs on hot winds. The silver melts at around 1200 degrees F which is still below the melting point of either copper or brass, so by using a carbon rod attached to one clamp of the power source and grounding the com with the other, I can generate plenty of heat to fuse these metals. Actually if I stay in contact with the com tab for too long, this setup will melt the brass and copper soon after melting the jeweler's silver. That's why it's a little tricky with thin wire like this as you have to time it right. Anyway, I think those are good working definitions of brazing and welding, so this is technically brazing as opposed to say resistive or spot welding. That's my story and I'm sticking to it

Super sano as always!

And interesting info about the flue cement.

John, have you ever thought of wrapping the stack with Kapton Tape instead of painting it with some insulating compound? The tape will handle 750 degrees F and it has a silicon-based adhesive.

Hi Dennis and thanks too! I have never tried Kapton tape, but did try several other tapes just to see how tape would work. Even the most flexible I tried which was plumber's teflon tape, was a nightmare to try and wrap the stack including behind the stack face. In the end I figured there had to be an applied coating that would work and the flue cement is by far the best I've tried. So far I'm batting 1000 with the stuf and haven't had any failures after doing maybe a couple dozen arms. It's really very easy to apply and since it's water cleanup, I just use an artist's brush and rinse it in water when done. With baking in the oven, I can wind over it in 15 minutes, so it's not much of a bother at all and protects MUCH better than epoxy...or even epoxy and high-temp paint over it in two coats. In practice, it's very nice to wind over too because it leaves a surface that's something like 600 sandpaper. The wire really stays put on it as you wrap the arm which makes those important first two layers significantly easier.

-john

#1329

Posted 07 March 2010 - 05:01 PM

#1330

Posted 07 March 2010 - 05:49 PM

Brazing is very strong, but more importantly it's much more heat resistant. It's kind of a PITA, but there really isn't much choice when the winds get really hot. These #29 doubles have been coming in at pretty much .2 ohm, which is definitely zippy...especially for a Mabuchi FT16D.

The cement doesn't give off any detectable smell when baking and as it's a water-based product that seems to be an actual "cement". Still, I bought an el-cheapo toaster oven for curing epoxy, paint and now the cement. I would NOT do any of this in your homes oven or any other used for cooking food for humans

#1331

Posted 07 March 2010 - 06:59 PM

Mr. Frank

Frank Elavsky

5/20/60-2/9/12

Requiescat in Pace

#1332

Posted 07 March 2010 - 07:35 PM

I intend to live forever! So far, so good.

#1333

Posted 07 March 2010 - 07:42 PM

-john

#1334

Posted 07 March 2010 - 08:24 PM

Mr. Frank

Frank Elavsky

5/20/60-2/9/12

Requiescat in Pace

#1335

Posted 07 March 2010 - 11:50 PM

Pictures pleeeese of your "wild thing-ieees"!!!

Thank you.

Ernie

#1337

Posted 08 March 2010 - 08:37 AM

I built a 4 motor car 7 years ago.

That car is too cool.. But the one i'm doing has 4 axles, 4 motors, 4 motor boxs and 4 wheels. Lets just say it's TRUE all wheel drive. More to come...

Mr. Frank

Frank Elavsky

5/20/60-2/9/12

Requiescat in Pace

#1338

Posted 08 March 2010 - 09:49 AM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#1339

Posted 08 March 2010 - 10:10 AM

That car is too cool.. But the one i'm doing has 4 axles, 4 motors, 4 motor boxs and 4 wheels. Lets just say it's TRUE all wheel drive. More to come...

Mr. Frank

Hopefully the car will not go around the track in four different directions.

As one who has built multi-engined 1:1 pulling tractors, feed all the motors into ONE shaft, then mate the power shaft to the rearend.

11/6/54-2/13/18

Requiescat in Pace

#1340

Posted 08 March 2010 - 10:43 AM

Hopefully the car will not go around the track in four different directions.

As one who has built multi-engined 1:1 pulling tractors, feed all the motors into ONE shaft, then mate the power shaft to the rearend.

Hopefuly the car will be bad fast and go forwars

4 MOTORS; As long as the falcooons are all new i don't think there will be any troubles, but will just have to see then.. wont we...

Mr. Frank

Frank Elavsky

5/20/60-2/9/12

Requiescat in Pace

#1341

Posted 08 March 2010 - 02:59 PM

The guy I built it for didn't want me to run it. It has 4 Plafit Cheetahs in it. As I said, I built this 7 years ago, before these little motors were made to go faster as they are today.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#1342

Posted 08 March 2010 - 03:14 PM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#1343

Posted 08 March 2010 - 05:52 PM

-john

#1344

Posted 09 March 2010 - 04:24 PM

Next up...a batch of five motors for Kim Lander, starting off with a Strombecker Hemi.

-john

#1345

Posted 09 March 2010 - 04:28 PM

In case anyone is interested I have uncovered a bunch of wire 25, 24.5 and a few other sizes. Mostly 12 lb rolls. If anyone is interested IM me.. Found lots of flat wire also but I dont think there is anything small enough...

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#1346

Posted 09 March 2010 - 05:57 PM

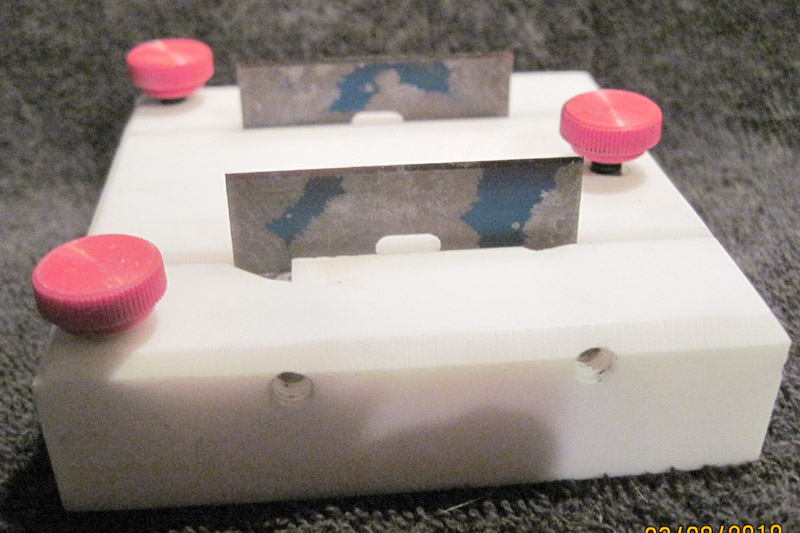

Rick's balancer is a great piece and I have one and use it every day just like the one in the picture. If you need a balancer, get it! BTW, you can crazy glue two gauge pins or drill blanks to two pieces of brass...or grind the edges off two razor blades and solder the pins to those and use the thing if you don't like razor blades.

-john

hehehe... I twisted his arm too

With all the blood on the arm. I knew it should run....And it does

OLPHRT

PHIL I.

#1347

Posted 09 March 2010 - 08:08 PM

John, excellent work as always.

In case anyone is interested I have uncovered a bunch of wire 25, 24.5 and a few other sizes. Mostly 12 lb rolls. If anyone is interested IM me..

Hi Tony and thanks.

hehehe... I twisted his arm too

My only complaint is I have almost slised of my finger

With all the blood on the arm. I knew it should run....And it does

Hmmm...maybe a little blood instead of arm dye for that "custom" touch eh Phil?

I just finished up motor #1 of 5 for Kim Lander...a nice clean Strombecker Hemi. It's a #29 single wind and sounds very very nice...probably about what a period rewind should sound like. With the strong magnets and endbell on these things, I probably could have gone hotter with no problems. Then again, I don't know where you'd get replacement brushes for these things (pencils???) so I stayed on the conservative side. Nice motors

Next up for my buddy Kim, a Champion 501 to rewind. Shaft is deeply notched, so that one will need a bit more attention.

-john

#1348

Posted 09 March 2010 - 09:22 PM

You never stop amazing me...that Hemi looks great, as I said...take your time, no hurry, like you said , those Hemis were good motors, one guy I raced with here in Macon in the 60`s and 70`sran nothing but Hemis, he won a lot to, any ways, I know the motors will be of quality, and will give me more to show off,the Havlicek logo will be known...thanks again...Kim

#1349

Posted 09 March 2010 - 09:49 PM

I finished-up Frank's two FT16D rewinds and they're pretty spiffy. I'm sure they'll look even better when Frank does his chassis thing and mounts them!

THANKS JOHN.I have a good place for them.. Wait and seee.

I'll make sure I brake them in before running.

Thanks again. You be the motor man

Mr. Frank

Next up...a batch of five motors for Kim Lander, starting off with a Strombecker Hemi.

-john

Frank Elavsky

5/20/60-2/9/12

Requiescat in Pace

#1350

Posted 09 March 2010 - 10:14 PM

I was hoping to shoehorn something I got from John into it but it won't fit…

In the middle is the arm that comes in it, on the bottom is a standard 16D from ProSlot for size comparison.

I think it maybe a good candidate for a rewind mini-motor though? But I think I will run it stock first to see how it runs and then tinker.

K

This topic is locked

This topic is locked