-john

#1301

Posted 01 March 2010 - 10:02 PM

-john

#1302

Posted 02 March 2010 - 09:31 PM

you know what I have in the planning, and I cant wait until I am finished with the Dynamic inlines and sidewinder, when they are finished I will put them on the track for display only and my hand will be the only one to drive them, other than that they will be on my history shelf. I think they will be awsome, I am going to start painting this weekend on the bodies I bought just for them...oh by the way...we got more of youre dadgum snow here in Ga. today, I told you to keep that crud up there...LOL............CYA.....Kim

#1303

Posted 03 March 2010 - 02:29 PM

Hi guys, a new arm i just finished a Parma 16D 55 turns of 29 Gauge as you can see it was a bit toasted. After the rewind i consider this motor a failure as it will not run past 10 volts on my power supply and draws a full 3 amps and it could give you a sun burn it runs so hot. I am not shore what's wrong with this one if anybody has any ideas i welcome them. I would like to test the arm for a short i have both a digital and analog meter but what do i set my meter to and how do i do the test. I would like to find out what i did wrong on this one so i don't make the same mistake again.

#1304

Posted 03 March 2010 - 03:23 PM

First off...VERY nice job of winding there, and that's no small thing.

Testing for a short at this time wouldn't reveal much as it's definitely a shorted arm now. The time to test is right after soldering (or even before if you're sure the wire is in good contact with the tabs). You actually don't need anything fancy to test for shorts, even a simple continuity tester with a flashlight bulb like you built in shop class (when they actually used to have shop class) would do. Anyway, with any kind of a tester...you set your tester to "continuity" and touch one probe against a com tab or even carefully against a com segment and touch the other probe against the outside of the stack if it's bare metal...or against the shaft. You should get no reading indicating that current cannoty flow between the magnet wire and the shaft and stack. If you aren't sure about the results (even though they should be very easy to read), you can set your meter to measure resistance (ohms) at the smallest scale and check the same way as above...again there should be no change in the meter from when it's touching wither the shaft or the stack and when it's not. While you have the meter set on resistance, you can check from pole to pole. Put one probe on one com tab and one on the next and note the reading. Then do the same moving in one direction two more times...the reading (if your meter is sensitive enough) should be approximately the same all three times. Minor variations can be chalked up to:

1)The inaccuracy of the meter at such a small scale

2)Slight differences in the length of wire on each pole

3)The fact that an indicated reading of say .8 ohm is really just under .9 ohm and the meter is "going back and forth" between the two readings.

If you have a major difference, then something else is wrong. 55T/#29 is starting to get into thinner gauge wire and you could easily over-tension the wire when winding. This could cause shorts or stretching of the wire which would effectively make it a smaller gauge right where it's stretched...creating a "choke point" for current flow that would cause heat. I don't know how to describe what the "proper" tension is for a particular gauge of wire other than saying you just need to feel that it's taught, but not damaging the wire. Copper is a very soft metal that can easily be pulled too hard...even more so when it's thin. 55T/#29 is NOT at all a hot wind and should be able to live even in an old Mabuchi with the auto-melt endbell (with a few additional cautionary measures).

So I guess it's possible that you did have a short, or that you stretched the wire by over-tensioning it as you wound the arm, but testing it now isn't going to give you any good info. Always test right after winding but before you irreversibly finish the arm.

-john

PS...it's not that far out that there was a problem with the com either and your wind may have been fine. If you don't have a com lathe, carefully clean the com by turning it as you pinch a piece of the finest scotchbrite around it. Shift the nposition of the Scotchbrite every so often until you get a new-brass look. Then, using the back end of the point of a new X acto blade, carefully make sure the slots between the com segments are free of debris as this can cause a short from segment to segment that would also make the arm run hot. When done, you can take a ball point pen and carefully run it up and down each slot to make sure any tiny burrs are burnished-down and then finish it off once more very quickly with the Scotchbrite. A quick rub with a cotton rag to take off any remaining debris should finish things up.

Hi Kim,

Please post pictures of those old cars when you get them done. You know there's a LOT of people here who just love that stuff. On the snow thing, I see you Georgians sent it back up here today

-john

#1305

Posted 03 March 2010 - 03:44 PM

#1306

Posted 03 March 2010 - 04:04 PM

When you unwound the crispy critter, did the end fiber insulators break off, as they normally do?

If they did, did you coat the bare metal arm stack with anything before you wound the wire on it?

If not, there my be your problem. Two things: (1) If you didn't radius the ends of the stacks prior to winding, those sharp corners probably dug into the first few turns of each pole as you were winding. (2) If there was no insulating material present, there was no way to prevent the touching of copper to steel and you ended up with shorts.

How to fix problems: (1) Take a file or some kind of motor tool ON SLOW SPEED and carefully radius the sharp corners off the end laminations of the stack. Parma's steel on the armature is pretty soft so a square rat tail hand file would probably work best. You can control it better. (2) After you do that you have to keep your wires from touching the bare metal of the stack. John recently discovered furnace cement. To me, that sounds like the way to go, but heck, you could even wrap a couple turns of narrow masking tape in there. I wouldn't recommend that for really hot winds, but 55T of #29 should be just fine. I had 100% success with that in the old days, but John's idea of the furnace cement, to me, sounds the best.

Parma's end fiber insulators are frail at best. I should know. I've unwound almost 50 of them over the years. Next time, if you want to save the insulators, pick an arm that isn't quite so cooked. The ones that aren't fried to a crisp seem to hold up better during the unwinding process.

Stay after it man. Once you get this little bit of learning curve behind you, you will be all set!!!

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#1307

Posted 03 March 2010 - 04:14 PM

ROBERT,

One thing I did notice is that you didn't put the fiber end plates on the arm. One of the things we always heve problems with is when going around the end of the laminations is that they are sharp cause of being stamped out. John uses a Dremel to round the edge slightly. Then puts a small coating of epoxy to cushin the wire more. Lately he has been working with a furnice paint to coat the laminations and the inside of the leg. Even with the epoxy. I still had some go bad cause of sliding the wire down the leg. Wanting to get the wire to lay just right and going threw the coating to bare wire. Don't use metal to move the wire around. I used thise big wood toothpicks. Find what works for you. Try not to kink or do a sharp corner TIGHTLY as it will cause heat sorce in the wire just like streaching a wire..

Nice looking job. Keep at it...

OLPHRT

PHIL I.

#1308

Posted 03 March 2010 - 04:45 PM

-john

#1309

Posted 03 March 2010 - 10:16 PM

#1310

Posted 04 March 2010 - 06:53 AM

I think that the problem is more likely to be the stack coating and it can seem as though it should be well-covered and still short. Over-tensioning the wire is also something to look out for, but probably a little less likely as the cause. The least likely cause from what I've seen is the commutator, but definitely worth looking at as I have had motors here for refurbishing that had this issue. As you inspect the com, each tab and plate needs to be separate from the adjacent ones and even the smallest amount of conductive gunk trapped in between them will cause problems. I recently had an open frame motor here that would smoke and draw a LOT of current because of this. However, the com segments on those are wide and a little rough which would cause brush dust to build up in there. The coms on the D cans are much smoother and less likely to have this problem, but anything is possible.

So I think it's still most likely the coating and the engine enamel may be fine for holding the coils together but may not be building a thick enough film...even with two coats.

-john

#1311

Posted 04 March 2010 - 09:25 AM

#1312

Posted 04 March 2010 - 12:02 PM

Just remember:

THEY ARE ALL DOOMED!

Fate

3/6/48-1/1/12

Requiescat in Pace

#1313

Posted 04 March 2010 - 03:41 PM

but first i have another idea for insulating the stacks i hope it works.

...OK, spill the beans. Inquiring minds wanna know what "secret sauce" you're going to put on there Robert

THEY ARE ALL DOOMED!

...true enough Rocky, but they oughtta have a lifespan of more than a minute or two. At least that's what I've been shooting for

-john

#1314

Posted 04 March 2010 - 07:06 PM

If I may questions…

What do you mean by it wont run past 10 volts…does the motoractually slow down and or stop?

The motor gets so hot it could burn you? – How fast does the motor actually run? – Slow?

Could it be possible that you produced a Hemi wind? Did you try and reverse the power connections and see if it runs better and cooler?

Try, Try, Again...

K

#1315

Posted 04 March 2010 - 08:02 PM

#1316

Posted 05 March 2010 - 02:15 PM

that is the thing I learned. If the joy is in the goal of a fast car on the track....WINNING, then you are going to be frustrated. I try to enjoy each step that starts with thinking about the project all the way to the final results.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1317

Posted 05 March 2010 - 02:48 PM

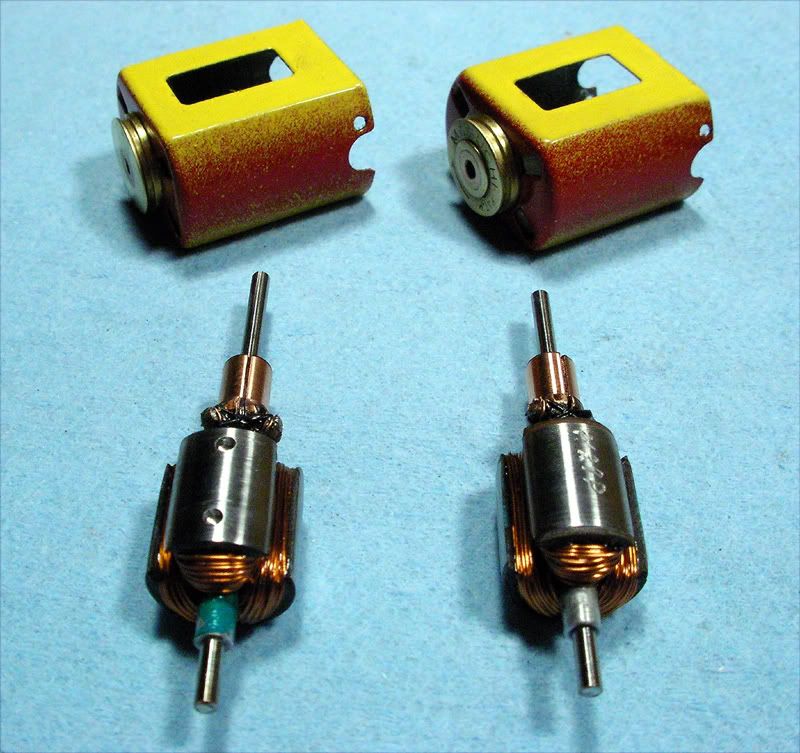

1)Modern D can magnets. These are very strong, they measure stronger than what was out then for sure, and fit the FT16D can perfectly.

2)I used a recycled Mura commutator because it just fits and gives some more protection...well actually a LOT more protection even though a #29S shouldn't be a major problem

3)Modern brush springs

It's a pretty motor that should be a solid runner too

-john

#1318

Posted 05 March 2010 - 03:00 PM

#1319

Posted 05 March 2010 - 05:45 PM

-john

#1320

Posted 05 March 2010 - 07:13 PM

Well here is another parma 16D rewind one of the guys at the track toasted this tuesday near the end of the race i believe it cost him the race in the last 10 laps, the first pic is of the burnt arm the second pic stripped down and you can also see what i used to insulate the stacks it's kind of a thin asphalt type material i got at the hobby store it's used as a road way for the little cars on a HO train layout last pic of the finished arm 50 turns 29 gauge wire it sits on the insulating material yes i had to cut the stuff by hand i think the cement would be much easier to use. Oh i almost forgot to mention this motor pulls less than 1 1/2 amps runs cool and strong up to 15 volts, it's about time i got another good rewind.

#1321

Posted 05 March 2010 - 07:24 PM

-john

#1322

Posted 05 March 2010 - 07:33 PM

#1323

Posted 05 March 2010 - 07:37 PM

-john

#1324

Posted 05 March 2010 - 07:52 PM

#1325

Posted 07 March 2010 - 01:25 PM

-john

This topic is locked

This topic is locked