#1251

Posted 22 February 2010 - 12:47 PM

Mike Boemker

#1252

Posted 22 February 2010 - 01:13 PM

If you don't blow up an arm now and again, you ain't really trying!

Fate

3/6/48-1/1/12

Requiescat in Pace

#1253

Posted 22 February 2010 - 03:35 PM

"Everything you love, everything meaningful with depth and history, all passionate authentic experiences will be appropriated, mishandled, watered down, cheapened, repackaged, marketed, and sold to people you hate." Von Dutch [Kenneth R. Howard] 1929-1992

."If there is, in fact, a Heaven and a Hell, all we know for sure is that Hell will be a viciously overcrowded version of Pheonix." Dr Hunter S Thompson 1937-2005

"Whither goest thou, America, in thy shiny car in the night?" - Jack Kerouac 1927-1969

"Hold my stones". Keith Stone

My link

#1254

Posted 22 February 2010 - 03:48 PM

Oh I was referring to the center drill's point angle and the length of the pilot. By the time you get to the wider section of the drill, the pilot is already so deep that it could cause a problem weakening the stack if you're off side-to-side. I don't really have any problems breaking the bits, more that after a couple of months they get dull...so I toss them

Stack weakening is never a problem till it lets go. I've had some arms with, "Journey to the center of the Earth," balancing holes that held up fine and others that seemed to know I didn't really want to replace the magnet it was about to break.

...welcome to my world Mike

If you don't blow up an arm now and again, you ain't really trying!

...hmmm, then I must treally be trying!

-john

#1255

Posted 22 February 2010 - 08:58 PM

If it grenades then that is fine, as it will be part of the learning curve.

Pablo – The balancer I am using is home made, try this link...if I did it correctly

http://slotblog.net/...ic=8714&st=1217

If not it's post 1218 of this thread.

Doug – Yes it's a ProSlot arm rewound, trying to use up some old arms as I practice. Once I think I know what I am doing I will try and move onto newer ones.

Thanks Everyone

K

#1256

Posted 22 February 2010 - 08:59 PM

Oh I was referring to the center drill's point angle and the length of the pilot. By the time you get to the wider section of the drill, the pilot is already so deep that it could cause a problem weakening the stack if you're off side-to-side. I don't really have any problems breaking the bits, more that after a couple of months they get dull...so I toss them

If one was using center drills to drill balance holes, you'd only use the pilot portion of the bit, otherwise you'd end up with a 1/8" dia. hole. If one pilot hole didn't remove enough material, you have the choice of drilling a second & third pilot hole or increasing the size of the first with a 1/16" or 5/64" bit. The tapered portion of a center drill works great when beveling holes for flathead screws in sheet metal & for cutting the surface area for a lathe's points to rest.

I have an Eclipse brand drill sharpener. It's a British made wheeled plastic guide holding the bit that gets rolled across some 320 grit or finer paper. It works fairly well when the bit just needs honing but if you got to remove any serious metal, you need a motorized unit.

I intend to live forever! So far, so good.

#1257

Posted 23 February 2010 - 01:51 AM

I too have 2 or 3 ProSlot arms I want to rewind but just don't have time to right now. I'm definately going to put hotter winds on them. I may even replace the comms and really make 'em rip.

While my plate is overflowing with other priorities right now, it's allowing me to think of very devious motors to build once I can get back to it.

Meanwhile, I'm glad to see others getting involved in rewinding. It ain't that hard and the rewards can be quite nice. Look at it this way: Thomas Edison found hundreds of ways not to make a sucessful light bulb. We don't have it that tough.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#1258

Posted 23 February 2010 - 07:30 AM

If one was using center drills to drill balance holes, you'd only use the pilot portion of the bit, otherwise you'd end up with a 1/8" dia. hole.

Gotcha Bill, and that's what I would do as well.

Kelley,

You and Robert have the right idea when it comes to this stuff. Dig in and just do it because it really doesn't matter at first what happens. You'll be gaining experience and a kind of mad-scientist enjoyment out of it all!

-john

#1259

Posted 23 February 2010 - 09:18 AM

I intend to live forever! So far, so good.

#1260

Posted 23 February 2010 - 09:32 AM

John, not to belabor the point further, the bradpoint bits I've seen & own are make for wood. They wouldn't be properly hardened or made from a steel for drilling in metals. How about trying one of the small Dremel milling bits for the flat-hole look? Next time you go to the dentist, ask if he's gotten an "dull" grinding burrs. You never know what you could end up with.

10-4 Bill...that's why I said it probably wouldn't work. Worse, it could be dangerous because if that thing grabs a lam and yanks the arm, it could drill your fingers

-john

#1261

Posted 25 February 2010 - 04:37 PM

-john

#1262

Posted 25 February 2010 - 06:55 PM

#1263

Posted 25 February 2010 - 07:27 PM

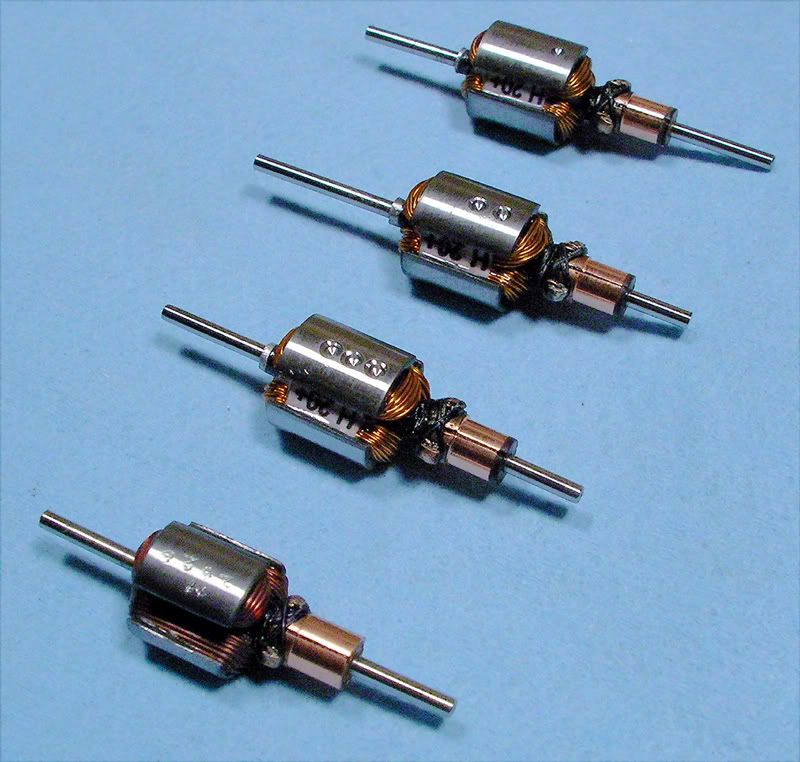

Thanks. The three tagged armes are #27 winds and the short stack arm is a #26. The three tagged arms are about .3 ohm and the shorty is .2 ohm and #26 wire makes a hot arm that is still sort of reasonable in the right setup.

-john

#1264

Posted 25 February 2010 - 08:35 PM

I intend to live forever! So far, so good.

#1265

Posted 25 February 2010 - 09:00 PM

Yeah they do don't they

-john

#1266

Posted 25 February 2010 - 09:02 PM

Yeah, buddy! ... That's the stuff!... WOW! ... Impressive....

John & I had discussed the 'Steube-20' arms I ran, as a kid... Bill would wind 35T of 27 wire on the then-available Mura .007 blanks, & I thought that this wind, in an older two-hole Mura set-up w/ longer-length magnets, would be a real kick to drive!... The Challenger I blanks are shorter than the original blanks Bill used, but that shouldn't be a problem... The ' H20+ ' tag lets the builder know that it's John's work, & a tad 'warmer' than a standard Gp20 wind....

As always, many, many thanks, John... Bob "Stork" Crane was kind enough to hand me a few older two-hole Mura C-can set-ups, w/ long-length Mura & Champion Blue Dot magnets in 'em, so I should be set to set 'em up, & let 'em spin!...

& yes, I will post photos... I love sharing my attempts at re-living my youth thru running John's armatures... As I build-up the motor, & assemble the chassis, I'm taken back to when I was 17 or 18 again... It's a BLAST !!!

Take care, everyone!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1267

Posted 25 February 2010 - 09:38 PM

-john

#1268

Posted 25 February 2010 - 10:20 PM

I intend to live forever! So far, so good.

#1269

Posted 26 February 2010 - 06:39 AM

-john

#1270

Posted 26 February 2010 - 12:09 PM

WOW!

I mean........HOLY S**T!

Well, I guess I made my point....absolutely fantastic and over and above! Thanks so very much!

Home of Area 51 Chassis Works

Steve Vogt, Sr.

#1271

Posted 26 February 2010 - 12:31 PM

I'm glad you liked it and it was my pleasure

-john

#1272

Posted 26 February 2010 - 06:00 PM

I can understand your excitement upon receiving a motor from Sir John H. I have to confess that each and everyday I need to take a look at the motors I've had the privilege of having "woundup" from Sir John and each and every time is like taking a peek at something I could not imagine I would own! Now - that's exciting!

Thanks again Sir John H. for your time, effort and generosity.

Ernie

#1273

Posted 26 February 2010 - 06:04 PM

Now I have to cut down the can to the right length, and I'm not sure where I wrote down that dimension

-john

#1274

Posted 26 February 2010 - 11:14 PM

I really need to have one now! What an awesome piece - as usual. So, you play guitar too?!!

Ernie

#1275

Posted 27 February 2010 - 07:13 AM

I've had a pretty good amount of interest regarding the "Walnut" motor. There have been all kinds of versions and variations of this sort of thing...mine is based on the short arms like the X-12 that go in C cans. Since the arm should be shorter than the magnets because the field generated by the moving coil doesn't just go out perpendicular to the arm but off the ends as well, it seems that these short arms are somewhere about "right" for the short magnets in a modern C can. Then when you stick one in a C can...the can seems kind of long for what's inside (leaving aside the role the can plays in producing the field along with the magnets). So hacking the length of the C can to just about the minimum without cutting the magnets seems like a good idea. The result is a short and light motor that still has a lot of punch with simple off-the-shelf parts that are inexpensive too (including regular ceramic magnets like Mura Red Dots). It would seem ideal to put this motor in a light perimeter frame with a body that has some air control to take advantage of both the rpms as well as the light weight and Jeff Easterly's car for his Walnut looks like a great example. We used to run G20 motors in cars like that and they were a boatload of fun. This is like an extreme example of that...with a lighter and faster motor.

I also have done something similar based on a cut down SCX can which is much slimmer and maybe even shorter than the C can-based Walnut thanks to the very slim magnets in there. Those are very cool too.

-john

(I play keys...organ, piano and synth, I even

This topic is locked

This topic is locked