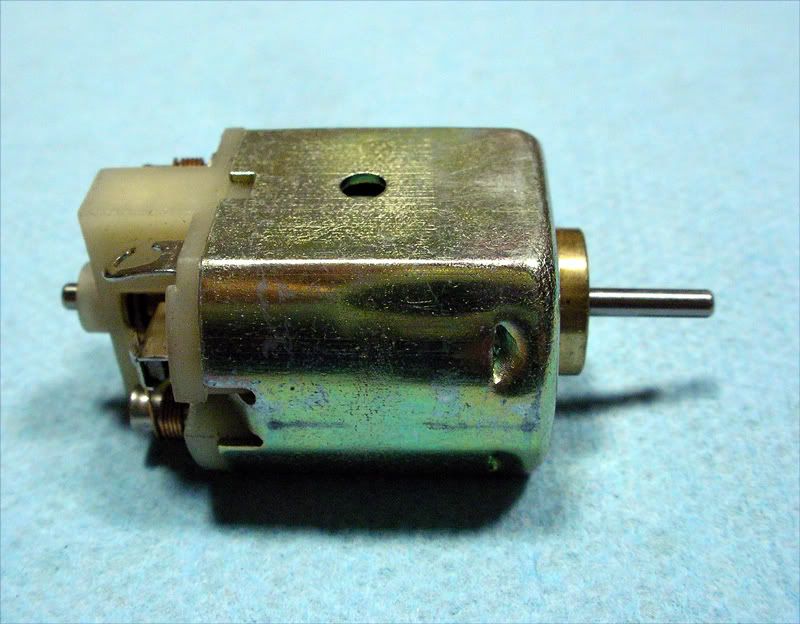

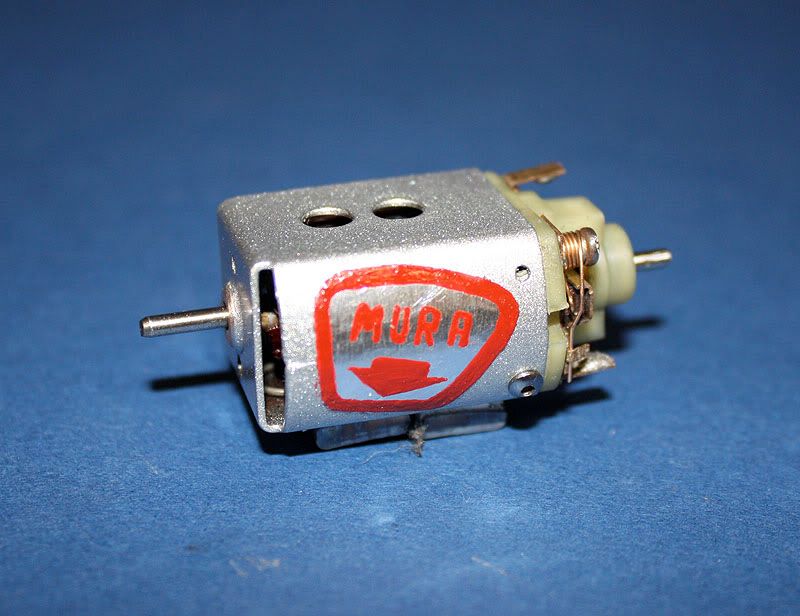

Vic, I got brush springs bigger than that motor!

Bill,

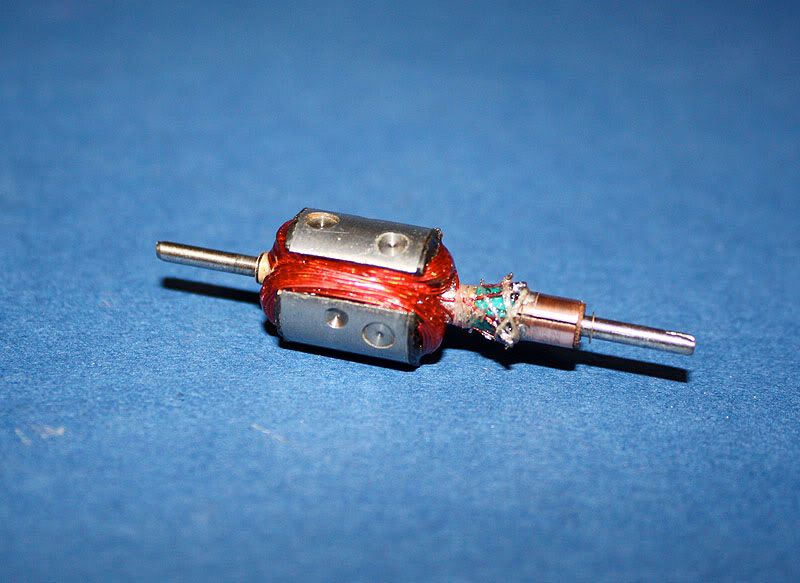

You wouldnt believe the rpm these little things put out . Its just the arms that seem to be the weak point.

And Bill remember,, Its not how big it is, but how you use it !!

Vic

Posted 20 March 2010 - 02:52 PM

Vic, I got brush springs bigger than that motor!

Posted 20 March 2010 - 03:32 PM

Posted 20 March 2010 - 04:35 PM

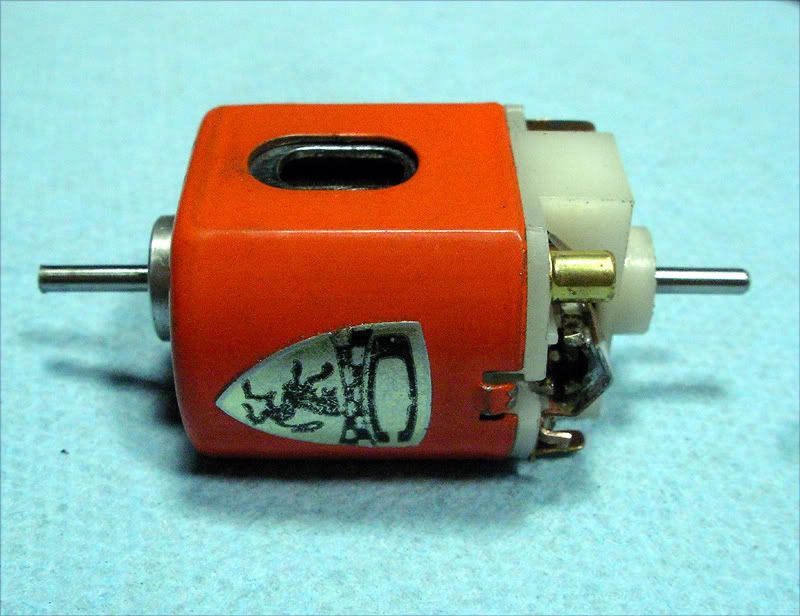

I got a Puppy Dog with the Chinese unbalanced arm in it and it didn't run worth a poop. I had an OLD X 12 P.S. with 38 degree advance that had worn the can end shaft out. After measuring it. I cut the can end spacer so the wires bearly cleared & the can bushing was riding on a new shaft. I then had to shorten the comm a bunch to make it fit. It JUST bearly clears the bottom of the brush hoods. I had to move the mags down to center the arm in the magnetic field. Does it runYea baby. It is one HOT runner.. After 20 laps. It turned the arm dye a dark red. Is it faster than the american arm Puppy dog? YES SIR. I would not try it a whole race tho..I just take it out & run it with the American arm puppy dogs...

Kinda makes them mad when they see another puppy dog out run them sooo bad. Maybe thats why the puppy dog 12 arms don't go that wild on timing

PHIL I.

Posted 20 March 2010 - 07:33 PM

Posted 20 March 2010 - 07:53 PM

Ernie, I think your right !! I just think its neet to have a new motor to toy with.

Posted 20 March 2010 - 09:17 PM

I'm guessing a cobalt 12 arm might be a better fit since it's wound on an arm blank that uses shorter spacers. But the arm stack length is still the same. I don't have one to try it.

Posted 20 March 2010 - 09:20 PM

Vic,

I concur that it's KOOL to have a new "Havlicek" motor to play with - how EXCITING! Actually any of my "Havlicek built" motors are fun and I have them sitting in compartments to look at and enjoy until I can built plastic/composite chassis' for them?!!!!!

I sure wish I was close enough to see and hear your motor run Vic!!!

Ernie

Posted 20 March 2010 - 09:56 PM

Posted 20 March 2010 - 11:30 PM

Phil,

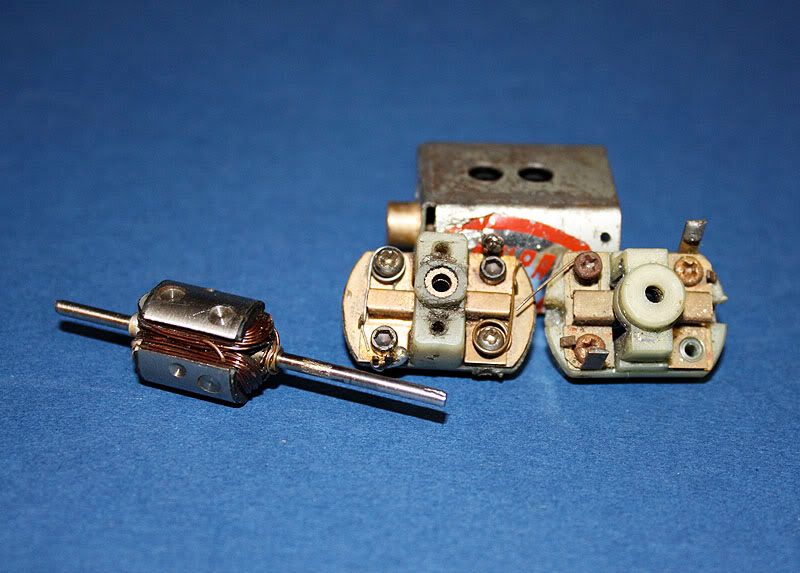

I tried to do the same thing. I had a Koford x-12 arm that I thought I would stuff in it. What I didnt give any thought to, was the fact that the com end is much longer. The stacks fit great, and I really thought I was on a roll until I went to install the endbellOops !!! not gonna work

My fault, I should have known the 12 arm was much longer. With the strong magnets that come in these motors, I would think an x-12 arm would be a rocket in this thing.

Did you gauss the mags in yours? I did, and I got a 988 and 979. Not bad for the size huh? That was after giving them a zap. I plan to have alot of fun with this thing !!

Vic

Posted 21 March 2010 - 07:58 AM

Posted 21 March 2010 - 11:19 AM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

Posted 21 March 2010 - 02:01 PM

Posted 21 March 2010 - 02:08 PM

Vic,

Please "tell all" when you've received the motor back from John and have done some "testing" on the track. Looking forward to the field report!!!

Ernie

Posted 21 March 2010 - 02:27 PM

Posted 21 March 2010 - 04:39 PM

Posted 21 March 2010 - 05:54 PM

Posted 21 March 2010 - 06:29 PM

Posted 21 March 2010 - 07:21 PM

Posted 21 March 2010 - 08:18 PM

Posted 21 March 2010 - 10:13 PM

Posted 21 March 2010 - 10:54 PM

Posted 22 March 2010 - 12:46 AM

Posted 22 March 2010 - 05:48 AM

Posted 22 March 2010 - 07:52 AM

Posted 22 March 2010 - 09:58 AM

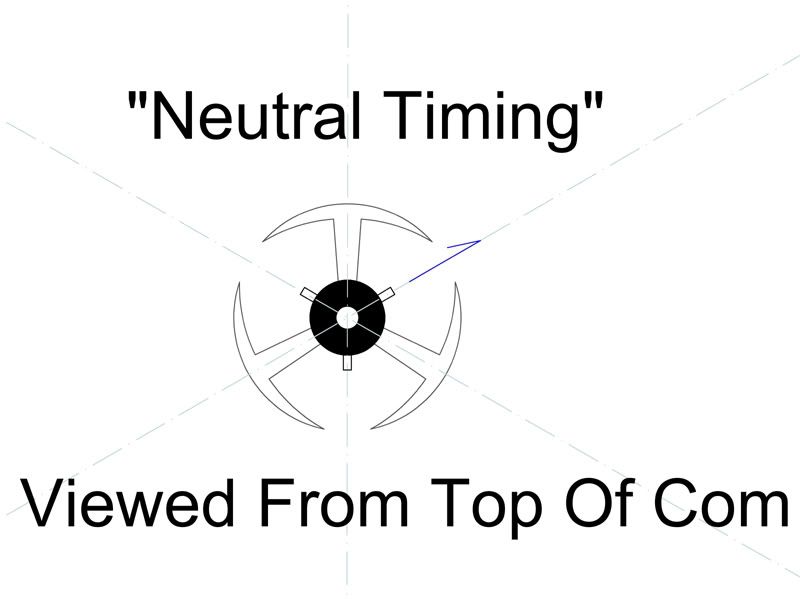

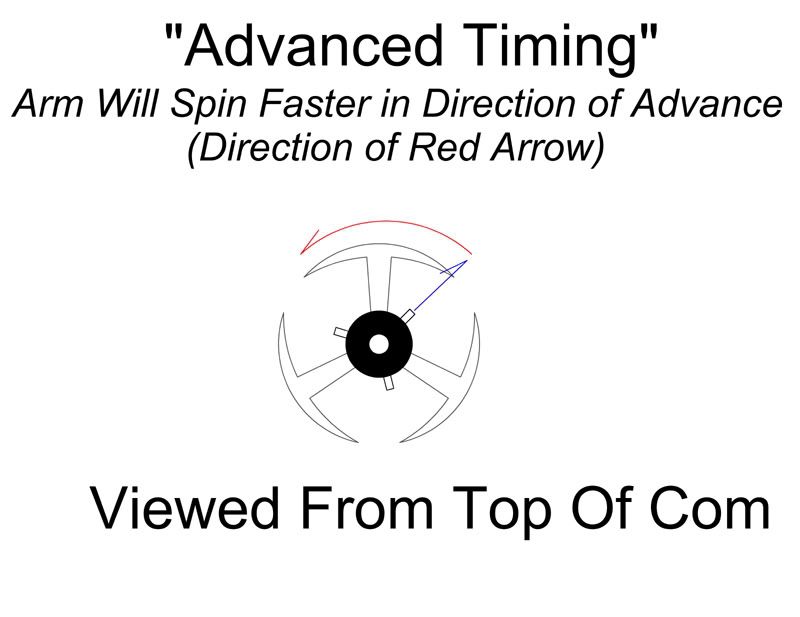

Thanks Phil and John, well i lined the comm tabs up with the center of each stack i thought that was neutral timing,