Thanks John those illustrations are great, that clears everything up, going by this my Mura motor is very advanced it looks like i will have to rewind it if i want to keep it alive for long might make a good drag motor though.

#1426

Posted 22 March 2010 - 10:51 AM

Thanks John those illustrations are great, that clears everything up, going by this my Mura motor is very advanced it looks like i will have to rewind it if i want to keep it alive for long might make a good drag motor though.

#1427

Posted 22 March 2010 - 11:32 AM

Your illustration really helps me to understand about setting timing! That's some tech sheet!!!!

Thanks John!

Ernie

#1428

Posted 22 March 2010 - 12:44 PM

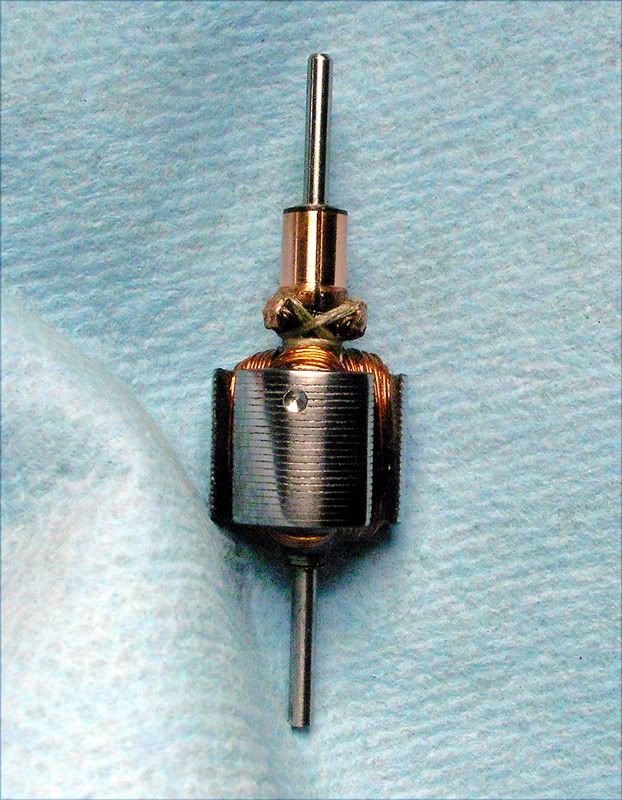

N-E-WAZE, I finished-up the Classic 26D I had been working on and I'm just sooper-stoked with this motor. As I had mentioned, I planned to do a double #28 wind, and that's what I did. Just like the recipe sez, it came in at .2 ohm and positively howls...especially for a Mabuchi. The arm is a Tradeship blank that got a new drill blank shaft (I have some a few thousandths under that don't need polishing-down to fit modern ball bearings) and a recycled Mura com so I could weld the tabs. I reshaped the point of the carbon rod I use for welding and have been getting good results on thinner gauge wire with it...whew! It's a real bummer to get an arm all done and then go to weld the tabs and have one vaporize on me. I guess that's what you get for duck hunting with a bazooka

Motor's all cleaned-up and a nice new pair of BF brushes and Camen springs installed. I got the brush tubes filed-out just enough so the brushes drop through without hanging-up. I can only test things at either 6V or 12V until I get my power supply thing straightened out, so a quick hit at 6V was all it got. Yikes!, the thing whistled like the theme from the Andy Griffith show. None of that "baby-rattle-in-a-can" sound that the Mabuchi bearings make, sounds more like a pretty warm Mura...what have I done!?

-john

#1429

Posted 22 March 2010 - 12:57 PM

John, you screwed up! You needed to do the shim hole so that it didn't show. How can you pass tech with a "stock motor" otherwise?

How do I know?

In the day, a lot of us went the route of using the 36d carriers in 16 and 26ds, but I don't remember anyone noticing nor do I remember anyone mentioning them in the magazines.

Though I admit that I goofed on one because I polished the stack, but again, the tech inspectors never noticed.

I have no idea why people do not build motors these days. But then I guess most racers just want to RACE and don't enjoy any part of the building part.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1430

Posted 22 March 2010 - 02:36 PM

It would be nice if there were such a thing as races with these old motors so I had to actually worry about such things. (sigh) Anyway, when I did the few races I actually participated in..."tech" meant basically having a body, not exceeding the width limit and clearing by 1/16". Nothing else mattered as far as I can remember and it made things very simple.

On the motor-building thing (I'm including winding), I haven't a clue why it's not been getting more attention since it really IS "retro"...certainly just as retro as scratchbuilding chassis. There are some people here (seemingly more lately) doing it besides you and I. Pablo does motors every so often, Doug Azary, Robert V, Kelly etc. Who knows, maybe Phillipe will goof around with motors at some point just for kicks. Steve O'Keefe has done some absolutely beautiful winds he showed me pictures of and I'm sure there must be one or two others I'm not even thinking of right now. All I know is that those who aren't are missing out on some of the best fun there is in slot cars.

There is the fact also that no real (other than I suppose "Open" class) racing program exists to support home-wound motors. That might be a "chicken or the egg" thing though since if there were enough people doing it...there might actually be an accompanying race program, but I doubt it. The way people are, the temptation to cheat and just stick a hot factory arm in a motor and say you wound it would be too hard to control. Best I can hope for is people to "just do it" and enjoy it.

-john

#1431

Posted 22 March 2010 - 08:26 PM

We used to have a race class called "Run What Ya Brung"...didnt matter if it was a hot factory wind or a home wind...just so long as it was the fastest you had....heck I would love to run rewinds again...but here everyone is spoiled on the factory motors...to me its a whole lot more fun to see a motor that you wound yourself run in a race...but everyone wants things to be equal other than driving skills (kinda like NASCAR where every car is the same)....anyways, I just like to race...Kim

#1432

Posted 22 March 2010 - 10:08 PM

Wow that arm looks amazing and i bet it really screams, one day i have to try a double wind after a bit more practice, 2 questions where do you get your drill blanks for the shafts and how many turns of 28 gauge did you use on that arm. I to wish we had a class for motor builders but i don't think we could get enough people together not in New York any way.

#1433

Posted 22 March 2010 - 10:31 PM

I think it's cool that these kinds of motors are still being run by people that have fond memories of them...like yourself. There are enough old and even new motors to support a run-what-you-brung class that would include homewinds, there just isn't enough interest on the part of racers. So, just have fun with them

Hi Robert,

Thanks. Yes, the motor really sounds great and the wind works well because of those magnets...but doubles seem to be safer in these old motors as they tend to run cooler and draw less current. I may get some #30 or #31 wire and try some triples...I think a triple #29 would be a little crazy. I'll PM you with the wind (I'm getting to the point where I have to have at least some secrets

-john

#1434

Posted 22 March 2010 - 11:07 PM

John/anyone,

What are the strongest slot car magnets available for C-can motors please? Someone at the track mentioned that Cobalt magnets are the most powerful.

Thank you.

Ernie

#1435

Posted 22 March 2010 - 11:50 PM

Here's the link:

http://www.slotcaril...ead.php?t=22080

Ernie

#1436

Posted 23 March 2010 - 12:06 AM

I've been going through my boxes of "stuff" and getting things ready to try some re-winding again.

Good to see some others getting into it too.

Ernie...

Koford (and I believe a couple of others) has all sorts of magnets.

Neodymium magnets can actually be stronger than Cobalts, but they are more temperature sensitive. If you get a Neo hot (like over 300 or so degrees) it does not regain as much of it's magnetic strength back after it cools down, like a Cobalt (or ceramic) will.

I see that there are Neo magnet C can drag motors now...which makes sense, because a drag motor doesn't have to run long enough to get really hot.

Check out the Koford catalog...they have Neo magnets for C cans.

Tom Hemmes

Insert witty phrase here...

#1437

Posted 23 March 2010 - 01:04 AM

Hmmmm, I think the drag guys can get them hot enough to dump. The amp draw just gets stupid with these things. I think Foamy could add to this post.

Mike Boemker

#1438

Posted 23 March 2010 - 01:19 AM

"I see that there are Neo magnet C can drag motors now...which makes sense, because a drag motor doesn't have to run long enough to get really hot."

Hmmmm, I think the drag guys can get them hot enough to dump. The amp draw just gets stupid with these things. I think Foamy could add to this post.

Probably should have researched a bit? I know drag motors can get rather hot...

I'll bet they could get quite hot after a few passes? How about after just one pass then allowed to cool? (use a fan?)

It would seem impractical to have to replace the Neo magnets after just a few passes...(guess that's cheaper than changing pistons/rod assemblies, etc. after every pass though

It would be very interesting to get an experienced slot drag racer's experience/opinions.

I have several years of experience running brushless motors (they use Neo's) in my R/C airplanes, but they have considerably more air flow around them during use, aye!?

I have thought about getting some of the Koford Neo C can magnets just to experiment, but I'm more into road racing, (we don't have a strip close by around he, that I know of anyway) and the heat issue has kept me from buying any.

Tom Hemmes

Insert witty phrase here...

#1439

Posted 23 March 2010 - 01:58 AM

One run can get things plenty hot. You seldom run back to back anyway.

The experimenting with Drag neos just got into high gear and finding out what airgaps gear ratios & winds they can tolerate is part of the game.

Some of the C can Neos found their way into D cans too.

Mike Boemker

#1440

Posted 23 March 2010 - 02:27 AM

I don't know what I was thinking...duh! (it's late...or make that early)

Thanks Mike

On another note, I have an old Tradeship static balancer...

I've been messing around with some stock (China made) 16D arms, and I'm really surprised at how much smoother and faster they run after just a static balancing job. I have been grinding the corners of the stack like the old Champion arms. (actually, I use a tungsten carbide cutter to "massage" the stack a wee bit)

I'm a little nervous about drill balancing...I don't have a drill press. I tried adding varnish and C-A glue to the light poles, but that took forever.

I bought a bunch of 16D arms from Ron H. some time ago, and plan on rewinding a few.

Tom Hemmes

Insert witty phrase here...

#1441

Posted 23 March 2010 - 05:58 AM

Love this thread...John, your work is inspirational

I've been going through my boxes of "stuff" and getting things ready to try some re-winding again.

Good to see some others getting into it too.

Hi Tom and thanks! I always wonder what people think about all this. I see that people do read the thread by the number of views, but the number of replies are relatively small and by only a few people. Ot's gratifying to know that my efforts may have played a small role in getting others to break out the magnet wire and start tearing-apart motors

Real nice John! I like the orange color - reminds me of the McLaren Race Cars!!

John/anyone,

What are the strongest slot car magnets available for C-can motors please? Someone at the track mentioned that Cobalt magnets are the most powerful.

Thank you.

Ernie

Hi Ernie,

Thanks as always

On another note, I have an old Tradeship static balancer...

I've been messing around with some stock (China made) 16D arms, and I'm really surprised at how much smoother and faster they run after just a static balancing job. I have been grinding the corners of the stack like the old Champion arms. (actually, I use a tungsten carbide cutter to "massage" the stack a wee bit)

Absolutely Tom. For most motors home winders would be doing, static balancing is completely appropriate and will produce significant improvements when done well. I've been saying for a long time that there really is no "need" to send arms out if you can practice and get good at static balancing. The real problem with static balancing an arm is when the shaft is in poor shape. You won't get any meaningful feedback on how an arm is balancing when it can't roll smoothly on the bearing surfaces...rods or razor blades.

I tried adding varnish and C-A glue to the light poles, but that took forever.

Neither has enough mass to be of any help and CA glue could be a bad thing as it will off-gas cyanide when the motor gets hot (the "C" stands for cyanoacrylate). You can use epoxy on the stack when there's not much of an "out of balance" situation, but you're better off removing weight than adding it.

It's also good to remember that brand new high-quality arm blanks and coms are available from Bill Bugenis who is a member right here, so there is another source besides Mura, who is expensive for what you get. There are old and new motors for rewinding...as well as sources for all the supplies people need to do the deed!

***It bears repeating that production motors have long been beyond what the home-winder could compete with. This all came about because Mabuchi and the like produced motors that were OK for their purpose, but it was easy to improve on those with very little in the way of technology and tooling. However, there's an awful lot of fun...even "excitement" that can be had by winding your own motors. I doubt that serious competitors will be using hand-wound arms ever again now that slot car motors have truly entered the space age, so we're able to do this purely for enjoyment of the craft!

-john

#1442

Posted 23 March 2010 - 12:39 PM

I have a question please.

I was at Radio Shack just browsing the electric motors. I saw different sizes and varied suggested voltage operation; 6 volts, 12 volts.

What are the variables that make for a motor's voltage threshold?

For example, a motor that is said to have a sustained max operating voltage of 8 volts, what are the mechanicals within the motor that prevent it from sustaining operation at 12 volts?

Thank you.

Ernie

#1443

Posted 23 March 2010 - 12:53 PM

There are no real rules on "voltage rating" when it comes to slot cars. Most of the rat shak motors are junk by our standards. Most use simple pressure pads and the spring tension of brass strips for brush contact, no real brushes and cheap leaf commutators.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1444

Posted 23 March 2010 - 01:24 PM

To expand a little on what Rocky said, motor voltage ratings are completely arbitrary. For example, there is no set of agreed-upon standards for calling a motor an "8 Volt" motor. If you take that 8 Volt motor and run it at 6 Volts, it will spin slower and probably last longer. Take that same motor and run it on 12 Volts and it will spin faster and probably live a shorter life. That's doesn't negate the possibility that someone might wind a motor to produce a certain amount of power and last an average of so-many hours at a particular voltage...it's just that there's no testing standard so anyone can call a motor say...a 12 Volt motor. In slot cars, you have situations where people run tracks at voltages significantly higher than 12Volts, I guess to make slower motors run faster. It seems odd to me, as they could just run motors that are faster at 12 Volts and not worry about blowing-up motors that are made to run at around 12 Volts. Confused?...me too!

-john

#1445

Posted 23 March 2010 - 02:43 PM

-john

#1446

Posted 23 March 2010 - 03:34 PM

That ought to whistle!

Mike Boemker

#1447

Posted 23 March 2010 - 03:57 PM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#1448

Posted 23 March 2010 - 04:07 PM

yes it should Mike! It's difficult to keep everything neat with these and I doubt I'll do many because of the extra effort...but I had to try it at least once anyway. This one will go in a Mura setup, I think putting this in a Mabuchi is pretty much asking for something to blow upThat ought to whistle!

I just love how the winds are held in check with that floss; gotta do SOMEthing to keep it from coming apart at max rpms!

...and to make sure, the floss is actually Kevlar thread Tex

-john

#1449

Posted 23 March 2010 - 10:02 PM

#1450

Posted 23 March 2010 - 11:06 PM

That is so KOOL - Wow - triple wind - triple threat!!!! John, please let us know how it runs/sounds when you put connect it to some juice!!!

Can't wait to see the finished product!

Ernie

This topic is locked

This topic is locked