#1676

Posted 21 May 2010 - 07:29 PM

I intend to live forever! So far, so good.

#1677

Posted 21 May 2010 - 08:19 PM

I've often thought about that, and the relative scarcity and cost of vintage parts could be a little off-putting for some folks on a budget (and who isn't on a budget these days). There are all kinds of choices using modern motors. The SCX RX 42B is a great motor for working on with really strong magnets and a decent endbell...but not as good as a modern D motor. Personally, I think the Mura Challenger I is tops for performance potential and I see Roger at Mid America has the Challenger I for $24. For that very reasonable price, you get a .007" arm, a great Mura com, a quality endbell and good magnets. Let me think about it, but I think you may be right that a modern motor might make more sense.

-john

#1678

Posted 21 May 2010 - 08:50 PM

I intend to live forever! So far, so good.

#1679

Posted 22 May 2010 - 06:50 AM

John, Challengers are Mura C-can arms, but they'd make a good writeup too. The only difference is the 1 is unbalanced while the 2 is balanced. Both arms have 55T of 30 gage wire on a .440" stack.

10-4 Bill. The more I think of it, I should do both and start with the D motor as you suggested. Reason being that the Mura Challenger I, even though unbalanced, is (I think) epoxied and that presents some ...er..."challenges" as to winding. The older short can (and some others of the bewildering array of Mura motor types) 2-hole Muras that come up from time to time were unbalanced and unepoxied and make a great platform, but those aren't around so much. I gotta dig through my "stuff" and start putting together the parts for a D motor rewind project. Thanks for the idea Bill.

-john

#1680

Posted 22 May 2010 - 08:00 AM

...next-up an old NCC 12 motor for Brian McPherson for a VERY VERY special project of his!:

-john

#1681

Posted 22 May 2010 - 12:25 PM

John, if you are doing a period motor, that arm, a mabuchi, would not be in that G12 can. Depending on the magnets, there were 3 G12 arms for that can. One used a 26d sized arm inside thinner magnets, the second was a wasp arm, 65/30 unbalenced, and the third was like the Challenger you mention about a 440 with 65/30 and unbalenced.

G.12 rules in the day were "any unbalenced arm". The thinking was that one could not get an unbalenced arm to live that was hotter. Didn't prove out even THEN, but those were the rules.

AND, commonly, the G.12s were dirt cheap. Kids would buy a 12 buck rtr like the dynamic anglewinder. Racing with friends they would replace the motor with something hotter, and you could usually pick up a slightly tatty 12 for a buck for the parts.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1682

Posted 22 May 2010 - 01:03 PM

John, if you are doing a period motor, that arm, a mabuchi, would not be in that G12 can.

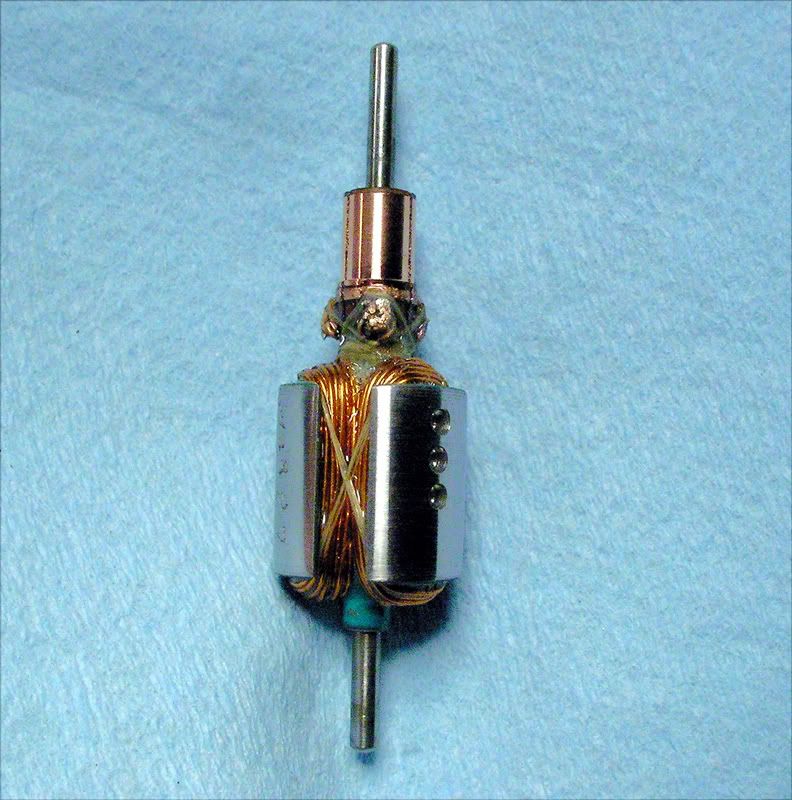

No Rocky, this won't be a strictly period thing, but it will be VERY special and I wish the car was mine, given who's involved!. The arm that was in the motor has a Mura com and the stack seems to have the same insulation as the later Muras, even though it's a .014" lam stack. It sure doesn't look like any Mabuchi I've ever seen with that com and stack insulation. In any case, the car that Brian is doing deserves a better stack, so I'll probably build him one out of loose .007" lams I have here, but reuse the Mura com.

-john

#1683

Posted 23 May 2010 - 10:21 AM

Quick & Dirty

-john

#1684

Posted 23 May 2010 - 10:49 AM

Here's a link to a short video my son and I did for oine of his engineering classes. It had to be under 5 minutes long, so I don't know how much good info is in there. It is what it is

Quick & Dirty

-john

Great video John !!

How do you know when you have removed enough weight for balance, and also make sure you dont remove to much?

Vic

#1685

Posted 23 May 2010 - 12:23 PM

How do you know when you have removed enough weight for balance, and also make sure you dont remove to much

Hi Vic. You know you've removed enough when the arm will stop on any of the poles randomely when rolled across the razor blades. If it keep stopping on one, then you have to keep drilling out material from that pole to lighten it. You make sure you don't remove too much by going slower and slower ...removing less and less as you start to get close to balance.

-john

#1686

Posted 23 May 2010 - 12:31 PM

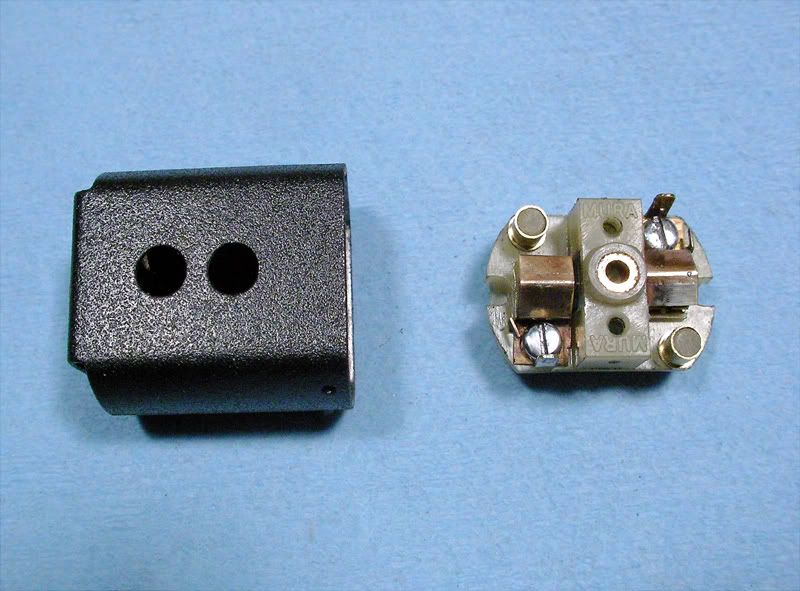

For the arm, I used a vintage .007" one I salvaged and cleaned up. Since it's a Mura setup and there's more "safety" built-in, I did a #27 single for Brian that should provide plenty of forward motion.

...and here's Brian's nice new/old Mura all dressed-up and ready for the party (I was able to shim the magnets .007" each):

I just love those old Muras

-john

#1687

Posted 23 May 2010 - 01:35 PM

As usual - very very nice work!!

John,

I remember in the late 1960's a hobby shop owner showed me his newly rewound epoxied armature. As I remember it did not look as "clean" as your epoxy coating. The epoxy on his armature was so thick it covered the windings completely. What is your perspective on this? A lot of weight?

Thank you!

Ernie

#1688

Posted 23 May 2010 - 02:47 PM

Paul Wolcott

#1689

Posted 23 May 2010 - 04:04 PM

-john

#1690

Posted 23 May 2010 - 04:10 PM

What do you use to shim your mags John? I have a few motors that Id like to shim for a little tighter gap.

#1691

Posted 23 May 2010 - 04:21 PM

Vic, if he says yes, I have enough to give you some, also, I have lots of aluminum .015 sheet. That is probably overkill, I know.

Just remember, Vic, those 45 year old endbells are the weak link. Shim the mags = more HP = more heat = melted endbell = skewed bushing/bound up arm = cooked motor

Paul Wolcott

#1692

Posted 23 May 2010 - 04:38 PM

I really liked that video you might consider doing a more in depth video on any one of the subjects, i to liked that Mura 27 gauge that should really spin i hope he has a good handling chassis for all that power.

#1693

Posted 23 May 2010 - 04:48 PM

As far as I know, sheet steel is the way to go because it's magnetic. I use shim stock from McMaster Carr and it's inexpensive. You don't want to distort the material when cutting so that it lays nicely against the curve of the magnets and can. I score the stuff may times with an X-acto knife and a dull blade at (I think) around 5/8". Then I lay a straightedge right on the score line with the material hanging off a table edge (my work glass) and carefully wiggle it until it breaks off. Then I score across that piece at the correct lengths and do the same. Afterwards, I debur each piece by rotating it on both sides against a piece of 320 grit paper. Then I round each corner of each piece slightly which makes it easier to insert without hanging-up or catching. The final thing I do I got from Rick T, and that's to put the appropriate curve on each piece. If you lay the piece on something with enough "give"...like sheet rubber or even a whole bunch of paper towel layered-up, you can then roll it with something with about a 1/2" or smaller diameter until it gets the right curve to fit cans. Hardwood dowel works fine, a piece of small pipe or even a fat round pencil. It takes a little effort, but you wind up with a whole bunch of shims for not much more cost than the work to make them. MUCH better than the old stanbys from the 60's...Scotch Tape, aluminum foil etc.

Just remember, Vic, those 45 year old endbells are the weak link. Shim the mags = more HP = more heat = melted endbell = skewed bushing/bound up arm = cooked motor

That's true Pablo if it's a Mabuchi. If it's a Mura with the improved endbell material, there's MUCH less chance of any of that. On the above motor, I had to do a lot of polishing to get the stack that flat as it had some imperfections in it. That allowed me to shim the magnets .007" and still have a "reasonable"

-john

#1694

Posted 23 May 2010 - 04:50 PM

i to liked that Mura 27 gauge that should really spin i hope he has a good handling chassis for all that power.

Thanks Robert...he's DEFINITELY got that part covered

-john

#1695

Posted 23 May 2010 - 05:07 PM

Vic, I'm glad you asked that question. I have some .005 copper sheet, John, is this OK for shims ?

Vic, if he says yes, I have enough to give you some, also, I have lots of aluminum .015 sheet. That is probably overkill, I know.

Just remember, Vic, those 45 year old endbells are the weak link. Shim the mags = more HP = more heat = melted endbell = skewed bushing/bound up arm = cooked motor

Thanks Pablo

The motors Im doing would all be newer motors that I've been working on, so I should be ok. Mainly drag motors.

Not that I haven't cooked a motor or two in my time

Vic

#1696

Posted 23 May 2010 - 05:17 PM

Dr. H says steel it must be; I do have a piece of .005 Parma steel that is enough for maybe 2 motors, Vic. Send me a PM if you want it.

Paul Wolcott

#1697

Posted 23 May 2010 - 07:27 PM

I just love those old Muras

-john

Me too! especially when they belong to me!

Looking real nice,John.

Wait till everyone see's what this little monster motor is going to what Chassis!

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

#1698

Posted 24 May 2010 - 05:03 AM

Thanks, but compared to the rest of the car the motor will probably go unnoticed

-john

#1699

Posted 24 May 2010 - 11:16 AM

As a note, there was a brief period when those of us building motors tried the "if some is good, more is better" with epoxy. Some of the thinking was to smooth the airflow over the stack. I don't think anyone did many arms that way because we found "mystery failure". What would happen is that the epoxy would hold the heat on the wire, and you would end up with a nice unblemished, unblown stack that was leaking across the stack internally as the heat broke down the varnish ON the wire.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1700

Posted 24 May 2010 - 07:04 PM

... we found "mystery failure". What would happen is that the [airflow-thick] epoxy would hold the heat on the wire, and you would end up with a nice unblemished, unblown stack that was leaking across the stack internally as the heat broke down the varnish ON the wire.

I just had a major AHH!! moment. Did there, been that. Lost big local race ca.-'65 as result. "...This...Explains.......SOOOOOO much....."

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

This topic is locked

This topic is locked