#1651

Posted 17 May 2010 - 10:32 AM

I intend to live forever! So far, so good.

#1652

Posted 17 May 2010 - 11:14 AM

Hey... I've cut so many FK shafts too short, & had to grab another motor from the motor box ( a storage box for embroidery thread ) that I'm not sayin' ANYTHING about cuttin' an arm shaft... NADA!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1653

Posted 17 May 2010 - 03:43 PM

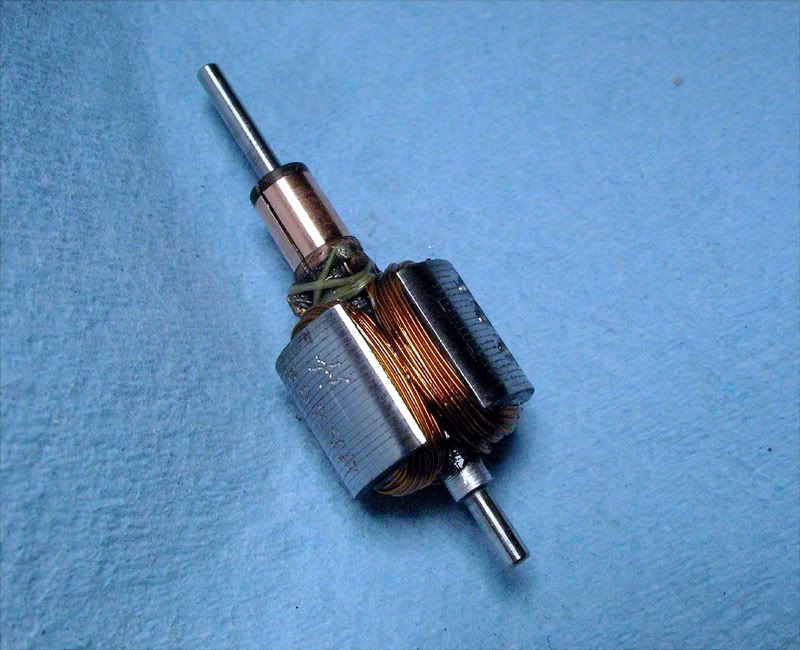

it's interesting how you tied the arm with the thread going in between the stacks never saw that done before

Hi Robert. There was a time when we (my friends and I) did all our arms this way and we copied it from others who were doing it that way. Someone asked about it here as well before and Philippe confirmed that it was a common practice back then and showed a group of lovely arms tied the same way that I believe Philippe wound himself! Those might be real collectibles I would think, because I haven't seen any of Philippe's arms on here before.

-john

#1654

Posted 17 May 2010 - 05:04 PM

If not... I have a bracket that is waiting...

J

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#1655

Posted 17 May 2010 - 05:44 PM

PM sent

-john

#1656

Posted 17 May 2010 - 06:34 PM

Guys...I guess I was the first to speak-up and ask for the arm?

I really appreciate it, and was thinking of using it in an Arco mag set up that I recently aquired.

My 1st "Thingie" will be on the jig soon.

Tom Hemmes

Insert witty phrase here...

#1657

Posted 17 May 2010 - 07:02 PM

Paul Wolcott

#1658

Posted 17 May 2010 - 07:34 PM

My 1st "Thingie" will be on the jig soon.

Tom, be sure to post some photos on here as you're building!

I intend to live forever! So far, so good.

#1659

Posted 17 May 2010 - 08:48 PM

Just recieved my box...what a suprize.....that is one cool motor...I`m thinking retro chassis inline....damn I cant wait.....way too much fun.....the Dynamic 26d is looking like you are going to have fun also.....you know if all of us on here keep building these Dynamic chassis cars we will need to get together and have a race with them....now wouldnt that be a blast from th past. Thanks again my friend.....Kim

#1660

Posted 18 May 2010 - 06:36 AM

Kim, sorry I missed your call. Yes, an inline F1 car or something like that is a natural and I can't imagine there's any that motor wouldn't fit in. Enjoy buddy!

-john

#1661

Posted 19 May 2010 - 07:12 PM

-john

#1662

Posted 19 May 2010 - 08:31 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#1663

Posted 19 May 2010 - 10:26 PM

-john

#1664

Posted 19 May 2010 - 10:35 PM

As always a very nice job on that arm, you said you removed 2 plates from the stack what advantage will that give the arm.

#1665

Posted 20 May 2010 - 05:45 AM

Hi John

As always a very nice job on that arm, you said you removed 2 plates from the stack what advantage will that give the arm.

Hi Robert,

Well there's a couple (at least!) of things going on. The strength of the field generated by an electromagnet, given a constant voltage, is directly proportional to the number of coils or turns. More turns means a stronger field. The resistance of the coil, for a given wire gauge, is directly related to the length of wire...but the more coils, the longer the length of wire per pole and the more resistance. A shorter stack (at least within reason) will allow more coils for a given length of wire so a stronger more compact field without adding much resistance is the thought. We'll see how this one works out, because the real limiting factor with these motors is always the endbell.

-john

#1666

Posted 20 May 2010 - 10:42 AM

It is amazing at the consistency of your rewinds in reference to the quality level! I sit in awe each and every time you post a photo - WOW! And the rest of you guys that are showing your winds are doing a great job too! In fact, it's got me itching to start up on one!!!

John - you're such a inspiration - thank you!!! You other guys have inspired me also - thank you too!

Now that I've added "rewinding" to my plethora of things to learn I have a plethora of questions. Here are a few to start with please.

How do you determine the wire size to employ?

How is the number of winds per pole calculated?

How do set timing? How does timing effect the performance and longevity? Can you just wind a motor with "zero" timing - no advance?

Do you wind the wire in a clockwise or counterCW direction?

Must each pole be wound in the same direction or does it matter?

How and where do you start the wire and secure it?

Do you solder each pole before going onto the next?

Is it necessary to coat the wires after all poles have been wound? Why are the wires coated?

Would it be possible to start a section explaining in detail the rewind process please and have a place for questions? I don't wish to be redundant in my questions and have you annoyed at my wasting bandwidth which is why I'm asking please!!

If this post is found to be detractive from the intent of this thread please let me know what must be done. Start a new thread perhaps?

Thank you.

Ernie

#1667

Posted 20 May 2010 - 03:43 PM

This is exactly the thread to answer your questions in, and I'm really happy that anything I might have done has inspired you or others to take up winding motors...so thanks! I'll have a whack at your questions:

How do you determine the wire size to employ?

Unless there's an overriding reason, the wire size (gauge) is pretty much up to the winder. For Mabuchis, you probably don't want to go any thicker than #28 wire, even with upgraded magnets. For later Champions, #27 wire is probably getting close to the limit. With the Mura Green Cans and current C cans, you can go all the way to #23 wire...but that's pretty nuts. If you wanted to do rewinding and were looking at a couple of wire gauges to keep things simple, I would say that #27/#28/#29/#30 are useable across a wide range of motors and the thinner stuff is also great for double winds.

How is the number of winds per pole calculated?

There are tables you can look up that give the resistance per foot of a particular gauge magnet wire. Keeping that in mind you can start working up winds and try to hit a ballpark resistance. Mabuchis, maybe somewhere in a range of from .4 ohm to .6 ohm, Champions maybe .3 ohm to .5 ohm, later Muras and current C can motors...from .1 ohm to .4 ohm. This will depend somewhat on the magnets, but you also need to add-in the resistance of the commutator, so actuasl resistance is best measured from com segment to com segment.

How do set timing? How does timing effect the performance and longevity? Can you just wind a motor with "zero" timing - no advance?

Do you wind the wire in a clockwise or counterCW direction?

I almost always wind the poles clockwise as you face a pole from the outside, with the timing advance set to favor CCW rotation (as seen from the endbell). Sometimes, I use Yradeship coms that have a built-in advance favoring CW rotation, in those few cases you have the option of winding CCW or CW as it doesn't really matter. With the advance favoring one direction or the other, the direction you wind has no effect.

Keeping the advance on the low side (say maybe 25 degrees or less) will let the motor run a bit cooler and won't screw with brakes so much. Youi certainly can do an arm with zero advance or neutral timing, but a little bit is fine and will improve performance in the direction of the advance.

Must each pole be wound in the same direction or does it matter?

While it shouldn't matter if you're just as neat in either direction and the total loength of wire is the same for each pole, practically-speaking you would have an easier time of it by doing all three poles in the same direction.

How and where do you start the wire and secure it?

I start with the wire under the tab preceding the first pole to wind, anjhd then run it up the com and around the shaft a few times. You just have to be careful not to pull too hard on the first turn of the first pole as you can undo the wire from the shaft. After the first turn, it shouldn't move. Speaking of pulling, you should develope a technique where you use the same tension all the time for a particular wire. You can pull harder on thicker wire and less on thinner wire. The neatness of the wind will depend heavily on how the first and to a lesser degree the second layer are wound. I use a toothpick or a plastic electronics probe (*depending on the wire gauge) to flatten each turn on the first layer as well as push each turn back towards the first one to keep things neat and tight. Don't push too hard or other wise abuse the wire doing this as you can easily cause a short. Speaking of shorts, spending time on insulating the stack and rounding off any sharp edges at the stack ends will pay off and help avoid getting an arm wound only to find it's got a short. Have a cheap multimeter handy and check for shorts after each pole, it can save you frustration and wasted wire.

Do you solder each pole before going onto the next?

I on ly solder (or braze) the com after the entire arm is wound. If there were a problem, it would be easier to take everything apart and redo the arm if it hasn't been soldered.

Is it necessary to coat the wires after all poles have been wound? Why are the wires coated?

If you mean epoxy, yes it is pretty necessary for all but the mildest winds. The epoxy will prevent the wire from shifting under the centrifugal force of the spinning arm...OR...worse yet, flying right off. Epoxying and tieing at the com will also strengthen somewhat those pesky com connections, especially if your epoxy can withstand some heat.

Would it be possible to start a section explaining in detail the rewind process please and have a place for questions? I don't wish to be redundant in my questions and have you annoyed at my wasting bandwidth which is why I'm asking please!!

Well, this thread right here should have most or all of the info you need. As to bandwidth, I'm only a guest here just like you. However, bandwidth gets gobbled up a lot quicker by pictures than by text. I think it serves the community far better to have all your questions, and those of anyone else for that matter, all together in this thread. That can make searching for information easier, and it might just help to inspire more people to dig into motors!

-john

#1668

Posted 20 May 2010 - 06:06 PM

I remember a thread about epoxy and thining it so it will wick in. I don't

remember what kind it was or the heat it will take or how it was thined. I do remember it was a slow epoxy.

Out of quereossity. Why would C.A. not work? I have used the thick on a few things that get very hot to the touch. Like blister your finger hot.

OLPHRT

PHIL I.

#1669

Posted 21 May 2010 - 06:16 AM

Out of quereossity. Why would C.A. not work? I have used the thick on a few things that get very hot to the touch. Like blister your finger hot

While CA might do OK mechanically at mild-to-moderate temperatures, it has at least one mechanical disavantage, it produces a very thin film (even the "thick" or "gel" )kind. It's really for joining surfaces that fit well together and a coil made up of round magnet wire (even thin magnet wire) has a LOT of gaps...even when wound really symetrically. It would take a ot of CA to "pot" an armature's coils and would probably have to be applied in several steps because of it wicking into the inner winds. CA has a chemical disadvantage as well, the cyanide fumes it can offgas when heated. It might be good for lifting fingerprints though

I remember a thread about epoxy and thining it so it will wick in. I don't

remember what kind it was or the heat it will take or how it was thined. I do remember it was a slow epoxy.

You can thin epoxy in several ways, chemicals and solvents like acetone and liquid styrene (not easily available) will work as well as (I believe) denatured alcohol but I never tried that one. These may or may not change the physical properties of the cured material though and I would do it myself. Most two-part resins I've worked with will thin dramatically by warming them as they cure which is the best way to do this. Keeping them cool as you apply them gives you more control to place the epoxy where you want it without it dripping all over the place. Afterwards, warming the epoxy will speed the cure AND let it fully penetrate the coils. Epoxy "speed-cured" this way will often be harder (but a bit more brittle) than epoxy cured at room temp.

Best yet is to use a low-viscosity epoxy that will penetrate the coils at room temp and will REALLY get down in there when warmed. It doesn't take much epoxy at all if it's the right kind. There are also very high temperature one and two part coatings that would seem to be ideal for potting arms...some with temperature ratings of up to 3350 degrees! These are typically a solid color (white, black or red even) and may be based on alumina, aluminum oxide or silica. I'm not familiar with them, so I haven't tried any and they typically have a long cure time (around 24 hours) that can also be accelerated with warming.

-john

#1670

Posted 21 May 2010 - 07:01 AM

H I use a 55 amp car starter, the carbon rod from inside a C cell oldstyle zince/carbon battery as a heater, a 50 amp momentary boat ignition switch mounted in a box so I can trip it with my foot, and jeweler's silver with brazing flux. The type of silver I use is relatively low temp and melts at around 1100 degrees or so which is below the melting point of the brass com tabs...but still plenty hot enough to melt the com's plastic. The whole thing happens fairly fast (about 2 seconds) and the heat is concentrated right at the com tab, so no damage is done to the com. A side benefit of the silver is that it's an excellent conductor. When done, there's not much chance of throwing a com wire connection because of heat because of the melting point of the silver.

-john

That is slick!

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#1671

Posted 21 May 2010 - 10:38 AM

Thank you for taking the time to answer my questions. You're a scholar and a gentleman!!

Ernie

#1672

Posted 21 May 2010 - 11:02 AM

When CA burns, and it does so at relatively low temps, the vapor is toxic.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1673

Posted 21 May 2010 - 11:33 AM

Just a thought concerning the above suggestion: it might be a good idea, in fact, to break out the basic rewinding info, as you give above, in a special pinned topic, just to give people this information without having to search through 88 pages... A page or two of the basics, easy to find, might encourage more rewinders, old and new alike.

Don

#1674

Posted 21 May 2010 - 01:02 PM

I intend to live forever! So far, so good.

#1675

Posted 21 May 2010 - 03:39 PM

Thank you for taking the time to answer my questions. You're a scholar and a gentleman!!

You're quite welcome Ernie. I really hope you do dig in to rewinding and if so, just ask away as you get started.

When CA burns, and it does so at relatively low temps, the vapor is toxic.

Yes, see my answer above Rocky. However, I don't think you even have to reach anywhere near cured CA's combustion temp. Just heating the stuff sufficiently will likely off-gas cyanide fumes.

Just a thought concerning the above suggestion: it might be a good idea, in fact, to break out the basic rewinding info, as you give above, in a special pinned topic, just to give people this information without having to search through 88 pages... A page or two of the basics, easy to find, might encourage more rewinders, old and new alike.

Good point Don. I'll have to search through this epic novel to distill the info sometime. Then again, so would anyone wanting to gather the info

John, the articles you have posted on Steve Okeefe's website might be sufficient for Don's proposed break out. Post them here with a permanent tag on them.

Hi Bill. Could be, but Steve edited the stuff and I consider it his intellectual property now...a part of his website. In deference to Steve and the work he's done on that fantastic website, I'll gather-up the stuff from here, and add what I need as I go along. Maybe I'll even start fresh with a tutorial (that sounds pompous as heck coming from a shadetree hack!) using a vintage Mabuchi, then one using a Champion, then one on a glorious Mura Green can. I'll have to clear it first with Philippe and Greg.

-john

This topic is locked

This topic is locked