#1601

Posted 30 April 2010 - 05:28 AM

Well, there's still only a few of us tearing into motors at this stage, but I have to hope that some others may be experimenting on their own and not posting their work here. I'd love to see rewinding become popular enough to support some sort of racing program or a class only allowing home-wound motors, but other than the odd thingie here and there that isn't likely to happen. So just to have guys like you join in the fun feels like a homerun to me.

-john

#1602

Posted 02 May 2010 - 04:03 PM

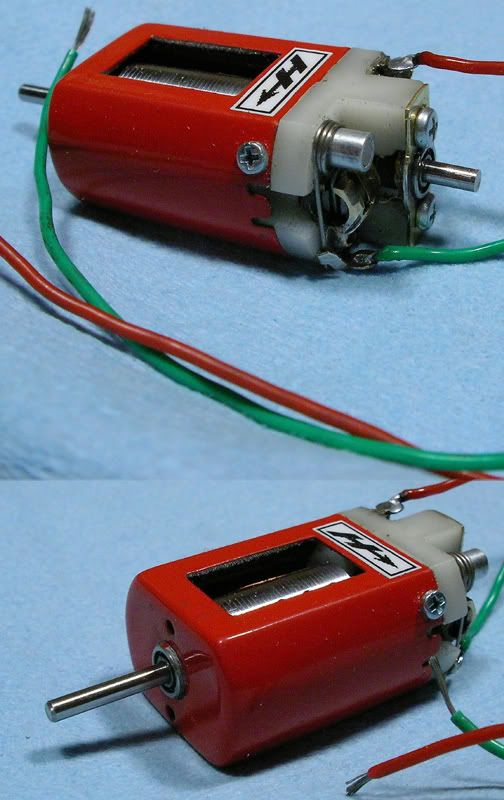

To start, the thicker SCX magnets meant either honing the setup or polishing-down the arm. Since I don't have any hones, I had to work on the arm...and a lot of work it was. The arm had to come all the way down to .473"

The setup got the usual stuff...sleeved posts, 2x5 open bearings in both ends, FT16D brush heatsinks installed using the stock hoods cut down and the endbell carved out a bunch and the above-mentioned SCX magnets epoxied-in. I also closed the magnet stops that are formed into the can and soldered/sanded them flush. Lastly, because the can used a fixed bushing instead of the caged type, I drilled the can for mounting screws to fit an FT16D bracket. A coat of primer and two top coats covers the body and fender work, s set of vintage leads and the motor is done . There goes about 10-12 hours of my life I'll never get back again

The motor is a very strong runner, doesn't seem to get scarey-hot, is pretty unique and I think looks cool. These 13UO rewinds probably are best if used only very lightly, but they are a neat little piece of slot car history that was missing from my collection.

-john

- MarcusPHagen likes this

#1603

Posted 02 May 2010 - 05:55 PM

The motor looks awsome John and i am shore it's got plenty of power, one question what are you using to grind that much of the stacks.

#1604

Posted 02 May 2010 - 07:15 PM

Thanks, the motor does seem to be pretty perky alright.

one question what are you using to grind that much of the stacks

Well, not having any machine-shop tools does limit your options, so I have to make do with the old standby...the Dremel. I chuck the arm and play various grades of emery against the spinning arm. In order to make up for any runout (they all have some), I do a little, then rotate the arm about 1/3 revolution and do some more. I also then flip the arm end over end and do the same thing to help avoid accumulating errors caused by how I play the paper against the arm as well as to average out any runout. If you're careful, it's no big deal to do a fairly good job here and arms taken down this way are usually good to within a couple of thousandths. If you don't take some precautions, things can get even worse since the runout of the Dremel plus any of the shaft itself can be additive and make a real mess. It's rare that I have to do this to this extent and the 13UO arm above is the most I've taken an arm down, but it's within the same couple of thousandths from pole to pole and top to bottom.

Actually, even a Dremel with the normal amount of runout can help you find shafts that are out. If you spin the shaft and see some visual runout and that runout changes when you loosen the chuck and rotate the arm to try it again and see a change in the amount of runout, that can only be accounted for by the shaft and not the Dremel. It's quick and dirty, but it can help you when you wanna know.

-john

#1605

Posted 02 May 2010 - 08:11 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#1606

Posted 02 May 2010 - 08:18 PM

Yeah, I also had never seen one like this. Don tells me there were a few different variations of the little guy, even though the majority were the normal ones we're familiar with. Maybe these variants were for specific RTR or homeset cars specified by the manufacturers. The can was originally very much like this color, pretty much "apple red" like (I think) the Monogram motors.

-john

#1607

Posted 03 May 2010 - 03:18 AM

It's just one I had in my box, and I think it came with one of the EJ's kits maybe a dozen years ago, so it would probably be a more modern type 13D motor. It never quite worked right (probably a small short in the arm), so I told John to torture it any way he wanted!

Don

#1608

Posted 03 May 2010 - 05:21 AM

o I told John to torture it any way he wanted!

...and torture I did!

-john

#1609

Posted 03 May 2010 - 11:09 AM

& your 'poorly-wound' hand-held armature would be a winner regardless, given how most of us would hand-wind one!

By using the SCX magnets, you created a great motor... These sure look like a prima candidate for a 1/32 scratchbuilt F1 chassis!

Again, great job, John... Always enjoy looking, as it stimulates my remaing brain cells!

Take care, buddy!

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1610

Posted 03 May 2010 - 11:17 AM

Regarding the stack polishing, I did try one thing that seemed to work pretty well. You have to be very careful, but, so what else is new, right?

I used a sponge sanding pad to true and polish the stacks on 3 of the arms I worked over the weekend. You can do it before you wind and after you insulate or you can polish it after you wind, but then there's that "careful" thing. Since the pad "gives" when you're spinning the arm on it, it might just grab at the winds and shear off insulation from the wire.....(you might think this may have happened to me.....

Back to the drawing board...........thanks.

Steve

Home of Area 51 Chassis Works

Steve Vogt, Sr.

#1611

Posted 03 May 2010 - 11:49 AM

The 13uo evolved over the years and included semi copies done by "Johnson" in the 70s. I would have liked to see the motor before you massauged it, but just from what I can see, I would place it in the 80s. Remember the current SCX motor IS a 13uo.

I saw them with a simple stamped in set up much like the Hemi, and with a lovely reinforced housing with a knurled bushing, but both versions are mid and late 70s at the earliest.

The difference between the Johnsons and the others is this: mostly the cans aren't painted but have a vague "goldish" look and the endbells have the sort of channel/tubing type brush mounts that we have talked about doing to the original 13uos to improve the heat issue.

I have mabuchis in grey, red, yellow, and so on, but painted.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1612

Posted 03 May 2010 - 11:58 AM

I think I'll stick to using emory paper and thre slowest speed setting on the Dremel. As it is, the emory gives a little too, but not enough to cause any problems. It sure would be nice to have a very small lathe equipped to cut mild steel for this and many other things, but the more you try working around one, the more you discover that you can sort of get by functionally. Still the beauty of precisely milled pieces is something to shoot for!

Hi Rocky,

It was definitely a Mabuchi and was red before I stripped it and filled-in the magnet stops. Same can (except for the bushing), same Mabuchi endbell and same "magnets".

-john

#1613

Posted 03 May 2010 - 10:46 PM

That particular red looks so "vintage" perfect. Very nice motor - as usual!

Ernie

#1614

Posted 05 May 2010 - 05:35 AM

Thanks!, I had the same reaction to the color...then again it is basically the color of the original. Lotta work in that little motor for pretty much a "collector" restoration, but I enjoy the work!

-john

#1615

Posted 05 May 2010 - 05:51 PM

It's all about the "journey" not the "destination".

#1616

Posted 06 May 2010 - 02:15 PM

Gary,

It's just one I had in my box, and I think it came with one of the EJ's kits maybe a dozen years ago, so it would probably be a more modern type 13D motor. It never quite worked right (probably a small short in the arm), so I told John to torture it any way he wanted!

Don

OH,YEAH MAN!

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#1617

Posted 06 May 2010 - 02:20 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#1618

Posted 07 May 2010 - 12:19 PM

I am not sure if we are miscommunicating or not. The various 13uos were mabuchis. LATER, in the 70s, the Johnson 111 was a copy, sort of. It is dimensionally the same, and you can cross/use all the bits, but it looks different. The cans are anodized with a slight gold sheen.

I don't remember saying the Kemtron wasn't a Mabuchi.

In the 70s, a lot of us were using the mabuchi and Johnsons as parts doners for our "P" cans until the guys in England started making Mura style robust cans in the same size...and endbell blanks. Prior to the "X" and 101 endbells from england, we were turning down C can endbells.

The modern SCX RX-42 motors and similar are, essentially, the 13uos with some development influenced by the old "P" can efforts of the 70s.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1619

Posted 09 May 2010 - 11:42 AM

I thought it was time for a new rebuild, First pic shows what i started with the arm smoked when put on the power supply and the end bell looks like it was rotted away around one screw hole never seen that before so i replaced the end bell, i rewound the arm 35 turns of 28 gauge tied with my new kevlar thread and given a coat of epoxy cut the comm and a little furnace cement on the inside of the stacks, this one runs really good pretty cool and draws a little over 2 amps at 12 volts and boy does it scream. The only thing left to do is drill the can to except some button head screws.

#1620

Posted 09 May 2010 - 12:53 PM

-john

#1621

Posted 09 May 2010 - 01:10 PM

Very sano 'restoration"...

Jeff Easterly

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#1622

Posted 09 May 2010 - 02:51 PM

Thanks guys at first i was just trying to get a decent rewind now i am trying to make them look a little neater also, i wanted to try a static balance but as you can see from the pics this one has already bin balanced and i don't think it's a good idea to do it twice might week in the stacks and fall apart, this one runs so good i am going to scratch build a new chassis for it. John i agree these old Mura motors are great and this one has the can in a can magnet setup and they look to be pretty strong i guess this is one reason for the good performance from this motor. I have another of these motors almost finished i will post it in a day or two.

#1623

Posted 09 May 2010 - 04:06 PM

Great job - it looks real nice! Can't wait to see the pix of the other motor you're doing.

Ernie

#1624

Posted 09 May 2010 - 06:40 PM

Thanks Ernie, you asked so here you go i thought i would not get to finish this one for a while but i did so here it is, another Mura with a double rewind 25 turns 29/30 gauge if the color of the wire looks odd it's because the 29 was red and the 30 was brown, the brush gear was a mess on this one both lead wire tabs were broken off as well as one spring retainer so i used some newer gear and cut it up with the dremel to make it fit, as i said rewound, tied, epoxy, cut comm and my first static balance runs pretty good but not as powerful as the other Mura. I added one extra picture of the other side of the can to show off the pretty magnum sticker.

#1625

Posted 09 May 2010 - 07:44 PM

my first static balance runs pretty good but not as powerful as the other Mura.

You know what Robert, I don't think it matters much if it runs as well as the other one. You're making motors by hand just like they did it in the dark ages, a rare and cool thing in my book. Sometime you should think about getting an engraver and start signing the arms!

-john

This topic is locked

This topic is locked