Boy, to me it sure looks like you have it figured out already.

-john

Posted 23 April 2010 - 03:54 AM

Posted 23 April 2010 - 06:21 AM

Posted 23 April 2010 - 07:29 AM

Posted 23 April 2010 - 09:10 AM

Posted 23 April 2010 - 10:02 AM

Posted 23 April 2010 - 10:46 AM

Posted 23 April 2010 - 12:21 PM

Posted 23 April 2010 - 12:44 PM

Posted 23 April 2010 - 01:24 PM

Hi Bill,

I think that's just a brass tail spacer (and one of the nylon spacers) on the com end???...or maybe it IS capped???

-john

Posted 25 April 2010 - 12:27 PM

Posted 25 April 2010 - 08:18 PM

Posted 25 April 2010 - 09:04 PM

Posted 26 April 2010 - 05:32 AM

I agree those bearings should be a big improvement over the stock setup

Posted 27 April 2010 - 11:19 AM

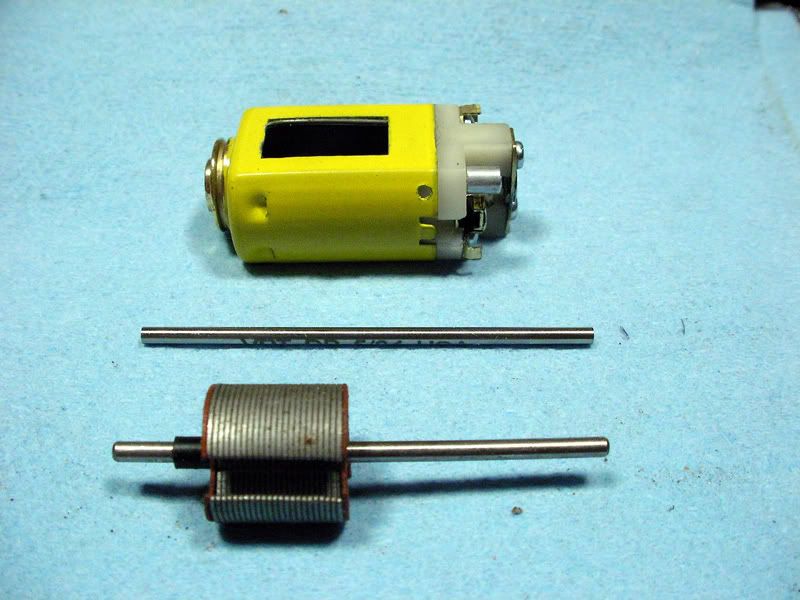

While I have a bunch of .007" lams salvaged from other motors that I can build new stacks from, even I didn't have the heart to use anything other than a Mabuchi stack for the motor

Posted 27 April 2010 - 12:16 PM

Posted 27 April 2010 - 08:40 PM

Posted 27 April 2010 - 09:20 PM

Posted 28 April 2010 - 11:02 AM

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

Posted 28 April 2010 - 04:40 PM

Man, that 60T's of 29 really filled that blank!

Posted 28 April 2010 - 10:58 PM

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

Posted 29 April 2010 - 05:31 AM

Posted 29 April 2010 - 01:36 PM

Posted 29 April 2010 - 02:52 PM

Posted 29 April 2010 - 06:18 PM

PS...I just noticed that "Arm Winding" is over 50,000 views! Somebody's looking!

Posted 29 April 2010 - 06:46 PM