#1976

Posted 31 October 2010 - 05:35 PM

#1977

Posted 31 October 2010 - 06:11 PM

#1978

Posted 31 October 2010 - 07:41 PM

-john

#1979

Posted 31 October 2010 - 07:51 PM

-john

#1980

Posted 31 October 2010 - 08:24 PM

That wind looks like a hand full....let me know what it turns , love the can to.....Kim

#1981

Posted 31 October 2010 - 08:29 PM

-john

#1982

Posted 31 October 2010 - 10:56 PM

#1983

Posted 01 November 2010 - 05:44 AM

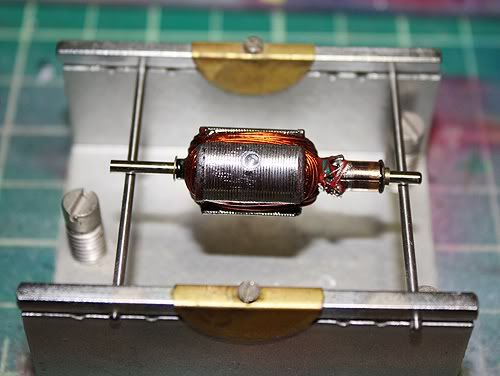

Thanks John, awsome work on that motor those bus bars look better than factory made, the stacks look like you took a lot of material off will you have to shim the magnets to close the air gap, 24 gauge it's going to scream.

Great work on yours too Robert. Thanks on the motor too. I usually don't make the buss bars so "stout", but it seemed appropriate for the B motor; it also made bending and fitting them a little more difficult than normal. I took very little off the stack, as the .007" lams polish out quickly. It's still just under .510" diameter and is a tight fit in the very thick Mura B magnets. The B motors had a reputation for getting too hot in any case, maybe partly because of the tight airgap...and maybe partly because all that metal held more heat than it radiated (others more in the know can fill in this info better than me). There have been some beautiful B motor builds here by Rick and Jairus that had originally inspired me and the project sort of got sidelined. I "rediscovered" the motor and figured it was time to get going on it again.

Enough of all this though, I'm looking forward to seeing yours "all dressed up for the party"!

-john

#1984

Posted 01 November 2010 - 08:53 AM

GREAT looking B-Can motor!

I have more If you want to do some more of them.

Slots-4-Ever

Brian McPherson

REM Raceway

"We didn't realize we were making memories, we just knew we were having FUN!"

#1985

Posted 01 November 2010 - 10:15 AM

When the B was first introduced it had two tiny holes on each side with the thoughts that a totally enclosed can increased the magnetic field. The early motors indeed got hot but what you have there is the last production motor can with the big hole needed for better airflow and improved cooling.

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#1986

Posted 01 November 2010 - 11:14 AM

Kim,

The motor ran like a demon...and then lost a com plate! Fortunately, the blown com only took out the motor brushes, but I guess that's what I get using recycled parts on such a crazy motor. I'm going to redo this thing again and use a new com, because it was a wonderful sounding motor...while it lasted!

-john

#1987

Posted 01 November 2010 - 01:34 PM

Time for an update, I tied the arm up using red Kevlar thread and gave it a coat of epoxy and heat-cured it then I painted the stacks with clear engine enamel.

I still need to cut the comm and do a static balance.

#1988

Posted 01 November 2010 - 02:17 PM

Nah... I've learned to become a little more philosophical about these things and sometimes a blown arm will tell you more information than one that lasts. In this case, the "post-mortem" revealed that, despite a pretty lengthy run at a full 12Vv/no load, everything but the comm was in perfect shape. In any case, a #24 is right at or near the upper limit so getting one to hold up the way it should seems like a worthy quest! I have plans for winding a second that don't include used parts.To bad the comm blew that is a cool motor, it may not have been your recycled comm as i have had a comm come apart on a pretty new Parma S16d still have that motor, time to rewind again

Your arm looks great Robert, and I betcha it's gonna be a real runner, too! Nice work.

-john

#1989

Posted 01 November 2010 - 02:49 PM

#1990

Posted 01 November 2010 - 04:49 PM

-john

#1991

Posted 01 November 2010 - 06:15 PM

Thanks, Vic and John. The pic below shows my high tech balance tool. I think it's made by Tradeship. I am not sure how much a static balance helps but I can tell you the motor ran a bit smoother after the balance so I guess it worked.

John is correct; this motor really goes and it does not run hot it should hold together as I ran it at 15 volts for about 10 seconds. If that didn't blow it I think it's a good one. One more post to follow and it's finished.

#1992

Posted 01 November 2010 - 06:15 PM

This arm deserves the full treatment, so I'm going to send it out to be dynamically balanced, but Bill's arms and comms are way more in line for what a motor like this needs.

BTW, these arms are made using .014" lams, and the motor sure isn't complaining... wonderful!

-john

#1993

Posted 02 November 2010 - 12:17 PM

John, remember: "They are all DOOMED"....

Grin.

I did all the way down to a 22 back in the late 60s, but nothing hotter than a 26 was a race winner for me given my limited driving talent.

Fate

3/6/48-1/1/12

Requiescat in Pace

#1994

Posted 02 November 2010 - 12:24 PM

That arm looks awesome John such neat work on that heavy 24 gauge wire can't be very easy, I bet that's a new comm this time.

Thanks, Vic and John. The pic below shows my high tech balance tool. I think it's made by Tradeship. I am not sure how much a static balance helps but I can tell you the motor ran a bit smoother after the balance so I guess it worked.

John is correct; this motor really goes and it does not run hot it should hold together as I ran it at 15 volts for about 10 seconds. If that didn't blow it I think it's a good one. One more post to follow and it's finished.

Robert, I remember these balancers very well. Every now and then you still see them on epay for sale.

#1995

Posted 02 November 2010 - 01:29 PM

Hi

John, remember: "They are all DOOMED"....

I never forget it Rocky, just trying to lengthen their lifespan. I've got one pretty crazy test arm in a motor that has 800 laps on it (using Bill Bugenis' parts)...and it's still ticking apparently.

I did all the way down to a 22 back in the late 60s, but nothing hotter than a 26 was a race winner for me given my limited driving talent.

Things have definitely changed in that regard Rocky. People are racing motors now I wouldn't have dreamed were possible.

-john

#1996

Posted 02 November 2010 - 04:09 PM

CONGRATULATIONS JOHN!

And thank you for one of the best and most inspiring threads ever to appear on a slot car forum.

Don

#1997

Posted 02 November 2010 - 04:32 PM

-john

#1998

Posted 02 November 2010 - 10:22 PM

#1999

Posted 02 November 2010 - 11:37 PM

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#2000

Posted 03 November 2010 - 12:14 AM

By the way, the HAWK came in the mail today - Thank you so much for your time John!!! I'm excited to have it along with my other motors you did "makeovers" on.

Ernie

This topic is locked

This topic is locked