Can any of you slide-rule smart guys out there please tell me the approx. OD of a 64P 50T spur gear? Thanks

Lotus Europa BP Foreign Production class race car

#26

Posted 10 July 2020 - 06:29 PM

Paul Wolcott

#27

Posted 10 July 2020 - 07:32 PM

I can tell you this because I just measured a 64P 51T = .828" and 48T =.780"

Don't have a 50T, but I do have a calculator.

Hopes this helps for now.

50T x .01625" =.812"D

#28

Posted 10 July 2020 - 07:55 PM

Yes Martin that gives me the info thanks my friend ![]()

I'm looking at 9/46 with .910 wheels, FDR of 5.62. Very close to what my very successful Lola is, 9/48 with .960 wheels at 5.56 FDR

Paul Wolcott

#29

Posted 11 July 2020 - 05:08 PM

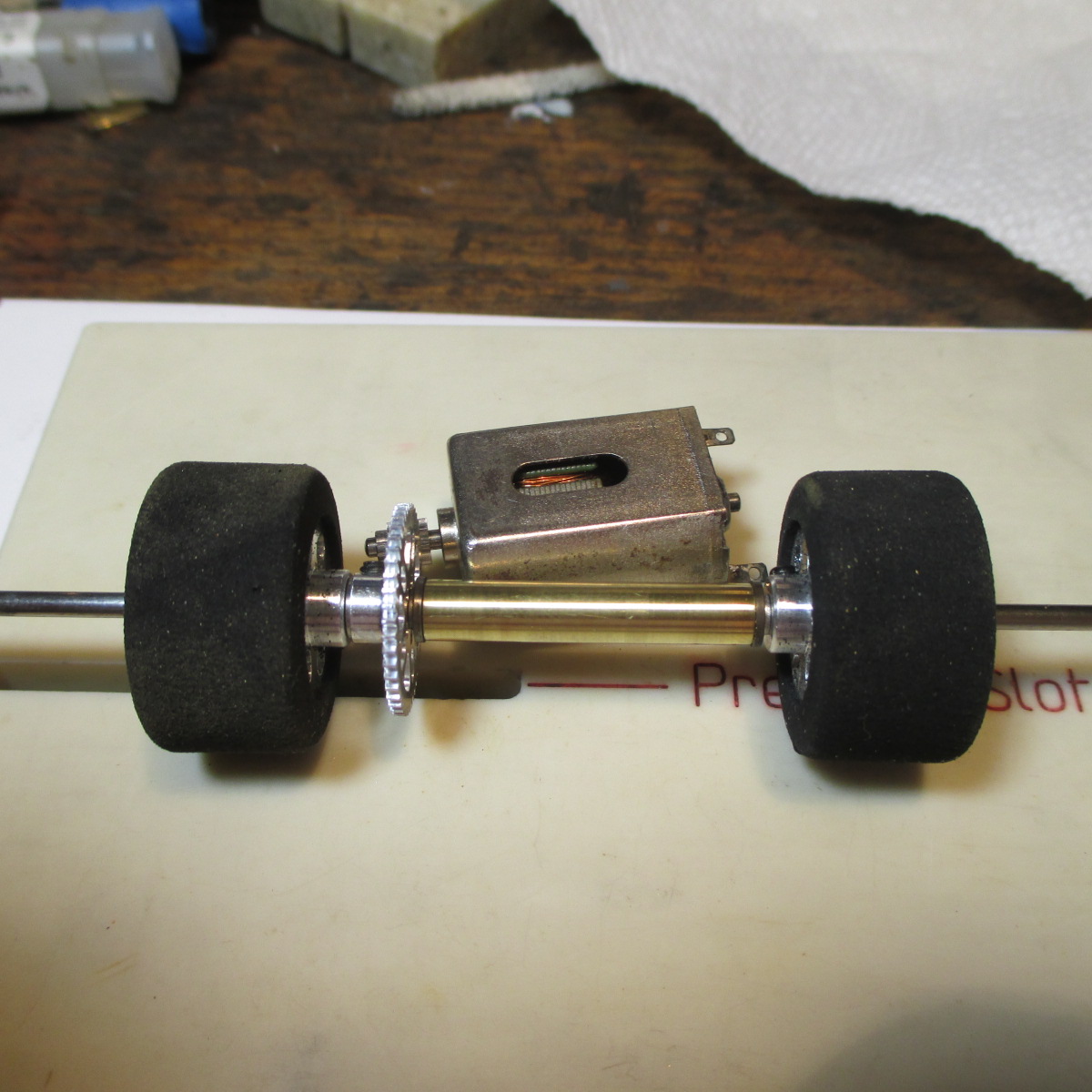

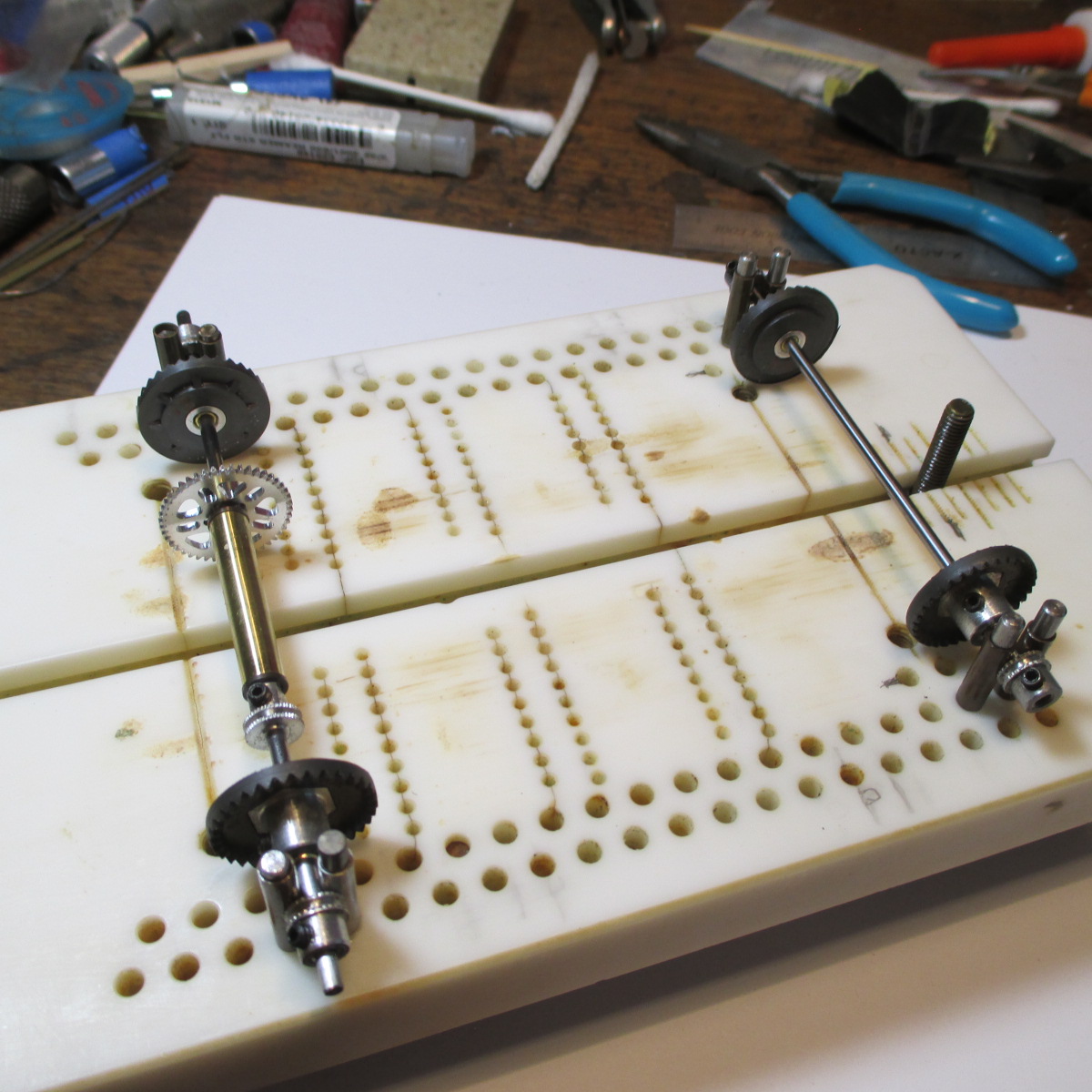

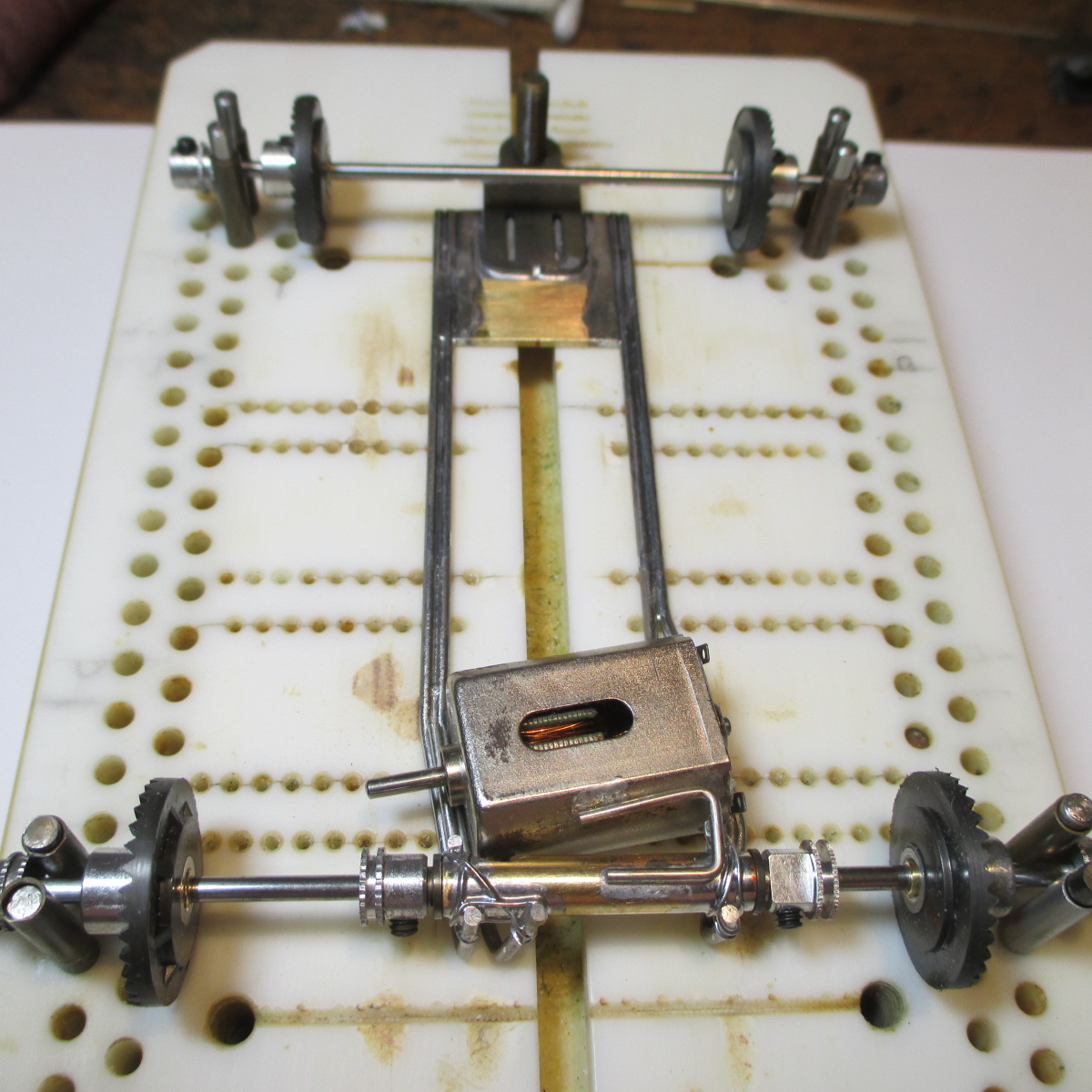

Gears 9/46, BB's, one 25 thou spacer per side, and a 1.148" tube with the ProTrack N5203 wheels gives exactly 2 3/4 width. If we can fiddle with the body and add more spacers to make it 2 7/8 or 3" so much the better.

This one is going to an anglewinder since the different rules allow smaller OD wheels

Paul Wolcott

#30

Posted 12 July 2020 - 12:13 PM

Don't know if these are actually Lotus flares, but are the closest I could find on the internet. Mine are buried in storage and I won't be getting any pictures of those any time soon. One is still in the clear plastic bag with the Lotus Components sticker and part number on it, so they were definitely sold through Lotus.

- Pablo likes this

#31

Posted 12 July 2020 - 01:15 PM

Gears 9/46, BB's, one 25 thou spacer per side, and a 1.148" tube with the ProTrack N5203 wheels gives exactly 2 3/4 width. If we can fiddle with the body and add more spacers to make it 2 7/8 or 3" so much the better.

This one is going to an anglewinder since the different rules allow smaller OD wheels

Good gear ratio for the Flat track. I think the anglewinder will provide a good weight distribution in the small car, as well. The Lola is way under regulation width and it is a great runner. I'm hoping the same for this one.

Eddie

- Pablo likes this

Team Boola (circa the '60s)

#32

Posted 12 July 2020 - 03:13 PM

To anyone contemplating the purchase of a Europa.... avoid the Renault power. The twin-cam Ford was much better and wasn't plagued by engine fires. The rear visibility was better as the 'wings' were reduced, The later Ford cars were also 5-speeds. And be prepared for stuff to fall off.

- Rotorranch likes this

Pete Varlan

60 years a slot racer

#33

Posted 12 July 2020 - 07:47 PM

I forget who, but somebody coached me of the advantage to Lexan windows. It's high up weight so any small savings is worthwhile. The stock plastic windows weigh 2.7 grams. The same in 7 thou Lexan weigh less than half that. ![]()

Easy enough to cut Lexan window pieces to size, but what glue to use? Experiment in progress, 3 different types of glue. We shall see which works best

I soaked the tires off a brand new set of JK 8746 IRRA style fronts (3/32 x .750 x .225) and re-rubbered them with Chicagoland Firm front donuts

Paul Wolcott

#34

Posted 12 July 2020 - 07:52 PM

somebody said try Go2 glue for windows.

Steve Lang

#36

Posted 14 July 2020 - 02:52 PM

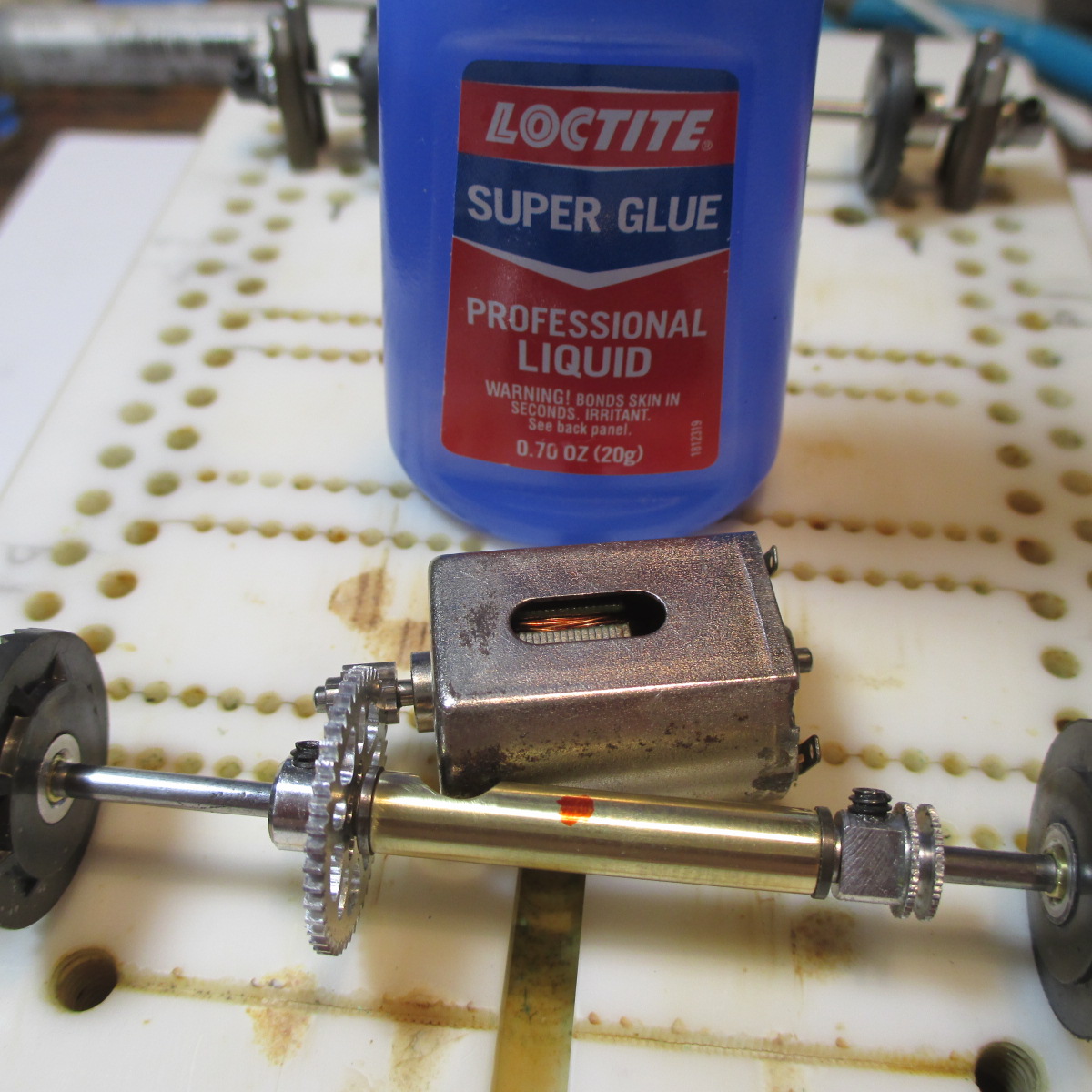

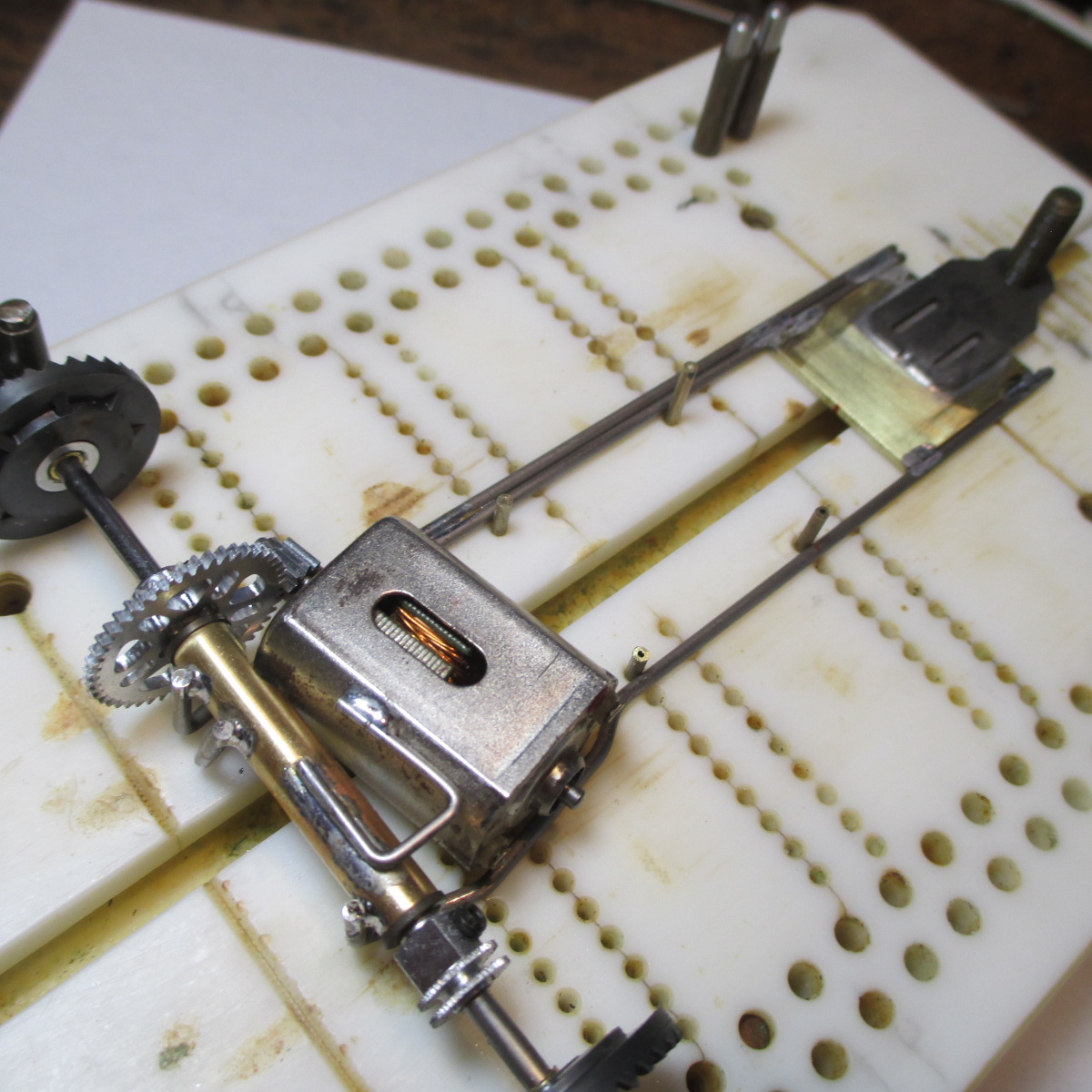

Tube notched; Sharpie dot marks the top, jig pinion CA glued to jig motor shaft, motor aligned where I want it. Carefully I elevate the jig in front, drop a dollop of CA slightly forward of the motor, and let gravity carry the glue home

Once the CA is dry, the motor is positioned (temporarily) perfect. From there I can start planning the rails ............

Paul Wolcott

#37

Posted 14 July 2020 - 03:06 PM

you didn't consider notching the motor for the rear axle to lessen the gear angle? those are straight cut metal gears.

Steve Lang

#38

Posted 14 July 2020 - 03:40 PM

I considered it, but I prefer to notch the tube and leave the motor alone.

The pinion is angled, not straight.

- Rotorranch likes this

Paul Wolcott

#39

Posted 15 July 2020 - 07:29 AM

The "flaring of wheel wells" subject became a source of teeth-gnashing yesterday for the rules maker, the car owner, and myself. I never intended to do any modifications of that sort here in my shop and I was against it from the beginning. The photos showing flares pertaining to this class, I have hidden, including my own. We don't want a bunch of Bunky back-yard engineers running around with mini-torches and spoons.

It's humorous, but I hope you can see, as I do, promotion of that sort in my subforum isn't good for BP's racing program. So if your post got canned, I'm sorry. If you want to start a new thread on wild fender flares, you are welcome to. I'll be right there with ya ![]() But leave BP out of it, please.

But leave BP out of it, please.

Back to soldering ..........

Paul Wolcott

#40

Posted 15 July 2020 - 09:16 AM

You can use double-sided tape to hold stuff temporarily in place for mock-up. Lets you move things around easier.

#41

Posted 15 July 2020 - 12:13 PM

You can use double-sided tape to hold stuff temporarily in place for mock-up. Lets you move things around easier.

Pablo's motto is measure twice and glue once...

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#42

Posted 15 July 2020 - 09:02 PM

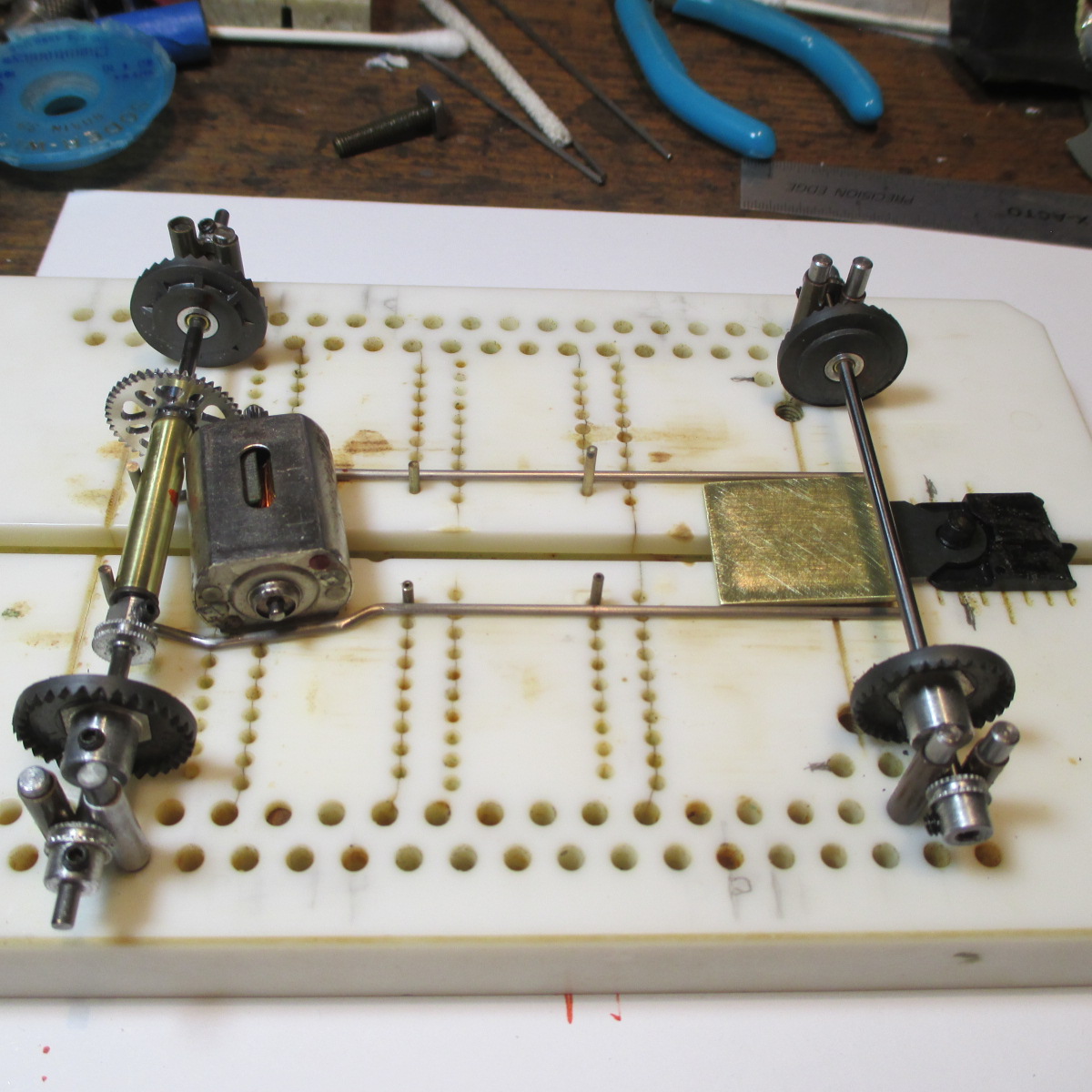

My method allows me to fiddle with it, get the perfect placement, then let the CA drool down and make it so. Whatever works for you is cool. Inner rails are bent and front .063 chunk is done. Nothing has been soldered yet ........

I broke all the rules on my right side rail, it has 5 bends. I don't recommend it ![]()

Paul Wolcott

#43

Posted 16 July 2020 - 01:12 PM

Chicagoland 2 degree tongue floated onto a 1" by .875" .063 thick chunk. At this point everything is just tack-soldered, except for the .047 wire motor brace atop the rear axle tube.

Haven't decided yet how to make the second right-side rail. For now, I gotta get those gears out and wash 'em, pronto! ![]()

Paul Wolcott

#45

Posted 16 July 2020 - 08:01 PM

this is probably a really dumb question, but what the heck are BP rules?

sorry, but i've never heard of 'em.

Steve Lang

#46

Posted 16 July 2020 - 08:39 PM

Buena Park raceway is where this car will race. ![]()

#47

Posted 16 July 2020 - 08:58 PM

aha.

Steve Lang

#48

Posted 16 July 2020 - 09:02 PM

Paul Wolcott

#49

Posted 16 July 2020 - 10:42 PM

Twin .063 rails trimmed up front, all solder joints finalized, rear axle tube wire wrapped to uprights. She passes the flatness test on my best block. A solid little race car. Next step is harnessing the front axle assembly - the goal being, wheels act as gentle outriggers but never ever disrupt the plant of the flag

- Al Hernandez likes this

Paul Wolcott

#50

Posted 17 July 2020 - 01:42 PM

I'm curious to see the next part of the puzzle come into play. There have been some interesting front axle assembly designs of late in Hardbody chassis. This will be interesting to add to the mix.

Eddie

Team Boola (circa the '60s)