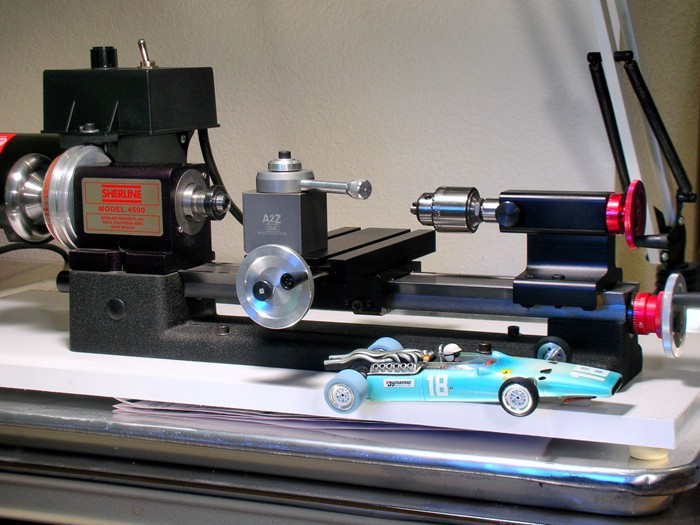

Hey Rick, what brand of lathe is that?

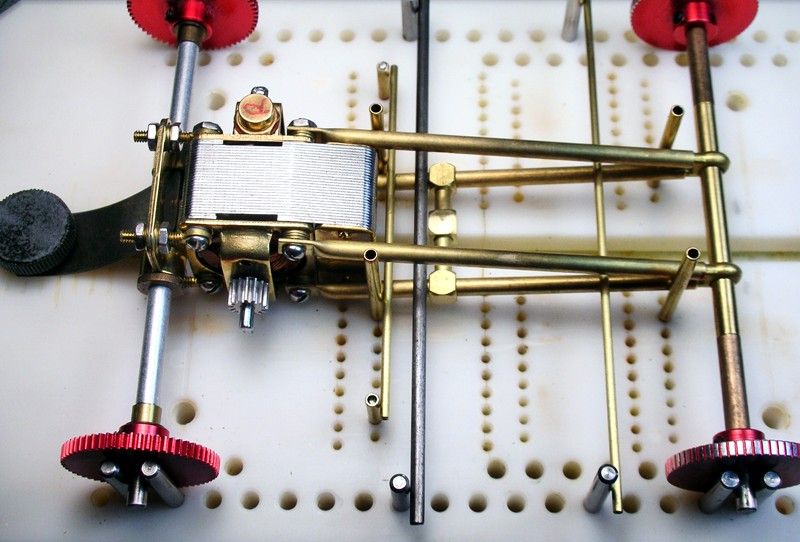

RAM and Kemtron motor mashup - the RAMtron 850

#26

Posted 31 July 2020 - 03:06 PM

???-2/31/23

Requiescat in Pace

#27

Posted 31 July 2020 - 03:31 PM

- slotbaker, Phil Smith and Peter Horvath like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#28

Posted 31 July 2020 - 04:41 PM

Nothing like the right tools...

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#29

Posted 31 July 2020 - 06:29 PM

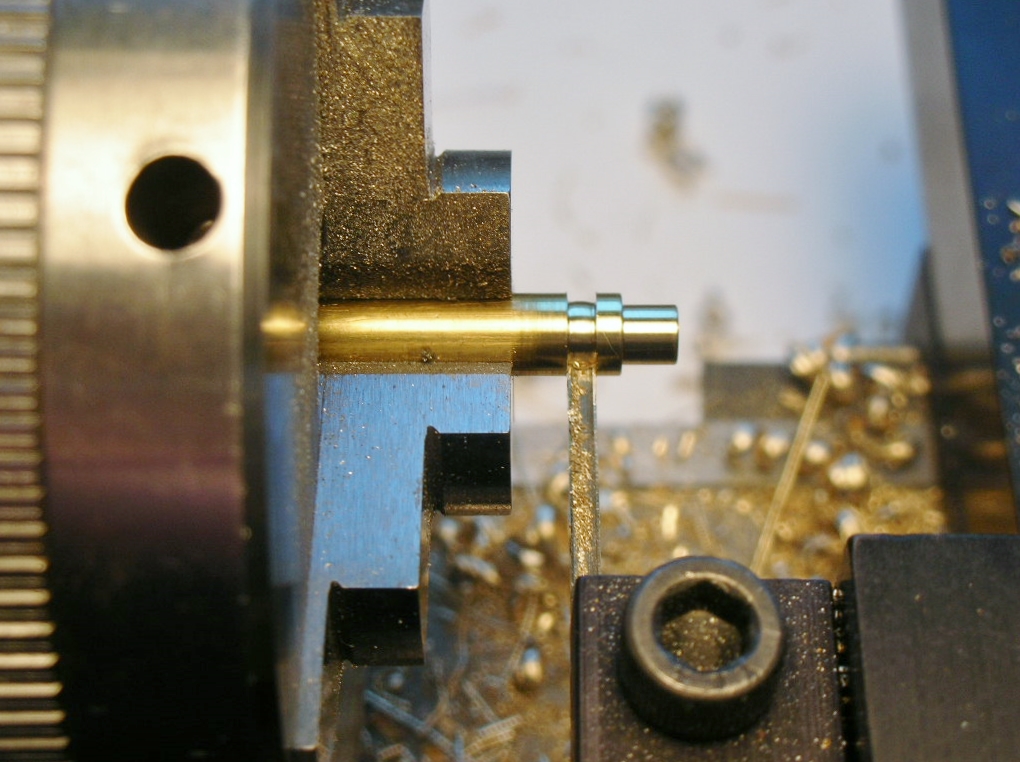

nice boring bar!

- Geary Carrier likes this

Steve Lang

#30

Posted 31 July 2020 - 07:53 PM

Nothing like the right tools...

And the knowledge of how to use them!

- tonyp likes this

Jay Guard

IRRA Board of Directors (2022-Present),

Gator Region Retro Racing Director (2021-Present)

SERRA Co-Director (2009-2013)

IRRA BoD advisor (2007-2010)

Team Slick 7 member (1998-2001)

Way too serious Retro racer

#31

Posted 01 August 2020 - 05:29 PM

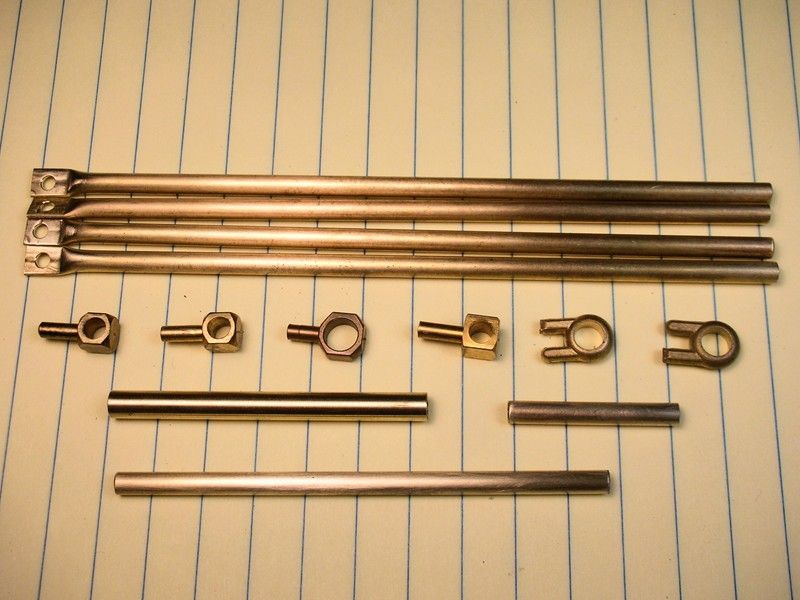

I had to get the tools out again. ![]() I had to make some gizmos to fit pin tube and plug the jumbo .136" holes in the Kemtron bracket:

I had to make some gizmos to fit pin tube and plug the jumbo .136" holes in the Kemtron bracket:

Some 3/16" brass bar stock did the trick:

They plug into the Kemtron bracket......

.......and my pin tube frame rails slip right in:

I'm still waffling on the chassis design.

- Jencar17 and Peter Horvath like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#32

Posted 01 August 2020 - 06:48 PM

nice cutoff tool too! i struggle with those.

Steve Lang

#33

Posted 01 August 2020 - 07:19 PM

Steve - I thought I was the only one that fights a cutoff tool everytime I use mine.

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#34

Posted 01 August 2020 - 07:59 PM

I used to avoid using a cutoff or parting tool at all costs. The chip would get stuck in the groove and BAM! Crash city Earl. ![]()

This little tool has a groove cut along the top edge that causes the chip to curl and narrow so it won't get stuck. For the small aluminum and brass jobs I do this little high speed steel tool works like a charm.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#35

Posted 01 August 2020 - 08:41 PM

it doesn't chatter?

Steve Lang

#36

Posted 01 August 2020 - 08:53 PM

No chatter on the small diameter brass and aluminum parts I cut in this hobby. I even cut without any cutting fluid and at higher speeds with no problems.

- Geary Carrier likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#37

Posted 02 August 2020 - 03:33 AM

Hey Rick,

I like pin tubing as much as the next guy, but don't you get tempted to use a big-bore tube once in awhile? I've used it on a couple cars, mostly with the Kemtron chassis parts, as a change of pace...

It would have simplified this build too... oh, I get it, never mind...

Don

#38

Posted 02 August 2020 - 08:29 AM

Right. I think I would have used the 1/8th tube just to keep it period correct. But the 1/16th tube will be lighter and add some flex. I remember that, as

cool and easy to build as these kits were, they were never great performers. Better designs were out by the time Kemtron started selling these.

#39

Posted 02 August 2020 - 10:06 AM

Hi Don and Dave,

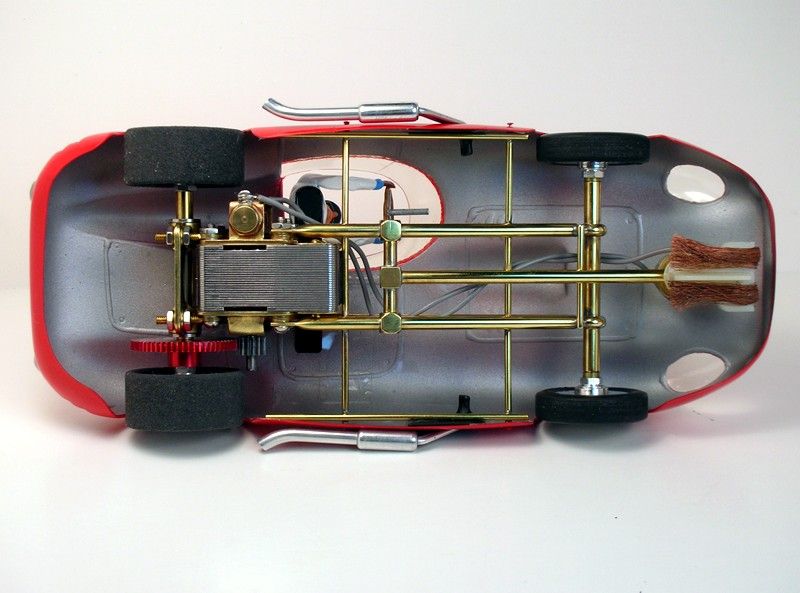

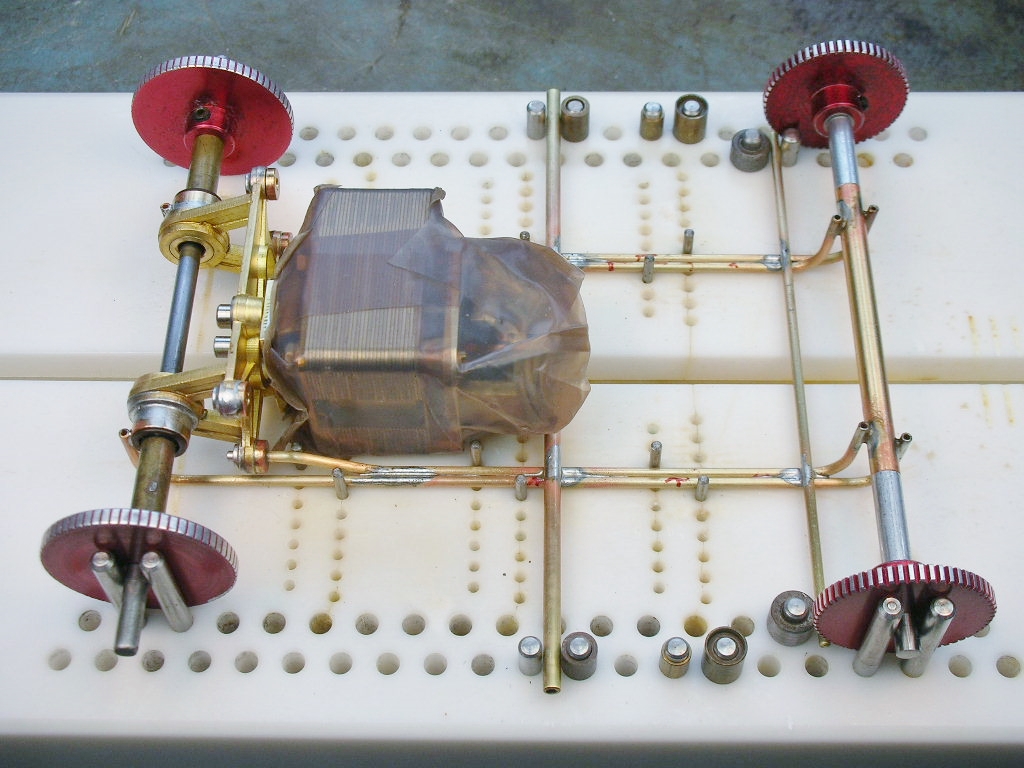

I built this Kemtron sidewinder car with a big tube frame almost 10 years ago:

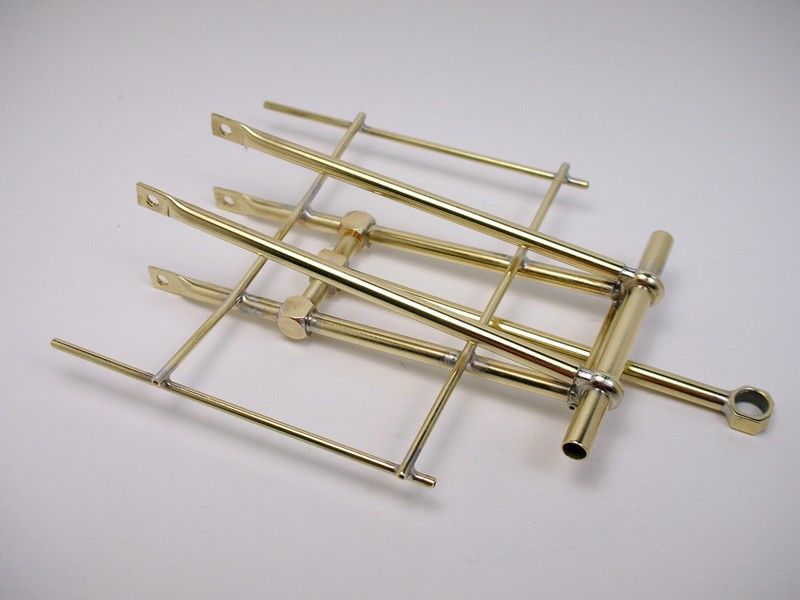

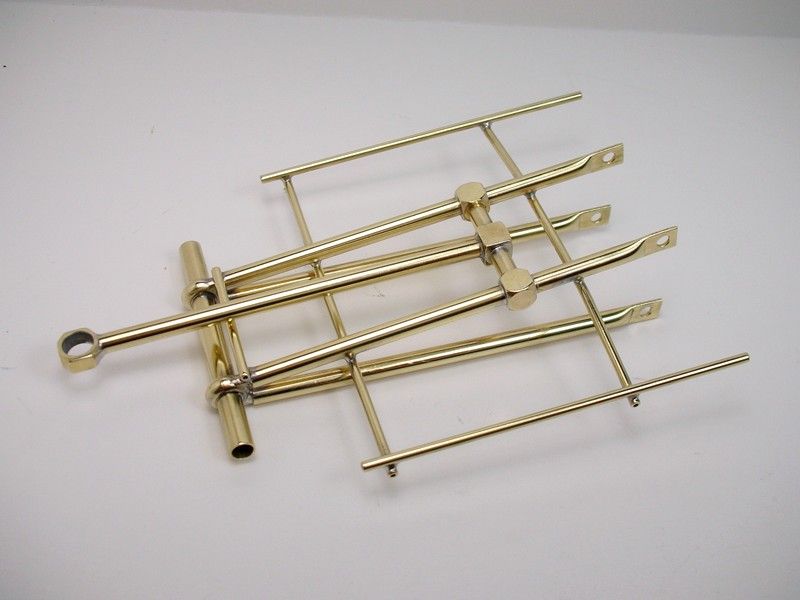

For the front half of the chassis I'm going old school. Kemtron offered these pieces to make a chassis and drop arm:

The tubes are 5/32" in diameter and look a bit big on a Kemtron. They look fine on a Pittman 85 but I decided to make my own form 1/8" tube. First, mark the tube where you're going to squish it and get it straight in the vise with a square if you want to be neat....Pete:

A little center punch and pistol drill action is next...

... followed by some chassis building bits from Kemtron and Speedway:

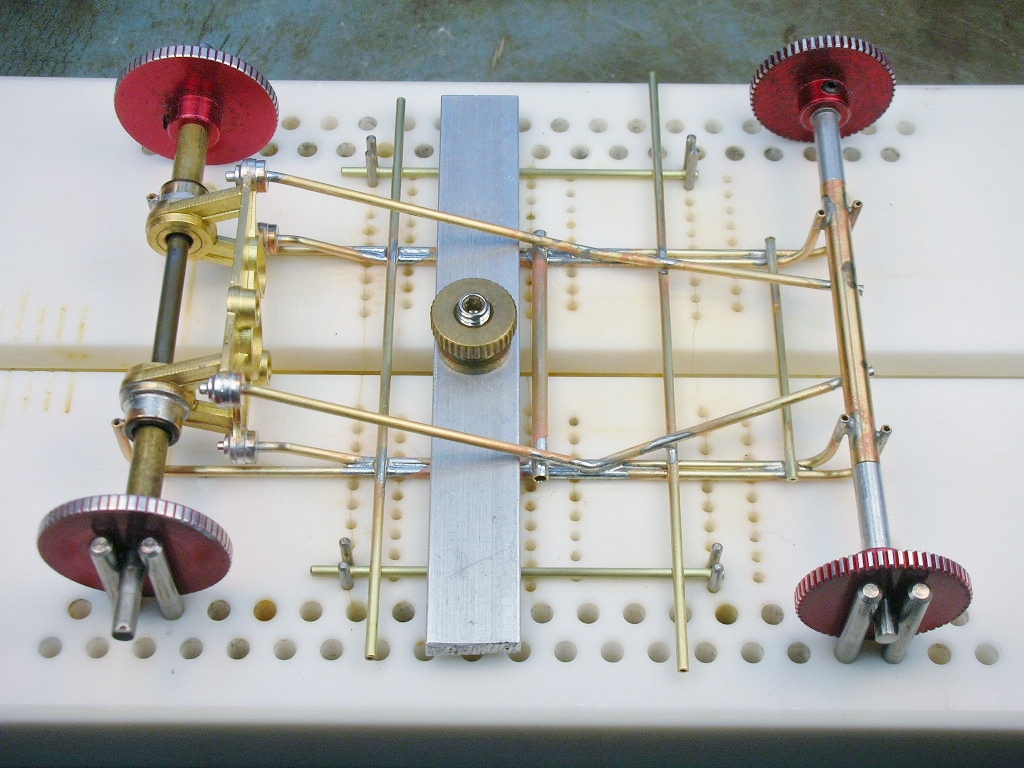

Here the pieces are all laid out to show what's what:

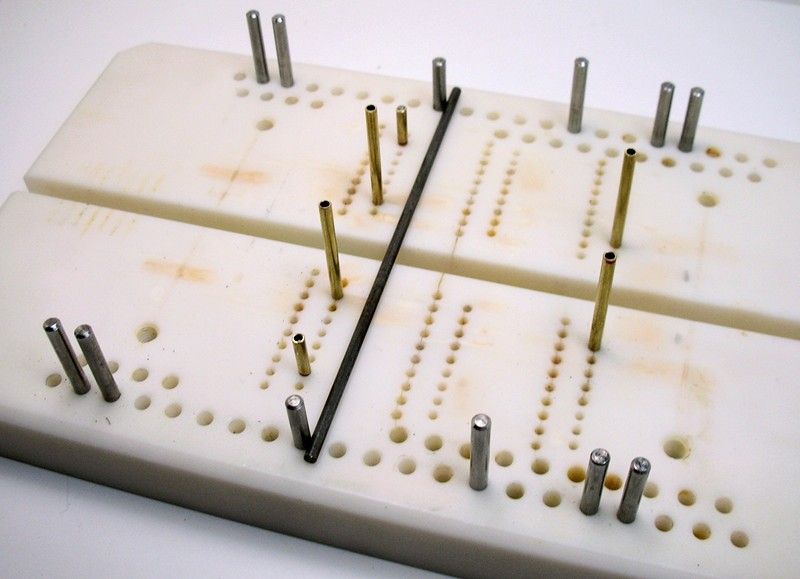

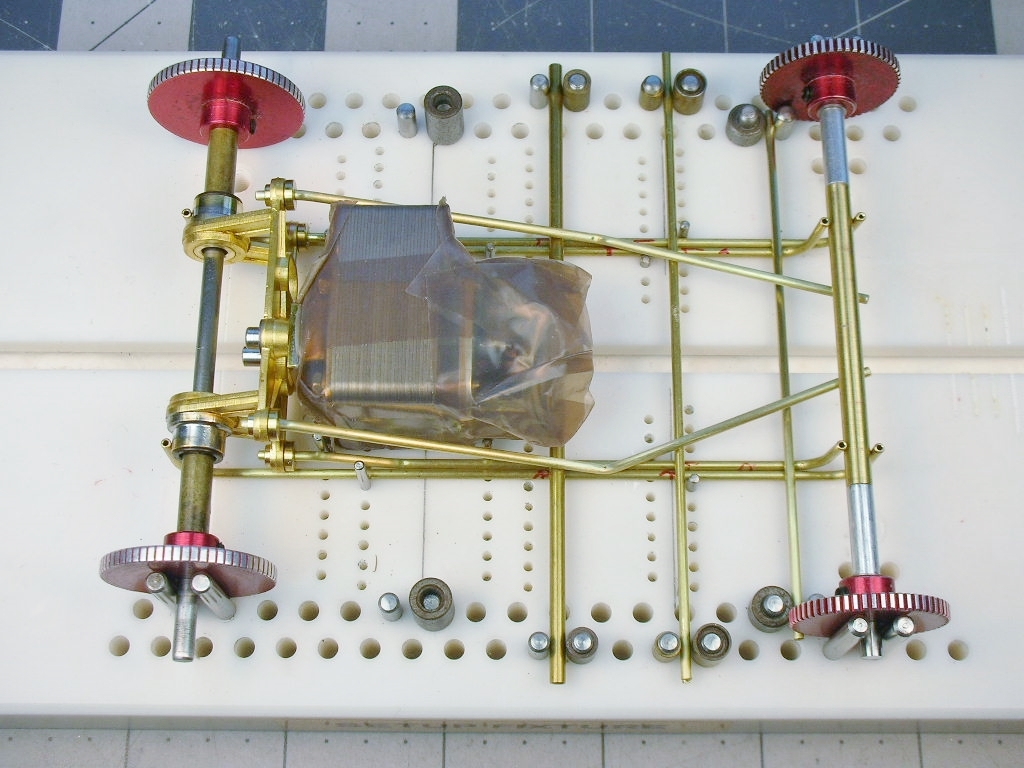

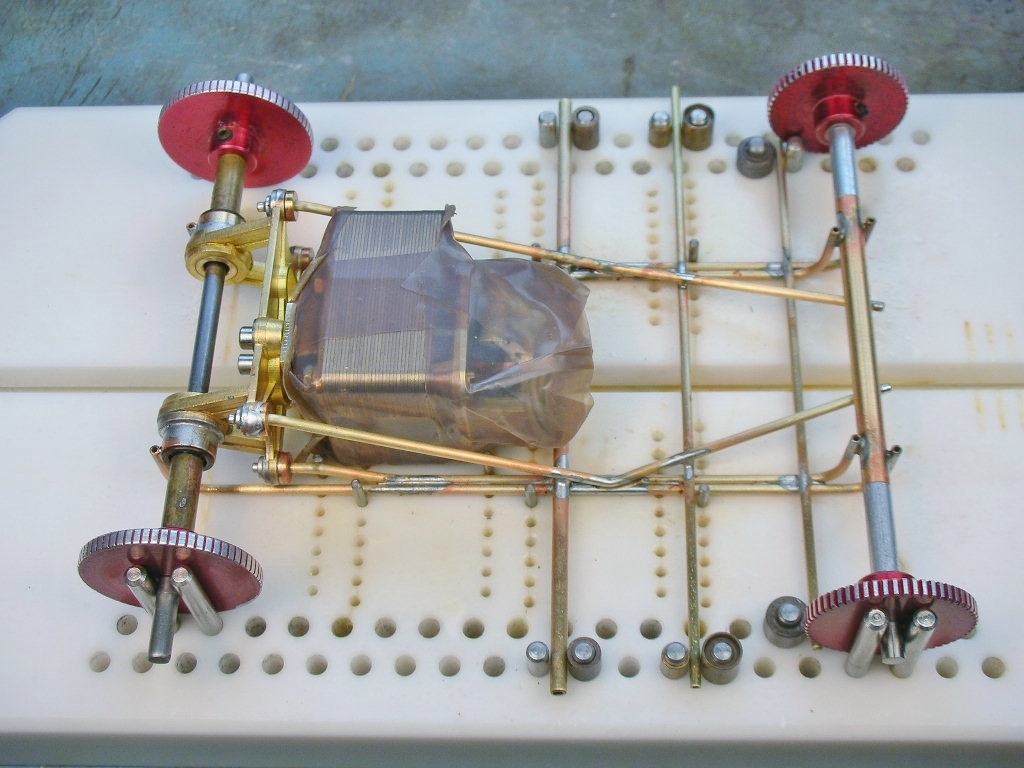

Everything jigged up in my Rick's Jig:

Here's my Rick's Jig with the chassis parts and motor removed showing all the alignment pins in place. This jig really makes scratch building FUN!

The finished chassis all cleaned up. Top view:

Bottom view:

Here's a link to the build:

The mighty Kemtron....

This time an inline in a space frame sounded like a fun thing to build..........and with a much style different body.

And Don, you know I don't do things the easy way. ![]()

![]()

![]()

- Jencar17, Tex, Uncle Fred and 3 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#40

Posted 02 August 2020 - 11:31 AM

Looks very nice. I missed that build. Those Kemtron tube connectors were real popular with the drag racers.

#41

Posted 04 August 2020 - 05:55 PM

Ok, I'm totally enthralled with this one ... please come up with a chassis design soon! Rick, I love how you engineer/MacGyver your way around any design obstacles you run into without flinching. This build rocks! ![]()

#42

Posted 04 August 2020 - 06:29 PM

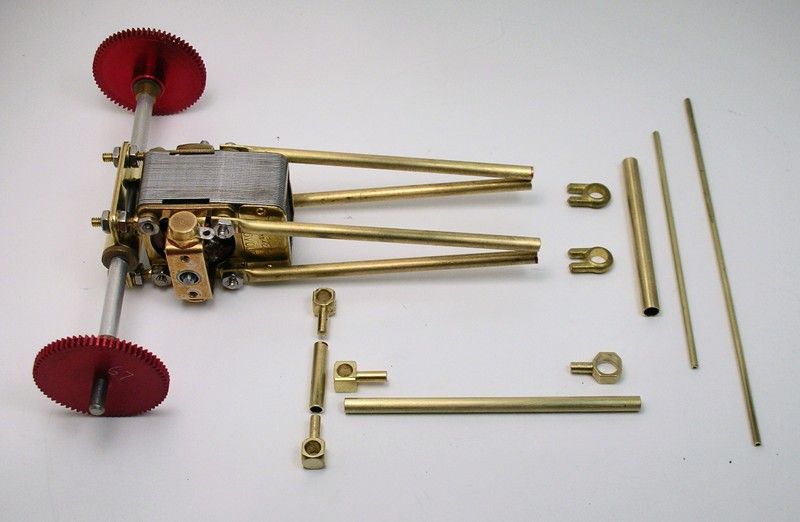

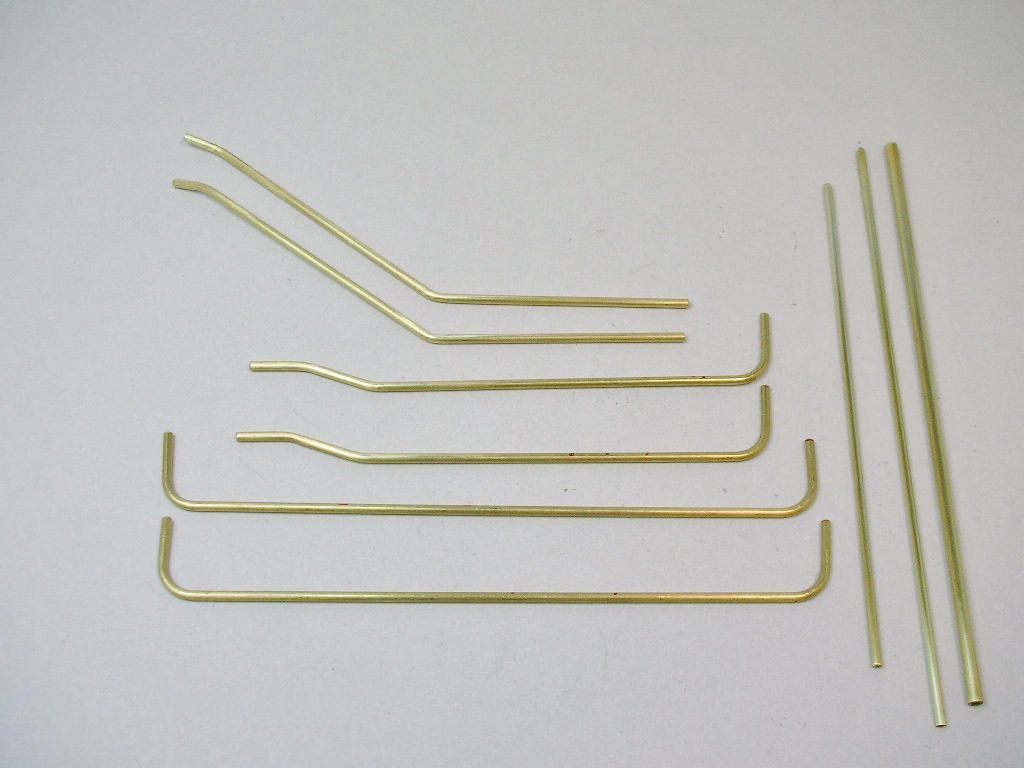

Thanks Larry, I'm up to my neck in MacGyvering right now. ![]() The specs on that lovely Kemtron bracket are a bit different from one side to the other. I'm having to fudge a bit here and there on the rails to get things to line up and look good but I'm getting there. I have a couple more rails to bend up.............

The specs on that lovely Kemtron bracket are a bit different from one side to the other. I'm having to fudge a bit here and there on the rails to get things to line up and look good but I'm getting there. I have a couple more rails to bend up.............

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#43

Posted 05 August 2020 - 01:03 PM

Hi, I found this very interesting. Here is a little historical addition. Back in 1965 I believe, MINRA ran their last mail in drag racing meet, which I entered both in the 1/32nd scale Top Eliminator Class and the 1/24th scale Top Eliminator Class. Although I had never actually entered a drag race before ( and I don't believe we yet had a functional drag strip in NY as Steinway Street had not yet built theirs) to my surprise, and many others, I won both classes. My 1/32nd scale was basically my Pittman 196 with a 65X armature from my regular race car with magnesium rails extending out front. My 1/24th was a magwinder (my first) which had a Ram armature and Kemtron magnet assembly, as described here! I believe that somewhere in my boxes I still have the remnants of this magwinder. As you may recall, magwinders eliminated the end plates that held the bearings and brush assembly and utilized part of the magnesium side rails to perform these functions, in order to save weight. As I recall I I used Pittman or Ram brushes. I don't recall seeing this article (it was 55 years ago after all), but I suppose I must have. As I recall, runner up in the 1/24th Top Eliminator was Ray Ramsey, who was the normal winner, and again as I recall, my best time was something like 1.25 seconds vs his of 1.45. In any event, it was very thrilling for this 15 year old. Sandy Gross

- S.O. Watt, Uncle Fred, tonyp and 2 others like this

#44

Posted 05 August 2020 - 01:21 PM

Hi Sandy,

Great story and thanks for sharing it.

And thanks for the clarification of the term "magwinder":

As you may recall, magwinders eliminated the end plates that held the bearings and brush assembly and utilized part of the magnesium side rails to perform these functions, in order to save weight.

"Magwinder" seems to be mistakenly applied to any and all vintage dragsters with one piece side rails. Even the great Gene Hustings Impossible rail was not a true magwinder as it utilized modified RAM motor end plates.

We'd love to see any of your cars..... ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#45

Posted 05 August 2020 - 04:36 PM

Amen..; and thanks for backing me up on the magwinder definition Sandy (we had a debate on that sometime in the last year).

Just found the Car Model report on the 1965 MINRA drags, in the December 1965 issue.

You did indeed win Top Eliminator, with a Fiat Competition Coupe, at an E.T. of 1.2970, after winning the Competition Coupe class ahead of Ray Ramsey, whose E.T. was 1.7281. Then you must have beat out the winners in the modified Roadster and Dragster classes. You were almost .20 faster than any other car in 1/24.

In 1/32, you finished 2nd in the Dragster class, at 1.3507, a few thousandths behind one B. Watkins of Mine Hill, NJ, who also won top Eliminator, at 1.2573.

Would love to see pics of any dragsters or other cars you have left.

Now, back to Rick's story...

Don

The report is just a couple pages, with almost a whole page taken up with a list of winners in all categories.

Didn't you also set fast time in 1/32 the next year with basically a modified Monogram kit car, that was eliminated on a technicality?

#46

Posted 05 August 2020 - 06:35 PM

Don,

Is there any slot car drag racing currently being done in France?

I intend to live forever! So far, so good.

#47

Posted 06 August 2020 - 02:54 AM

None that I know of Bill.

There was a guy in Dijon who had built a nice strip and organized some races, but haven't heard anything from him in awhile.

Don

#48

Posted 07 August 2020 - 04:37 PM

My chassis design is mostly done. I'm again influenced by Mike Morrissey's construction article April 1966 Car Model Magazine article, "Team Russkit Builds To Win".

Here's a link to it. It's a fun read:

Here are the pin tube pieces for the first part of the build. Compound bends in 4 of the 6 frame rails:

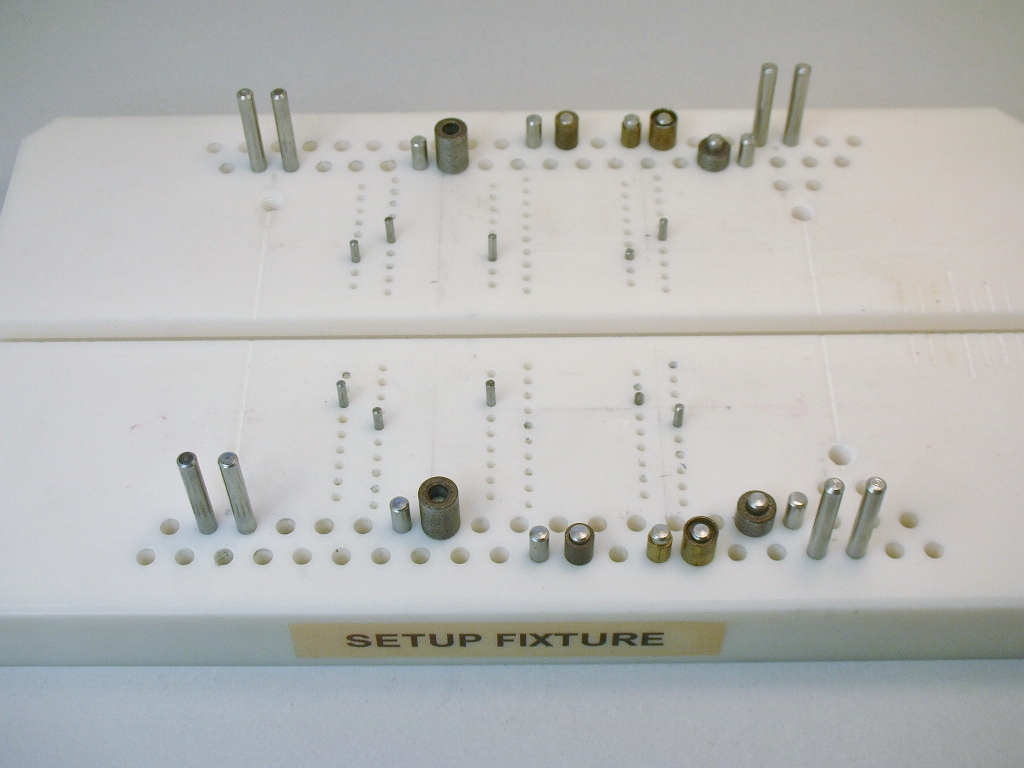

My setup jig all ready to align things. The pins and spacers will be transferred to my construction jig:

And the parts positioned in the setup jig for a final check. The 6 frame rails are cut to final length and the holes in the ends countersunk and chamfered:

Time to plug in the Ungar iron..........

- slotbaker, Tex, Peter Horvath and 1 other like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#49

Posted 12 August 2020 - 10:41 AM

I got the frame soldered up and then ran into a big problem. But first here were the steps in the frame's construction. The lower 2 frame rails along with the drop arm hinge tube and up-stop:

Then the upper frame rail along with the front body mount. The upper rail ties the drop arm hinge and front body mount to the lower rails:

Then the motor came out and the rear body mount went on. It was at this point the project ground to a halt:

I discovered the body I built the chassis for had mysteriously developed a case of "split-tonius crackidus". The 50+ year old butyrate plastic developed cracks in the front and back of the body.

The only thing I can figure is that I imparted stress in the body while I was trying to get a twist out of it the night before. I carefully and slowly twisted the body in the opposite direction trying to straighten it out. No cracks appeared during this process but the next day there they were. ![]()

![]()

Just gently picking the body up you can hear the two sides of the cracks popping against each other. These splits are also a half inch long and visually stand out like a sore thumb. I know I didn't miss seeing them after my untwisting process. There is also that sickening sound when a body cracks (don't ask how I know this) and I heard nothing. I can repair the current cracks but how many more will develop as I finish trimming and mounting that body.......no thanks, I'm not going to find out.

So there I was with a chassis with a set wheelbase and rear track width that I had to come up with a body for. It also had to fit that big Kemtron motor sticking up into the driver compartment.

There were a lot of bodies made in the late 1965 time period that would work but it's not like I can order a new one from the Auto World catalog. Luckily I found one that works. It's a bit "newer" than I wanted being early 1966 but it's all trimmed out, mounted and even the interior which had to fit around part of the Kemtron motor is all done.

Now I can get back to finishing the chassis.............

- Peter Horvath likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#50

Posted 12 August 2020 - 10:56 AM

Hey Rick, are you using the hot water method to reshape bodies?

What was the body you were working with? I will check my stock.